Estate Swing E-SC 400 User manual

This manual suits for next models

1

Table of contents

Other Estate Swing Gate Opener manuals

Estate Swing

Estate Swing E-S 500 User manual

Estate Swing

Estate Swing E-S 1600 Series User manual

Estate Swing

Estate Swing Classic Series User manual

Estate Swing

Estate Swing E-S 1000D Series User manual

Estate Swing

Estate Swing E-S 1000H Series User manual

Estate Swing

Estate Swing E-S 1600 Series User manual

Estate Swing

Estate Swing E-S 1000H Series User manual

Estate Swing

Estate Swing E-S 1600L Series User manual

Estate Swing

Estate Swing E-S 300 User manual

Estate Swing

Estate Swing E-SC 1600 Series User manual

Popular Gate Opener manuals by other brands

Centurion

Centurion D10 installation guide

tousek

tousek FOLD 330/L Connection and Installation Guide

AGS

AGS 900 How to install

Microbrain Intelligent Technology

Microbrain Intelligent Technology ITS-AXX user manual

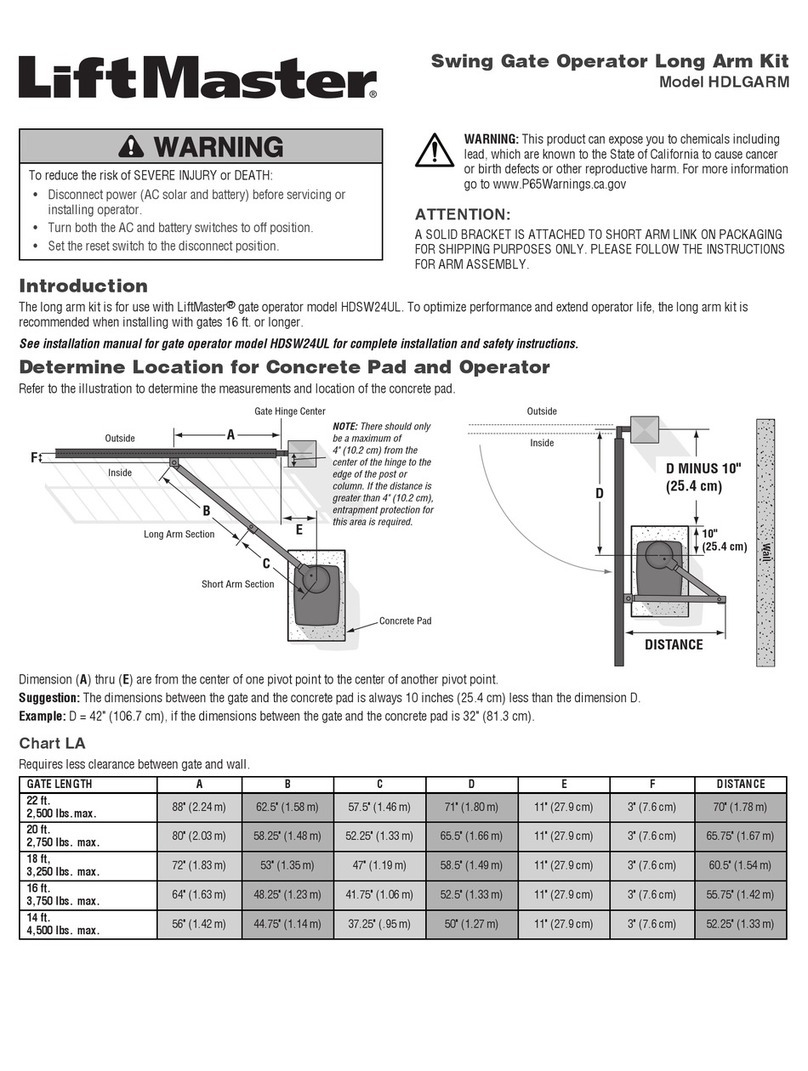

Chamberlain

Chamberlain HDLGARM quick start guide

Nice

Nice Naked Sliding NKSL400 Instructions and warnings for installation and use

GATEMASTER

GATEMASTER 900 HD installation manual

Automatic Technology

Automatic Technology Easy Slider installation instructions

Ghost Controls

Ghost Controls TSS1 Installation and owner's manual

Alutech

Alutech AM-5000KIT Assembly and operation manual

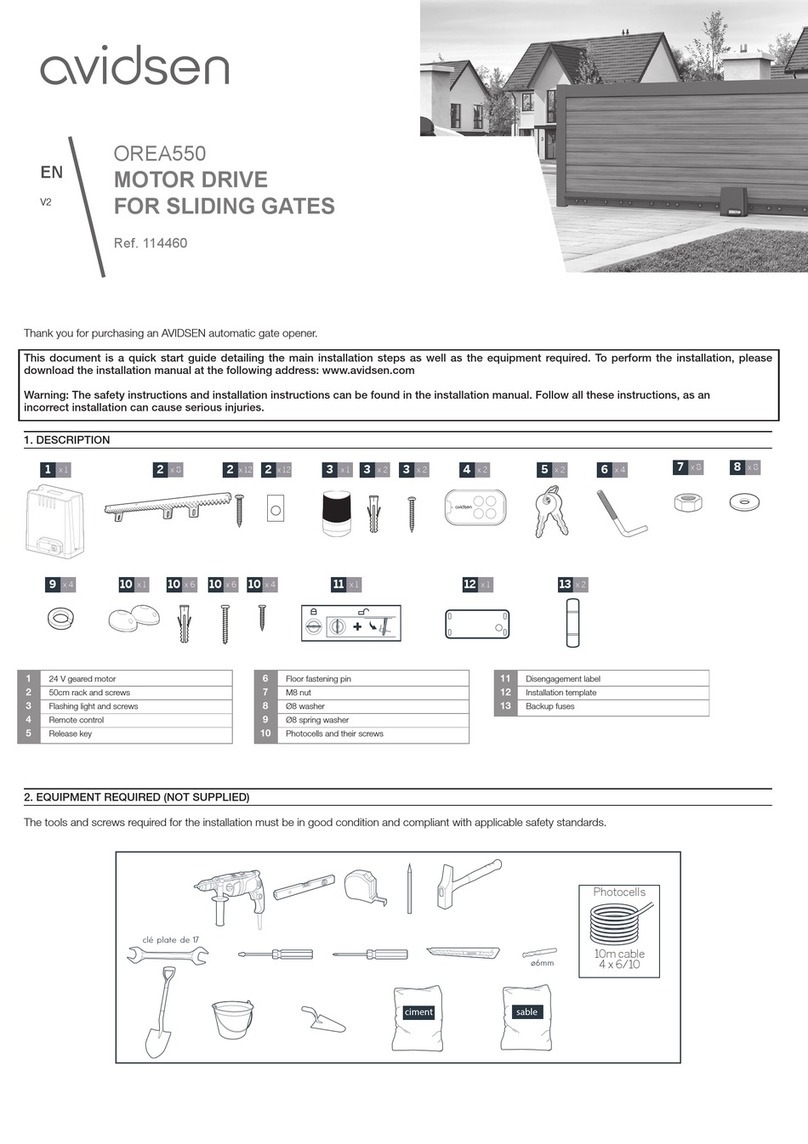

Avidsen

Avidsen OREA550 quick start guide

SOMFY

SOMFY tecnoShades NR0-Rn Programming instructions