Sentinel JetFlush X100 Manual

Technical Information

Page 1 of 3 V1. Aug 2018

Sentinel JetFlush Test Kit

For identifying problem areas in systems older than 6 months

Test Kit Components

•Sentinel X100 Test Kit

•Turbidity Tube

•TDS Meter

•Mini IR Thermometer

•Conductivity/TDS Standard (1413µS/989ppm)

Introduction

The JetFlush Test Kit is designed for use in conjunction with the Sentinel JetFlush Rapid® domestic central heating

system flushing unit. It will rapidly identify where problems exist due to the build up of corrosion and scale debris

and allow you to demonstrate the effectiveness of the flush once it has been completed. The Survey Report can be

printed and it allows you to record relevant information, both pre and post flushing, to show the improvements to

the system. The completed report can then be left with the customer.

Procedure

Mains Water

Take a sample of cold mains water and measure the TDS using the meter supplied and following the instructions

below. Record the reading in the appropriate box on the Survey Report.

Heating system - Pre-flushing

After setting the boiler thermostat to a temperature below 40°C, as per the JetFlush Rapid® Manual, and allowing

the system to stabilise, a survey of the system should be carried out as follows using the Survey Report:

1. Locate each radiator and record the locations on the Survey Report.

2. Measure the temperature at 5 points on each radiator surface by pointing the IR thermometer at the following

points:

•Bottom left (BL)

•Top left (TL)

•Centre (C)

•Bottom right (BR)

•Top right (TR)

Record the readings on the Survey Report and note those radiators with substantial cold spots.

3. Record the settings of any TRVs before opening them to their maximum.

4. Locate the system drain valve and allow to run to waste for 1 minute taking appropriate care to avoid burns by

using heat resistant gloves. Take a sample of water and carry out the following:

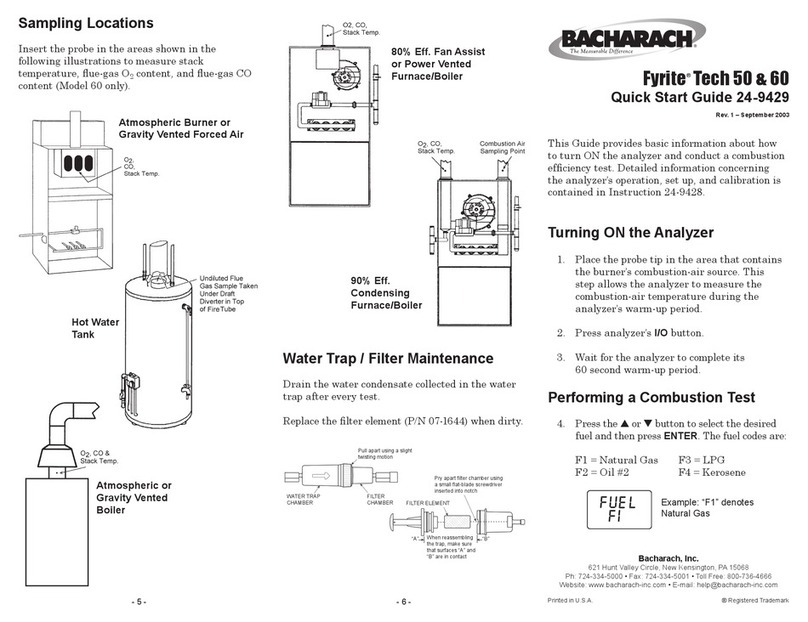

•Fill the Turbidity Tube to the top mark (200ppm) and look through the column of water. If the black

concentric circles can be seen then record the turbidity as <200ppm.

•If the circles cannot be seen, remove small volumes of water until they are visible. At the final water

level take the reading off the side of the tube and record on the Survey Report.

Technical Information

Page 2 of 3 V1. Aug 2018

Heating System – Flushing

To determine whether the system is completely flushed, take a sample of water from the drain valve and carry out

either or both of the following two tests:

1. Fill the Turbidity Tube to the top mark again (200ppm) and look through the column of water. If the black

concentric circles are visible then the system is sufficiently clean. If the circles are not visible, then further

flushing is required until the circles can be seen. Record the final reading on the Survey Report e.g. <200ppm.

2. Measure the TDS of the water, using the meter supplied. If this value is within 10% of the TDS of the cold mains

water (previously measured) it indicates that the system has been flushed satisfactorily to remove the cleaning

chemical. Record the TDS reading on the Survey Report once a satisfactory reading has been obtained.

Heating System – Post-flushing

Once the final flush has taken place and Sentinel X100 scale and corrosion inhibitor has been added, take a further

system sample and check for correct levels of Sentinel X100 using the Sentinel Test Kit. Once a satisfactory level

has been achieved record this on the Survey Report in the appropriate place.

Finally, return each TRV to its original position, switch on the boiler and allow it to come up to temperature without

resetting the thermostat. The radiators must then be bled as necessary and a further temperature survey of the

radiators carried out as detailed in the Pre-flushing section above. The new temperatures must then be recorded

on the Survey Report in the appropriate place.

Test Equipment Instructions

Turbidity Tube

The Turbidity Tube is an excellent way of assessing the clarity of the system water. It is calibrated along the length

of the tube in terms of parts per million of suspended solids and also turbidity units. The simple process of using

the tube is as follows:

3. Fill the tube to the top line (200ppm) with system water

4. Look through the column of water. If the black concentric circles can be seen then the level of suspended solids

is <200ppm and, for most situations, this would indicate a satisfactory quality of water.

5. If the circles cannot be seen then remove water from the tube until they are visible. At the final water level take

the reading off the side of the tube.

TDS Meter

Operation

1. Remove the probe cap, and then press the power button. The LCD should now show “000”.

2. Dip the probe into the water without exceeding the water level limit.

3. Stir gently until the display stabilises and then remove the meter from the water. (The reading will

automatically hold).

4. Read the value on the display expressed in ppm.

5. To reset the reading when in use, press the power button. The LCD should now show “000”.

6. After measuring, gently shake the meter 2-3 times to remove residual water and then close the probe cap. The

meter will automatically turn off after approximately 40 seconds.

7. To turn the meter off manually, press the power button for 3 seconds.

Calibration

1. Remove the probe cap, and then press the power button. The LCD should now show “000”.

Technical Information

Page 3 of 3 V1. Aug 2018

2. Dip the probe into the Conductivity/TDS Standard without exceeding the water level limit.

3. Stir gently until the display stabilises and then remove the meter from the water. (The reading will

automatically hold). The reading should be 989 +/- 25ppm.

4. If the reading is incorrect, remove the battery compartment cover to access the calibration button.

5. Turn the calibration button with a screwdriver until the reading shows 989ppm.

Battery Replacement

1. To replace the batteries, remove the battery compartment cover and install a new CR2032 lithium

battery into the battery holder. Make sure the battery is properly placed with the positive “+” side up.

2. Close the battery compartment cover. Then press the power button. The LCD should now show “000”. If

the LCD does not light up, repeat the above steps.

Error Codes

•"Err” Reading above 1999ppm

Mini Infrared Thermometer

Operation

1. Point the unit at the surface to be measured. Ensure that the meter is approximately 12” (30cm) away from the

surface. The light spot is used for aiming at the target.

2. Press the button and the temperature reading will be updated on the LCD. When the operator releases the button,

the reading will automatically be held on the LCD for 10 seconds. After 10 seconds the thermometer will power down.

3. The temperature units can be changed by using the °C/°F switch.

Measurement Notes

1. If the surface of the object under test is covered in oil, grime etc clean before taking measurements.

2. If the surface of the object is highly reflective, apply masking tape to the surface before measuring.

3. Steam, dust, smoke can obscure accurate measurements.

Battery Replacement

When the low battery symbol appears on the LCD, replace the meter’s 1.5V batteries. Detach the battery compartment

cover by pushing the engraved pattern on the handle and pull down. Replace the 1.5V x 2 batteries with new ones and

replace the battery compartment cover.

Sentinel Test Kit

Instructions for use

1. Place one No. 1 tablet and one No. 2 tablet in the plastic tube.

2. Fill the tube brim-full with a fresh sample of water from the central heating system.

3. Stopper the tube and shake well.

4. Leave for 5 minutes for the colour to develop, shaking occasionally.

5. Hold the tube up against the white panel on the colour comparison card.

6. If there is sufficient Sentinel X100 present to protect the system, the liquid in the tube will be a darker colour than the

yellow card.

7. If the liquid in the tube is a lighter colour than the card, add more Sentinel X100 to the system and repeat the test.

8. Rinse the tube thoroughly with tap water after use.

Sentinel Performance Solutions Ltd

7650 Daresbury Park, Warrington, Cheshire, WA4 4BS, UK

Tel: +44 (0) 1928 704 330 www.sentinelprotects.com

Table of contents

Other Sentinel Test Equipment manuals