Sentrol ZX300 Assembly instructions

1

Installation/

Programming

SENTROL ZX300/ZX310

Expandable Security System Control

2

3

Table of Contents

TABLE OF CONTENTS

ZX300/ZX310 Wiring Diagram......................................................................................5

Control Board Terminal Descriptions.........................................................................6

Zone Wiring....................................................................................................................7

Class ‘B’ End-Of-Line Resistor Supervised Zones ......................................................7

Non-Supervised Closed Circuit Loop (No EOL Resistor Supervision)........................7

ZXEX08 Zone Expander Module............................................................................. ... 7

Wireless Devices ..........................................................................................................8

Control Station Addressing and Supervision............................................................9

SSD, LCD, and VFD Control Stations......................................................................... 9

ICON Control Stations..................................................................................................9

LED Control Stations..............................................................................................9

Unsupervised and Supervised Control Stations..................................................... 9

Control Station Troubleshooting ..............................................................................10

12 VDC Outputs .........................................................................................................11

Operating the System ................................................................................................13

Powering Up The Control ...........................................................................................13

Testing ...............................................................................................................13

Installer Arming and Disarming ..................................................................................13

Trouble Conditions .....................................................................................................13

Clearing Trouble Messages .......................................................................................13

Installer on Premises..................................................................................................13

Programming the Control.................................................................................................14

Introduction ...............................................................................................................14

Local Programming ....................................................................................................14

Programming Zone Names....................................................................................... 14

Installer Level Programming .....................................................................................15

Menu Options .............................................................................................................15

Program Function Map....................................................................................15

Entering a New Value at a Location................................................................15

Programming the Account Code and Telephone Number Digits....................16

Additional Programming Notes .......................................................................16

Program User Codes.......................................................................................16

Restore Factory Defaults ................................................................................16

Hours Until Next Comm Test...........................................................................17

Program RF Data............................................................................................17

Programming RF Zone Devices Into the RF Gateway ...................................17

Programming RF User Devices Into the RF Gateway....................................18

Programming RF Devices Into the Control Panel...........................................18

4

TABLE OF CONTENTS

Specifications And Features .....................................................................................19

List of Compatible Accessories................................................................................22

SIA and Contact ID Formats......................................................................................23

Agency Requirements ...............................................................................................25

National Fire Protection Association (NFPA) Rules................................................27

FCC Compliance.........................................................................................................30

5

FIGURE 1 Suggested UL Household Burglar Alarm and/or Fire (ƒƒ) Alarm Hookup

ZX300/ZX310 Wiring Diagram

WIRING DIAGRAM

7167-1459:114

6

Two-Wire

Smoke Terminal

Connect a 16.5 VAC 15 VA UL Class II transformer minimum using 18 gauge

minimum 2 conductor wire. Do not exceed 50 feet.

(+)12 VDC. Combined alarm current should not exceed 1.0 amps.

Overcurrent protected at 1.35 amps (PTC2). A 1500 Ohm EOL resistor

(CR854) must be connected between the Bell and Neg terminals; otherwise

a bell output fault will occur.

BLACK WIRE - (-)12 VDC. Negative connection for Control Stations, ODM,

RF receiver, zone expander, motion detectors, bell output, and other devices.

RED WIRE - (+)12 VDC 500 mA continuous power connection for Control

Stations, ODM, zone expander, and RF Gateway. Overcurrent protected at

1.35 amps (PTC1). CAUTION: Use the KP+12V and the +12V AUX

terminals when calculating total current drain.

GREEN WIRE - Connection for Control Stations, zone expander, ODM and RF

receiver. Use 22 gauge wire up to 1000 ft. Use 18 gauge wire up to 2000 ft.

WHITE WIRE - Connection for Control Stations, zone expander, ODM and RF

receiver. Use 22 gauge wire up to 1000 ft. Use 18 gauge wire up to 2000 ft.

Each loop requires a 1500 Ohm end-of-line resistor (P/N CR854). A common

negative is shared among all zones. The need for end-of-line resistors may be

eliminated on all Burglar defined zones through programming.

Current limited 100 mA terminal. Connection for two-wire/four-wire smoke

detectors, glass break detectors, and devices requiring resettable power. The

maximum series loop resistance for a two-wire smoke loop is 20 ohms. The

maximum Alarm Impedance is 500 ohms.

(+)12 VDC 500 mA continuous power. Overcurrent protected at 1.35

amps (PTC1). Used for powering motion detectors, CO detectors, and other

accessories. CAUTION: Use the KP+12V and the +12V AUX terminals when

calculating total current drain.

TERMINAL FUNCTION DESCRIPTION

Control Board Terminal Descriptions

TERMINAL DESCRIPTIONS

AC

BELL

NEG

KP+12V

GREEN

DATA

WHITE

DATA

2WS

+12V AUX

AC Input

Supervised Bell Output

(power-limited)

Common Negative

Keypad Power

(power-limited)

Local Data Bus In

Local Data Bus Out

Zone Inputs

Auxiliary Power

(power-limited)

NEG

Zone 1

Zone 2

Zone 3

Zone 4

NEG

Zone 5

Zone 6

NEG

Zone 7

Zone 8

7

Class ‘B’ End-of-Line Resistor

Supervised Zones

A Class ‘B’ zone must be supervised with a 1500

Ohm1/2Wattend-of-line resistor(P/NCR854). This

resistor should be installed in series at the furthest

point from the control. This configuration must be

used whenever both Form A and Form B devices

are connected and provides a high degree of pro-

tection against compromise or tampering. The con-

trol monitors the voltage level across the zone and

uses the zone voltage levels in Table 1 to determine

whether the zone is normal, open, or shorted. The

operation of a zone is programmable (see Program-

ming Record Book). Maximum total loop wire and

contact resistance (not including EOLs) must not

exceed 100 Ohms for the loop to function prop-

erly. The 1500 Ohm EOL resistor is optional for

Form A connections but is required for Form B.

Zone Wiring

ZONE WIRING

Non-Supervised Closed Circuit

Loop (No EOL Resistor

Supervision)

The EOL resistor is not required on Burglar zones.

Aconventionalclosed circuit loopmaybe connected

directly to a zone and the zone will have either a

short or an open condition. See Programming

Record Book for programming an unsupervised

zone. Fire zones may not be installed as unsuper-

vised.OnlyBurglar definedzonesmay bewirednon-

supervised.

ZXEX08 Zone Expander Module

This module provides an additional 8 zones (zones

9-16)fortheZX300/ZX310 control.These zones are

wired the same as the 8 on-board zones and the

JP1 jumper must be in place.

Mount the module in a ZX310 enclosure as shown

in the ZXEX08 insert using the screws and stand-

offs provided. For mounting with the ZX300 or in a

remote location, use a suitable enclosure, like the

EB1511.

Connect the module to the ZX300/ZX310 local data

bus using either the "quick connection" or the data

bus terminals on the module. The "Active" LED

flashestoindicate the moduleiscommunicating with

the control.

NOTEONLY BURGLAR DEFINED ZONES MAY

Zone Open Infinite Ohms 9.75 - 13.85 V

Zone Normal 1500 Ohms 2.82 - 9.74 V

Zone Shorted 0 Ohms 0.00 - 2.81 V

CONDITION NOMINAL LOOP RESISTANCE VOLTAGE READING

Table 1 Zone Troubleshooting Chart

1500Ω1/2W

Primary Zone

Normally

Open

Normally

Closed

Figure 2 Zone Wiring

NOTE

For UL Listed systems, EOL Supervision is required.

8

The ZX300/ZX310 provides an option for including

Wireless(orRF) Devices. TheRFDevices may con-

sist of RF Zone Devices (Universals, Door Con-

tacts,Glassbreaks,PIRsand SmokeDetectors)and

RF User Devices (Handhelds). These RF Devices

require that an RF Gateway be attached to the sys-

tem. The ZX300/ZX310 is compatible with either a

model4710or 4720 RFGatewaywhich areULlisted

for household fire and burglary and commercial fire.

If a 4720 RF Gateway is used, it must be set to ad-

dress ‘1’. Refer to the RF Gateway instructions for

address selection.

• 4710 RF Gateway - provides up to 8 RF Zone

Devices and up to 8 RF User Devices. It can

only provide for zones 9-16.

• 4720 RF Gateway - provides up to 16 RF Zone

Devices and up to 8 RF User Devices. It can

provide for zones 1-16.

MounttheRFGateway asdescribedinthe RFGate-

way instructions. Wire the local data bus to the ter-

minals: +12V - RED; DATA A - GREEN; DATA B -

WHITE; NEG - BLACK. Set Address switch. Rein-

stall the cover.

See Installer Level Programming - Programming RF

Data Into the RF Gateway.An RF User Device must

be mapped to a valid user passcode by program-

ming.

The RF Gateway and RF Zone Devices should be

temporarily mounted in their desired locations until

theyhavebeentested with theControlPanel. These

devices may need to be re-oriented or moved to

achieve optimal reception. After testing has been

completed, they should be permanently mounted.

To test the Received Signal Strength of each RF

Zone Device, use Test 6 - RF Signal Strength Test.

From the Control Station press the “8” key, followed

by the Installer Code (9632) and then press the “6”

key. Next press the RF Zone Device Number (1-16).

The Control Station will display and sound the Re-

WIRELESS DEVICES

Wireless Devices

ceived Signal Strength of the last transmission sent

by the RF Zone Device. See results below:

Strong Signal (5 Control Station beeps): a strong or

high level RF signal was measured by the receiver

for that location of the transmitter. This is a good

location for the transmitter and receiver.

Acceptable (3 Control Station beeps): a normal or

acceptable level of RF signal was measured by the

receiver for that location of the transmitter. This is a

good location for the transmitter and receiver.

Low Signal (1 Control Station beep): a low or not

acceptable level of RF signal was measured by the

receiver for that location of the transmitter. Make

multipletesttransmissions,makingsure thatobstruc-

tions between the transmitter and receiver are nor-

mal but minimized (hands away from units, metal

ladders away from receiver, etc.) during these tests.

The transmitter and/or receiver will need to be relo-

cated to obtain ACCEPTABLE level readings.

No Signal (1 long Control Station beep): no RF sig-

nal or an extremely low RF signal was measured by

the receiver for that location of the transmitter. Bring

the transmitter to the RF Gateway and activate the

transmitter. The red LED on the RF Gateway should

blink. If it does not, then the transmitter is not work-

ing. If the red LED does blink, but the signal strength

is still NO SIGNAL, then a programming error ex-

ists. Check the programming of the zone in the RF

Gateway. If the signal strength is STRONG or AC-

CEPTABLE,thenthe transmitter and/or receiverwill

need to be relocated to obtain ACCEPTABLE level

readings. Be sure to power down the control to clear

out all signal strength levels before testing the trans-

mitter at its new location.

After testing has been completed, the RF Gateway

andRFZoneDevicesshouldbepermanentlymounted.

NOTE

Series 4000 RF Gateways and transmitters

whicharenotULlabeledarenot allowedin

UL Certificated installations.

9

All LCD Control Stations are shipped from the fac-

tory as Control Station #1 (#3 for Icon Control Sta-

tions) and supervised. They may be set to other ad-

dresses and to unsupervised as described below.

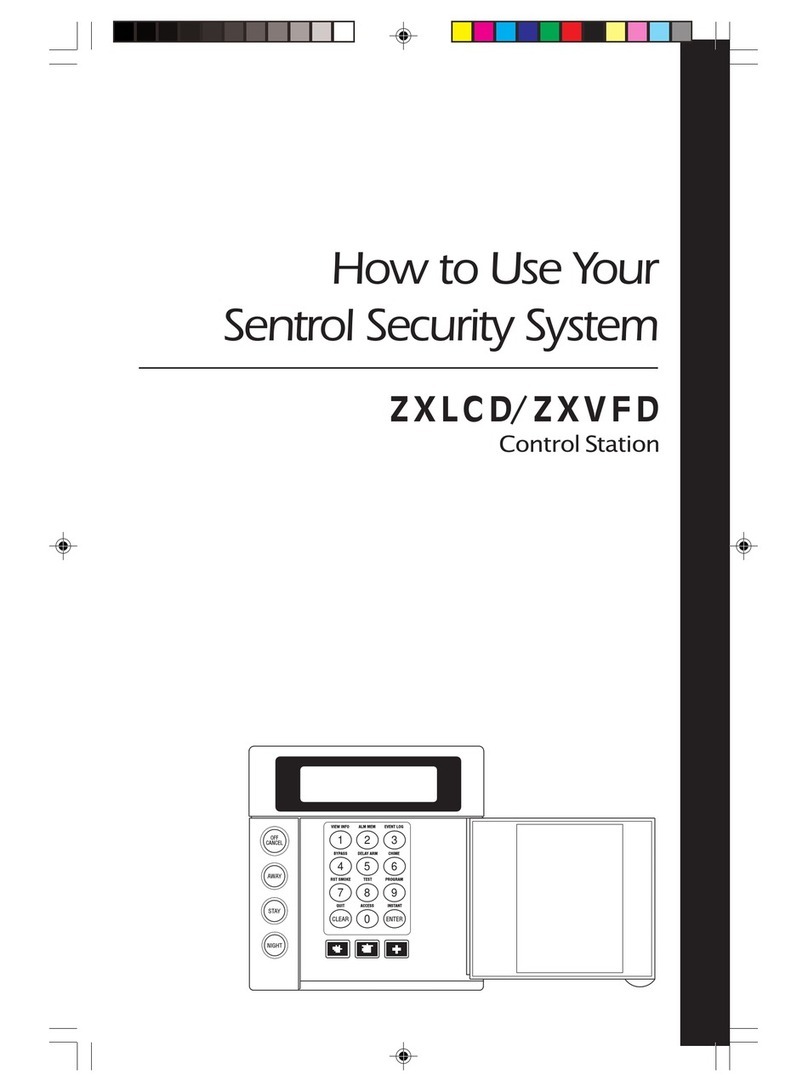

SSD, LCD, and VFD Control

Stations

These Control Stations have a four position DIP

switch on the circuit board to set the address and

supervision. To change the Control Station to unsu-

pervised, move DIP switch 4 to the ON position. To

change the address, the DIP switch setting must be

positioned according to Figure 3.

ICON Control Stations

These Control Stations have two jumpers on the cir-

cuit board to set the address and supervision. To

change the address of Control Station #3 to Control

Station #4, remove JP2 (see Figure 4).To change a

Control Station to unsupervised, remove JP1 (see

Figure 4).

Control Station Addressing and

Supervision

CONTROL STATION ADDRESSING AND SUPERVISION

Figure 3 Control Station DIP Switch Settings

LED Control Stations

These Control Stations have two jumpers on the cir-

cuit board to set the address and supervision. To

change the address of Control Station #1 to Control

Station #2, remove JP2 (see Figure 4).To change a

Control Station to unsupervised, remove JP1 (see

Figure 4).

Supervised and

Unsupervised Control

Stations

A supervised Control Station is reported as missing

when the system fails to get any response from it.

If more than one supervised Control Station is set to

aparticularaddress,then none ofthoseControl Sta-

tions will function properly. Only one supervised

Control Station may be used at an address.

An unsupervised Control Station can be removed

from the system without the system detecting that it

is missing. The advantage of an unsupervised Con-

trol Station is that a system can have as many Con-

trol Stations as the power supply can support. Mul-

tiple unsupervised Control Stations may be used at

any address. When unsupervised SSD, LCD, and

VFD Control Stations are used, they must be set to

address3or4. By addingadditionalpowersupplies,

liketheHCP12SULC,ControlStations maybe added

up to a total of 18 bus devices on the system.

For UL listed systems, unsupervised Control Sta-

tions are not allowed.

If an unsupervised Control Station is set to the same

address as a supervised Control Station, then the

unsupervised Control Station will not function. Do

not mix a supervised Control Station with unsu-

pervised Control Stations at the same address.

Figure 4 LED & ICON Control Station Jumpers

JP1

JP2

Remove JP1 to unsupervise

Remove JP2 for keypad 2 (LED) or

keypad 4 (ICON)

10

Control Station Troubleshooting

CONTROL STATION TROUBLESHOOTING

No Control Station display or LEDs Black or Red Wire removed or cut

No response from key presses Green Wire removed or cut

Two supervised Control Stations at the same address

LEDs flash and may display White Wire removed or cut

“No Communication From Control” code Green/White Wires reversed

Green & White Wires shorted together

SYMPTOM CONDITION

If a Control Station is incorrectly wired, it will not accept key-

stroke entries. The following symptoms may appear:

from Common Negative to GRN DATA ~ 9.3 VDC

from Common Negative to WHT DATA ~ 10.7 VDC

from Common Negative to KP+12V ~13.8 VDC

The nominal voltage at the control (with a single Control

Station connected) should measure as follows:

TERMINAL VOLTAGE

11

The control is supplied with one keypad power

output, one auxiliary power output, one bell out-

put, and one programmable (PGO1) low current

output. (See Figure 1). The low current output on

the control can supply 10 mA @ 3VDC.

Additional outputs can be added with the ZXODM

Output Driver Module. The module receives its

data from the local data bus and provides ten ad-

ditional programmable outputs. The ODM outputs

provide +12 VDC on activation and must be lim-

ited to 40 mA of current draw.

The ODM comes defaulted from the factory as

ODM1. You may use multiple ODMs provided that

power restrictions are followed. All ODMs must

be addressed as ODM1 and they all will provide

identical ouputs. Connect the ODM to the control

as shown in Figure 5. Use the twelve (12) wire

cable provided with the ODM for the outputs as

shown.

Output conditions can be programmed as one of

many conditions. Refer to the Programming

Record Book for programming information and re-

strictions.

12 VDC Outputs

12 VDC OUTPUTS

The outputs on this module have lim-

ited transient immunity and should

not leave the enclosure. Mount mod-

ule via the double-sided tape pro-

vided on the back of the ODM to the

inside of the control enclosure.

Figure 5 ZXODM Wiring Diagram

NOTE

12

Outputs may be wired to indicator devices or relay

module triggers (like the MPI-206) provided the 40

mA current draw condition is not exceeded. Figure

6 shows a wiring example for a relay to ODM 1 Out-

put 2. Figure 7 shows a wiring example of ODM 1

Output 1 to trigger an LED.

Figure 6 Output Connected to a Relay

Do not exceed 250 mA of total cur-

rent through the Red (+12V) and

Black wires (Negative) of the twelve

wire cable. Add 18 gauge wire from

the appropriate control panel termi-

nals for total current drains in excess

of 250 mA.

+12V NEG TG+ TG - COM NC NO

MPI-206

Red Wire

Black Wire

Pink Wire

TAN WIRE

BLACK WIRE

*

Connects to J3 (part of 12-wire cable)

Output 1

Neg

* A 470-1000Ωresistor may be used

12 VDC OUTPUTS

NOTE

Figure 7 Output Connected to an LED

NOTE

The LED and current limiting resis-

tor shown in Figure 7 are not sup-

plied.

NOTE

13

Powering Up The Control

Thecontrolcomesfrom the manufacturerwithafac-

tory set (default) program. The factory default code

for user passcode No. 1 is “1234”. This passcode is

authorized to perform all user level functions. The

default setting for the installer passcode is “9632”.

The installer passcode performs the installer level

functions. For purposes of discussion, the installer

and the end user are both considered system us-

ers, but have different levels of authorization (see

the Programming Record Book).

When a Control Station is powered-up, it briefly dis-

playsatestpattern followed byitsdatabus address.

The Control Station will then begin displaying infor-

mation from the control panel. During the first fif-

teen seconds after power-up, the control panel will

instruct the Control Station to display the panel’s

software revision and flash the AWAY, STAY and

NIGHT LEDs.

If the system is armed when it is powered up, viola-

tions from all the Burglar zones are ignored for three

minutes. This allows all armed PIRs to stabilize with

out causing false alarms.

Testing

The ZX300/ZX310 provides the following testing ca-

pabilities: Walk Test, Battery Test, Bell Test, Com-

municatorTest, KeypadTest and RFSignalStrength

Test. Refer to the appropriate User Guide for in-

structions on performing these tests. Always en-

sure that a Walk Test (and an RF Signal Strength

Test when applicable) is performed on a new instal-

lation.

Installer Arming and

Disarming

The installer passcode may be used to arm the sys-

tem. It may be used to disarm, but only if the sys-

tem was armed by the installer passcode. It may be

used to silence alarms and to silence trouble condi-

tions. When it is used to silence a Burglar alarm, it

will not disarm or cancel the alarm unless the sys-

OPERATING THE SYSTEM

Operating the System

Trouble Conditions

The possible trouble conditions are:

AC Power Failure Fire Trouble

Low Battery Silenced Fire Alarm

Memory Error Zone Missing

Communication Failure RF Point Not Reporting

Missing Keypad Smoke Trouble

RF Jamming RF Point Tamper

Bell Fault RF Point Low Battery

Telco Line Fault RFUser Device Low Battery

Zone Trouble

If RF Jamming is detected for at least 90 seconds,

then all RF Burglar zones will be faulted.

Clearing Trouble Messages

Most trouble conditions are cleared automatically

when the condition that initiated the trouble is re-

stored or is eliminated. Three trouble conditions

(MemoryError,SmokeTroubleandMissing Keypad)

may be cleared manually by pressing and holding

the Clear key for three seconds (until two beeps are

heard). This action is also required to turn off the

Duress output after it has been activated and to

cause an "Installer Off Premises" event. A Bell Si-

lenced trouble condition can only be cleared by per-

forming a smoke reset operation.

Installer On Premises

Thefirsttimethat an Installerlevelpasscodeis used

to perform a function, an "Installer On Premises"

event is logged to be reported. Before leaving the

premises, press and hold the CLEAR key for three

seconds and an "Installer Off Premises" event will

be logged to be reported.

tem was armed by the installer passcode. For a

detailed description of arming and disarming proce-

dures, see the appropriate User Guide.

14

Introduction

The control may be programmed locally from any

SSD, LCD, VFD, or ICON control station. Program-

ming with an LED Control Station is not supported.

Local Programming

Therearetwo levelsofControlStationprogramming:

User level and Installer level.

User Level

User level programming provides the ability to add,

change, or delete user passcodes.Auser passcode

with authority level 1 is required to access the user

level programming. See the appropriate User Guide

for more information regarding user level program-

ming.

Installer Level

Installer level programming allows total

customization of the control’s operating features.

The installer passcode (User 9) is required to ac-

cess installer level programming. Anyone attempt-

ing installer level programming should be familiar

withthecontentsof this publicationpriorto program-

ming the control panel.

If the installer code is lost or forgot-

ten, it may be impossible to program

the control locally.

PROGRAMMING THE CONTROL

Programming the Control

NOTE

Programming Zone Names

Zone names may be programmed on LCD and VFD

Control Stations without going into Installer Level

Programming. To program zone names:

1. Press the CLEAR and ENTER keys simulta-

neously. The control station prompts you to en-

ter the zone number you wish to program/

change.

2. Enter a number corresponding to the Zone ID

and press Enter. Once a valid Zone ID is se-

lected, the control displays the Zone ID and the

current Zone Name with the cursor on the first

character. Press the key associated with each

character. Each keypress changes the display

to the next character listed for that key. Amaxi-

mum of 10 characters, including spaces, may

be used for each zone name.

The following table lists the characters available

for the Zone name.

3. If the ENTER or CLEAR key is pressed and no

changes have been made, the control station

returns to the Zone ID prompt. If the CLEAR

key is pressed and changes have been made,

all changes are cleared and the control station

displays the original Zone Name. To save

changes to the Zone Name, press the ENTER

key. The control station returns to the Zone ID

prompt. Press the CLEAR key to return to

Ready mode.

yeK sretcarahC

1#@?>=<;:9876543210

2#CBA

3#FED

4#IHG

5#LKJ

6#ONM

7#SRQP

8#VUT

9#_^]¥[ZYXW

0#/.-,+*)('&%$#"!ecaps

cinaPtfeLnoitisopenotfelrosrucehtsevom

cinaPthgiRnoitisopenothgirrosrucehtsevom

15

Entering a New Value at a Location

While the Control Station is displaying the value at

a location, you can enter digits to change the value

at that location. The new value is displayed as you

enter the digits. Other keys work as follows:

ENTER - if pressed after new digits are

entered,thedisplayed valueis

stored at the current location.

- if pressed with no new digits

entered, then it will go to the

next location.

Right Panic Key - if pressed, it will go back one

location and ignore any digits

entered.

CLEAR - if pressed after new digits are

entered, the new digits will be

erased and the original value

will be re-displayed at the lo-

cation.

- if pressed with no new digits

entered, then it will return to

the LOCATION prompt.

OFF CANCEL - if pressed, momentarily dis-

plays the present location

number (SSD Control Sta-

tion).

When you press the ENTER key to

store the new value, the system will

store the value as entered. It is the

responsibility of the programmer to

enter a value within the specified

range. If the value entered is out of

the range, then undesirable operation

may occur.

NOTEWHEN YOU PRESS THE ENTER KEY TO

STORE THE NEW VALUE, THE SYSTEM

WILL STORE THE VALUE AS ENTERED.

IT IS THE RESPONSIBILITY OF THE

PROGRAMMER TO ENTER A VALUE WITHIN

THE SPECIFIED RANGE. IF THE VALUE

ENTERED IS OUT OF THE RANGE, THEN

UNDESIRABLE OPERATION MAY OCCUR.

Menu Options

This section will describe Installer Level Program-

ming as performed locally from a Control Station.

For upload/download capabilities, please contact

Technical Support at 800.800.2027.

To enter Installer Level Programming, press the

PROGRAM (9) key and enter the installer passcode

(default=9632). The ControlStation willthenprompt

you to select a programming option from 1 to 9

where:

1 = RESERVED FOR FUTURE USE

2 = RESERVED FOR FUTURE USE

3 = PROGRAM FUNCTION MAP

4 = RESERVED FOR FUTURE USE

5 = PROGRAM USER CODES

6 = RESTORE FACTORY DEFAULTS

7 = SET HOURS UNTIL NEXT COMM TEST

8 = RESERVED FOR FUTURE USE

9 = PROGRAM RF DATA

Program Function Map

Press the ’9‘ key and enter the installer passcode to

enter programming mode. Press the ‘3’ key to enter

Program Function Map mode. The Control Station

will prompt you for a location to be programmed.

SeetheProgramming RecordBook forlocationnum-

bers, definitions, and valid entries for the locations.

From this mode, you may program the entire Func-

tionMapexcept for UserCodes. (SeeInstaller Level

Programming - Program User Codes).

From the LOCATION prompt, enter digits for the

desired location number. The digits entered will be

displayed. If more than three digits are entered, the

first digit entered will be discarded. If you make a

mistake, you may press the CLEAR key to clear out

the location and start over. When the desired loca-

tionnumberis displayed, presstheENTER key. The

Control Station will then display the current value

programmed at that location.

Installer Level Programming

INSTALLER LEVEL PROGRAMMING

NOTE

16

Programming the Account Code and

Telephone Number Digits

When the location being programmed is an account

code or telephone number digit the value will be dis-

played as an “H” followed by a single digit. The “H”

indicates that this location is a Hexadecimal field.

The valid entries for these locations are “0” through

“F”, where A - F correspond to 10 - 15 respectively.

To program a digit, enter digits as normal. To enter

an A - F, enter a ‘1’ followed by a ‘0’ through ‘5’.

As in programming normal fields, if too many digits

are entered, the first digit entered will be discarded.

The ENTER, OFF CANCEL, Right Panic, and

CLEARkeyswill work thesameas describedabove.

Additional Programming Notes

To exit out of Edit Function Map mode and return

theControlStation totheidle state,pressthe CLEAR

key from the LOCATION prompt. (You may need to

press the CLEAR key several times to get to the

LOCATION prompt). When the installer passcode

is used for the first time, an "Installer on Premises"

event is logged to be reported. Before leaving, the

CLEAR key must be pressed and held for 3 sec-

onds to log an "Installer off Premises" event to be

reported.

When programming the value at the last program-

ming location, the Control Station will return to the

LOCATION prompt if the ENTER key is pressed.

Program User Codes

The installer passcode has the authority to edit user

passcodes locally. The control may be programmed

with up to 8 user passcodes and the installer

passcode (USER 9). See the Programming Record

Book for instructions on setting the authority level

for the 8 user passcodes. To program or change a

user or installer passcode:

1. Press the ‘9’ key and enter the installer passcode

to enter programming mode.

2. Pressthe‘5’key toProgramUserCodes. TheCon-

trol Station will prompt you to enter the User ID of

the passcode that you wish to program/change.

INSTALLER LEVEL PROGRAMMING

3. Enter the ID number then press the ENTER key.

4. Enter the new four-digit passcode. The Control

Station will beep twice and return to the User ID

prompt.

5. Enter a new ID number or press the CLEAR key

to return to the Ready mode.

To view an existing passcode, press the ENTER key

after each digit is displayed. If the new passcode

being entered is a duplicate of an existing one, the

Control Station will sound an error tone and return

to the first digit location so that you may try again.

If you wish to make a User passcode inoperable,

enter “0,0,0,0” as the new four-digit passcode.

Restore Factory Defaults

Thisfunctionprovidesameanstocompletely wipeout

the panel’s memory and restore it to a factory default

state. If successfully completed, the panel will:

•default the entire Function Map (including User

Passcodes and Zone Names)

•clear the Event Log

•clear all alarm, trouble and armed conditions

•not affect RF Data in the RF Gateway

Press the ’9‘ key and enter the installer passcode to

enter programming mode. Press the ‘6’ key to enter

Restore Factory Defaults mode. The Control Sta-

tionwillprompt youtore-enter the installerpasscode

for verification.

If it is entered correctly, the Control Station will go

into a locked out state for a few seconds and then

may display the No Communication condition be-

fore displaying the panel revision and returning to

the Ready mode.

17

Hours Until Next Comm Test

The scheduling ofAutomatic Communications Tests

requiresprogrammingthe numberof“Days Between

CommTests”.If“Days BetweenCommTests”is zero,

then no automatic comm tests will occur. Other-

wise, a comm test will occur on an interval deter-

mined by the “Days Between Comm Tests”.

The time that an auto comm test occurs will be the

same time on each comm test day. That time is

automatically set via a random number whenever

the system is powered-up.The time can also be ad-

justed by setting the ”Hours Until Next Comm Test“.

Press the ’9‘ key and enter the installer passcode to

enter programming mode. Press the ‘7’ key to set

the Hours Until Next Comm Test. The Control Sta-

tion will display zero (0).

Enter a number between 1 and 255. If a mistake is

made, press the CLEAR key to start over. If a num-

ber greater than 255 is entered, the first digit en-

tered will be discarded. When the desired number

of hours is displayed, press the ENTER key. The

Control Station will return to idle. To exit out of this

function without setting the number of hours, press

the CLEAR key.

Program RF Data

In order for an RF Zone Device or RF User Device

to be received by the RF Gateway, the address of

the RF Device must be programmed into the RF

Gateway. The ZX300/ZX310 can support up to 16

RF Zones and 8 RF User Devices. The RF Zones

are programmed into the RF Gateway as devices 1-

16 corresponding to zones 1-16. The RF User De-

vices are programmed into the RF Gateway as de-

vices 17-24 in any order (there is no correlation be-

tween these devices and the Control Panel’s configu-

ration data). The 4710 RF Gateway is restricted to

devices 9-16 for zones 9-16 and devices 17-24 for

eight RF User Devices.

INSTALLER LEVEL PROGRAMMING

Programming RF Zone Devices Into the

RF Gateway

Press the ‘9’ key and enter the installer passcode to

enter programming mode. Press the ‘9’ key to Pro-

gram RF Data. The Control Station prompts you to

select an RF Device to program.

Enter 1 thru 16 to select an RF Zone and press EN-

TER. The Control Station displays the eight digits

that are currently programmed in the RF Gateway

for that zone. The digits are displayed one at a time.

For each digit, you may program a new value by

pressing a digit key. The Control Station will auto-

matically move to the next digit. To move to the next

digit without changing the current digit, press the

ENTER key.

The first digit to enter is the Supervision setting

where: 0 = Unsupervised

1 = Reserved

2 = Reserved

3 = 4 Hours

4 = 24 Hours

The next seven digits to enter come directly off of a

label on the RF Device.

If you make a mistake while entering the eight dig-

its, press the CLEAR key and the Control Station

returns to the first digit.

After the last digit is entered, the data is sent to the

RF Gateway and is confirmed and the Control Sta-

tion returns to the RF Device selection prompt. If

the data is successfully loaded into the RF Gate-

way, theControlStation beepstwice. Ifthe RFGate-

way does not respond, the Control Station sounds

an error tone and briefly displays an error message.

Check the data bus connections to the RF Gate-

way. If the 8 digit number entered for the RF Zone

isalreadystoredinthe RFGatewayforanotherzone,

the Control Station sounds an error tone and briefly

displays a message indicating the duplicate zone.

FromtheRF Device prompt,selectanother RFZone

Device or press the CLEAR key to exit.

18

Check the data bus connections to the RF Gate-

way. If the 8 digit number entered for the RF User

Device is already stored in the RF Gateway for an-

other device, the Control Station sounds an error

tone and briefly displays a message indicating the

duplicate device.

FromtheRFDevice prompt, selectanotherRFUser

Device or press the CLEAR key to exit.

Programming RF Devices Into the Control

Panel

After the RF Devices have been programmed into

the RF Gateway, they must also be programmed in

the Control Panel. The programming options for the

Control Panel’s Function Map are described in the

Programming Record Book. When RF Devices are

used in an installation, be sure to consider the fol-

lowing:

For an RF Zone Device, the zone data must be pro-

grammed for the selected zone. The ZoneType and

ZoneAttributes locations are programmed as usual.

The Zone Supervision must be programmed to 7

(wireless zone).

For an RF User Device, a user passcode must be

created (see Installer Level Programming - Program

User Codes) that consists of the last four digits of

the RF Device’s address. An appropriate authority

level must also be programmed for that user.

Once all the above steps are per-

formed, the Control Station may

sound a Trouble tone. The Con-

trol Station will display ”Trouble-

RF Point Not Reporting“ for each

RF Zone. These conditions are

cleared as a proper transmission

is received from each wireless

Zone Device.

If the Trouble condition does not

clear, then there is an error in the

programming of the Gateway or

control or the RF Gateway is not

responding to the RF signal from

the sensor.

INSTALLER LEVEL PROGRAMMING

Programming RF User Devices Into the RF

Gateway

Press the ‘9’ key and enter the installer passcode to

enter programming mode. Press the ‘9’ key to Pro-

gram RF Data. The Control Station prompts you to

select an RF Device to program.

Enter 17 thru 24 to select an RF User Device and

pressENTER. TheControl Stationdisplaysthe eight

digitsthatarecurrently programmed intheRFGate-

way for that device. The digits are displayed one at

atime. Foreach digit, youmayprogram anewvalue

by pressing a digit key. The Control Stations will

automatically move to the next digit. To move to the

next digit without changing the current digit, press

the ENTER key.

Enter ‘1’ for the first digit.

The second digit to enter defines the operation of

the key(s) on the RF User Device, where:

SEC KEY KEY KEY KEY

DIGIT A B C D

1 AWAY STAY NIGHT OFF/CANCEL

2 AWAY STAY ACCESS OFF/CANCEL

3 AWAY STAY PANIC/HOLDUP OFF/CANCEL

4 AWAY STAY AUX/MED OFF/CANCEL

5 AWAY STAY NOT USED OFF/CANCEL

6 AWAY PANIC/HOLDUP NOT USED OFF/CANCEL

7 STAY PANIC/HOLDUP NOT USED OFF/CANCEL

8 STAY PANIC/HOLDUP AUX/MED OFF/CANCEL

9 AWAY NOT USED NOT USED OFF/CANCEL

The next six digits to enter come directly off of a

label on the RF User Device.

If you make a mistake while entering the eight dig-

its, press the CLEAR key and the Control Station

returns to the first digit.

After the last digit is entered, the data is sent to the

RF Gateway and is confirmed and the Control Sta-

tion returns to the RF Device selection prompt. If

the data is successfully loaded into the RF Gate-

way, theControlStation beepstwice. Ifthe RFGate-

way does not respond, the Control Station sounds

an error tone and briefly displays an error message.

NOTE

19

ZX300/ZX310 Control Board

•Eight (8) two-wire zones, each supervised with

a 1500 Ohm end-of-line resistor. Expandable to

16two-wirezones with ZXEX08 zoneexpander.

•Two-wire smoke detector zone on control (can

be used in place of zone 8).

•Three (3) Control Station activated panic zones.

•Nominal current drain for control board only 50

mA.

•Watchdog microprocessor monitoring.

•Superior six (6) stage lightning/transient protec-

tion.

•One assignable high current alarm output. (Su-

pervised Bell Output).

•One assignable low current output (10 mA @ 3

VDC).

•Expandable to eleven (11) low current outputs

via an output driver module.

•Continuous battery monitoring.

•Low voltage detection monitoring @ 11.3 volts

threshold.

•Automatic system shutdown if voltage falls be-

low 9.8V.

•Operating temperature range inside the enclo-

sure: 32°F to 122°F (0°C to +50°C).

•Two or four-wire smoke zones available.

•Keypad Programmable.

•Loop response time: 320 msec (general pur-

pose hardwired zones), 1600 msec (two-wire

smoke zone).

Power Supply

•Fully regulated 13.8 volt 900 mA supply avail-

able with a 16.5 VAC 35 VA transformer.

•Optional 16.5V 25 VAtransformer provides 500

mA power.

•Reverse polarity protection on battery inputs.

•Float charging circuit: 13.8 volts DC.

Specifications And Features

SPECIFICATIONSAND FEATURES

Recommended Batteries

(supplied separately)

•Rechargeable 12 VDC 7 Ah sealed lead acid.

Use two (2) batteries to meet CSFM and House-

holdFire requirementof24-hour standby at450

mA.

•Rechargeable12VDC17.2Ahsealedleadacid. Use

one(1)batterytomeetCSFMrequirementof24hours

of standby at 450 mA.

Recommended Transformers

(supplied separately)

•UL Listed Class II plug-in; 16.5 VAC 15 VA sec-

ondary; 120 V 60 Hz primary connected to 24-

hour unswitched outlet.

•Optional UL Listed Class II plug-in 16.5 VAC 25

VA secondary, 120 V 60 Hz primary connected

to 24-hour unswitched outlet.

• For ULCommercial Burglary, the transformer to

be used is a 16.5 VAC 35 VAULClass II Basler

BE 116220.

Enclosure

•Twenty (20) gauge metal cabinet with knockout

for optional cam lock. Dimensions: 9"W x 10"H

x 2.875"D (228.6 mm x 254 mm x 73.02 mm).

•Optional EX1414 20 gauge locking metal cabinet

with two keys. Dimensions 14"W x 14"H x 3.5"D

(356 mm x 356 mm x 89 mm).

•TC1100 Tamper Resistant Enclosure: extra high

security cover (uses EX1414 option).

•Optional pre-configured assembly: ZX310

(ZX300ControlBoardmounted into theEX1414

enclosure).

Digital Communicator

•DTMF Touchtone™ or Rotary (pulse) dialing.

Rotaryspeed: 10pps,(selectable U.S.style60%

break, 40% make or International style 67%

break, 33% make).

•Ringer equivalence: 0.0B.

•Transmission formats include: Contact ID, SIA

Level 1, Pager.

20

•Reports to most major Central Station receiv-

ers.

•Primary phone number can have up to 20 dig-

its.

•Secondary phone number can have up to 20

digits.

• Pager phone number can have up to 20 digits.

•Reporting capabilities: two 6-digit account num-

bers, report by zone, opening and closing re-

ports,forcearm/bypass reports, restoralreports,

troublereports,cancelreporting, low battery,AC

failure/restoral.

•Dual and split reporting capability.

•Pager capability with 16-digit programmable

message and 2-digit coded messages.

•Disable call waiting.

Control Stations

•Color-coded four-wire data bus connection.

•19-Button keypad with audible feedback.

•Three (3) Control Station panic button zones.

•Surface mountable; mounts to any standard

single or double gang electrical box.

•Built-in piezo sounder.

•Easy-to-read arming level: AWAY, STAY, and

NIGHT backlit LEDs.

•Backlit keys with door.

•Unsupervised Control Stations allows up to 18

Control Stations.

ZXICON Control Station

•Two seven-segment display digits.

•Plain English icons.

•AddressableasControlStation#3 or#4. Jumper

change makes Control Station unsupervised.

•Nominal current drain: 50mA.

•Size: 5.0"H x 4.5"W x 1.0"D (127 mm x 114.3

mm x 25.4 mm).

SPECIFICATIONSAND FEATURES

ZXLCD Control Station

•Backlit display.

•Two lines x 16 characters LCD display.

•Addressable with DIP switches, supervised/un-

supervised.

•Plain English display.

•Nominal current drain: 20mA - 110mA.

•Up to four (4) supervised Control Stations per

system.

•Size: 5.33"H x 6.08"W x 1.024"D (135.4 mm x

154.4 mm x 26.0 mm).

ZXLED12 Control Station

•Twelve (12) LEDs annunciate general purpose

zones 1 through 12.

•Ready, trouble, and fire alarm LEDs.

•AddressableasControl Station#1or #2.Jumper

change makes Control Station unsupervised.

•Nominal current drain: 23mA - 31mA.

•Size: 5.0"H x 4.5"W x 1.0"D (127 mm x 114.3

mm x 25.4 mm).

ZXLED8 Control Station

•Eight (8) LEDs annunciate zones 1 through 8.

•Ready and trouble LEDs.

•AddressableatControlStation #1 or#2.Jumper

change makes Control Station unsupervised.

•Nominal current drain: 23mA - 31mA.

•Size: 5.0"H x 4.5"W x 1.0"D (127 mm x 114.3

mm x 25.4 mm).

ZXSSD Control Station

•Three 0.56" (14.2 mm) seven segment display

digits.

•Ready and trouble LEDs.

•Up to four (4) supervised Control Stations per

system.

•Addressable with DIP switches, supervised/un-

supervised.

•Nominal current drain: 23mA - 116mA.

•Size: 5.0"H x 4.5"W x 1.0"D (127 mm x 114.3

mm x 25.4 mm).

This manual suits for next models

1

Table of contents

Other Sentrol Security System manuals

Sentrol

Sentrol ZX400 User manual

Sentrol

Sentrol ZXLCDL User manual

Sentrol

Sentrol Arrowhead SC800 Assembly instructions

Sentrol

Sentrol ZXLCD User manual

Sentrol

Sentrol X440F User manual

Sentrol

Sentrol ZX200 Installation guide

Sentrol

Sentrol ZX400 Operating instructions

Sentrol

Sentrol ZXLED8 User manual

Sentrol

Sentrol ZXCD Operating instructions

Popular Security System manuals by other brands

KALEAS

KALEAS KlimaDetector operating instructions

Nortel

Nortel Alteon Link Optimizer 150 Installation and Maintenance

Magos

Magos SR-500 user manual

Secure Care

Secure Care Advantage 500DE installation manual

Panasonic

Panasonic KX-HNS105AZ installation guide

Cooper safety

Cooper safety CSA 462-NS quick start guide