SENSORWORX SWX-900 Installation instructions

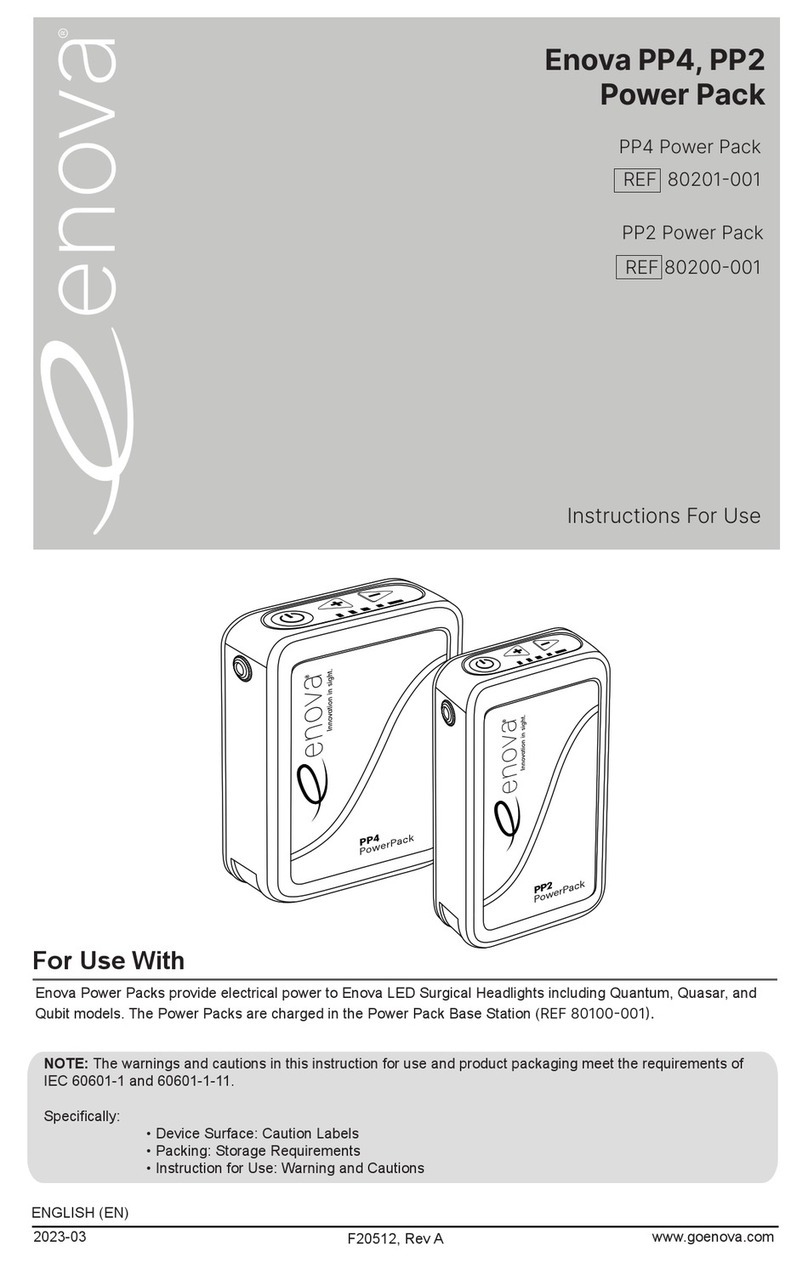

POWER PACK

INSTALLATION & OPERATION INSTRUCTIONS

CATALOG NUMBERS DESCRIPTIONS

SWX-900 POWER PACK

SWX-910 SECONDARY RELAY PACK

SWX-900-AX POWER PACK WITH AUXILIARY SWITCH INPUT

SWX-999 LOW VOLTAGE WIRING CHAMBER

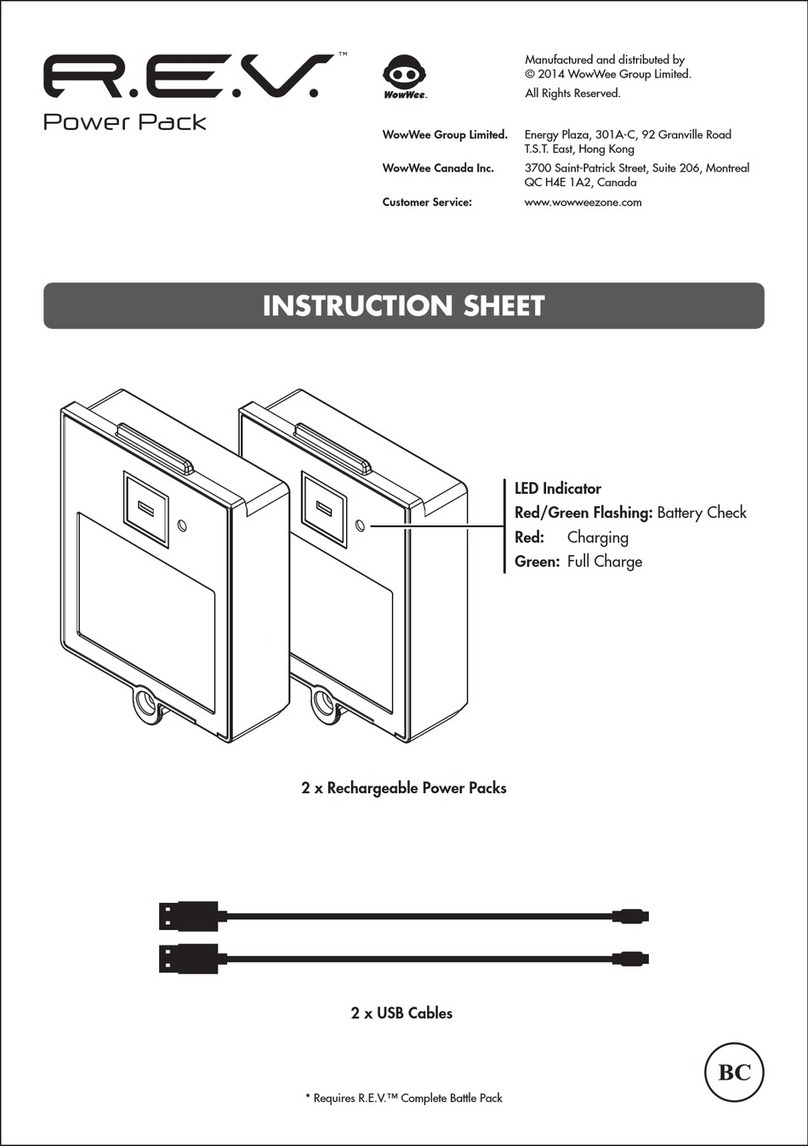

POWER PACK LOW VOLTAGE WIRING CHAMBER [OPTIONAL]

PROVIDES 3 KNOCKOUTS

FOR CONDUIT CONNECTIONS

CHASE NIPPLE HAS SNAPS THAT ENABLE QUICK

INSTALLATION THROUGH ANY 1/2” KNOCKOUT

TEST/PROGRAMMING BUTTON

LED INDICATOR

SNAPS DIRECTLY

TO MAIN HOUSING

WIRING CHAMBER *LOCK NUT SNAP-ON COVER

*CONNECT LOW VOLTAGE CHAMBER TO CONDUIT BEFORE

CONNECTING TO POWER PACK. CONDUIT SHOULD BE

APPROPRIATELY SUPPORTED BY OTHER MEANS AND

NOT USE THE LOW VOLTAGE CHAMBER FOR SUPPORT

OVERVIEW

SENSORWORX power packs transform incoming line voltage power to Class 2 low

voltage as needed by sensor(s) or other control device(s). Additionally, they switch on/off

power to the connected lighting load as directed by the sensors and controls.

FEATURES

Powers Low Voltage Sensors

Switches Line Voltage Loads

Electronically Timed Switching Ensures Long Relay Life

Integrated Test/Programming Button

Optional Snap-On Attachment Provides Chamber for Low Voltage Wire

Connections

Optional Switch Input for Manual On, Hold On, or Hold Off Operations

Plenum Rated (UL 2043)

INSTALLATION INSTRUCTIONS

SPECIFICATIONS

ELECTRICAL

OPERATING VOLTAGE

120/277 VAC

CLASS 2 OUTPUT RATINGS

18 VDC, 150 mA

RELAY CURRENT REQS

55 mA

LOAD RATINGS

20A @ 120 V -

General Purpose Plug Load

20A @ 120/277 VAC -

General Purpose, Tungsten, Magnetic

Ballast

16A @ 120/277 VAC -

Electronic Ballast, LED Driver

DC LOAD RATINGS

20A @ 28 VDC (MAX)

1A @ 5 VDC (MIN)

MOTOR LOAD

1 HP

ENVIRONMENTAL

OPERATING TEMP

-10°F to 122°F (14°C to 50°C)

RELATIVE HUMIDITY

0-95% Non-Condensing,

Indoor Use Only

ROHS COMPLIANT

PHYSICAL

SIZE

3.00” H x 2.25” W x 1.88” D

(7.62 cm x 5.72 cm x 4.78 cm)

WEIGHT

6.00 oz.

COLOR

Blue

MOUNTING

1/2” Knockout

MOUNTING

INSTRUCTIONS

Power Packs are designed to

attach to electrical enclosures

with 1/2” knockouts.

INSTALLATION NOTES

1For supply connections, use

14 AWG (90°C) or larger wires.

Wire all circuits exiting chase

nipple as Class 1 circuits.

2Suitable for plenum use.

3Risk of Electric Shock - More

than one disconnect switch may

be required to de-engergize the

equipment before servicing. WARNING: TURN POWER OFF AT THE CIRCUIT BREAKER BEFORE WIRING

RED

BLK

RED

BLK BLU

YEL

BLK

BLU

WHT

WHT WHT

N

277V

120V 120V/

277V

OR

CONTROL INPUT

COMMON

+VDC

LOAD

CLASS 1

WIRING

CLASS 2

WIRING

* CAP UNUSED BLACK OR YELLOW WIRE

*

*

SWX

POWER

PACK

SWX

LOW

VOLTAGE

SENSOR

RED

BLK BLU

YEL

BLK

BLU

WHT

WHT

BLK

YEL

N

277V

120V 120V/

277V

OR

CONTROL INPUT

COMMON

+VDC

LOAD

CLASS 1

WIRING

CLASS 2

WIRING

SWX-900

POWER

PACK

RED

BLK

WHT

SWX

LOW

VOLTAGE

SENSOR

RED

BLK

WHT

RED

BLK

WHT

SWX

LOW

VOLTAGE

SENSOR

SWX

LOW

VOLTAGE

SENSOR

* CAP UNUSED BLACK OR YELLOW WIRE

*

*

RED

BLK BLU

YEL

BLK

BLU

WHT

WHT

BLK

YEL

CONTROL INPUT

COMMON

+VDC

RED

+VDC

LOAD 1

CLASS 1

WIRING

CLASS 2

WIRING

SWX-900

POWER

PACK

BLK

WHT

CONTROL INPUT

COMMON

* CAP UNUSED BLACK OR YELLOW WIRE

*

*

*

*

RED

BLK

WHT

SWX

LOW

VOLTAGE

SENSOR

BLU

YEL

BLK

BLU

WHT

SWX-900

POWER

PACK

N

277V

120V 120V/

277V

OR

LOAD 2

WIRING

STANDARD WIRING

MULTIPLE SENSOR WIRING

MULTIPLE POWER PACK WIRING

COMMON LINE FEEDS

RED

BLK

YEL

BLK

WHT

WHT

BLK

YEL

CONTROL INPUT

COMMON

+VDC

CLASS 1

WIRING

CLASS 2

WIRING

RED

BLK

WHT

CONTROL INPUT

COMMON

+VDC

RED

BLK

WHT

SWX

LOW

VOLTAGE

SENSOR

BLU

YEL

BLK

BLU

WHT

SWX-900

POWER

PACK

SWX-900

POWER

PACK

277V

120V

OR

N

277V

120V 120V/

277V

OR

LOAD 2

BLU

BLU

LOAD 1

N

120V/

277V

* CAP UNUSED BLACK OR YELLOW WIRE

*

*

*

*

RED

BLK

WHT

BLK

YEL

CONTROL INPUT

COMMON

+VDC

RED

BLK

WHT

CONTROL INPUT

COMMON

+VDC

RED

BLK

WHT

SWX

LOW

VOLTAGE

SENSOR

BLU

SWX-910

SECONDARY

RELAY

PACK

LOAD 2

BLU

YEL

BLK

BLU

WHT

LOAD 1

CLASS 1

WIRING

CLASS 2

WIRING

SWX-900

POWER

PACK

N

277V

120V

OR

BLU

120V/

277V

* CAP UNUSED BLACK OR YELLOW WIRE

*

*

WHT

WIRING CONT.

MULTIPLE POWER PACK WIRING

SEPARATE LINE FEEDS

POWER PACK w/ SECONDARY RELAY PACK WIRING

BRN

RED

BLK

BLK

BRN

RED

BLK

BLU

YEL

BLK

BLU

WHT

WHT WHT

N

277V

120V 120V/

277V

OR

CONTROL INPUT

COMMON

COMMON

+ VDC

5-24 VDC

+VDC

LOAD

CLASS 1

WIRING

CLASS 2

WIRING

* CAP UNUSED BLACK OR YELLOW WIRE

*

*

SWX-900-AX

POWER

PACK

SWX

LOW

VOLTAGE

SENSOR

EXTERNAL

SYSTEM

[ i.e. BMS TIMER ]

YEL

RELAY

STATUS

OUTPUT

WIRING CONT.

POWER PACK CONNECTED TO SWITCH (requires -AX option)

Some energy codes require Manual On (also called Vacancy) operation where an occupant is required to initially switch on lighting. The sensor then ensures lights are

turned off once the space is unoccupied

Interfacing momentary switches such as the SWX-801-xx or SWX-803-xx are recommended, however maintained switches can also be utilized

For momentary switches, the power pack will react on the leading edge of a pulse on the brown input wire

For maintained switches, any change of state on the brown wire that lasts longer than 0.5 seconds will be read by the power pack as one action

If no sensor is present, tie power pack low voltage white wire to low voltage red wire

POWER PACK w/ SWITCH SIGNAL FROM EXTERNAL SYSTEM

Typical for Hold On and Hold Off applications

BROWN switch input can be activated by external signals +5VDC or higher (i.e. logic high)

For hold on and hold off applications, switch input can also be congured to activate on logic low

If no sensor is present, tie power pack low voltage white wire to low voltage red wire

BRN

RED

BLK

RED

BLK

BLU

YEL

BLK

BLU

WHT

WHT WHT

N

277V

120V 120V/

277V

OR

CONTROL INPUT

COMMON

+VDC

LOAD

CLASS 1

WIRING

CLASS 2

WIRING

* CAP UNUSED BLACK OR YELLOW WIRE

*

*

SWX-900-AX

POWER

PACK

SWX

LOW

VOLTAGE

SENSOR

YEL

RELAY

STATUS

OUTPUT

MAINTAINED

SWITCH

YEL

BRN

SWITCH OUTPUT

RED

BLK

BRN

RED

RED

BLK

BLK

BLU

YEL

BLK

BLU

WHT

WHT WHT

N

277V

120V 120V/

277V

OR

CONTROL INPUT

COMMON

+VDC

SWITCH INPUT

RELAY STATUS

LOAD

CLASS 1

WIRING

CLASS 2

WIRING

* CAP UNUSED BLACK OR YELLOW WIRE

*

*

SWX-900-AX

POWER

PACK

SWX

LOW

VOLTAGE

SENSOR

SWX-801

SWITCH

YEL

RELAY STATUS INPUT

**

** IF NO SENSOR, CONNECT

WHITE WIRE TO RED WIRE

MOMENTARY SWITCH

MAINTAINED SWITCH

SWX-900 series power packs can supply power to several occupancy sensors and additional secondary relay packs. Following the below formula ensures adequate power will

be available. Note the SWX-900’s relay has already been factored into the formula.

[ (# of PIR SENSORS*) x2mA ] +[ (# of DUAL TECH SENSORS) x10mA ] +[ (# of SWX-910) x55mA ] <[ (# of SWX-900) x95 mA]

PIR SENSORS OR

LOW VOLT. WALL SWITCHES

+

DUAL TECH SENSORS

+

SECONDARY PACKS

SWX910

=

TOTAL

POWER

REQUIRED

<

POWER

SUPPLIED

BY ONE

SWX900

#POWER

REQUIRED #POWER

REQUIRED #POWER

REQUIRED

15 30mA + 0 0 + 0 0 = 30mA < 95mA

15 30mA + 0 0 + 1 55mA = 85mA < 95mA

0 0 + 9 90mA + 0 0 = 90mA < 95mA

7 14mA + 8 80mA + 0 0 = 94mA < 95mA

POWER PACK CAPACITY

EXAMPLE COMBINATIONS

TESTING & TROUBLESHOOTING

TEST MODE

To test unit by toggling the relay, press and hold

pushbutton. LED will turn blue while the button is held.

Release button to return to normal operation.

RESET

To restore factory settings, press and release the push-

button 3 times, wait 2 seconds, then press and release

the push-button 3 times again.

LED INDICATION

During normal operation, the LED regularly ashes

white as a status “heartbeat”.

The LED will ash blue once when the unit switches.

If the LED repeatedly double ashes blue, the power

supply is overloaded. This is probably due to having

too many sensors or secondary relay packs connected.

Remove excess low voltage load from the red wire

until blue double ash stops.

If the LED regularly ashes blue, both blue relay wires

are connected to power when the relay is open. This

indicates probable miswiring.

Five-Year Limited Warranty.

Complete Warranty Terms Located at: sensorworx.com/warranty

INS900 | REV 001–190925

SENSORWORX | 3 Essex Sq, Essex, CT 06426

203.678.4224 | www.sensorworx.com

© 2019 BLP Technologies, Inc. All rights reserved.

CONFIGURATION SETTINGS ___________________________________

OPERATIONAL MODES

Standard power packs (model SWX-900) and secondary packs (model SWX-910) close

their relays automatically when a connected sensor signals occupancy. Versions with the

Auxiliary Switch Input option (e.g. model SWX-900-AX) have several additional modes of

operation that are listed below. Auto On/Auto Off (Setting #2) is the default mode.

TO CHANGE THE OPERATIONAL MODE

1Read through the above list and note the number of the desired setting

2Press and release the unit’s pushbutton twice, then wait 2 seconds.The White LED will

blink back the number of the current setting (e.g. 2 = Auto On / Auto Off).

3Press the pushbutton the number times equal to the new desired setting (e.g. 3 =

Manual On / Auto Off). The White LED will blink back the new setting as conrmation.

4New setting is saved after White LED blinks conrmation 3 times. If Blue LED double

ashes at any time, start process over.

LED OPERATION

To disable the LED from continuously ashing white as a “heartbeat”, press and release the

push-button 4 times, wait 2 seconds, then press and release the push-button 4 times again.

RELAY LOGIC

The power pack’s relay closes in response to occupancy being detected. To reverse this

logic (such that the relay opens in response to occupancy), press and release the push-

button 5 times, wait 2 seconds, then press and release the push-button 3 times again.

ADDITIONAL OPERATION NOTES

When in Auto-on/Auto-off mode, if lights are manually switched off when there are still occupants in a space (to show a presentation for example), they will remain off until either

switched back on manually or the sensor times out once the space is empty.

When in Manual On / Auto Off mode, if the switch is pressed but no occupancy is ever sensed, the lights will come on for 1 minute and then shut off. If no occupancy sensor is

present, tie the power pack’s white input wire to red (+VDC).

SETTING # MODE DESCRIPTION

2 Auto On / Auto Off Mode* (Occupancy Mode) Lights come on automatically when occupancy is detected and turn off automatically after sensor's time delay expires.

3 Manual On / Auto Off (Vacancy Mode) Lights must be manually switched on via a connected switch, but turn off automatically after sensor's time delay expires.

4 Unused NA

5 Override On / Logic High Lights are held on when auxiliary switch input wire is logic high (5-24VDC). Occupancy is ignored.

6 Override On / Logic Low Lights are held on when auxiliary switch input wire is logic low (< 5VDC). Occupancy is ignored.

7 Override Off / Logic High Lights are held off when auxiliary switch input wire is logic high (5-24VDC). Occupancy is ignored.

8 Override Off / Logic Low Lights are held off when auxiliary switch input wire is logic low (< 5VDC). Occupancy is ignored.

CONFIGURATION QUICK REFERENCE TABLE

FUNCTION SETTING DESCRIPTION

2 => Operational Modes 2 Auto-On / Auto Off (Occupancy Mode)

3 Manual On / Auto Off (Vacancy Mode)

4 Not Used

5 Override On, Logic High

6 Override On, Logic Low

7 Override Off, Logic High

8 Override Off, Logic Low

3 => Reset 3 Restore Factory Defaults

4 => LED Operation 2 LED Enabled

4 LED Disabled

5 => Relay Logic 2 Normal Relay Logic

3 Inverted Relay Logic

This manual suits for next models

3

Table of contents

Popular Power Pack manuals by other brands

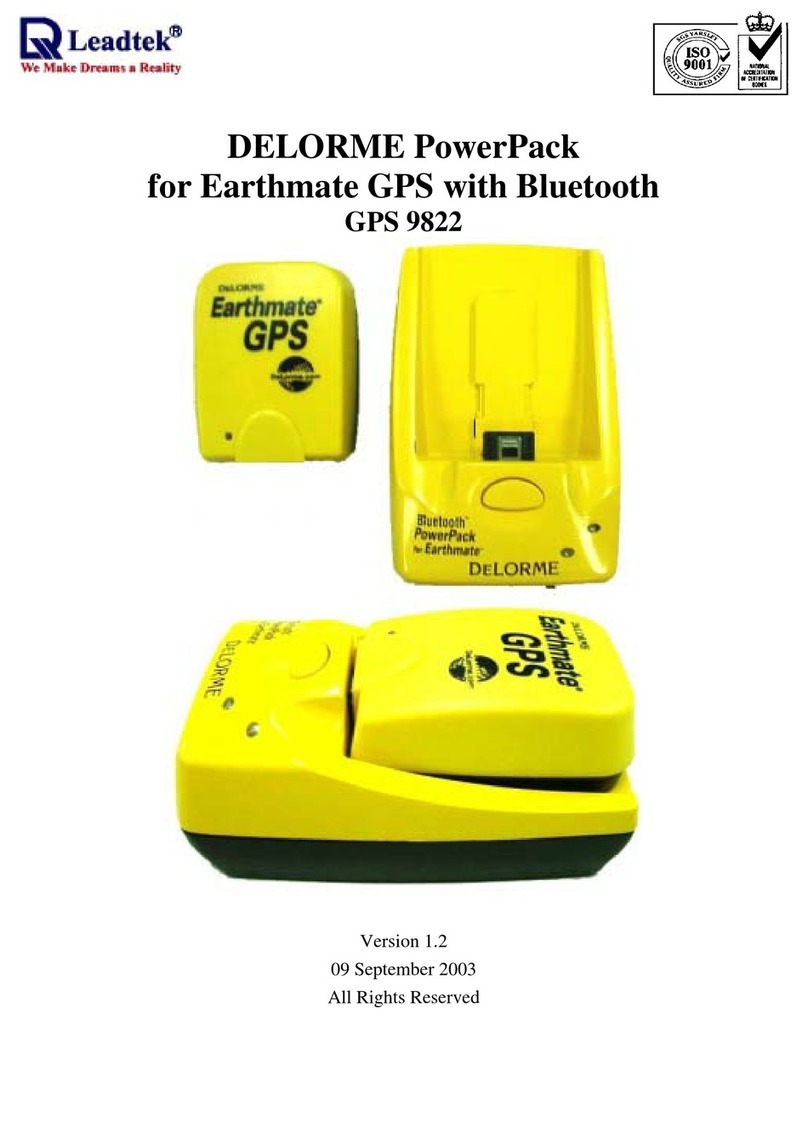

DeLorme

DeLorme Earthmate PowerPack manual

Varta

Varta Powerpack 2600 quick start guide

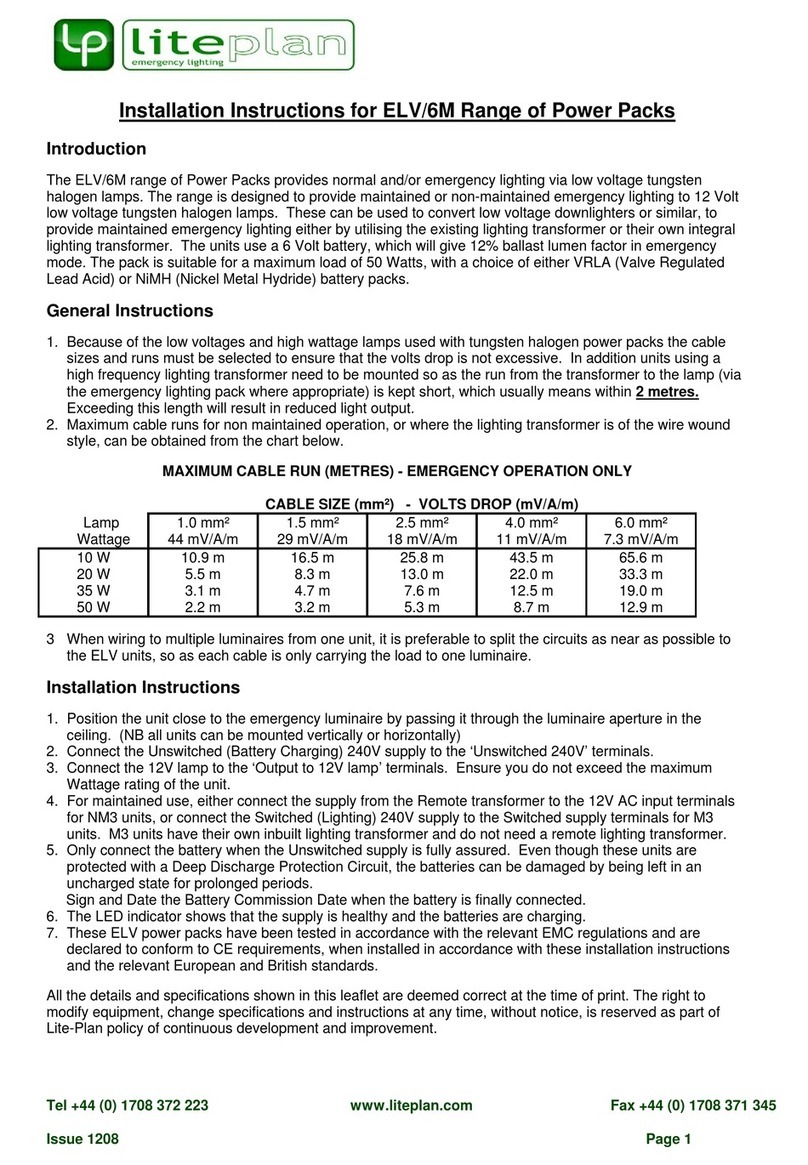

Liteplan

Liteplan ELV/6M Series installation instructions

HAWE Hydraulik

HAWE Hydraulik A 100 Original assembly instructions

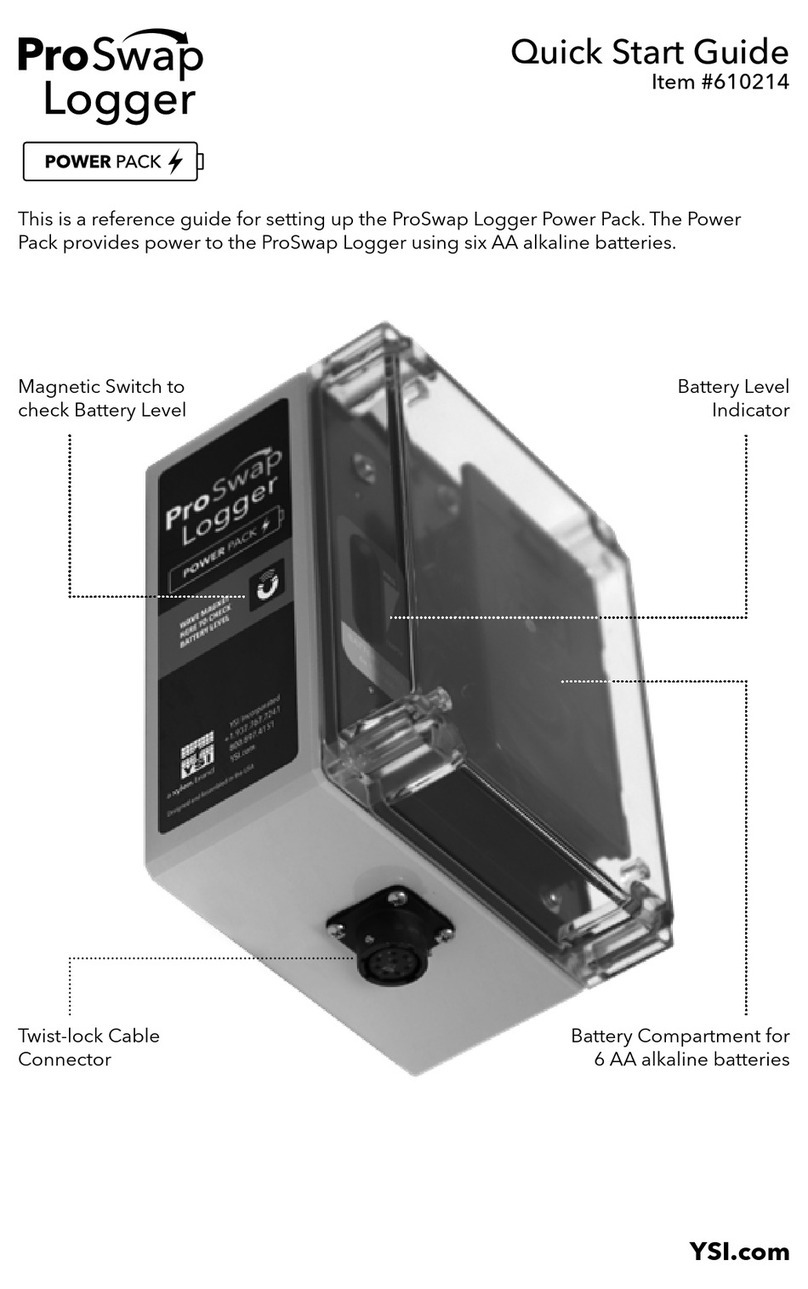

Xylem

Xylem YSI ProSwap Logger Power Pack quick start guide

Haug

Haug EN SL LC operating instructions