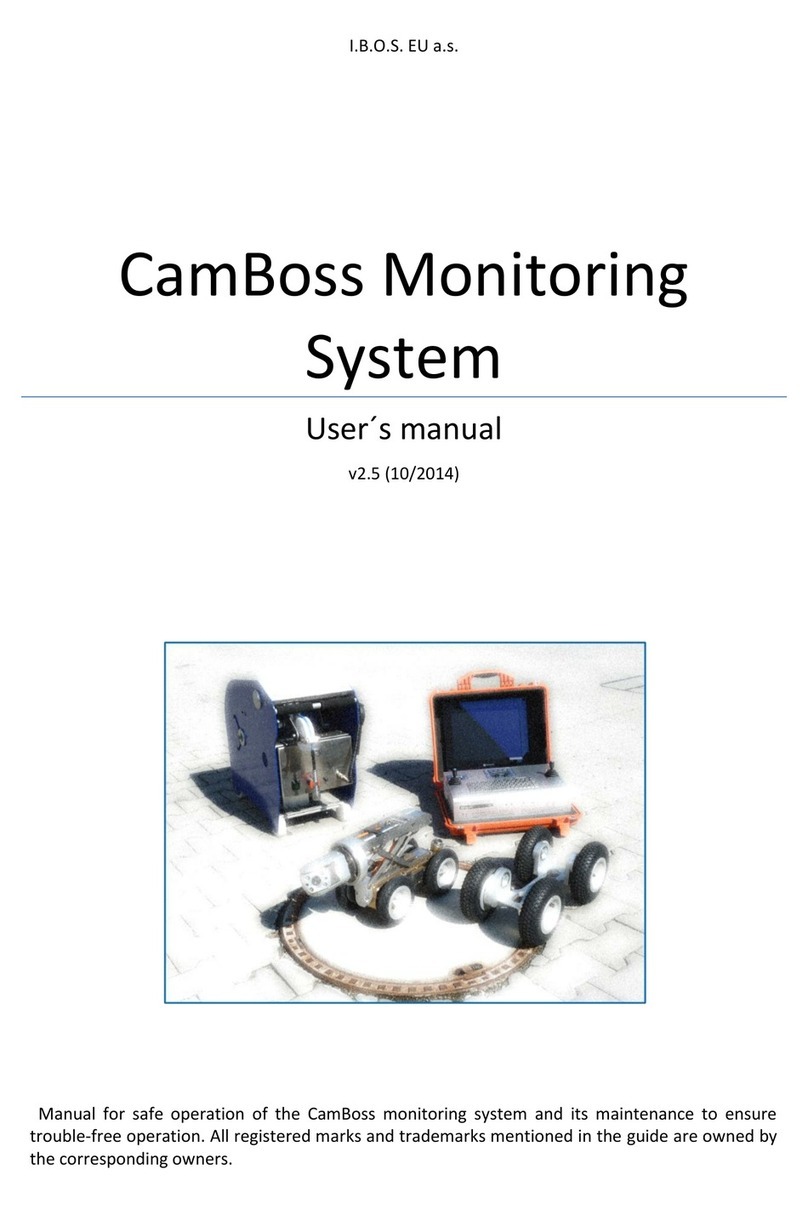

Sensotec Rapidox 1100ZR3-H-PFC User manual

Rapidox 1100ZR3-H-PFC

Oxygen Analyser

(Heller Version)

Instruction Manual

Revision 1.2

Cambridge Sensotec Limited

Unit 29 Stephenson Road

St Ives

CAMBS

PE27 3WJ

Tel. +44 (0)1480 462142

Fax +44 (0)1480 466032

Mobile (07866) 624236

Sales@Cambridge-Sensotec.co.uk

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Declaration of Conformity

Manufacturer: Cambridge Sensotec Ltd.

Unit 29 Stephenson Road

St Ives

Cambs

PE27 3WJ

Product Names: Rapidox portable oxygen gas analyser

Model Numbers: RX1100ZR3-H-PFC

Conform to the following specifications:

EMC: EN 61326:2006 Electrical equipment for measurement,

control and laboratory use

Declaration: I declare that the above products conform to the applicable

requirements of the LVD Directive 2006/95/EC and the EMC Directive 2004/108/EC

and is CE marked accordingly.

Signature:

Name: Dr. Mark Swetnam

Title: Managing Director

Company: Cambridge Sensotec Limited

Date: 16th December 2013

WEEE Regulations 2006

Cambridge Sensotec takes its responsibilities under the WEEE

Regulations extremely seriously and has taken steps to be compliant in

line with our corporate and social responsibilities. In the UK,

Cambridge Sensotec has joined a registered compliance scheme

“WeeeCare” (WeeeCare registration number WEE/MP3538PZ/SCH).

UK users only: If you have purchased any electronic or electrical product from

Cambridge Sensotec since 2007 and would like to dispose of it correctly under the

WEEE scheme, please contact us and we will be happy to either arrange the

collection of the waste or have it returned to our offices for recycling. All our in-

house manufactured products are scheme compliant and carry the WEEE label

indicating that it is NOT allowed to be disposed of in a landfill site.

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Contents

1. Introduction .......................................................................................................... 1

2. Features ................................................................................................................. 1

3. Heller Specific Features........................................................................................ 2

4. Technical Specification........................................................................................ 3

5. Precautions............................................................................................................ 4

6. Warning ................................................................................................................. 4

7. Rapidox Operating Instructions........................................................................... 4

7.1 PFC Connections ........................................................................................... 5

7.2 The Rapidox Analyser - Menu System......................................................... 6

7.3 Getting Started............................................................................................... 6

7.4 Display Behaviour ......................................................................................... 6

7.5 Pump Control................................................................................................. 7

7.6 Menu Access / Passwords ............................................................................. 7

7.7 Rapidox Calibration....................................................................................... 8

7.8 Programming the Multiplex........................................................................ 10

7.9 Cleaning the Sensor..................................................................................... 11

7.10 Alarms.......................................................................................................... 12

7.11 Analogue Outputs........................................................................................ 13

7.12 Setting the Display Units ............................................................................ 17

7.13 Setting the Display Options ........................................................................ 17

7.14 Pressure Correction Mode........................................................................... 18

7.15 Setting the Baud Rate .................................................................................. 18

7.16 RS232 / RS485 Port...................................................................................... 19

7.16.1 RS232 Protocol ..................................................................................... 19

7.16.2 RS485 protocol ..................................................................................... 21

7.17 Printing......................................................................................................... 21

7.18 Load Defaults ............................................................................................... 22

8. Rapidox Software Instructions........................................................................... 23

8.1 Software Installation ................................................................................... 23

8.2 Getting Started............................................................................................. 23

8.3 On-Screen Help ........................................................................................... 24

8.4 Configuration Page ...................................................................................... 24

8.5 Reconfiguring the Analyser ........................................................................ 25

8.5.1 Config 1 Screen ........................................................................................ 26

8.5.2 Config 2 Screen ........................................................................................ 27

8.5.3 Alarm Config Screen................................................................................ 28

8.6 On-Screen LCD ............................................................................................ 29

8.7 Remote Calibrating and Cleaning............................................................... 30

8.8 Calibration Error Messages ......................................................................... 31

8.9 Software Utilities......................................................................................... 32

8.10 Setting Analyser Date and Time................................................................. 33

8.11 Log Diagnostics For ..................................................................................... 33

8.12 Show / Hide LCD ......................................................................................... 33

8.13 Image Grabber.............................................................................................. 33

9. Data-Logging Software........................................................................................ 34

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

9.1 Introduction ................................................................................................. 34

9.2 Auto-Log Feature ......................................................................................... 34

9.3 Setting up the Data Logger.......................................................................... 34

9.4 Running the Data Logger............................................................................. 36

9.5 Auto Date Stamped Files............................................................................. 36

9.6 Live Time Graphing Screen ........................................................................ 37

9.7 Main Graph Window................................................................................... 38

9.8 Plot Colours.................................................................................................. 38

9.9 Graph Titles and Labels .............................................................................. 39

9.10 Plot Co-ordinates ......................................................................................... 39

9.11 Last data point ............................................................................................. 39

9.12 Using the Cursor.......................................................................................... 39

9.13 Zooming ....................................................................................................... 40

9.14 Y-Axis Graph Units ..................................................................................... 40

9.15 Oxygen Scale ............................................................................................... 40

9.16 Second Y Axis.............................................................................................. 40

9.17 Loading an Old Run .................................................................................... 40

9.18 Printing Graphs............................................................................................ 41

9.19 Data Logging in the Background................................................................. 41

9.20 Pausing the Data Logging ............................................................................ 41

9.21 Changing the Data Logging Parameters Mid-run....................................... 41

9.22 Working with Spreadsheets ........................................................................ 41

9.23 Disaster Recovery ........................................................................................ 42

9.24 DDE Protocols .............................................................................................. 42

10. Troubleshooting .............................................................................................. 44

10.1 Warranty ...................................................................................................... 45

10.2 Conditions of Warranty:.............................................................................. 45

11. Appendix 1: Proportional Flow Control ........................................................ 47

11.1 Connections ................................................................................................. 48

11.2 Software Description................................................................................... 48

11.3 Prop. Flow Control tab ................................................................................ 49

11.4 SW Alarm Config tab................................................................................... 52

11.5 Data-logging with PFC................................................................................. 53

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 1 Last printed 22/07/2015 18:00:00

1. Introduction

The Rapidox 1100ZR3-H-PFC (Z=zirconia sensor R=rear panel gas input 3=three

channel multiplexer H=Heller version PFC = Proportional Flow Control) oxygen

analyser allows fast and accurate oxygen analysis over the oxygen range 1ppm to

100% O2. The analyser provides continuous on-line oxygen analysis, with a

typical response time of less than 4 seconds for a 90% response to a step change in

gas compositions.

The Rapidox 1100ZR3-H-PFC is a fully integral unit complete with a powerful

diaphragm pump to provide variable gas sampling up to approximately 1.2 litres

per minute. The analyser has three separate gas inlets that can be independently

programmed to sample gas sequentially OR in various combinations using manual

operation. This is referred to as the multiplex in this manual.

The sensor head is located inside the analyser and comprises a zirconia ceramic

tube that needs to be heated to 650°C before it will conduct oxygen ions. The

analyser supplies heat to the sensor, which is controlled very accurately by a

regulated power supply incorporated in the instrument. An internally mounted

pressure sensor compensates for any fluctuations in pressure or vacuum caused

by differing flow conditions. The sample gas is collected from one or more of the

three gas inputs controlled by a series of electric solenoid valves.

The analyser is packed with features including programmable alarm circuits,

programmable analogue outputs, easy calibration (user selectable gases), RS232

communications and complete communications / data-logging software.

This version of the Rapidox is specially configured with PFC (Proportional Flow

Controller) output that that is programmed using the Rapidox software. See

Appendix 1 for more details.

2. Features

Multiplex gas analyser with three separate sample gas inlets

Very fast measurement response (typically 4 seconds for a 90% response).

Wide measurement range available (1ppm to 100% O2).

Accuracy ± 1% of the actual measured oxygen.

Easy calibration procedure requiring any two or three gas mixtures (ordinary

room air is usually one).

Low maintenance, sensor life expectancy typically 17,500 hours

Powerful variable speed diaphragm pump fitted for sampling the gas

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 2 Last printed 22/07/2015 18:00:00

Large back-lit LCD display (16 x 2 characters).

RS232, 0-10V and 4-20mA current loop outputs (both fully programmable).

Fully programmable alarm circuits.

Full data-logging software accessed via RS232 connection to a PC (RS485

available on request).

PIN code protection available

Optional printer attachment

3. Heller Specific Features

Internal carbon trap fitted to the sample gas line

Heller model name on the boot up screen

Voltage input on rear panel to enable / disable the sample pump

Modified software

PFC control loop outputs

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 3 Last printed 22/07/2015 18:00:00

4. Technical Specification

Property

Specification

Supply Voltage

90-260VAC, 50/60Hz

Power consumption

100W (max)

Analyser dimensions

350mm X 263mm X 150mm

Weight

4.0 kg

Display

16

6 play0mmimensions0/60 Hzed con

Warm up time

3-4 minutes at 20°C

Normal operating temperature

5-35°C

Sensor Range

1ppm to 100% O

2

taken from three

independent sample inputs.

Sensor Accuracy

±

1% of the actual measured oxygen

content

Outputs: O2voltage

0-10V (user-programmable) into minimum

5k

O2 current

4-20mA current loop (user-programmable)

into maximum 500

O2 PID control

4-20mA current loop (user-programmable)

into maximum

500

All data and parameters

RS232 or RS485 - data streamed on

demand

Sample Pump

Long-life vacuum pump

Flow Rate

0-1.2 L.min-1

Max. gas temperature on input

60°C

Calibration

Requires 2 or 3 user-selectable gas

compositions (air is default plus another

two)

Table 1: Rapidox 1100ZR3-H-PFC technical specification

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 4 Last printed 22/07/2015 18:00:00

5. Precautions

Make sure you read and understand these instructions and keep them safe for later

use. The unit should not be exposed to extreme temperatures < -5°C or > 60°C.

Normal operating temperature is 5-35°C. Avoid direct sunlight. Do not use liquid

cleaners, aerosols or solvents to clean the case. Use a damp cloth for cleaning. Do

not use this equipment near water. Avoid touching the LCD display as this may

cause permanent damage. Make sure the rear ventilation slots and the fan on the

rear panel are free of obstruction. There are no user serviceable parts in this unit.

Do not attempt to repair yourself. Refer all servicing to qualified Cambridge

Sensotec personnel.

6. Warning

This unit is NOT designed for use in life support situations. No responsibility can

be held for injury or loss of life caused by inappropriate use of this equipment.

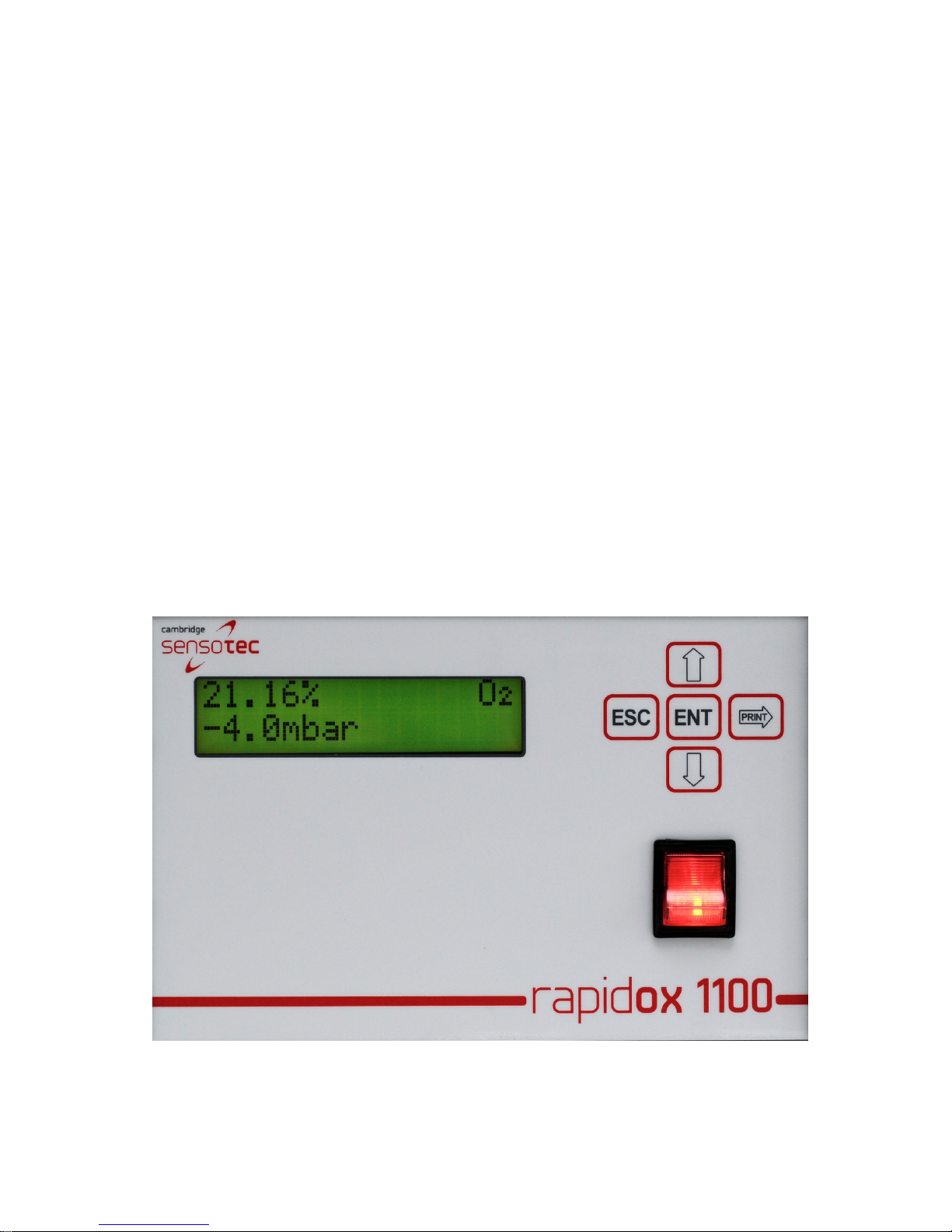

7. Rapidox Operating Instructions

Figure 1: Rapidox 1100ZR3-H-PFC front panel. Numbers are referred to in the text.

1

2

5

1

2

5

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 5 Last printed 22/07/2015 18:00:00

Figure 2: Rapidox 1100ZR3-H-PFC rear panel. Numbers are referred to in the text.

7.1 PFC Connections

On the rear of the PFC coded machines are two terminals labelled “PFC Valve 4-

20mA” and “Supply Valve (In)”.

Figure 3: Rear Panel Terminal Strip

a) PFC Valve 4-20mA: These connections provide the 4-20mA signal to

control the gas valve. The signal is generated by the PID control loop

parameters entered by the user.

b) Supply Valve (In): This connection requires a 12-24V connection from the

oven to indicate when it is operation. The PFC output and the analyser

sample pump are disabled when there is no voltage signal present.

3

4

6

7

8

9

2

1

+ve

+ve

-ve

-ve

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 6 Last printed 22/07/2015 18:00:00

7.2 The Rapidox Analyser - Menu System

All of the user-programmable functions are accessed via a menu system which is

controlled using the front panel Keypad (2). To access the menu press the ENT

button and to escape and return to the operating screen press ESC at any time.

The menu system flow chart is shown in Appendix 2 below.

7.3 Getting Started

Ensure that the Rapidox analyser is located away from extreme heat and dirt

environments. Plug the unit in to a suitable supply (noting the information on the

serial sticker and using the power cable supplied) using the rear power socket (8).

Make sure that the cooling fan (9) is not obstructed during operation.

Push the gas sample tube (6mm OD/4mm ID) on to any of the three

GAS IN (3) connectors on the multiplex and fit the retaining collar hand tight. If

other sample tubes are to be connected repeat this until all three sample points are

used. Repeat for the GAS OUT (4) connector should an outlet tube be required.

The pump will draw gas at a flow rate depending on the value set either in the

software or from the menu. The default setting is one hundred percent.

Turn the unit on using the red power switch on the front (5). The LCD (1) will

display the firmware version followed by the message “HEATING SENSOR”. The

sensor will take approximately four minutes to come up to temperature, after

which the Rapidox will begin to take measurements. The progress of the sensor

heater is shown in the form of a bar graph on the LCD (1).

Allow thirty minutes for the box to stabilise fully. This allows the components of

the analyser to reach a stable working temperature. During this warm-up period it

is common for the baseline oxygen to drift by a small amount, which may be

corrected by re-calibrating (see section 7.7).

7.4 Display Behaviour

Once at temperature the LCD display will show the oxygen reading (in percent or

ppm) on line 1. The bottom right corner of the LCD shows the three multiplex

inlets as circles “” representing “1,2,3” If a channel is currently being sampled

by the multiplex then this circle goes black e.g. “” to represent channel 1. If

the multiplex is in Manual mode then the word “MAN” alternates on the display

to remind you. See section 7.8 for a full description of the multiplex system. The

symbol AL1 or AL2 may also appear in the bottom right of the LCD if the alarm

system is enabled and an alarm condition applies. The oxygen sensor reading

may flash or show “O/Range” when its limits are reached, and error messages will

be displayed if there is a fault with the sensor. See Table 2 for more details:

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 7 Last printed 22/07/2015 18:00:00

Oxygen Sensor Display Possibilities

O2Reading > 9999.9%

Display shows “O/Range”

O2Reading >0.5ppm and < 9999.9%

Display shows the normal oxygen reading in % or ppm

O2Reading <0.5ppm

Display shows <0.5ppm flashing

O2Reading is flashing

Indicates that the pressure sensor is out of range and

automatic pressure correction is on.

O2Sensor takes > 10 minutes to warm up

Display shows “Possible sensor Fault” because the sensor

heater is failing.

O

2

Sensor has failed completely or become

disconnected

Display shows “No sensor or sensor Fault”

O2 Sensor is OK but the pressure sensor is faulty and

the auto pressure correction mode is selected

Display shows “Fault” flashing.

Pressure Sensor Possibilities

Pressure Reading is >1000mbar

Display shows “O/Range Press.”

Pressure Reading is >-1000mbar and <1000mbar

Display shows the normal pressure reading in mbar, bar,

kPa, torr or psi

Pressure Reading is <-1000mbar

Display shows “U/Range Press.”

Pressure sensor has failed completely or become

disconnected

Display shows “Fault Press.” With the word “Fault”

flashing

Table 2: Different display possibilities depending on the sensor reading.

7.5 Pump Control

Please note that the pump speed is fixed at 100% on Heller coded machines.

The flow rate of gas drawn into the analyser from the multiplex can be controlled

using the menu option 9: “Set Pump Flow”. The unit is supplied with the flow

rate set to 100% which equates to approximately 1.2 Litres per minute. If you

wish to change the flow rate press ENT and select menu option 10. Use the UP &

DOWN arrows to change the value from OFF – 100% in steps of 10% increments.

When using the unit with a pressurised (flowing) gas source the pump can be left

switched off. Note that on Heller units coded “PFC” the pump will be deactivated

if there is no voltage signal supplied to the supply valve (In) terminals on the rear

panel. Please see section 11.1 for further details.

7.6 Menu Access / Passwords

The analyser has an option to set a password that will restrict access to the menus.

The password menu is disabled by default in the factory. If you wish to password

protect the analyser press ENT and scroll down to the PASSWORD option (Menu

option 12). Pressing ENT again will ask you for the default password which is

“0000”. Enter this using the UP and DOWN arrows. Once the password has been

entered successfully you can chose between ENABLE and DISABLE in the menu

using the UP and DOWN keys.

The other option is to RESET the password to a new value. The password must be

4 digits long and can be any combination of numbers from 0-9. Make sure that the

new password is noted down!

If the password function has been enabled then in the future each time the menu

system is accessed then the password prompt will display. After the correct

password is entered then the full menu will be accessible. You can make as many

changes as you want to the options and only press ESC once you have finished.

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 8 Last printed 22/07/2015 18:00:00

Pressing ESC takes you out of the password protected area and you will have to re-

enter the password to go back in again.

If the password has been forgotten please contact Cambridge Sensotec who will

advise you on how to recover it.

7.7 Rapidox Calibration

Please note that when calibrating you must apply calibration gas using Gas 1 input

only. Gas 2 and Gas 3 inputs are disabled in the calibration process to avoid cross

contamination via the multiplex.Disconnect any tubing from inlets Gas 2 & Gas 3

for complete isolation.

Full calibration is a simple procedure requiring only two or three gases (one of

which is normally air – 20.95%). The gas values are user-selectable and can be

changed by using the front keypad (2) or the communications software described

in section 8, and the calibration values can be stored on file for later use.

Care must be taken to calibrate the analyser so that, whenever possible, the range

of measurement lies between the two calibration point extremes. For example, if

you are working at 10ppm but have calibrated the analyser between 21% and

100% then the analyser will be inaccurate. You would need to calibrate at, say,

1ppm and 1000ppm to be sure of good accuracy. The procedure is as follows:

1) Bearing in mind the points made above, decide which two (or three) gases

you are going to use for calibration. If you are constantly working at a

particular range of compositions then it would be wise to obtain small

cylinders of calibration gas with analysis certificates. Cambridge Sensotec

can supply these. Press the ENT button on the front panel keypad (2) to

access the menu system. The calibration function is option 1 on the menu

list, which can be scrolled using the UP and DOWN arrows. Press ENT

again to enter the calibration menu. The message “Use Calibration Gas on

Channel 1” is displayed for a moment. Use the UP and DOWN arrows to

select O2HIGH, O2MIDDLE or O2LOW and press ENT to proceed. The top

line of the display shows the current calibration gas stored and the bottom

line of the display shows the prompts. If the gas value is not what you

require you can edit the value (in ppm scientific notation) using the up and

down and right arrows on the keypad. The cursor flashes underneath the

digit to edit. For example air (20.95%) should be entered as 2.095E+05ppm

(209,500ppm). Note that you cannot go backwards to edit a digit to the left

of the cursor. Instead keep pressing the RIGHT button and the cursor will

wrap around back to the beginning. Alternatively press ESC to start again.

Press ENT when you are ready to proceed.

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 9 Last printed 22/07/2015 18:00:00

Scientific

Format

Meaning

Equivalent

ppm

Equivalent

Percent

1.000E+06ppm

1.000 x 1,000,000

1,000,000ppm

100.00%

2.095E+05ppm

2.095 x 100,000

209,500ppm

20.95%

1.000E+05ppm

1.000 x 100,000

100,000ppm

10.00%

1.000E+04ppm

1.000 x 10,000

10,000ppm

1.000%

1.000E+03ppm

1.000 x 1,000

1,000ppm

0.100%

1.000E+02ppm

1.000 x 100

100.0ppm

0.010%

1.000E+01ppm

1.000 x 10

10.00ppm

0.001%

1.000E+00ppm

1.000 x 1

1.000ppm

0.0001%

Table 3: Examples of common scientific format with their equivalent ppm and percent

values

2) The sensor needs to be exposed to the first calibration gas from a cylinder

(or exposed to ambient air, 20.95% if this is the calibration gas of choice)

using Gas 1 input on the rear. Allow several minutes to pass to flush the

sensor properly. Wait for the top line of the display (1) to become stable.

To complete the calibration press and hold the ENT button for two seconds.

During this time you will see a bar graph progress across the lower display.

The analyser will then recalibrate and display “O2recalibrated” and then

return to normal run mode. The display will now correctly read the value

of the first calibration gas. Note that if the ENT button is released before

two seconds have elapsed, the recalibration will be aborted and when the

analyser eventually returns to run mode it will use the existing calibration.

3) Note that the analyser should ideally be calibrated at normal ambient

pressure. If the pressure correction mode is set to AUTO then it is still

possible to perform an accurate calibration at pressures other than ambient.

However above 25mbar (gauge) or below -25mbar (gauge) the display will

flash and “P?” will display to warn you that the pressure is either above or

below the range recommended for accurate calibration.

4) The analyser predicts the correct signal from the sensor during calibration

and if this is outside the range of expected values then the display will flash

and display “G?” to warn you that either the cal gas flowing over the sensor

is different to the value you have programmed OR the sensor may be old

and approaching the end of its life. Check before proceeding!

5) To calibrate against the second or third calibration gas, repeat the

procedure from 2 but this time press ENT followed by the UP or DOWN

button to scroll through to the “O2Middle” or “O2Low” screen. Flush the

sensor chamber with the second calibration gas allowing several minutes

for the new gas to flush through. Again please remember to always use

Gas1 input to apply calibration gas. Wait for the display to become stable

before pressing the ENT button for two seconds. The analyser will then

recalibrate and display “O2recalibrated” and then return to normal run

mode. The display will now correctly read the value of the calibration gas.

6) The analyser is now correctly calibrated and will read accurately between

these two calibration points. Note that this procedure can be performed

remotely using the software described in section 8. You can now repeat

this process for the third calibration gas if required.

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 10 Last printed 22/07/2015 18:00:00

7) If at any time, you encounter difficulties and wish to restore the machine to

its factory set calibration, use the configuration software provided and load

the default settings (described in section 7.18 below). Each machine is

provided with a unique file that contains the factory settings. This is

located on the memory stick provided and is copied onto your PC during

the installation process.

8) Note that the three calibration points are independent of each other so you

can calibrate the analyser in any order you desire. However please note

that O2HIGH must always be greater than O2MIDDLE which must always

be greater than O2LOW. Typically the factory settings are: O2

HIGH=20.95%, O2MIDDLE=0.1% (1000ppm) and O2LOW=0.001%

(10ppm).

NB You must always perform a FULL calibration to achieve good accuracy.

7.8 Programming the Multiplex

The Rapidox 1100ZR3-H-PFC is fitted with three independent gas inlets on the

rear panel allowing up to three separate gas samples to be analysed. The

multiplex unit allows one or more of the sample gases to pass over the sensor and

can be programmed by the user to work automatically, sampling each gas in turn

for a given time, or manually where each gas inlet channel can in turn be switched

on or off:

1. Automatic:When the multiplex is set to Auto then each gas channel is

sampled for a set period of time (or switched off) by the user. The sequence

is repeated continuously until the user changes the program. For each gas

channel the user can select a sample time of 1,2,3,4,5,10,15,30 minutes or

1,2,6,12 or 24 hours. In addition the user can switch one of the channels

off. In this case the remaining two channels will sample alternatively. At

least two gas channels have to be on for the automatic mode to work. The

front LCD displays three circles indicating to the user which channel is

currently being sampled. If channel 1 circle is flashing then this indicates

that the closed loop output is under PFC control. See Table 4 for more

details.

2. Manual: When the multiplex is set to manual mode the user can set any

channel to “on” or “off”. Any possible permutation is allowed in this mode

including switching all three off. Note however in this instance the internal

pump will automatically switch off to preserve itself. This mode is useful if

only one single sample is required, or sampling the same gas from different

locations is desired. The front LCD displays three circles indicating to the

user which channel(s) is/are currently being sampled. In this mode the

letters “Man” also appear every few seconds to indicate that the analyser is

operating in this mode. If channel 1 is set to “on” and channels 2 and 3 are

set to “off” then the PFC closed loop is active and the channel 1 circle will

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 11 Last printed 22/07/2015 18:00:00

flash to indicate this. See Table 4 for more details.

Symbol

Meaning

+/- “Man”

In automatic mode sampling channel 1 for selected time.

In manual mode channel 1 on and 2 & 3 off.

If the black circle is flashing then the closed loop output is under PFC control. If it is not

flashing then PFC closed loop control is suspended.

+/- “Man”

In automatic mode sampling channel 2 for selected time.

In manual mode channel 2 on and 1 & 3 off.

PFC closed loop control is suspended.

+/- “Man”

In automatic mode sampling channel 3 for selected time.

In manual mode channels 1 & 2 off and 3 on.

PFC closed loop control is suspended.

+ “Man”

In manual mode only all three channels are off. Note that the pump switches off if this mode

is set. PFC closed loop control is suspended.

+ “Man”

In manual mode only all three channels are on. PFC closed loop control is suspended.

+ “Man”

In manual mode only channels 1 & 2 on and 3 off. PFC closed loop control is suspended.

+ “Man”

In manual mode only with channels 1 & 3 on and 2 off. PFC closed loop control is suspended.

+ “Man”

In manual mode only with channels 1 off and 2 & 3 on. PFC closed loop control is suspended.

Table 4: Different permutations of channel indicator lights on the LCD

To program the multiplex press ENT on the keypad (2) and select menu option 2

using the up and down arrows or using the software described in section 8.6.

Press ENT to proceed. Use the UP and DOWN arrows to select “Auto” or

“Manual” and ENT to proceed. If “Auto” is selected then use the UP and DOWN

arrows to select a time period (1,2,3,4,5,10,15,30 minutes or 1,2,6,12,24 hours or

OFF) for each gas sample inlet in turn. If “Manual” is selected use the UP and

DOWN arrows to select “on” or “off” for each gas sample inlet in turn. Once all

three are programmed then the multiplex will start the sequence of sampling from

gas 1 inlet.

Note that you can only have one of the channels switched on at any time in the

auto mode. If “on” is selected then the option disappears from further menus as

you continue the programming sequence. You can have any combination of “off”

and “on” in manual mode.

7.9 Cleaning the Sensor

You can clean the sensor at any time by pressing ENT on the keypad (2) and

scrolling down to option 3 “Clean Sensor” or using the software described in

section 8.6. Press the ENT button to proceed. The screen displays “Clean

Sensor?”. Press ENT again and the cleaning will take place. The procedure takes

approximately five seconds and the LCD display shows the progress of the

operation. Once finished the analyser will take a moment to re-stabilise. The

sensor is cleaned each time the unit is switched on prior to operation. If you are

operating in gases with large amounts of soot, there is a risk that the sensor

surfaces will become contaminated with particulates, which will impair

performance if allowed to build up. The cleaning operation pumps oxygen

through the zirconia tube, which burns the particulates away from the sensor

surface.

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 12 Last printed 22/07/2015 18:00:00

7.10 Alarms

The Rapidox is fitted with two independent and fully programmable alarm relay

outputs, which can be programmed to be either normally open N/O (closes on

alarm) or normally closed N/C (opens on alarm). You have the option of assigning

each alarm to the oxygen, or pressure (internal) as well as enabling the alarm relay

circuits, enabling an audible buzzer and enabling a visual warning on the screen.

The alarms can be programmed by the user via the keypad (2) on the front panel

or using the software provided (section 8.5.3 ). To change the alarm settings scroll

down the menu to no. 4 “Set Alarms” and press ENT. Now use the UP & DOWN

arrows to select “Alarm 1” or “Alarm 2” and press ENT. The next screen shows

the message “Assign To:”. Use the UP and DOWN arrows to select O2, or Pressure

depending on which measurement you want the alarm to work with, and press

ENT to proceed. The default is O2.

The next settings configure the behaviour of the alarm. Use the UP & DOWN

arrows to select ON or OFF for the following parameters:

1. OUTPUTS: This enables the rear panel relay outputs when ON is selected

2. AUDIBLE: This enables or disables the audible buzzer inside the unit

which will sound in an alarm condition

3. VISIBLE: This enables or disables warning messages on the LCD screen on

the front of the Rapidox. During an alarm condition either “AL1” or “AL2”

(or a combination of both) will flash at the bottom right hand corner of the

display.

4. POLARITY: This determines whether you are setting a rising or falling

alarm. Use the arrows to change the direction of the alarm to up or down.

A rising alarm means that the alarm will be silent at values below the set-

point but as soon as the value rises above the set-point the alarm will be

triggered

5. SETPOINT: The current alarm set-point is displayed in scientific notation

with a flashing cursor under the first digit. Use the UP & DOWN arrows to

change the digit and the RIGHT arrow to progress until the correct value is

displayed. When done, press ENT to proceed to the next setting.

6. CONTACTS: The relay outputs can be set to either normally open (N/O) or

normally closed (N/C). The factory default is N/O, meaning the contacts

will close when an alarm condition occurs. Press ENT to save all the above

settings for the selected alarm.

Alarm 2 can be set in exactly the same way as described above and both alarm

circuits are completely independent of each other. Note that you must programme

all the parameters for each alarm for the settings to be saved. The bottom line of

the LCD will display “Alarm x set” (where ‘x’ is the selected alarm channel) to

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 13 Last printed 22/07/2015 18:00:00

confirm that the settings have been saved.

The alarm circuit relays are accessed via the terminal block on the rear panel and

are clearly labelled. Alarm 1 is assigned to the terminals labelled “Alarm High”

and Alarm 2 is assigned to the terminals labelled “Alarm Low”. The relay circuit

is rated at 24V 0.5amps maximum. Under certain conditions (e.g. the sensor

becomes disconnected) the Rapidox will set the alarm channel to OFF to prevent

false alarms, and the relay contacts for the affected channel will go to the

programmed N/O or N/C setting. For more information please refer to Table 5 in

section 7.11 below.

7.11 Analogue Outputs

The Rapidox analyser provides various analogue outputs. The standard industrial

analogue outputs (0-10V and 4-20mA) for both oxygen, and internal pressure are

accessible via the terminal block (6) on the rear panel. These outputs have a 12

bit resolution (approximately 1 in 4000) and the lower and upper values are fully

user-programmable using the keypad (2) or the software provided (section 8). In

the case of oxygen, three output mode options are provided for setting the outputs,

in order to give the user maximum flexibility:

1. LIN (ppm): The linear oxygen output mode setting produces an output that is

scaled linearly between 0 and 10V (or 4 and 20mA). So, for example, if the

scale is set 0V = 0% O2and 10V = 100% O2then 5V would indicate an oxygen

reading of 50% O2. The scaling of this example is shown in the following plot,

from which other intermediate values can also be read. This setting is more

suitable for medium to high ranges of oxygen, or where the user wishes to

monitor oxygen over a narrow range.

Figure 4: Graph showing the linear output mode option for oxygen

"Lin(ppm)"

Linear output mode

0

1.25

2.5

3.75

5

6.25

7.5

8.75

10

010 20 30 40 50 60 70 80 90 100

O

2

(%)

O

2

Volts output

4

6

8

10

12

14

16

18

20

O

2

mA output

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 14 Last printed 22/07/2015 18:00:00

The following general formulae can be used to calculate the oxygen from the

voltage or current outputs when set to the linear output mode:

Output type Formula for calculating oxygen from analogue output signal

0-10V O

2

= V

out

/ 10 * (O

2H

- O

2L

) + O

2L

4-20mA O

2

= (mA

out

– 4) / 16 * (O

2H

- O

2L

) + O

2L

Where: O2L = user setting of oxygen for 0V or 4mA output 1

O2H = user setting of oxygen for 10V or 20mA output 1

Vout = the measured voltage output in volts

mAout = the measured current output in mA

1O2, O2L and O2H must all be in the same units.

2. LOG (ppm): This setting produces an output that is scaled logarithmically

between 0V and 10V (or 4 and 20mA). So, for example, if the scale is set to 0V

= 0.0001% (1 ppm) and 10V = 100% (1,000,000 ppm) then 5V would indicate

an oxygen reading of 0.1% (1000 ppm). This scale is more suitable for large

ranges of oxygen down to very low ppm levels. The scaling of this example is

shown in the blue line in following plot, from which other intermediate values

can also be read. For comparison, the red line shows the limitations of using

the linear oxygen output mode over the same range.

Figure 5: Graph showing the logarithmic output mode option for oxygen (blue) compared with

linear mode (red).

The following general formulae can be used to calculate the oxygen from the

voltage or current outputs when set to the log output mode:

"Log(ppm)": Log output mode

0

1.25

2.5

3.75

5

6.25

7.5

8.75

10

0.0001 0.001 0.01 0.1 110 100

O

2

(%)

O

2

Volts output

4

6

8

10

12

14

16

18

20

-4 -3 -2 -1 012

log(O

2

(%))

O

2

mA output

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 15 Last printed 22/07/2015 18:00:00

Output type Formula for calculating log10(O2) from analogue output signal

0-10V log

10

(O

2

) = V

out

/ 10 * log

10

(O

2H

/ O

2L

) + log

10

(O

2L

)

4-20mA log10(O2) = (mAout – 4) / 16 * log10(O2H / O2L) + log10(O2L)

Where: O2L = user setting of oxygen for 0V or 4mA output 2

O2H = user setting of oxygen for 10V or 20mA output 2

Vout = the measured voltage output in volts

mAout = the measured current output in mA

2O2, O2L and O2H must all be in the same units.

Note: O2= 10 log(O2)

3. RAW (mV): This setting is for certain customers who like to monitor the raw

sensor EMF signal. The signal from a sensor goes from approximately -50mV

at 100% O2through zero at approx 5% O2and to +1000mV at extremely low O2

levels. So, for example, if the scale is set to 0V (output) = -50mV (sensor

voltage at approximately 100% O2) and 10V (output) = 250mV (sensor voltage

at approximately 1ppm O2) then 5V would indicate a sensor voltage of 100mV.

The scaling of this example is shown in the following plot, from which other

intermediate values can also be read.

Figure 6: Graph showing the raw sensor mV output mode option for oxygen

The following general formulae can be used to calculate the oxygen sensor raw

voltage (O2mV) from the voltage or current outputs when set to the raw sensor

voltage output mode:

"Raw(mV)"

Sensor mV output mode

0

1.25

2.5

3.75

5

6.25

7.5

8.75

10

-50 050 100 150 200 250

Raw sensor voltage (mV)

O

2

Volts output

4

6

8

10

12

14

16

18

20

O

2

mA output

Cambridge Sensotec Rapidox 1100ZR3-H-PFC O2Analyser Instruction Manual

Version 1.2 16 Last printed 22/07/2015 18:00:00

Output type Formula for calculating sensor mV from analogue output signal

0-10V O

2mV

= V

out

/ 10 * (O

2mVH

- O

2mVL

) + O

2mVL

4-20mA O2mV = (mAout – 4) / 16 * (O2mVH- O2mVL) + O2mVL

Where: O2mVL = user setting of oxygen mV for 0V or 4mA output

O2mVH= user setting of oxygen mV for 10V or 20mA output

Vout = the measured voltage output in volts

mAout = the measured current output in mA

To modify the oxygen analogue output range scroll down the menu to option 5

“Set Outputs” and press ENT. Use the UP & DOWN arrows to select the output

type either “lin(ppm)”, “log(ppm)” or “raw(mV)” and press ENT. You can now edit

the lower and upper values using the UP & DOWN and RIGHT arrows. Once

programmed the new values remain in the memory until they are edited again in

the future.

Note that the voltage (0 to 10V) and current (4 to 20mA) outputs are locked

together, so that these outputs cannot be set independently of each other. In

normal operation therefore, 0V output always corresponds to 4mA and 10V

always corresponds to 20mA output.

During initial warm up of the Rapidox when the display reads the serial number

the output sent to the rear terminal for oxygen will stay at 2mA (1V) which is the

standby signal. If at any stage a sensor becomes disconnected internally, or the

signal exceeds the measurable range for that sensor, then the display will indicate

there is a fault and the outputs will change to 1mA (0.5V) which is the sensor fault

signal. This will recover as soon as the sensor is reconnected and the fault

cleared. Additional current and voltage signals are provided by the analyser to

give an indication of various conditions and these are described in Table 5 below,

together with the status of the alarms during the condition:

O2Analogue Outputs

Description Explanation Alarms (3)

Current (1)

(4-20mA)

Voltage (2)

(0-10V)

1mA 0.625V Fault

There is a sensor fault on the oxygen

sensor, and/or the temperature sensor

has a fault condition, and/or the

pressure mode is set to automatic

(pressure compensation active) and

the pressure sensor has a fault

condition.

De-activated

2mA

1.25V

Start up

The analyser is still initialising.

De-activated

2.5mA

1.5625V

Sensor under range

The sensor reading is under range.

Active

3mA

1.875V

Sensor over range

The sensor reading is over range.

Active

3.5mA 2.1875V Sensor operating out of

specification

The sensor reading is in range but the

temperature sensor reading is out of

range, and/or the pressure mode is set

to automatic (pressure compensation

active) and the pressure sensor is out

of range.

Active

4 to 20mA 0 to 10V Normal operating output

The O

2

sensor and associated (1)

sensor(s) are operating normally and

readings are in range.

Active

Table 5: Analogue output settings and alarm status for certain conditions

Table of contents

Other Sensotec Analytical Instrument manuals