HD Electric FACT-1 Instruction Manual

2

MPORTANT SAFETY NOTES

IMPORTANT! Please read the Operator's Manual thoroughly before operating the unit.

Having a complete understanding of the Feeder Ammeter Clear Test (FACT-1) operation

and issues that may influence its performance is key to obtaining the maximum

effectiveness of this unit.

The FACT-1 outputs 120VAC to the cable under test and therefore extreme caution must

be exercised to prevent electrical shock.

Never obstruct the intake or exhaust grills in the cord storage compartment.

Never attempt to close the cover while the unit is operating or while any cables are

connected.

Do not connect the FACT-1 unit to a GF protected circuit.

Before connecting the FACT to any circuit, test and ground that circuit to verify it is both

de-energized and discharged.

DO NOT use the FACT-1 if any chance of a back feed exists.

The FACT-1 contains sensitive electronic parts. Although the housing is rugged, care

should be taken to prevent any impact to the unit. An impact could damage the internal

circuitry or display. The unit should never be opened except by the manufacturer. No user

serviceable parts are inside.

3

FACT-1 DESCR PT ON

Alternating Current (AC) Ammeter Clear tests are used to indicate the presence of either

grounds or short circuits on a primary feeder's three phase conductors or either grounds

or short circuits on transformer secondaries.

ntentional grounding of the feeder cables may occur during some types of maintenance.

Failure to remove these grounds at the end of the maintenance procedure is unintentional

but nevertheless could cause potential damage if an attempt is made to put the feeder

back in service.

The Feeder Ammeter Clear Test Set has been specifically designed for utilities that do not

or cannot disconnect their transformers from the primary cable under test. A 120V AC,

60Hz source is used to check for grounds or short circuits. The AC signal is also adequate

to energize the transformers connected to the feeder sufficiently enough to detect

grounds left on the secondary side of a transformer.

n the primary phase-to-ground fault scenario, the LCD ammeter display will indicate a

fault current of approximately 5 Amps with a nominal line voltage of 120V. A maximum of

5 Amps is provided by the Test Set and is limited by an internal 24 ohm power resistor. n

the primary phase-to-phase fault scenario, the LCD ammeter display will also indicate a

fault current of approximately 5 Amps with a nominal line voltage of 120V.

n the secondary side fault scenario, a short circuit fault from a feeder transformer

secondary conductor to ground occurs. This allows more current to flow through the

primary windings of this transformer which current then flows through the primary

feeder. The value of the current flowing will depend on the nominal voltage of the

feeder being tested since the turns ratio of the transformer will vary. For example,

when a 13.8kV primary feeder connected to a transformer with a 120V secondary

is tested, the LCD ammeter display reading would be about four amperes while on

a 27kV feeder with a transformer to 120V, the LCD ammeter display reading would

be about 1.4 amperes. These are only estimates and can vary depending on feeder

voltage and the type of wire (impedance) used to ground the feeder.

Under a "No Fault" condition, the LCD ammeter display will generally indicate a fault

current of less than about O.3A and will indicate that No Fault has occurred. This ammeter

reading would then represent the sum of transformer excitation currents on a given typical

feeder should said transformers not be disconnected from feeder on the primary side.

4

FACT-1 FRONT PANEL DESCR PT ON

1. TEST CABLE CONNECTOR - 3 binding posts for making connections to the individual

phases of the feeder. Each post is labeled to correspond to a particular phase of the feeder.

2. LCD DISPLA - The Liquid Crystal Display (LCD) for displaying instructions, messages,

and ammeter current.

3. SELECTOR KNOB - This rotary switch selects which phase is being tested at any

given time. When the knob is in the STANDBY position, no phase is selected.

4. SELF-TEST - Pressing this button initiates the Feeder All Clear Test Set the self-test

mode to assure proper operation. The test cable assembly must be removed during

the self test.

5. POWER - This button is the master power switch for the Feeder Ammeter Clear Test

Set. t is a latching pushbutton type. Pressing this button powers up all the electronics

and fan for operation

6. AMMETER CLEAR - Pressing this button provides 120V AC to the selected binding

post (Phase). t is a momentary pushbutton type. The button should not be pressed for

long periods of time since substantial heat can develop in the unit when there is a

ground on the feeder.

7. POWER CORD - Power cord for the unit. Cord must only plug into a 120V AC, 60Hz,

non-GFC 15 ampere outlet.

1

2

3 5

4

6

5

US NG THE FACT-1

CAUTION: Steps 1 through 6 should he performed with the feeder "grounded".

1. Make sure test cable assembly is NOT connected to the FACT-1.

2. Plug the FACT-1into a 120V, 60Hz, 3-prong outlet. The outlet should be rated for

a minimum of 15 Amps. Press the Red POWER switch to turn on the unit. The

POWER switch should illuminate and the fan located in the cord cavity should start.

IMPORTANT: The FACT-1 is not designed to work with any type of GFC protection device.

n a situation where a ground is left connected to the feeder, the FACT-1 will output current

on the corresponding phase however, the return current will be on the neutral/sheath of

the feeder and/or earth ground. Therefore the GFC device will detect the large differential

in current and open the circuit, prohibiting the unit from operating.

3. Perform a "Self-Test" of the unit prior to normal operation (see "Diagnostics").

IMPORTANT: The test cable assembly should NOT be connected to the FACT-1

during the Self-Test or the results may be incorrect and the test leads will become

energized with 120V.

4. Turn off the power to the unit by pressing the POWER switch again. The POWER switch

should no longer be illuminated and the fan will stop.

CAUTION: Assure that the feeder cable being connected to the FACT-1 is not energized.

The Feeder Ammeter Clear Test Set is not designed to be used or connected in the presence

of voltages greater than 300V.

5. Connect the test cable assembly to the FACT-1. Connect the appropriate test leads to

the A, B and C phase of the cables under test. Connect the ground lead to the neutral.

6. Turn the power on to the unit by pressing the POWER button.

NOTE: f for some reason the 3rd prong safety ground is not connected properly, a

message will be displayed on the LCD to repair the 3rd prong ground before operating.

CAUTION: The Feeder grounds need to be removed at this point. Assure there is no back

feed condition or voltage being applied to the feeder prior to the removal of the grounds.

IMPORTANT: The FACT-1 has been designed to also operate in situations where the polarity

of the 120 VA C outlet is "reversed". When the polarity is reversed, the output post that

becomes "live" when the AMMETER CLEAR button is pressed is also reversed. This will

be indicated on the LCD so that the operator does not have to remember; he simply

rotates the selector knob until the phase he wishes to test is indicated on the display.

The table below describes the internal logic:

6

120V Source Rotary Switch Phase to Ground Test Phase to Phase Test

Polarity Position (Output Phase) (Output Phase/Return Phase)

Correct Standby OFF OFF

Correct A PHASE A PHASE A to PHASE B

Correct B PHASE B PHASE B to PHASE C

Correct C PHASE C PHASE C to PHASE A

Reversed Standby OFF OFF

Reversed A PHASE B PHASE B to PHASE A

Reversed B PHASE C PHASE C to PHASE B

Reversed C PHASE A PHASE A to PHASE C

7. After the unit initializes, rotate the Selector Knob to Position A. The LCD will indicate

which phase the 120V AC voltage will be applied to.

8. Press and hold the AMMETER CLEAR button for several seconds. f there is any significant

current flow, the digital ammeter will display the current flow in 0.25Amp increments. f

there are no grounds connected to the phase either on the primary or secondary of a

transformer, and the phase indicated is not shorted to another, then the "NO FAULT"

message will be displayed:

A-ALIVE

NO FAULT DETECTED

Depending on the number of transformers connected to the network feeder during the

test, some small current (<0.3Amp) could be detectable due to the excitation currents of

the transformers. f the FACT-1 detects maximum current flow in the "live" (selected)

phase only, a phase to ground fault exists and is displayed:

A-ALIVE

PHASE A TO GND FAULT

f the FACT-1 detects maximum equal current in the output phase and the return phase,

then a phase-to-phase fault exists and is displayed:

B-ALIVE

PHASE B TO C FAULT

f the FACT-1 is operating with the transformer primaries connected to a feeder and a

ground is present on the secondary, the FACT-1 will detect its presence and display only

a partial reading. The actual reading obtained for a secondary fault will be dependent on

the windings of the transformer (turns-ratio) and the size (gauge) of the grounding

conductor. The heavier the grounding wire, the higher the current will be for secondary

faults. When secondary faults exist, they will be displayed as a phase-to-phase fault.

B-ALIVE

PHASE B TO C FAULT

7

9. After the selected phase has been tested and the AMMETER CLEAR button is released,

rotate the select knob to another position to test the other phases and repeat step 7

for each phase. The LCD will always indicate which phase that is being tested.

THERMAL OVERLOAD

The FACT-1 contains several resistors to limit the current supplied to the selected phase.

Since these resistors are required to dissipate several hundred watts, significant heat can

build up inside the case if the AMMETER CLEAR button is pressed for a long time on a

faulted cable. f the internal sensor detects a temperature that is too high, a message will

be displayed to the LCD:

Unit Temperature is Too High. Please Allow to Cool (with power switch on)

f this situation occurs, leave the FACT-1 plugged in with the POWER switch ON. This will

operate the fan and reduce the internal temperature. When the unit temperature' drops to

an operational level, the message will disappear and the unit may be used for testing again.

REVERSED POLARIT OPERATION

The FACT-1 has been designed to not only protect against an incorrectly wired outlet, but

to operate normally if such a situation arises. f the unit detects incorrect polarity, a message

is displayed to the operator to alert him of the situation. The operator must then press the

SELF-TEST button momentarily to clear the notice:

NOTICE: L NE CORD POLAR TY S REVERSED PRESS SELF-TEST TO CONT NUE

DIAGNOSTICS

The FACT-1 has built-in comprehensive diagnostics to assure that the FACT-1 is operating

correctly. The test cable assembly should NOT be connected to the FACT-1 during the Self-

Test. The Self Test mode is entered by pressing the SELF-TEST button. f at any time, you wish

to exit the Self-Test mode, simply press the SELF-TEST button a second time. The FACT-1 will

guide the operator through the Self-Test procedure using messages on the LCD.

Once Self-Test mode is entered, a message will be displayed to rotate the selector knob

to the correct position:

Rotate Switch to Pos A, then Press & Hold Ammeter Clear Button

(Self-Test to Cancel)

f the selector knob was already in that position or if the selector knob is rotated to that

position, the LCD will instruct the operator to press & hold the AMMETER CLEAR button

until a test PASS or test FA L message is displayed. Once the AMMETER CLEAR button

is released, the operator will be instructed to rotate the selector knob to each of the

remaining positions and to press the AMMETER CLEAR button.

At the conclusion of the test, an ALL TESTS PASSED or TEST FA LURE message will be

displayed before returning to normal operation.

The FACT-1 should never be operated outside of its maximum operating temperature

range of -20C to +60C (-4F to +140F). Operating the FACTS outside of its temperature

range may permanently damage the unit.

HD Electric Company is committed to ongoing review and improvement of its product lines,

and thus reserves the right to modify product design and specifications without notice.

HD Electric Company® products are available through HDE® sales representatives worldwide.

Printed in U.S.A. © HD Electric Company 2016 • Bulletin No. FACT M-200c

LIMITED WARRANT AND LIMITATION OF LIABILIT

This warranty applies to all products sold by HD Electric Company (the "Products"); provided, however, that the term Products does not include any

third party products purchased through HD Electric Company, for which no warranties are made (the "Third Party Products"). Third Party Products

may be subject to a separate manufacturer's warranty; [should you have any question regarding whether a separate warranty applies, please contact

HD Electric Company].

NOT CE: READ TH S L M TAT ON OF WARRANTY AND L AB L TY BEFORE BUY NG OR US NG THE PRODUCTS CONTA NED HERE N.

t is impossible to eliminate all risks associated with the use of the Products. Risks of serious injury or death, including risks associated with electrocution,

arcing and thermal burns, are inherent in work in and around energized electrical systems. Such risks arise from the wide variety of electrical systems

and equipment to which Products may be applied, the manner of use or application, weather and environmental conditions or other unknown factors,

all of which are beyond the control of HD Electric Company.

HD Electric Company does not agree to be an insurer of these risks, and shall have no liability for any claims arising from such risks.

WHEN YOU BUY OR USE THESE PRODUCTS, YOU AGREE TO ACCEPT THESE R SKS.

HD Electric Company warrants to the original purchaser that the Products (excluding any third party products purchased through HD Electric Company,

for which no warranties are made) will be free from defects in material and workmanship, under normal use and regular service, and preventative

maintenance for a period of one (1) year (ten (10) years for HDE Capacitor Controls) from the date of shipment (the “Warranty Period”). Should any failure

to conform with this warranty be found during the Warranty Period, you must notify HD Electric Company of your claim within thirty (30) days of discovery,

and within the Warranty Period. Your failure to give notice of claims of breach of warranty within the Warranty Period shall be deemed an absolute and

unconditional waiver of claims for such defects. HD Electric Company will have no responsibility to honor claims received after the date the applicable

Warranty Period expires.

Upon notice of your claim, HD Electric Company will provide a return authorization number, and further instructions on how to return the product for

service. You must follow HD Electric Company’s instruction. You are responsible for all Product removal, handling, re-installation, and shipping (both

to and from HD Electric Company). Products returned for repair, as well as repaired or replacement Products shall be sent postage / freight prepaid. After

receipt of a product which HD Electric Company determines is defective, HD Electric will, at its option, either (1) repair (or authorize the repair of) the

Product or (2) replace the Product, subject to the following: The Products are made using parts sourced from a variety of manufacturers. Due to the rapidly

changing technology environment, parts may become obsolete / unavailable over time (end of life). n the event that a Product cannot be repaired or

replaced due to unavailability of parts, HD Electric Company will use commercially reasonable efforts to obtain substitute parts or conduct work around

design, but cannot guarantee its ability to do so.

tems not found defective will be returned at your expense, or failing receipt of instruction from you on return of such items within five (5) business days

of our notice to you that the product is not defective, HD Electric may dispose of the product at its discretion and with no liability to you. HD Electric

Company’s determination of defects is final. Products repaired or replaced during the Warranty Period shall be covered by the foregoing warranties for

the remainder of the original Warranty Period or ninety (90) days from the date of delivery of the repaired or replaced Products, whichever is longer.

LIMITATIONS:

This warranty is void in the event of misuse, alteration, faulty installation, or misapplication of the product.

This warranty does not cover failure of product or components due to any ACT OF NATURE; lightning, floods, hurricanes, tornadoes or any other such

catastrophic events.

HD Electric Company does not warrant any third party products or associated hardware or their performance or suitability for use and application. Such

items are provided “as-is”.

All repairs must be authorized by HD Electric Company. Unauthorized repairs will not be reimbursed under any circumstances.

HD Electric Company is not required to make replacement or loaner equipment available while Products are being repaired or replaced, or to compensate

you for any in/out labor charges or expenses associated with removal, handling or re-installation of the Products.

TO THE MAX MUM EXTENT PERM TTED BY LAW, TH S WARRANTY AND THE REMED ES SET FORTH ABOVE ARE EXCLUS VE AND N L EU OF ALL OTHER

WARRANT ES, REMED ES AND COND T ONS, WHETHER ORAL OR WR TTEN, EXPRESS OR MPL ED. HD ELECTR C EXPRESSLY D SCLA MS ALL OTHER

WARRANT ES OF ANY K ND, EXPRESS OR MPL ED, NCLUD NG W THOUT L M TAT ON MPL ED WARRANT ES OF F TNESS FOR A PART CULAR PURPOSE,

MERCHANTAB L TY AND NON- NFR NGEMENT.

N NO EVENT SHALL HD ELECTR C COMPANY BE L ABLE FOR ANY ND RECT, NC DENTAL, CONSEQUENT AL OR SPEC AL DAMAGES RESULT NG FROM THE

USE OR HANDL NG OF THESE PRODUCTS. TH S SHALL NCLUDE BUT, NOT L M TED TO, LOST PROF TS OR REVENUE, LOSS OF USE OF THE PRODUCTS,

COST OF SUBST TUTE PRODUCTS, FAC L T ES OR SERV CES, OR DOWNT ME.

N NO EVENT SHALL HD ELECTR C COMPANY HAVE ANY L AB L TY FOR ANY TH RD PARTY PRODUCTS OR ASSOC ATED HARDWARE, OR

CUSTOMER-OWNED SYSTEMS, EQU PMENT OR SOFTWARE.

HD Electric Company must have prompt notice of any claim so that an immediate product inspection and investigation can be made. Buyer and all

users shall promptly notify HD Electric Company of any claims, whether based on contract, negligence, strict liability, or other tort or otherwise be barred

from any remedy.

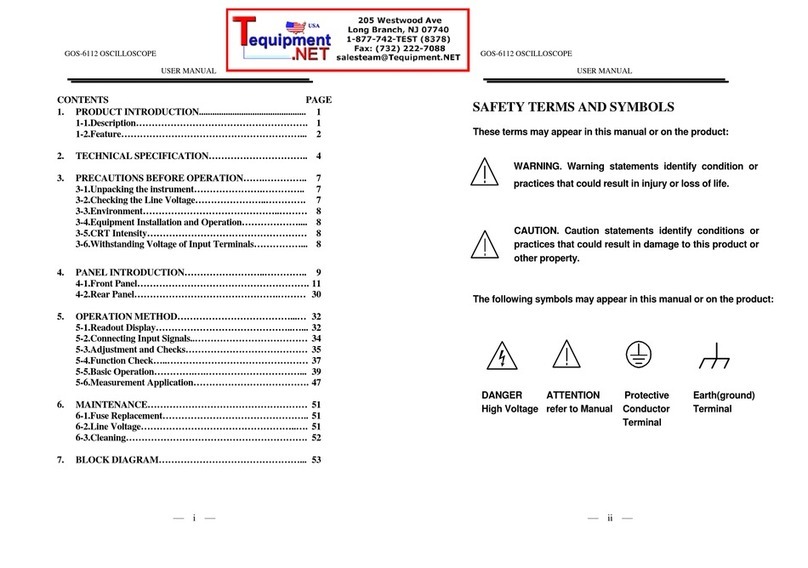

Table of contents

Popular Test Equipment manuals by other brands

GW Instek

GW Instek GOS-6103C user manual

Project Fire

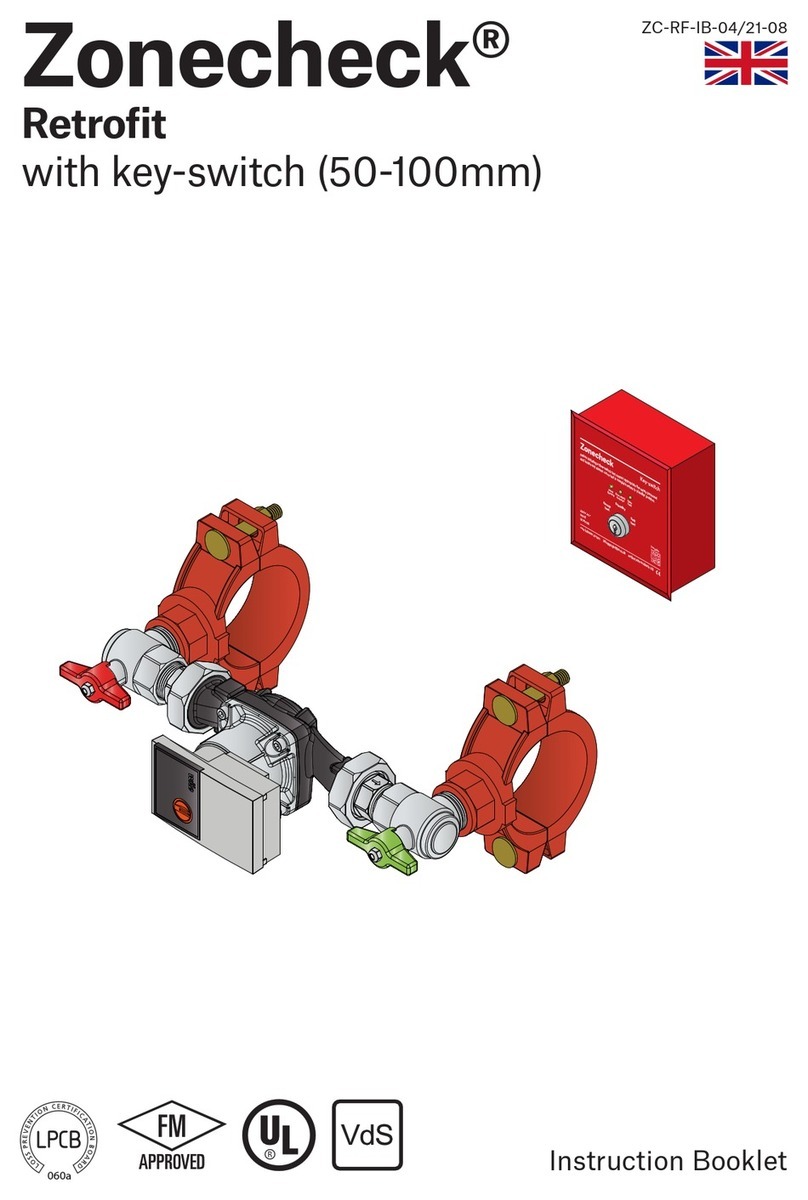

Project Fire Zonecheck Retrofit ZC450-R50 Instruction booklet

Agilent Technologies

Agilent Technologies N9360A Quick reference guide

Vega

Vega VEGAMET 381 Ex operating instructions

Klein Tools

Klein Tools VDV512-007 manual

Elcometer

Elcometer 139 user guide