Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

-

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

furnished with 60’ (18.29m) 4

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

furnished with 60’ (18.29m) 4

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

furnished with 60’ (18.29m) 4

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

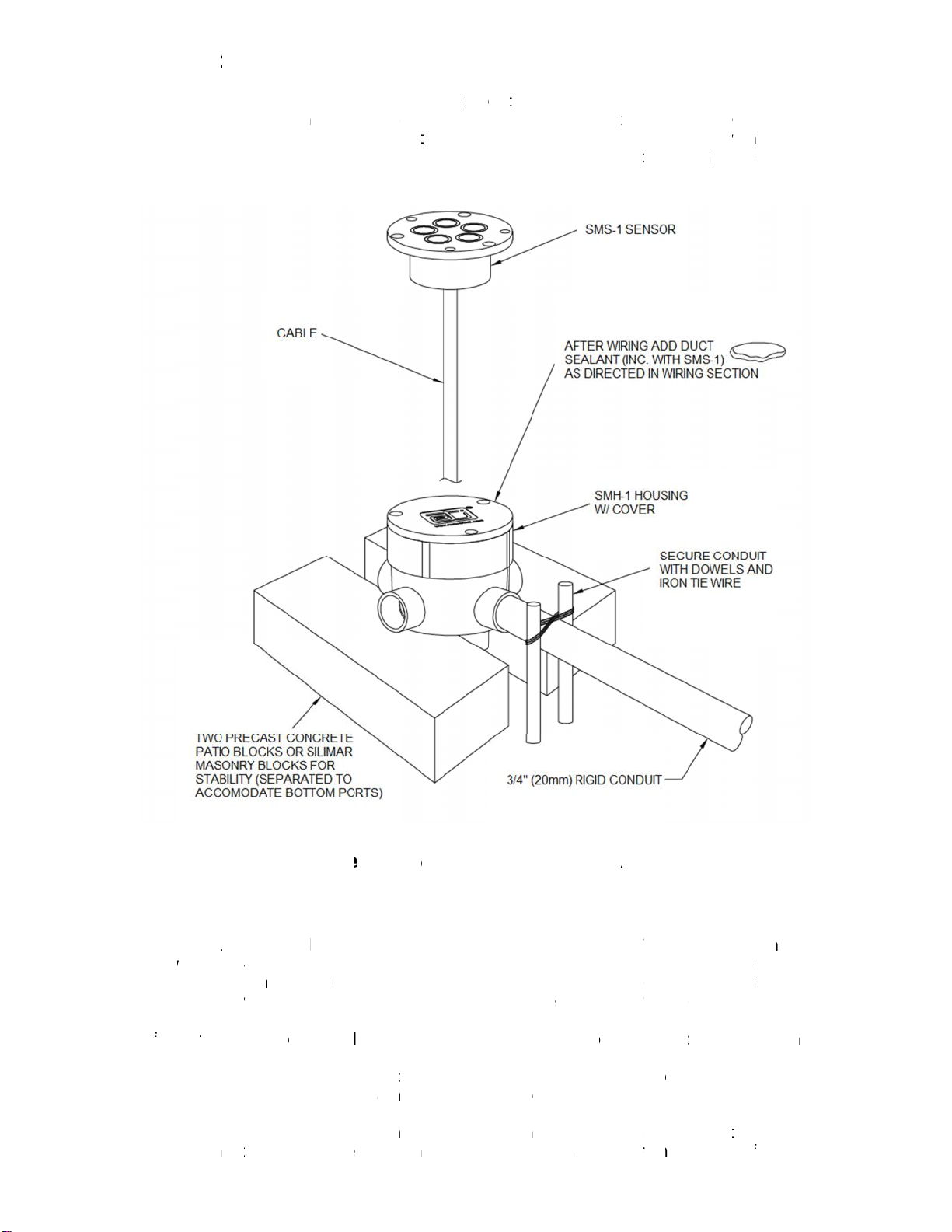

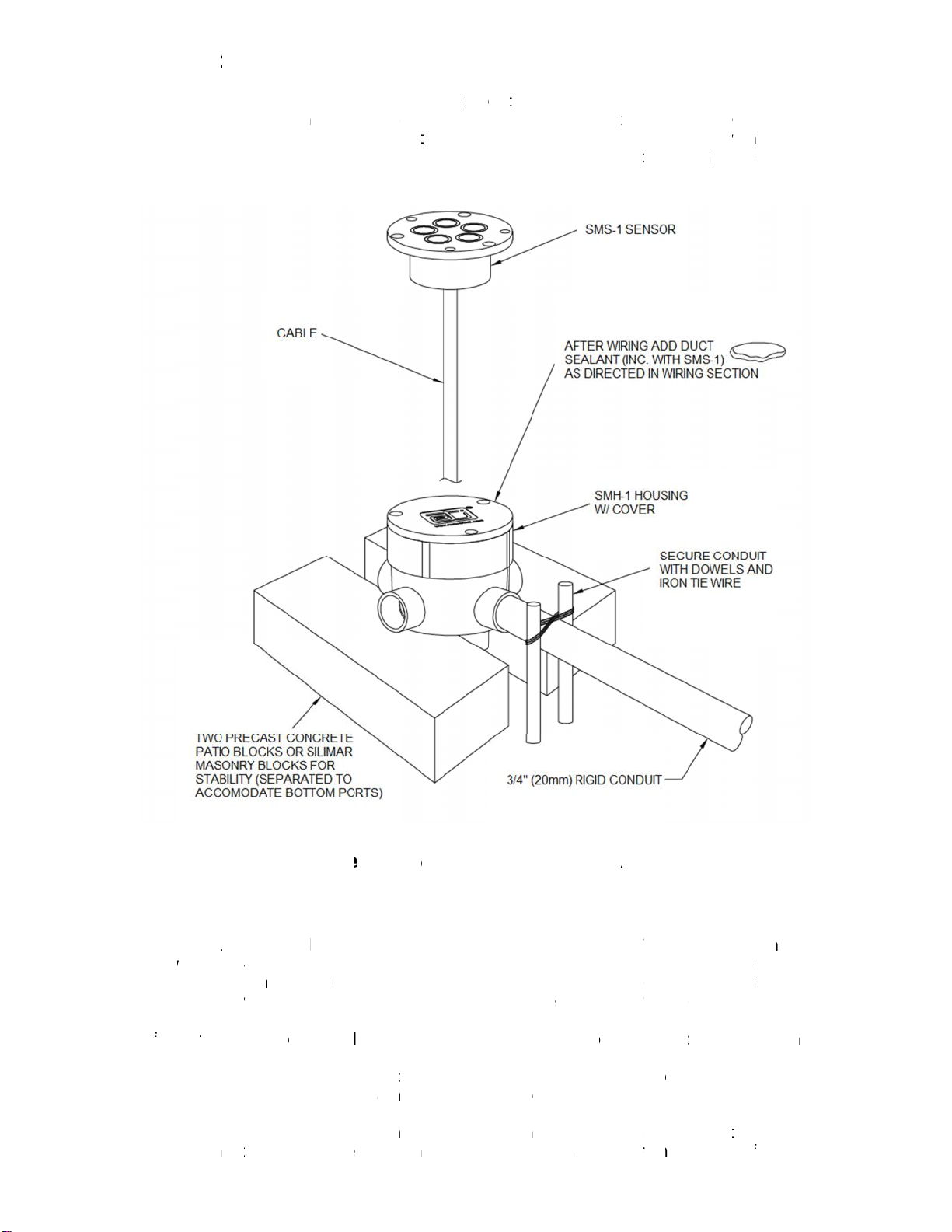

Figure 1. INSTALLATION DIAGRAM.

furnished with 60’ (18.29m) 4

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

Figure 1. INSTALLATION DIAGRAM.

furnished with 60’ (18.29m) 4

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

Figure 1. INSTALLATION DIAGRAM.

furnished with 60’ (18.29m) 4

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

Figure 1. INSTALLATION DIAGRAM.

furnished with 60’ (18.29m) 4

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

Figure 1. INSTALLATION DIAGRAM.

furnished with 60’ (18.29m) 4

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

Figure 1. INSTALLATION DIAGRAM.

furnished with 60’ (18.29m) 4

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

Figure 1. INSTALLATION DIAGRAM.

furnished with 60’ (18.29m) 4

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

depressed under these joints, as necessary.

Figure 1. INSTALLATION DIAGRAM.

furnished with 60’ (18.29m) 4

-

conductor jacketed #18 AWG field leads. The

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

Figure 1. INSTALLATION DIAGRAM.

conductor jacketed #18 AWG field leads. The

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

Figure 1. INSTALLATION DIAGRAM.

conductor jacketed #18 AWG field leads. The

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

Figure 1. INSTALLATION DIAGRAM.

conductor jacketed #18 AWG field leads. The

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

Figure 1. INSTALLATION DIAGRAM.

conductor jacketed #18 AWG field leads. The

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

Figure 1. INSTALLATION DIAGRAM.

conductor jacketed #18 AWG field leads. The

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

Figure 1. INSTALLATION DIAGRAM.

conductor jacketed #18 AWG field leads. The

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

Figure 1. INSTALLATION DIAGRAM.

conductor jacketed #18 AWG field leads. The

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

the sensor against possible ice damage. Refer back to Figure 1.

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

Figure 1. INSTALLATION DIAGRAM.

conductor jacketed #18 AWG field leads. The

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

Figure 1. INSTALLATION DIAGRAM.

conductor jacketed #18 AWG field leads. The

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

conductor jacketed #18 AWG field leads. The

unswitched 24 VAC power supply is connected across red and black wires

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

conductor jacketed #18 AWG field leads. The

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

conductor jacketed #18 AWG field leads. The

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

sensor housing leaving enough space for the sensor electronics and wiring. Prope

the duct sealant will minimize the accumulation of water and ice in the housing and protect

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

conductor jacketed #18 AWG field leads. The

the grounded conductor. Output relay NO contact connections are made via the two relay

res without discrimination. These are white, green, yellow, orange, or blue.

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

the duct sealant will minimize the accumulation of water and ice in the housing and protect

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

expansion or control joints. For sensors embedded in slab on grade, conduit should be

conductor jacketed #18 AWG field leads. The

the grounded conductor. Output relay NO contact connections are made via the two relay

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

the duct sealant will minimize the accumulation of water and ice in the housing and protect

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

Use individual 3/4" (20 mm) rigid conduit for the entire installed length of the sensor cable,

taking care to ensure that all embedded or outdoor couplings and terminations are made

re conduit with other wiring. Do not route conduit across pavement

conductor jacketed #18 AWG field leads. The

the grounded conductor. Output relay NO contact connections are made via the two relay

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the

the duct sealant will minimize the accumulation of water and ice in the housing and protect

Next, place wiring and electronics into the housing. Check for alignment between the sens

and pavement surfaces. If the sensor and pavement are not aligned, remove sensor from

2

After wiring the sensor, kneed the supplied duct sealant till pliable. Pack duct sealant into the