Table of contents

1General...................................................................3

2Types......................................................................3

2.1 Type plate...............................................................3

2.2 Materials.................................................................4

3Safety instructions ..................................................4

3.1 Quality instructions / purpose..................................4

3.2 Marking of notes.....................................................4

3.2.1 Marking of notes in these operating instructions............4

3.2.2 Marking of notes on the product.....................................4

3.3 Dangers in case of inobservance of the safety

instructions .............................................................4

3.4 Safety conscious working........................................4

3.5 Intended use...........................................................5

3.6 Approved installation-, maintenance

and operating personnel .........................................5

3.7 Personal protection for maintenance and service....5

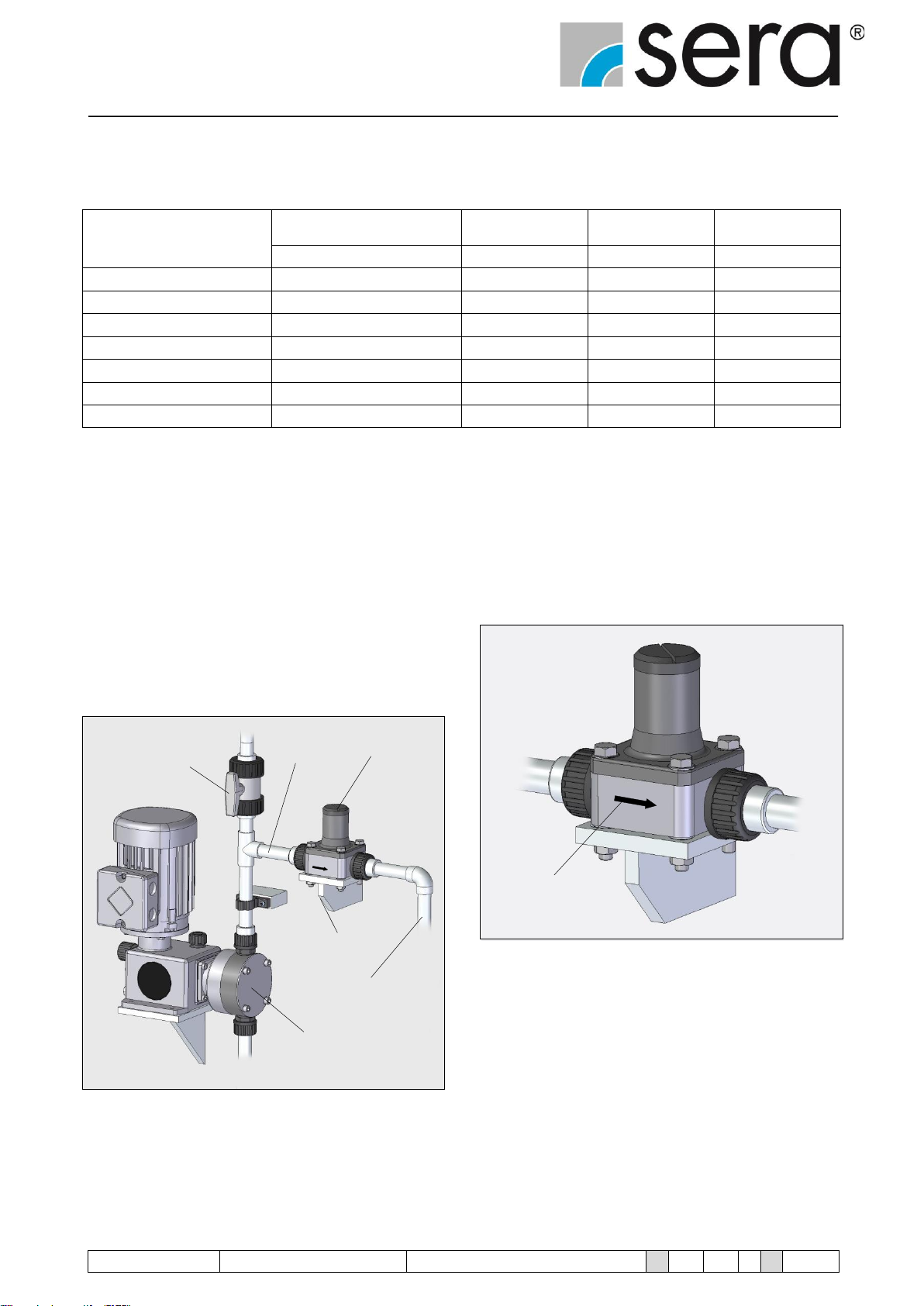

4Areas of application and function............................6

5Test / identification..................................................6

6Checking the packaging at the place

of destination ..........................................................6

7Storage...................................................................6

8Technical specifications..........................................7

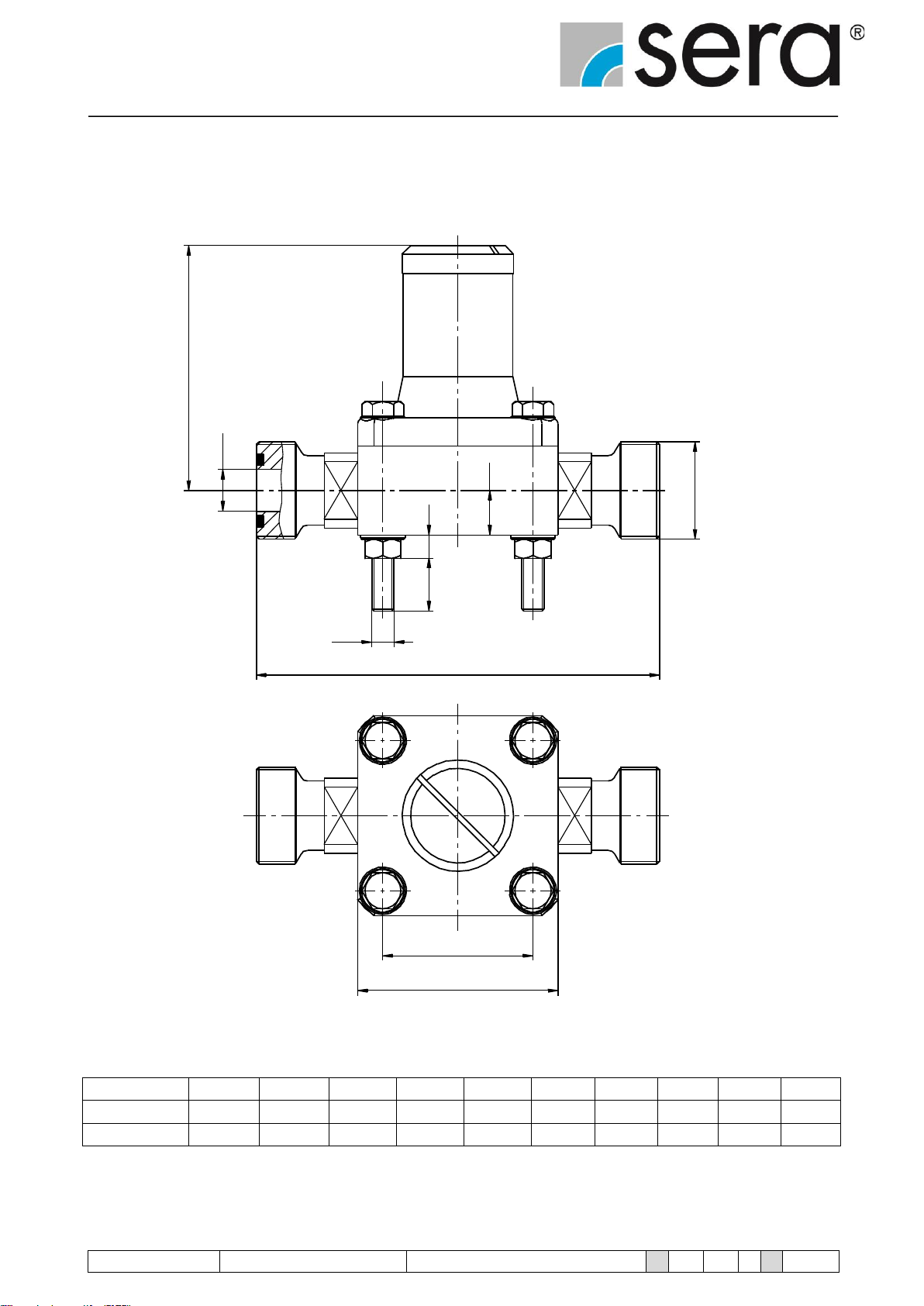

8.1 Dimensions of the diaphragm relief valve................7

8.1.1 PP-, PVC-, PVDF-, PP-GFK-, PVDF-GFK-design.........7

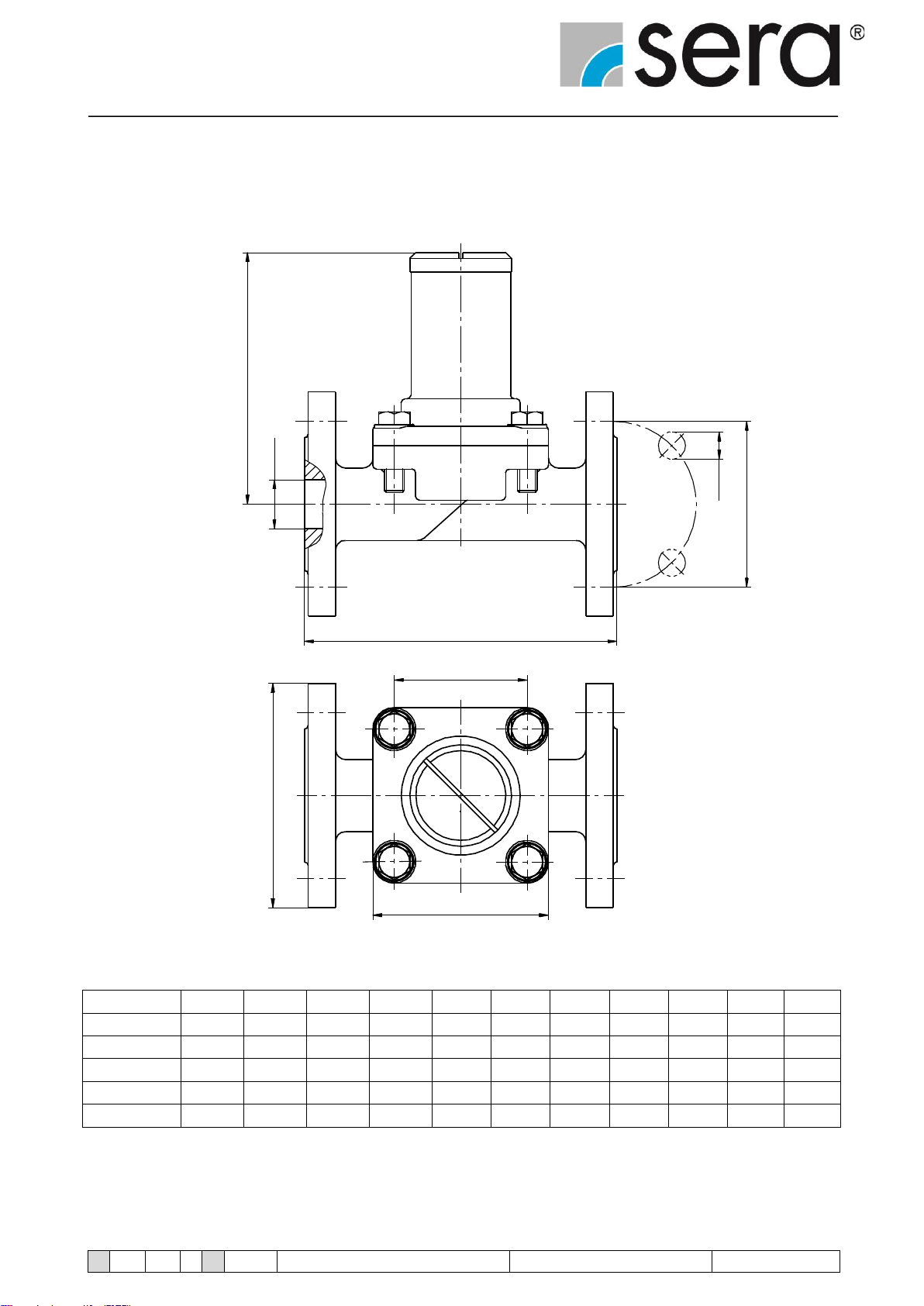

8.1.2 1.4581-design.................................................................8

8.1.3 GG-, GG-rubber-coated, 1.4581-design ........................9

8.2 Technical specifications........................................ 10

9Installation ............................................................10

9.1 Supply line............................................................ 11

9.2 Return line............................................................ 11

10 Start-up.................................................................11

11 Adjustment............................................................12

12 Operation in explosion-hazardous areas...............12

13 Spare- and wearing parts......................................12

13.1 Spare- and wearing parts kit .................................13

14 Changing the diaphragm.......................................15

14.1 General.................................................................15

14.2 Changing the diaphragm.......................................15

15 Shut-down.............................................................16

16 Disposal................................................................16

16.1 Dismantling and transport......................................16

16.2 Complete disposal.................................................16

17 Clearance Certificate.............................................17