SENZARY IoTlogIQ Rotary IQ User manual

Table of Contents

Bob Assistant Overview

Purpose of predictive maintenance

Differentiating factors of the Bob Assistant

1. Quick Start-up Guide

1.1 What’s in the Box

1.2 Setting up your account online

1.2.1 Account and location (company address) creation

1.2.2 Adding device to the selected location

1.2.3 Setting up alert system

1.2.4 Setting up report system

1.2.5 Tracking the Bob Assistant

1.3 Gateway installation guide

1.3.1 LED

1.4 Bob Assistant assembly

1.4.1 Magnets –default configuration

1.5 Quick Installation Guide

1.5.1 Turning Bob Assistant ON

1.5.2 Start-up

1.5.3 Turning Bob Assistant OFF

2. Installation and Configuration

2.1 Bob Assistant assembly options

2.1.1 Rivet

2.1.2 Screw

2.1.3 Fixation Plate

2.2 Bob Assistant fundamentals

2.2.1 Learning stages

2.2.2 Reporting mode

2.2.3 Monitoring

2.2.4 Troubleshooting

3. Frequently Asked Questions

3.1 Which type of equipment is well suited for Bob

ASSISTANT?

3.2 What is the temperature limit?

3.3 When should Bob ASSISTANT be installed on the

equipment?

3.4 Can we start Bob ASSISTANT on a machine that is

not running?

3.5 Can Bob ASSISTANT or the machine be moved

without disrupting its operation?

3.6 What is the autonomy of Bob ASSISTANT sensors?

3.7 How do I interpret the gateway’s LED lights?

4. Customer Support

1

2

3

4

4

4

5

7

8

9

9

10

11

11

12

13

13

14

15

15

15

16

17

17

17

18

18

19

19

19

20

20

20

21

22

V1.0 | 03.28.2020 | Page 1

Bob Assistant Overview

The Bob Assistant is a low-power LoRaWANTM(a type of low-

power, wide-area wireless network) compatible vibration

sensor for indoor and outdoor predictive maintenance

industrial applications, coupled with a temperature sensor

for environmental conditions, a push-button, and an RBG LED

light for user interface.

Bob Assistant Overview

Bob Assistant measures and analyzes vibrations, temperature, and movement to

detect abnormal behaviors for a wide range of industrial machines, with artificial

intelligence capable of detecting operating anomalies before a failure occurs. Its

“Edge AI” allows it to analyze the vibrations coming from your machine. This vibration

data is then optimized and secured to guarantee the device’s ability to function

independently for several years.

Equipped with a dust and waterproof casing, the Bob Assistant is very easy to install

and does not require any configuration. Simply place the Bob Assistant on your

machine, start it, and after a few hours of learning, it will be able to detect any

abnormal behaviors from your machine.

When a machine starts breaking down, vibration drift is the first measurable symptom:

Purpose Of Predictive Maintenance

The Bob sensor uses AI to predict when equipment breakdowns might occur. In the process, saving costs

in machine evaluations.

However, a distinction must be made between breakdowns due to wear and tear (slow drift) and

breakage (fast drift). In certain cases, the vibration/movement/temperature anomalies can occur only a

few days before the failure. Your maintenance team will be able to analyze and intervene on the

equipment when the Bob Assistant reports an anomaly.

V1.0 | 03.28.2020 | Page 2V1.0 | 03.28.2020 | Page 2

Purpose of predictive maintenance

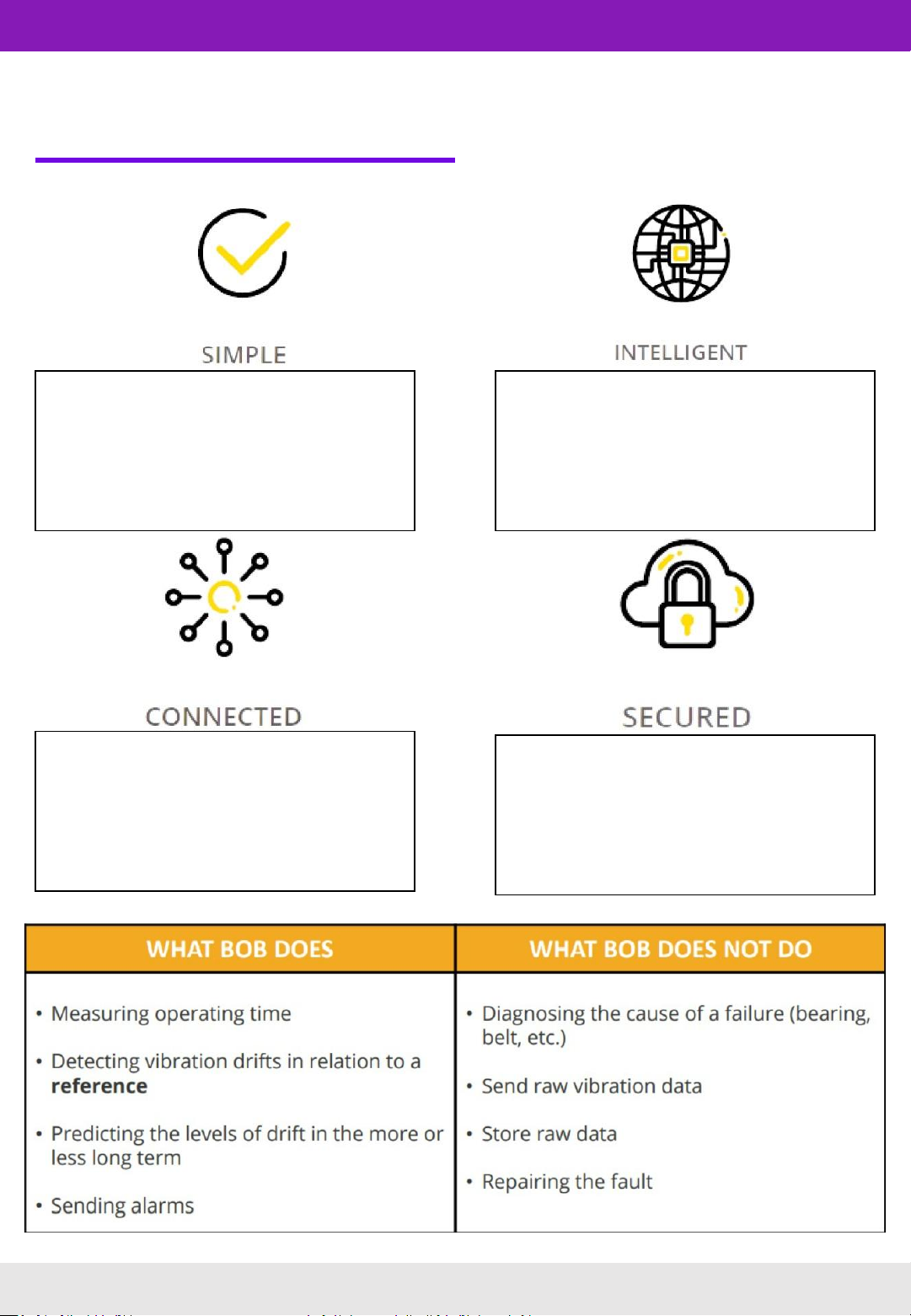

Differentiating Factors Of The Bob Assistant

Unlike traditional predictive maintenance

sensors, the Bob Assistant has zero infra,

zero wiring, and zero configuration. To

install Bob, simply place it on your

equipment. Bob can then work

autonomously for several years.

Bob uses its AI to learn quickly and learn

well! It applies analysis algorithms

embedded in its sensor to understand and

monitor all of your equipment.

Bob communicates across LoRaWAN®

networks, perfectly adapted to the

Internet of Things (IoT). The maximum

range for minimal energy consumption and

long battery life!

Your equipment production data is safe

with Bob. It retains it and sends only

encrypted scan reports.

V1.0 | 03.28.2020 | Page 3

Differentiating Factors of the Bob Assistant

1) Quick Start-up Guide

1.1 What’s in the box

KERLINK IFEMTOCELL Gateway 1x

NKE- Bob Assistant 1x

Magnets and nuts for Bob Assistant 2x

1.2 Setting up your device online –IOTLOGIQ SETUP

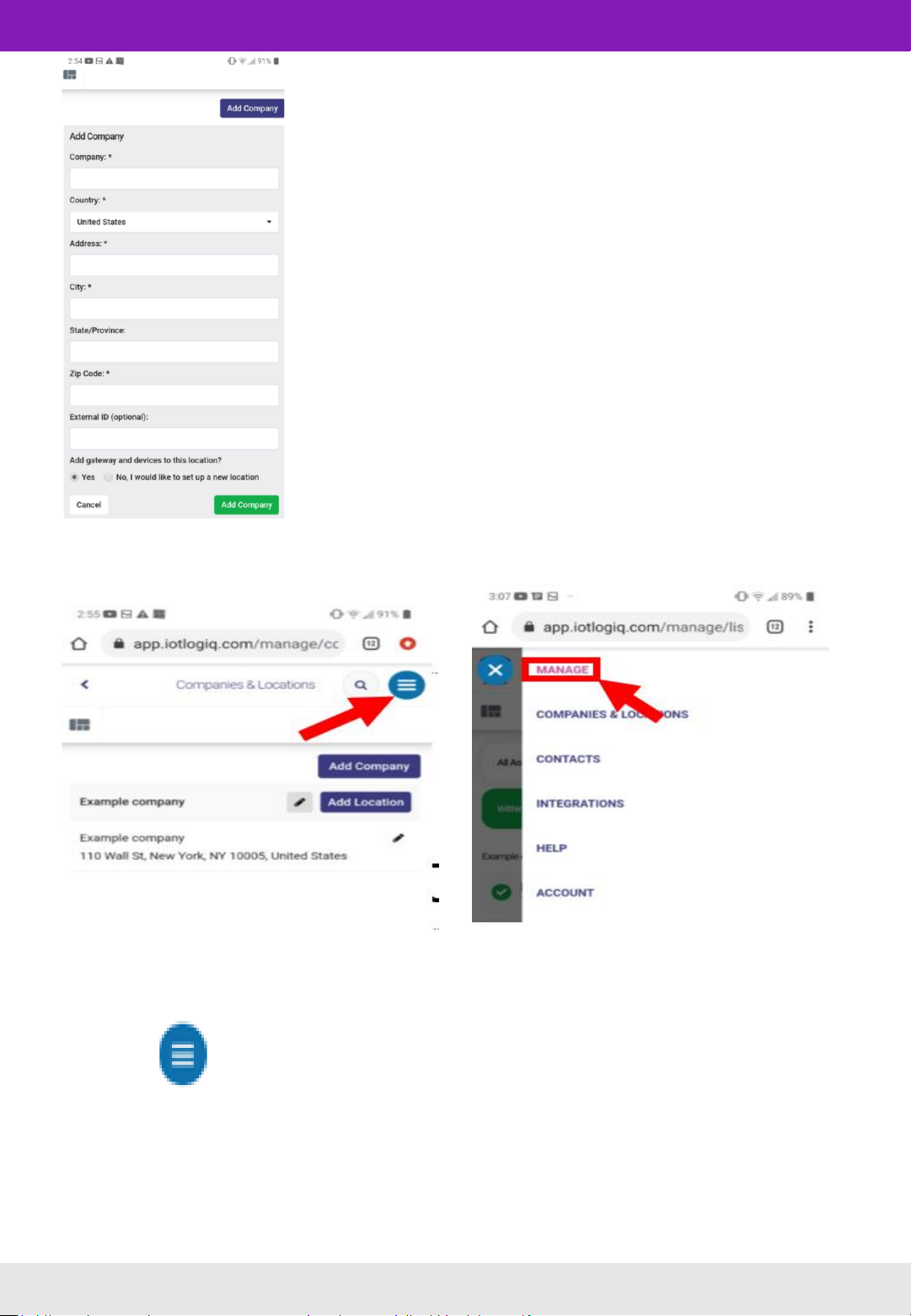

1.2.1 Account and location (company address) creation

Click on image for video

To add and view data and performance of

any sensors provided by Senzary LLC, first

create an account at app.iotlogiq.com

V1.0 | 03.28.2020 | Page 4

1.1 What’s in the Box | 1.2 Setting up your device online

This video will show you

- Setting up an account

- Adding your Bob sensor

- Using your mobile app

- Configure alerts and reports

icon on the upper right side and click on MANAGE.

Include your company information

and location to continue. This will

allow you to allocate, track and

manage all devices in your

specified location.

At least ONE location must be

created to associate a sensor to

the account

1.2.2 Adding devices to the selected location

To add the Bob Assistant sensor to the list of devices used by your

company, go to the MANAGE LIST page. Here you will be able to manage

and track the performance of each device. To access this, click on:

V1.0 | 03.28.2020 | Page 5

Quick Start-up Guide

1.2 Setting up your device online

To set up the Bob Assistant sensor to your company, tap on the button. Then tap on the option.

You will then be taken to an Add Device page. Scan the QR code or enter

the Device ID to add the sensor.

V1.0 | 03.28.2020 | Page 6

1.2 Setting up your device online

You will then be directed to the Smart monitoring set up page, where you can edit alert and report

settings. An alternative way to set up and edit alerts is to return to the MANAGE page by tapping on

the icon on the upper right side. Here, tap on the

1.2.3 Setting up the alert system

button for your device, and then the

button. Then add or edit an alarm.

The Anomaly Level Alert Settings page allows for editing of alert

notifications sent to you.

Alert name: Create names for the type of alert being set up.

Threshold above: If vibration and temperature go above the listed

percentage of the norm, an alert notification will be set off.

Threshold below: If vibration and temperature go below the listed

percentage of the norm, an alert notification will be set off.

Reading(s) in a row before alert is sent: Change the number of times

an anomaly in vibration/temperature/movement has to go above or

below the threshold for an alarm to be sent

Rules (optional): Specific conditions for the alert to be set off can be

edited here

Notify Contact: Set up who receives notifications here

V1.0 | 03.28.2020 | Page 7

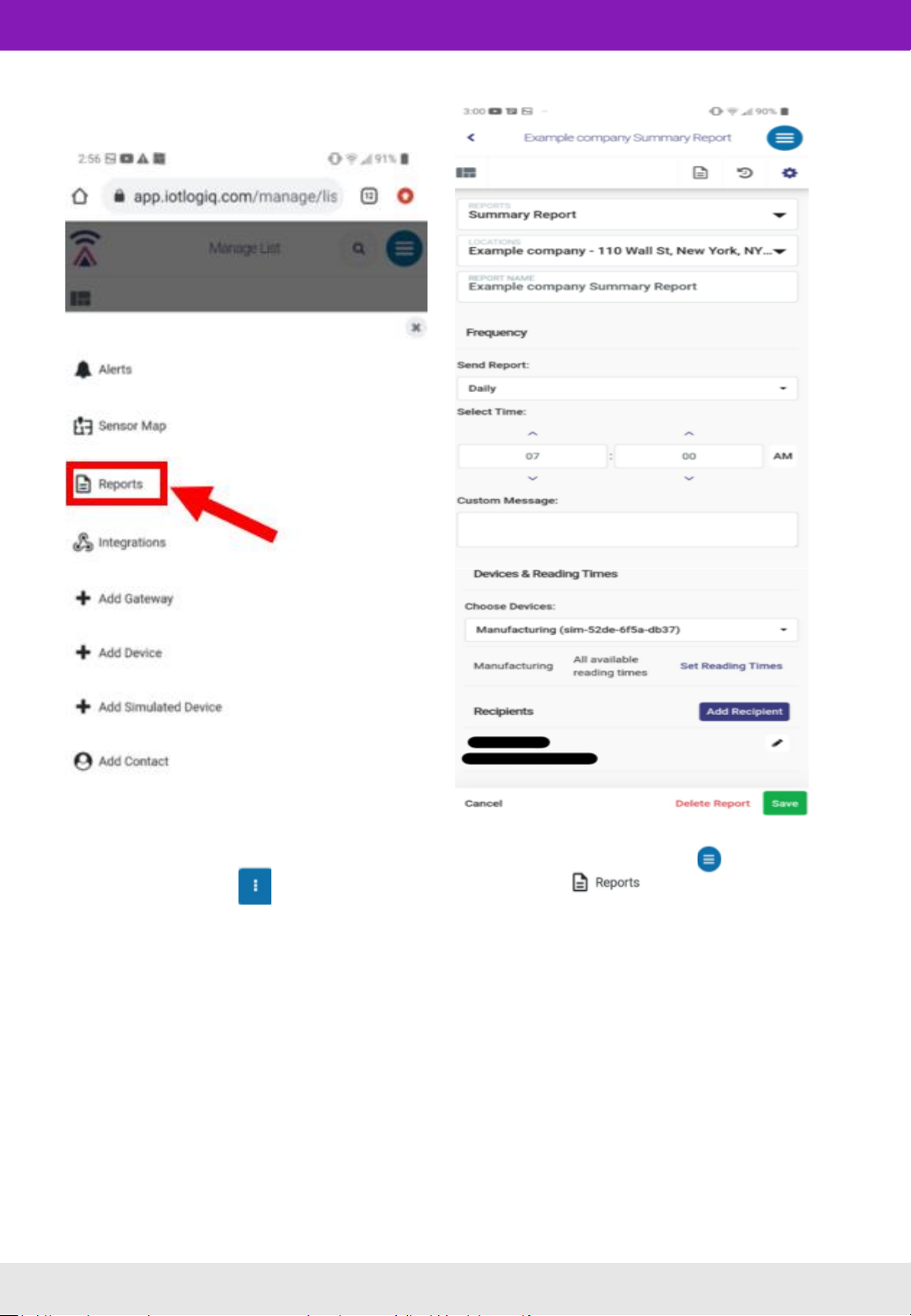

1.2 Setting up your device online

button of your device, and then the

The Summary Report page allows you to edit the type of report received and the frequency it is received.

To access the summary report page, return to the MANAGE page by tapping on the

1.2.4 Setting up the report system

icon on the upper

right side. Here, tap on the button. Then add or edit a

report.

V1.0 | 03.28.2020 | Page 8

1.2 Setting up your device online

1.2.5 Tracking the Bob Assistant

To view the status of all devices added, tap the icon on the

upper right side. Then tap MANAGE. Then tap on your company

name to view all devices associated with said company.

Tap on your device to see detailed and historical reports given

by the Bob Assistant.

V1.0 | 03.28.2020 | Page 9

1.2 Setting up your device online | 1.3 Gateway installation guide

To view more detailed data in the form of columns, click on

the icon on the upper left side of the MANAGE page.

Select your device on the list of options shown.

The dashboard shown allows you to download data, view

the operating status, view reports, anomaly distributions,

and average unnatural vibration reports.

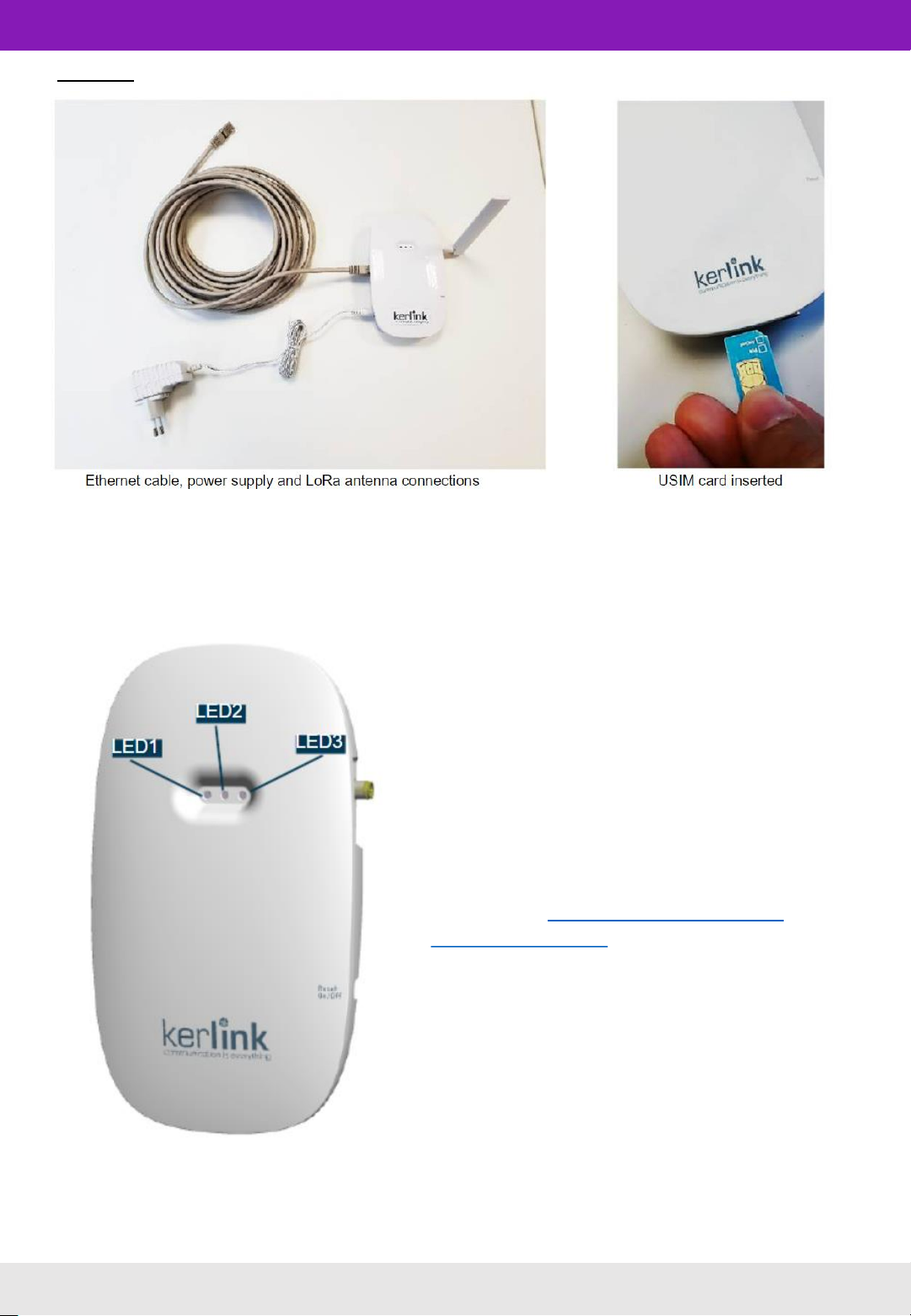

1.3 Gateway installation guide

The gateway serves as a wireless access portal that allows the Bob Assistant to connect to the

cloud. Without it, you will not be able to access your device online. With its

LoraWancompatibility, the gateway can be placed up to 100 meters away from the Bob Assistant.

To access the internet, the device can be connected in the following ways:

-Through Ethernet connection: Plug the gateway into an ethernet connection through an RJ45

cable (not included)

-Through a 4G/3G cellular connection (only applicable for select gateways): Insert a USIM (not

included) with a data subscription (not included) to the gateway

Note that both configurations can be used in parallel.

Example:

Once the LoRa RF antenna, the Ethernet cable (if used) or the 4G/3G (with USIM card

inserted) and the power supply jack connector are plugged, the Wirnet™iFemtoCell-

evolution can be powered ON by connecting the power supply.

If both LED 1 and LED 2 are solid green and do not

blink, the device is operational.

For more information on interpreting the gateway’s

LED lights see §3.3.7 How do I interpret the

gateway’s LED lights?

V1.0 | 03.28.2020 | Page 10

1.3 Gateway installation guide

1.3.1 LED

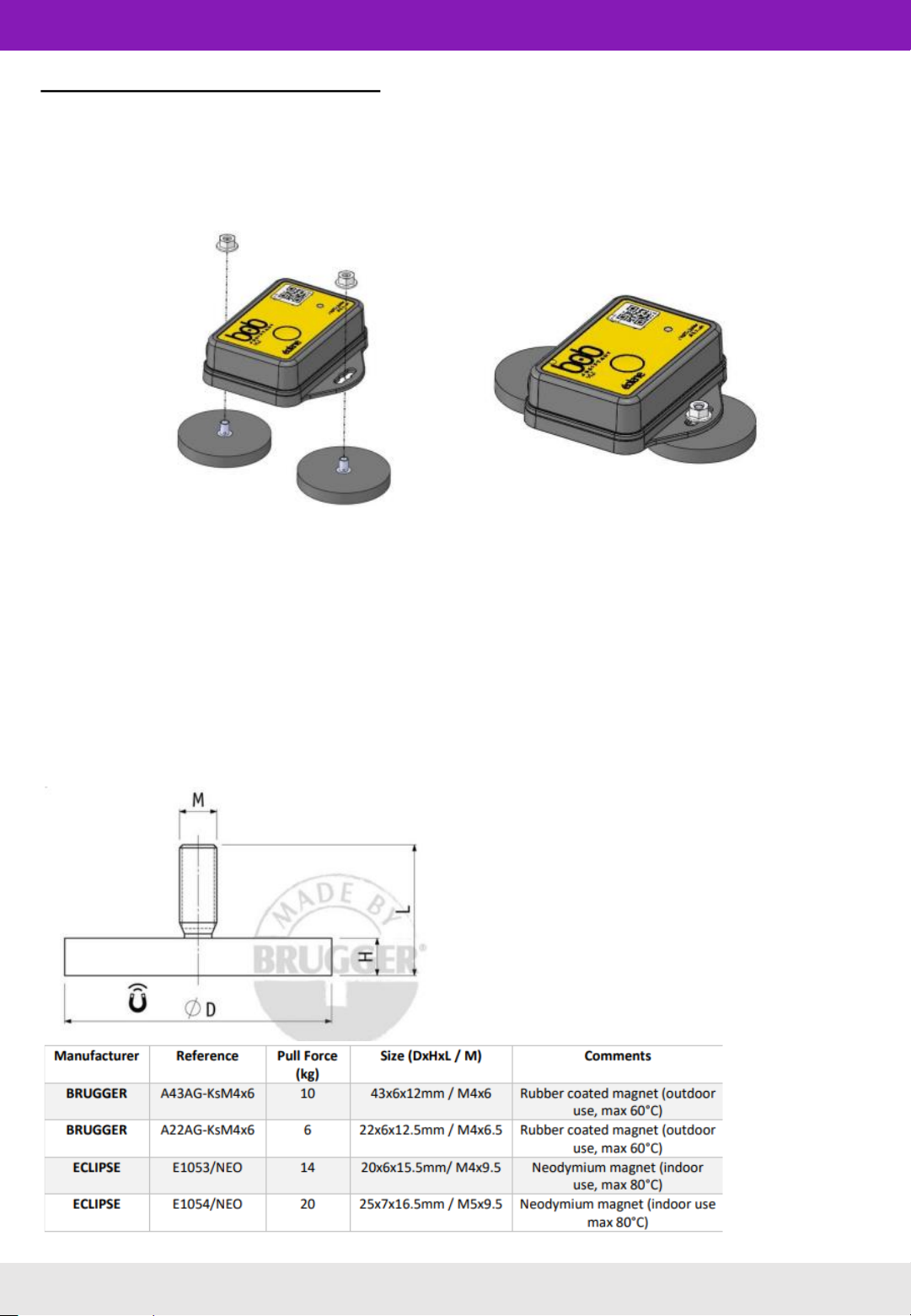

1.4 Bob Assistant assembly

1.4.1 Magnets - default configuration

Bob Assistant is delivered with a magnet kit, so you can put your device on your machine out of

the box. To assemble, follow the image below:

Default configuration: -

Magnet (x2):

•Manufacturer: BRUGGER MAGNET

•Reference: A22AG-KsM4x6

Nut (x2):

•Manufacturer: BOSSARD

•Reference: BN11207 / 3061765

Validated references:

These magnet references have been successfully

tested as compliant with ETSI 300-019 class 5.2

when mounted on Bob ASSISTANT.

Class 5.2: all types of road vehicles used in areas

with a well-developed road system, except tracked

vehicles, motorcycles, scooters, and other vehicles

with low mass. The equipment can be mounted on

surfaces that may be subjected to flying stones. The

equipment may be mounted on passenger car

instrument panels to which high-frequency

vibrations from the engine, or from other parts

connected to the engine, may be transmitted. This

class also applies to forklift trucks and trains with

soft suspension and shock reducing buffers

V1.0 | 03.28.2020 | Page 11

1.4 Assembling Bob Assistant

1.5 Quick installation guide

Click on image for video

To install the Bob Assistant, simply place it on the device you’re measuring.

The first step when you install Bob ASSISTANT on a machine you want to monitor will be to start

the device, and make sure that:

o the LoraWanNetwork is reachable ( TWO GREEN LIGHTS ON YOUR GATEWAY )

o there is a certain vibration level of the machine

Refer to §1.5.1 Turning Bob Assistant ON for further instruction on how to turn the device on

Please be advised:

o if the vibration level was high enough at startup, but then is going below the minimum level of

detection in the first 7 days, the device might get stuck in a Learning Session. In this case, we

suggest changing Bob location on the machine to put it as close as possible to the vibration

source, or on a less vibration-insulated element.

o If a new machine cycle appears after the first seven days (e.g. production rate increase), it

might be considered by Bob ASSISTANT as an anomaly. In this case, you will have to send a

Downlink command to Bob ASSISTANT in order to add this cycle to the dataset.

Note: Bob Assistant can learn up to 32 different patterns of operation. It will learn automatically

during first SEVEN days, but you can also send a message to add a new learning pattern if a new

operating scheme will be added. ( different material, additional speed or other change affecting

the performance of the motor being monitored )

V1.0 | 03.28.2020 | Page 12

1.5 Installation guide

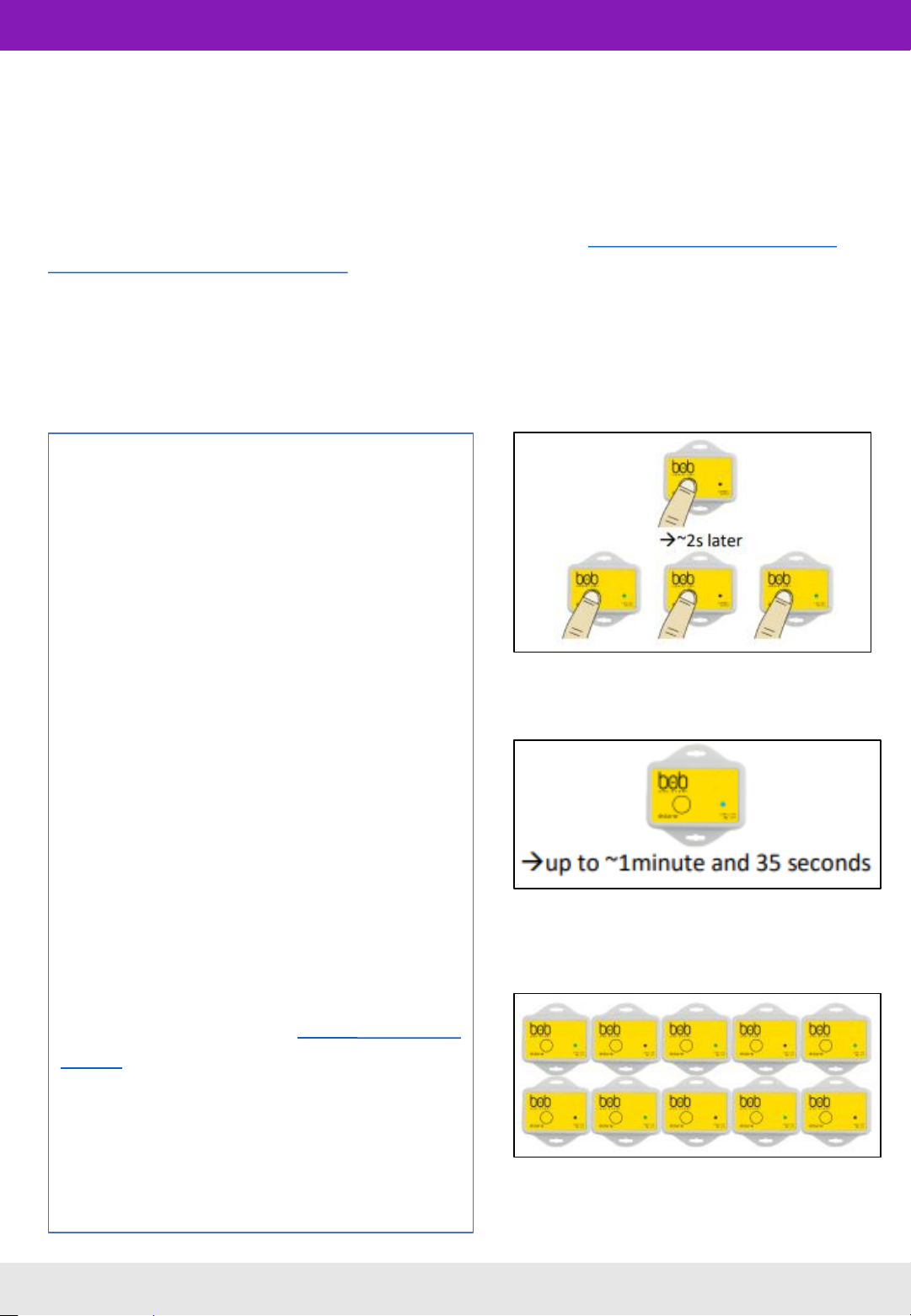

1.5.1 Turning Bob Assistant ON

To turn the device on, push and hold the button for 5 seconds. The LED will blink green twice and a

blue light will show for 15 seconds.

Bob ASSISTANT is OFF by default when delivered. In order to start Bob ASSISTANT, you need to:

•Place Bob ASSISTANT on the machine you want to monitor (see §1.4 Assembling Bob Assistant,

§2.1 Bob Assistant Assembly Options)

•Turn the device ON by pushing on the button for more than 2 seconds, the LED will then blink

twice in green. You can then release the button, the device is ON

Once switched ON, Bob Assistant starts

its initialization mode.

It then tries to reach the LoRaWAN

Network using OTAA (Over The Air

Activation) and ensures that the minimal

perceived vibration level is sufficient

(>0.01g). During this mode, the LED is

continuously blue ( ).

The initialization mode lasts for around 1

minute and 35 seconds (depending on

LoRaWAN Network coverage) A the end

of this initialization mode, if the device

has reached the Lora Wan Network, and

the perceived vibration level of the

machine is sufficient (>0,01g), then the

device will blink 5 times in green , the

LED will stay OFF and Bob Assistant is

ready to start its duty and enter the

Learning mode (see §2.2.1 Learning

stages)

Bob Assistant will then send a state

message to warn that the device has

started, and everything works fine.

V1.0 | 03.28.2020 | Page 13

1.5 Installation guide

Turn Bob Assistant ON

(2 green LED blinks)

Start up and initialization

(Continuous blue LED)

End of initialization

(5 green LED blinks)

Ensure that the machine connected to the Bob Assistant is vibrating. The device is going to try

to connect to the LoRaWAN network 6 times. If it does not connect after 3 hours, try to reset

the device by pushing the BUTTON for 15 seconds.

(For troubleshooting help, see §2.2.4 Troubleshooting)

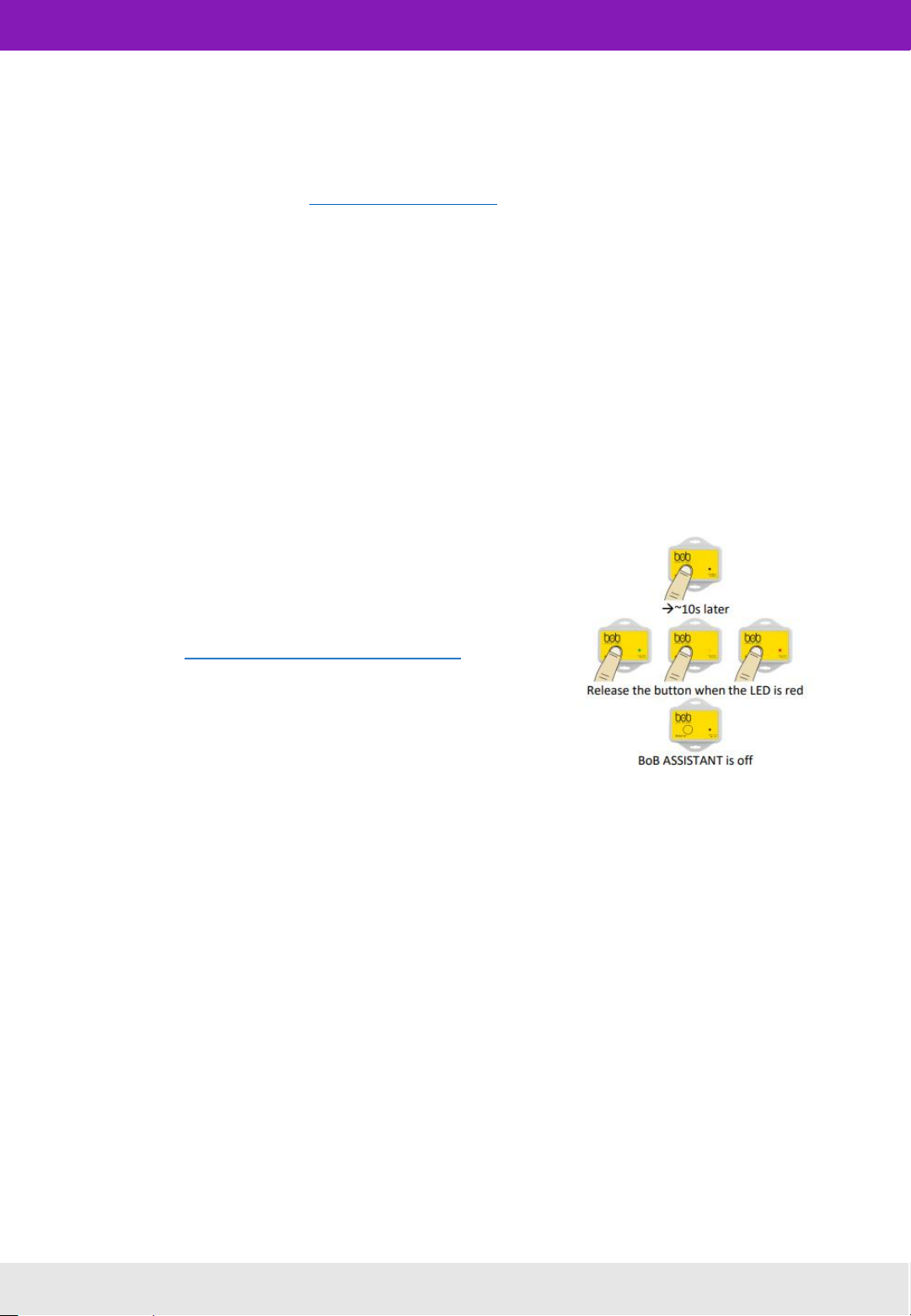

1.5.3 Turning Bob Assistant OFF

In case you need to move Bob Assistant from one machine to another and reset the vibration

learning, it is possible to turn Bob Assistant off.

To do so, push the button for ~10/12s, until you see the green/yellow/red sequence on the

LED. Once the LED is red, you can release the button, the device is off

Turn Bob Assistant is OFF (green->orange->red)

To turn Bob Assistant back on, follow the steps

described in §1.5.1 Turning Bob ASSISTANT ON

V1.0 | 03.28.2020 | Page 14

1.5 Installation guide

2) Installation and configuration

2.1 Bob Assistant assembly options

2.1.1 Rivet

Rivet properties: Ø4mm, length 7/10.2/13.3mm

Drilling: Ø4.1mm / Ø4.2mm

2.1.2 Screw

V1.0 | 03.28.2020 | Page 15

2.1 Bob Assistant assembly options

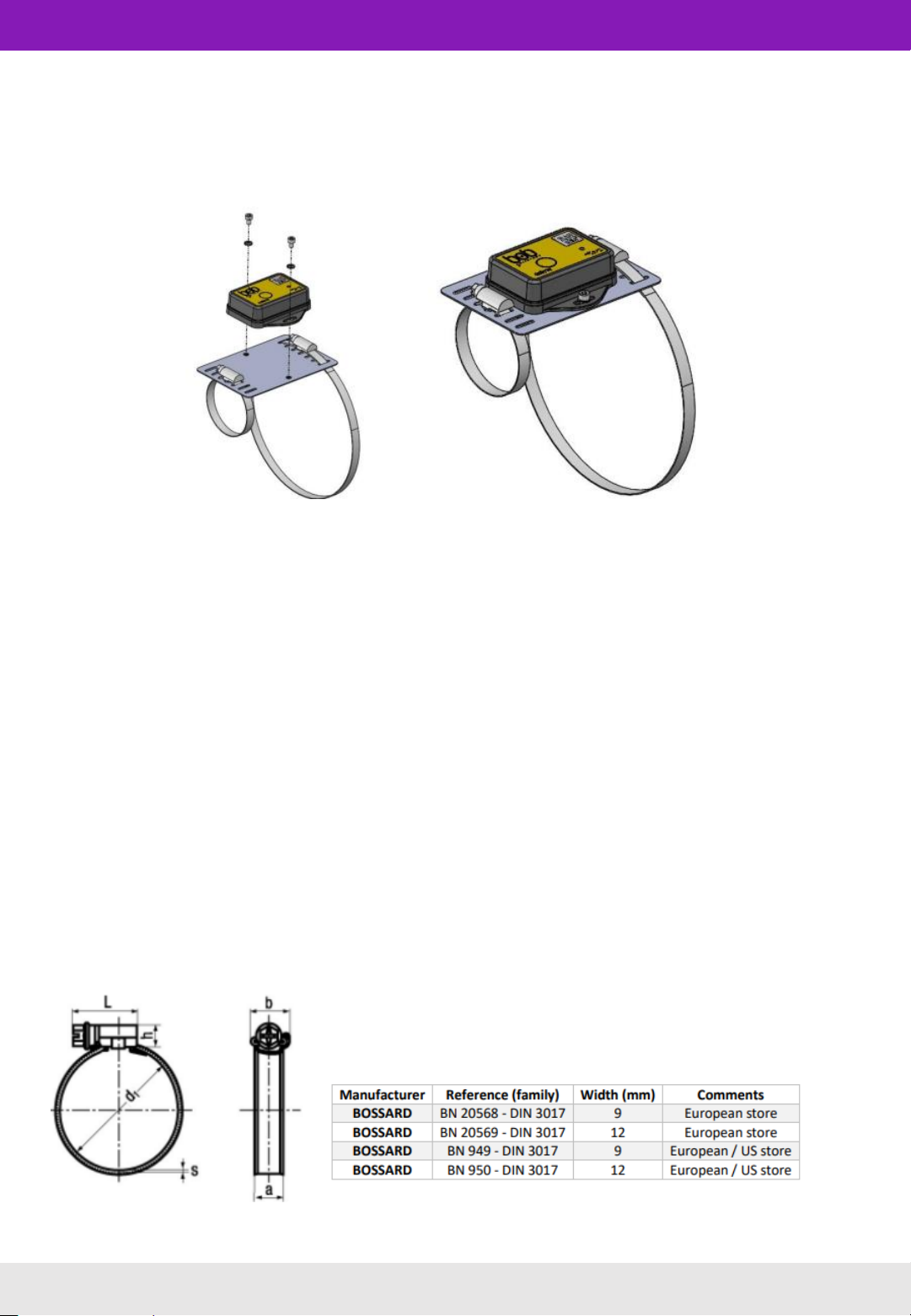

2.1.3 Fixation plate

In order to fasten Bob ASSISTANT on a circular surface, a fixation plate has been designed. It

can be fastened using hose clamps:

Default configuration:

- Fixation plate (x1):

•Manufacturer: EOLANE

•Reference: EOM1000200

- Hex socket head cap screw M4x6 (x2)

•Manufacturer: BOSSARD

•Reference: BN 612 - 1208152

- Serrated lock washer M4 (x2):

•Manufacturer: BOSSARD

•Reference: BN 4880 –1184040

Hose clamps references:

max value for width (a) = 15mm

V1.0 | 03.28.2020 | Page 16

2.1 Bob Assistant assembly options

2.2.1 Learning stages

Once the Bob Assistant is installed, it will start to learn the machine cycle(s). The Bob Assistant

will start its first learning sessions which will last for a few hours (~1 to 4 hours for a machine

with a simple vibration cycle, e.g. Air Conditioning unit).

In the next first seven days of operation, Bob Assistant will continue to its second learning

session. This session takes ~7 days and will continue to monitor new vibration signatures and

add them to the dataset.

During a learning session, Bob Assistant will wake up every 60 seconds (default values

configurable). The device will also send messages to keep you posted on the learning percentage

(0 to 100%).

2.2 Bob Assistant fundamentals

2.2.2 Reporting mode

After the first Learning session, Bob ASSISTANT will switch to the reporting mode, where it will

analyze the machine vibration every 5 minutes:

Bob ASSISTANT will process each sample to define whether a new learning session is needed, or

to prepare a report of the activity sent in periodic reports (every 3 hours, not configurable)

concerning the health of the machine during this period, regarding:

•the operation time of the machine,

•its vibration level,

•the vibration drift percentage,

•and prediction on potential failure distance in time, based on the vibration analysis of the last

24 hours, the last 30 days, and the last 6 months

The system will also report immediately when the machine starts and stops.

V1.0 | 03.28.2020 | Page 17

2.2 Bob Assistant fundamentals

2.2.3 Monitoring

After the learning mode, Bob ASSISTANT will switch to Monitoring mode, where it will continue

its reporting activity, and will start sending alarms if the drift in the vibration signature pass a

defined threshold (default value is 25% drift).

For each signal sampling (every 5 minutes by default), Bob ASSISTANT will process the sampled

signal, and compare it to its dataset.

2.2.4 Troubleshooting

Please be advised: If the LoraWan Network was unreachable or if the vibration level is below

the minimum level, the device will not start its duty, but will go back to deep sleep mode. To

restart the device, follow §1.5.1 Turning Bob Assistant on

V1.0 | 03.28.2020 | Page 18

2.2 Bob Assistant fundamentals

This manual suits for next models

1

Table of contents