Contents

1 About this document........................................................................ 5

1.1 Purpose of this document........................................................................ 5

1.2 Scope......................................................................................................... 5

1.3 Target groups of these operating instructions........................................ 5

1.4 Additional information.............................................................................. 5

1.5 Symbols and document conventions...................................................... 6

2 Safety information............................................................................ 7

2.1 General safety notes................................................................................ 7

2.2 Intended use............................................................................................. 7

2.3 Requirements for the qualification of personnel.................................... 8

3 Product description........................................................................... 9

3.1 General description.................................................................................. 9

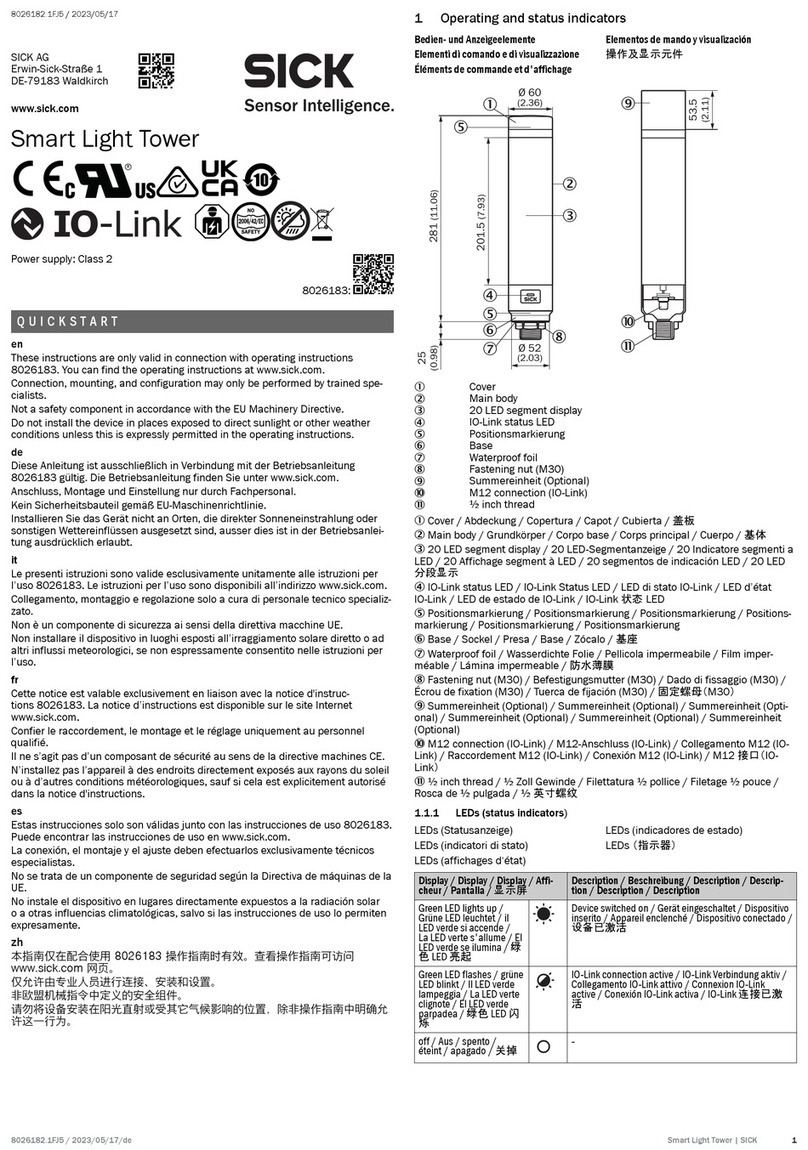

3.2 Control elements and status indicators.................................................. 10

3.3 Function of the Standstill Monitor .......................................................... 11

3.4 External device monitoring (EDM)........................................................... 12

4 Project planning................................................................................ 13

4.1 Manufacturer of the machine.................................................................. 13

4.2 Operating entity of the machine.............................................................. 13

4.3 Integrating the equipment into the electrical control............................. 13

4.3.1 External device monitoring (EDM).......................................... 13

4.3.2 Operation with DC motors....................................................... 13

4.3.3 Operation with electronic motor controllers........................... 14

4.3.4 Motors with switched windings............................................... 14

4.3.5 Connection diagrams.............................................................. 15

4.4 Testing plan............................................................................................... 17

4.4.1 Planning the thorough check during commissioning and in

certain situations..................................................................... 17

4.4.2 Planning the regular thorough check..................................... 18

5 Mounting............................................................................................. 19

5.1 Mounting the Standstill Monitor.............................................................. 19

5.2 Removing the Standstill Monitor............................................................. 19

5.3 Plug-in terminal blocks............................................................................. 19

5.4 Removing the pluggable terminal blocks................................................ 20

6 Electrical installation........................................................................ 21

6.1 Device connection.................................................................................... 21

6.1.1 Internal circuitry....................................................................... 23

7 Commissioning.................................................................................. 24

7.1 General acceptance ................................................................................ 24

7.2 Commissioning......................................................................................... 24

CONTENTS

8027992/1CUN/2022-11-14 | SICK O P E R A T I N G I N S T R U C T I O N S | MOC3ZA 3

Subject to change without notice