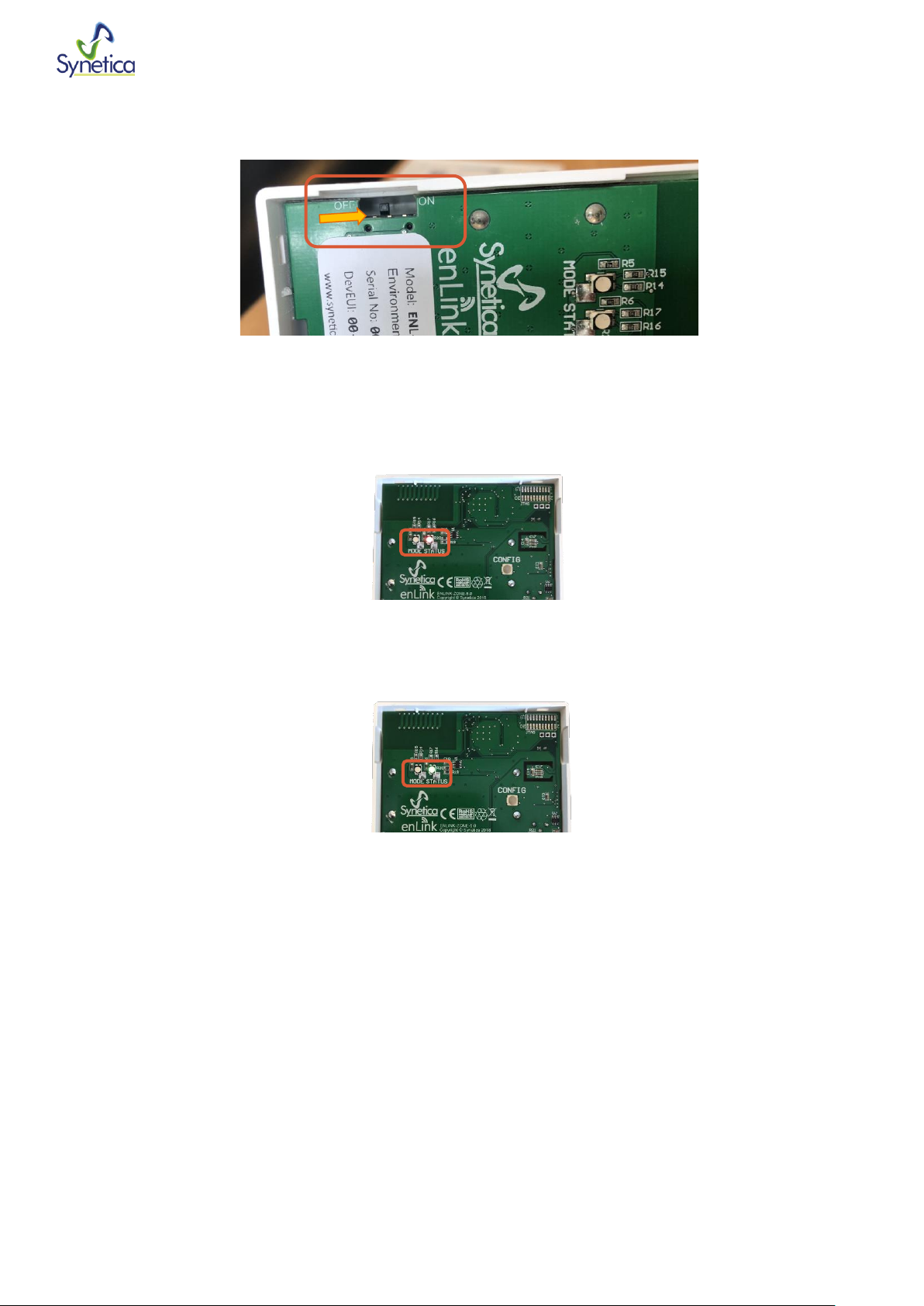

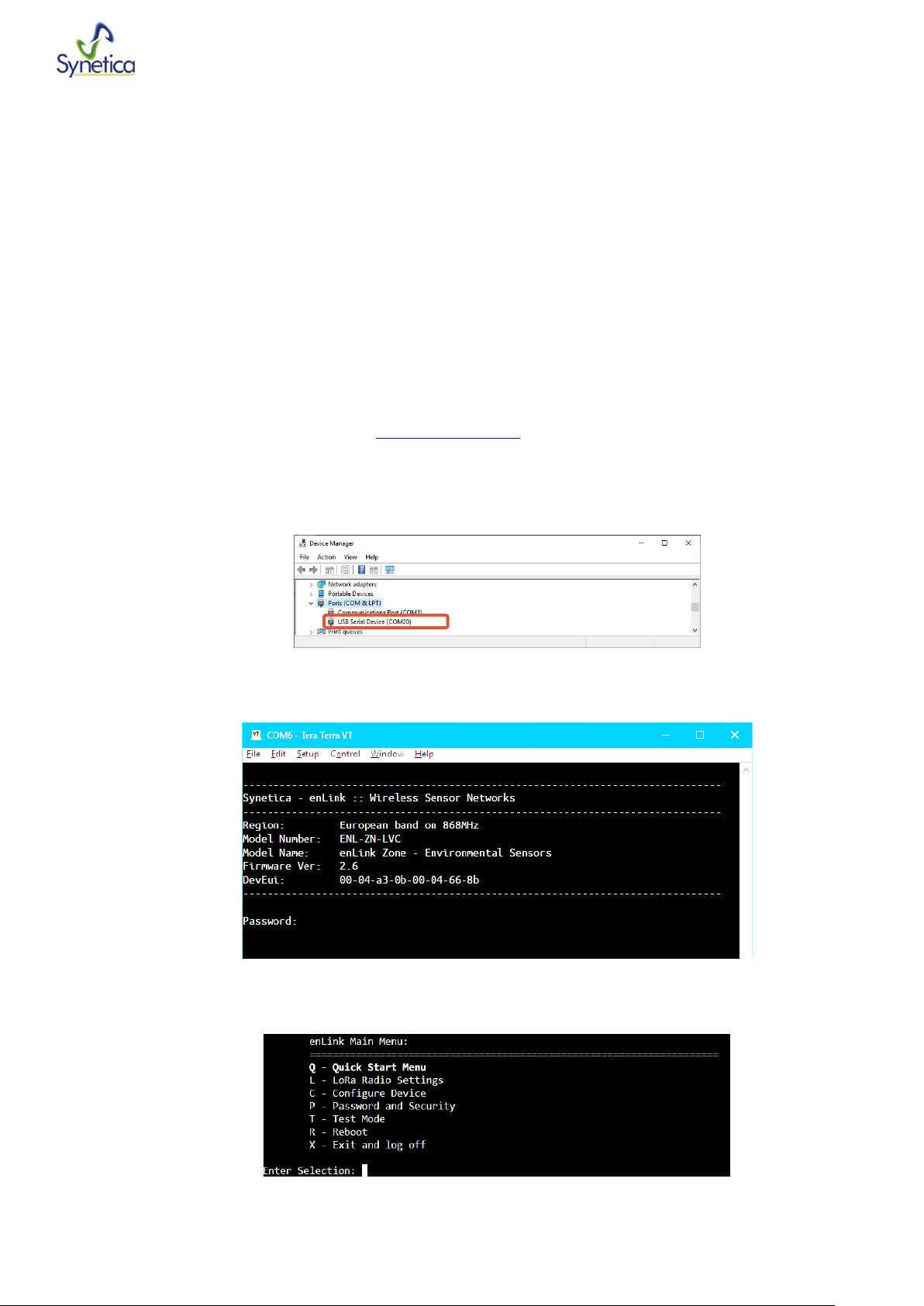

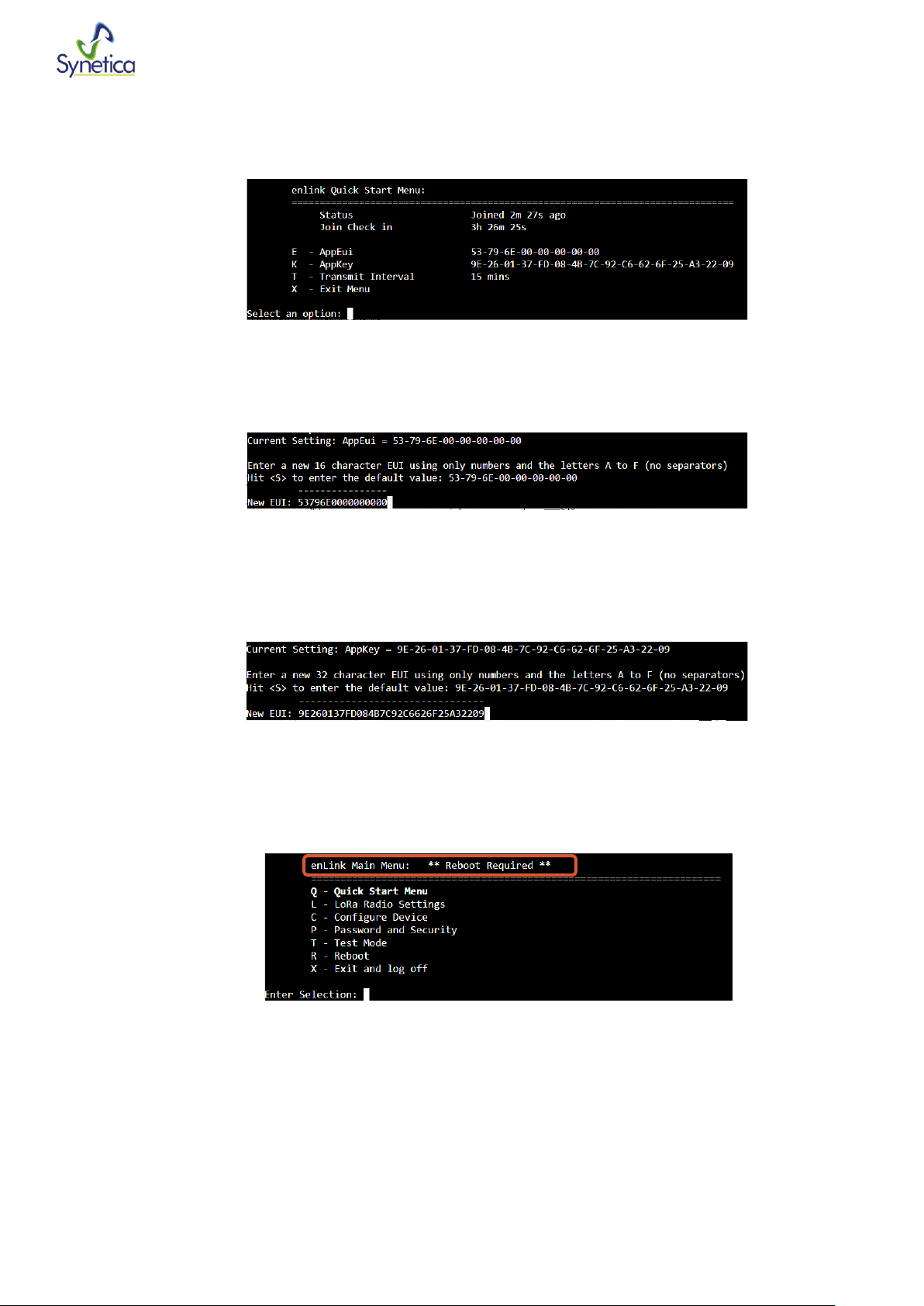

Battery Installation / Replacement

enLink devices use SAFT LS14500 AA size 3.6 Volt Lithium Thionyl Chloride (Li-SOCl2) batteries (non-rechargeable) or direct

equivalent.

No other batteries are approved for use in the device.

Lithium Thionyl Chloride batteries have very high energy capacity and must be used and handled with care observing the guidance

below.

WARNING

Risk of death or serious injury from explosion or fire.

•Keep out of sight and reach of children.

•Fire, explosion and burn hazard - do not recharge, short circuit, crush, disassemble, incinerate

•Due to the high terminal voltage (3.6V), they are not suitable as direct replacements for other battery technologies in the same can sizes.

•When not in use the Batteries must be stored in a non-Hazardous Area.

•Do not change batteries in an explosive gas atmosphere.

•When installing batteries, do not snag the battery terminal on the clip or the battery may be damaged. Do not apply excessive force.

•Do not drop. Dropping the battery may cause damage. If a battery is dropped, do not install the dropped battery into the unit. Dispose of dropped battery

promptly per local regulations or per the battery manufacturer’s recommendations.

Guidance

•Always install the batteries correctly as per instructions taking great care to observe the battery polarity.

•Ensure that the contact points are clean and conductive.

•All batteries must be the same model from the same manufacturer.

•Do not mix old and new batteries or batteries from different manufacturers.

•Do not heat or attempt to recharge the battery.

•Do not dispose of in a fire.

•Only install approved batteries: SAFT LS14500 Lithium Thionyl Chloride AA Battery 3.6 Volt, or direct equivalent.

Safe disposal

•Please recycle responsibly, a wide range of schemes are available.

•Do not dispose of in normal waste or in a fire.