SERAD IMD / 1 User manual

IMD-GI/EN

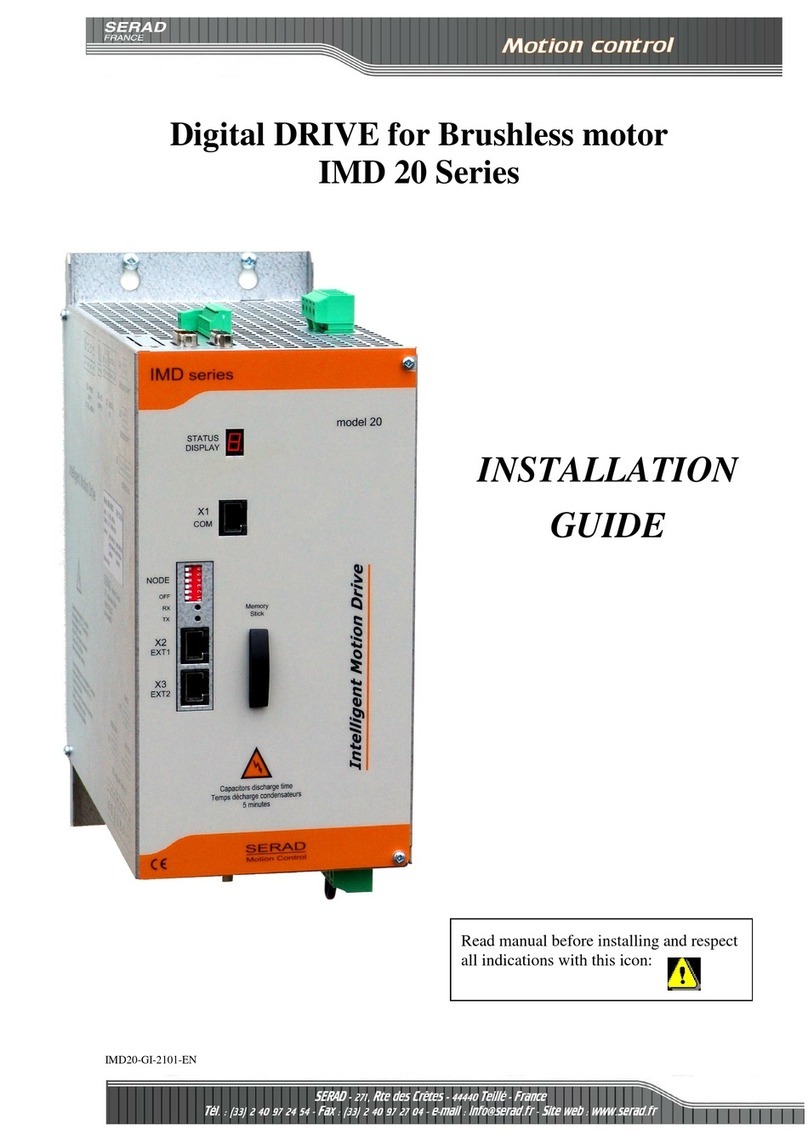

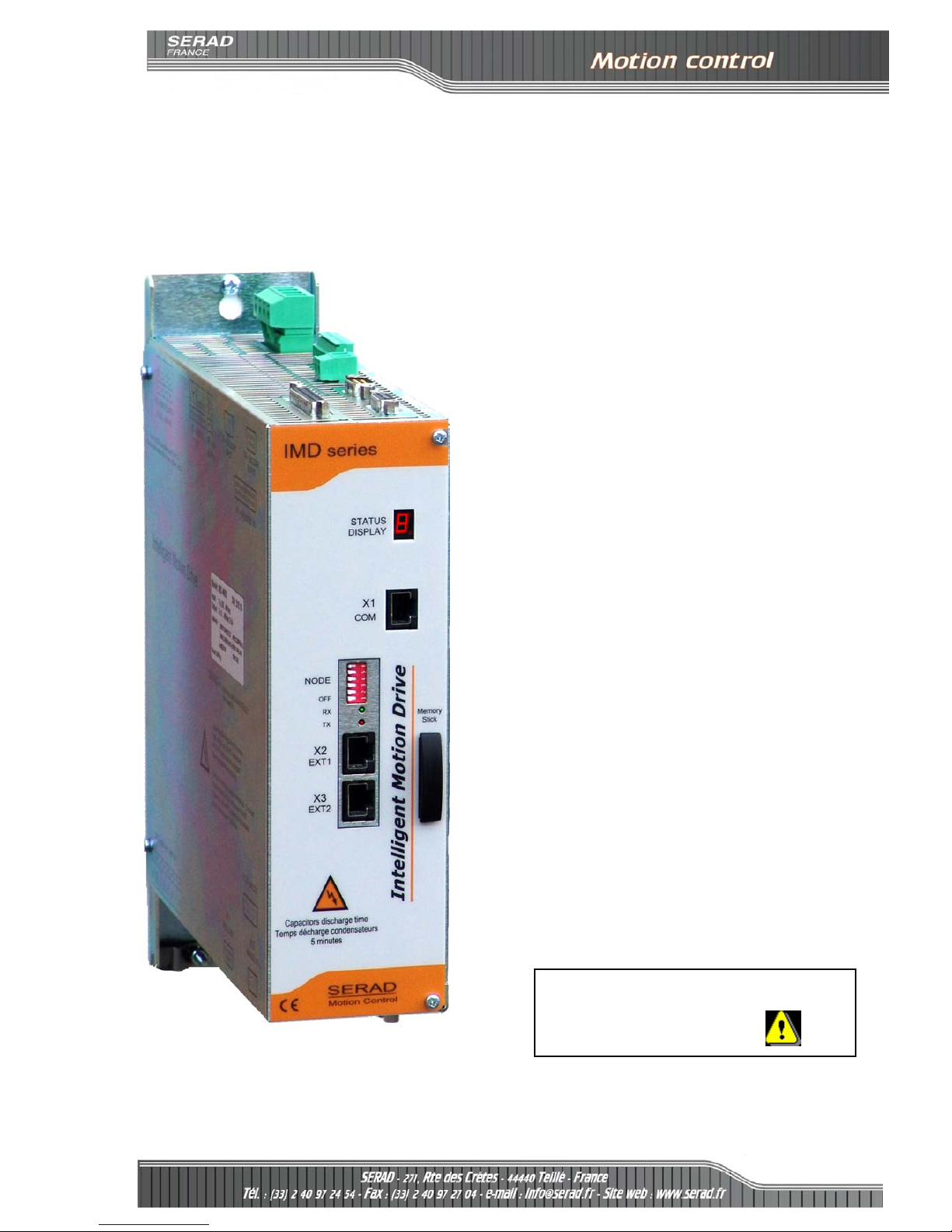

Digital DRIVE for Brushless motor

IMD Series

Read manual before installing and respect

all indications with this icon:

INSTALLATION

GUIDE

IMD Drive installation guide

R722 - 3 - SERAD S.A

Table of Contents

1- Introduction .................................................................................................. 4

1-1- Warning...................................................................................................... 4

1-2- MD series drive description....................................................................... 5

2- Installation .................................................................................................... 7

2-1- General....................................................................................................... 7

2-2- Front view .................................................................................................. 8

2-3- Top view ..................................................................................................... 9

2-4- Bottom view.............................................................................................. 10

2-5- Mounting .................................................................................................. 11

2-6- Connector pin assignments ...................................................................... 12

2-7- Cables....................................................................................................... 12

2-8- Connection diagrams / Protections ......................................................... 22

2-9- Stand-alone drive ..................................................................................... 22

2-10- Drive controlled by a motion controller ................................................ 24

2-11- Connecting a motor brake...................................................................... 25

2-12- System checks before starting ................................................................ 25

2-13- Error messages: ..................................................................................... 26

IMD Drive installation guide

R722 - 4 - SERAD S.A

1- Introduction

1-1- Warning

Read this manual before first installing, nonobservance may result in property

damages and in personal injuries.

Only suitable qualified personnel should undertake the mounting, installation,

operation and maintenance of the equipment must be complied with the general setup

and safety regulations for work on power installations (e.g. DIN, VDE, EN, IEC or

other national and international regulations).

It is important that all safety instructions are strictly followed. Personal injury can

result from a poor understanding of the safety requirements.

The following safety regulations should be followed:

•VDE 0100 Specification for the installation of power systems

up to 1000 V

•VDE 0113 Electrical equipment of machines

•VDE 0160 Equipment for power systems containing electronic

components.

-Never open the equipment.

-Dangerous high voltages exist within the equipment and on the connectors.

Because of this, before removing any of the connectors, it is necessary to remove

the power and wait at least 5 minutes to allow the capacitors to discharge.

-Never connect or disconnect the drive with power applied.

-Some of the drive’s surfaces can be very hot.

Some of the drive's components are susceptible to damage from electrostatic

discharges. Always handle the equipment using appropriate anti-static precautions.

We have gone to great lengths to ensure this documentation is correct and complete. However, since it

is not possible to produce an absolutely error-free text. No responsibility will be assumed by SERAD

for all damages caused by using this documentation and software.

We reserve the right to make changes to all or part of the specification without prior notice.

IMD Drive installation guide

R722 - 5 - SERAD S.A

1-2- MD series drive description

Supply : 230V to 400V AC ±10% three phase or 230V AC ±10% single phase

Auxiliary supply : 24 V DC ±10%, 0.4A typical (0,7A max if all options)

Supply filter : Integral

Switching frequency : 6.67 kHz sine-wave PWM

DC bus voltage : 310V to 680V

Integral : 75 ohms 60W

Possibility to add an external resistor :

Min value Max. cont. power Imp power

Braking resistance :

60Ω5KΩ10KΩ

Short circuit between phases, phase to earth, over current, I2t

Over voltage, under voltage

Protection :

Motor feedback fault

Resolver

Motor feedback : SinCos encoder Hiperface (option)

Incremental encoger

Absolute encoder SSI

SinCos encoder Hiperface (option)

Master encoder :

Virtual

Encoder emulation : Incremental : A, /A, B, /B, Z, /Z 1 to 100 000 points per rev

Diagnostic : STATUS display

RS 232 MODBUS RTU

IMDBUS : for master/slave application

CANopen (option): DS 402, SDO, PDO, master or slave

PROFIBUS DP* (option)

Communication :

SERCOS 16Mb* (option)

4 inputs (with 2 fast inputs I3 and I4)

12 additional inputs with expansion module (with 2 fast inputs I15 and I16)

Type: PNP, 24V DC, 8mA per input and 15 per fast input

Logic 0: Between 0 and 5 V

Digital inputs :

Logic 1: Between 8 and 30 V

2 outputs as standard

S1 : Relay, 48V dc / 48V ac, 3A max

S2 : NPN (open collector) 24V dc, 100mA

8 additional outputs with expansion module

Type : PNP 24V dc, 500mA max per output

Digital outputs :

Protected against short circuit and over temperature.

2 inputs :

Input voltage : ±10 V

Maximum voltage : ±12 V

Input impedance : 20 Kohms

Analogue inputs :

Resolution : 16 bits for input 1 and 12 bits for input 2

1 output :

Output voltage : ±10 V

Maximum current : 5 mA

Analogue output :

Resolution : 8 bits

IMD Drive installation guide

R722 - 6 - SERAD S.A

Processor :150 MHz DSP and 100 000 gates FPGA

FLASH memory for programs and parameters

RAM memory for data

FRAM memory for variables

Architecture :

Real-time, multi-tasking kernel

Current loop : 75 µs

Speed loop : 150 µs

Control loops :

Position loop : 150µs

Torque mode

Speed mode

Position mode

Stepper Mode (pulse input, direction)

Motion functions (absolute, relative and infinite movements, S profile)

Operating modes :

Advanced motion functions (gearbox, CAM profiles, CAMBOX functions, triggered movement)

Operating temperature : 0 to 40°C

Storage temperature : -10 to 70°C

Degree of protection : IP 20

Weight 3,6 Kg

Drive Rated current Peak current ( 2s ) Rated power Dimensions w x h x d

IMD / 1 1,25 Aeff 2,5 Aeff 0,7 kVA 72 x 293 x 233

IMD / 2 2,5 Aeff 5 Aeff 1,4 kVA 72 x 293 x 233

IMD / 5 5 Aeff 10 Aeff 2,8 kVA 72 x 293 x 233

IMD / 10 10 Aeff 20 Aeff 5,6 kVA 72 x 293 x 233

IMD Drive installation guide

R722 - 7 - SERAD S.A

2- Installation

2-1- General

It is very important to adhere to the following:

A badly earthed connection can damage electronic drive components.

The drive must be installed vertically in free air to ensure cooling by natural

convection.

It must be protected from excess humidity, liquids, and dirt.

The motor, resolver and encoder cables must be screened, the screen being earthed

at both ends of the cable.

The analogue I/O must use screened cable, the screen being earthed at one end

only.

The cable for the RS 232 serial link between the drive and the PC must be screened,

the screen being earthed at both ends of the cable. It should be disconnected from the

drive when no longer in use. All of these cables, as well as the I/O cables, should be

run separately from the power cables.

Diodes must be fitted across the loads on all static digital outputs (Q2 to Q10).

These diodes must be positioned as close to the load as possible. The supply and

signal cables must be free from over-voltage transients.

Safety standards specify a manual reset after a stop caused either by a supply

interruption, or by an emergency stop or by a drive fault.

For all serious faults, it is obligatory to remove the high voltage supply to the drive.

The Drive Ready output should be connected in series in the emergency stop loop.

In the case of axis over-travel, the over-travel limit switches must be connected to

the limit inputs or in series with the emergency stop loop. It is also recommended to

use the software limits.

If the drive is configured in speed loop, the drive enable input should be controlled

by the supervisory controller (CNC, PLC etc).

If the drive is configured in position loop, the parameter "Maximum following

error" should be set appropriately.

If the drive contains an application program developed using iDPL, connect a

signal ‘Cabinet supplies OK’ to one of the digital inputs and monitor it in a non-

blocking safety task. On detection of an excess following error the drive will be put in

open loop mode and the drive ready relay will be opened. If another action is required

you should use the SECURITY instruction.

IMD Drive installation guide

R722 - 8 - SERAD S.A

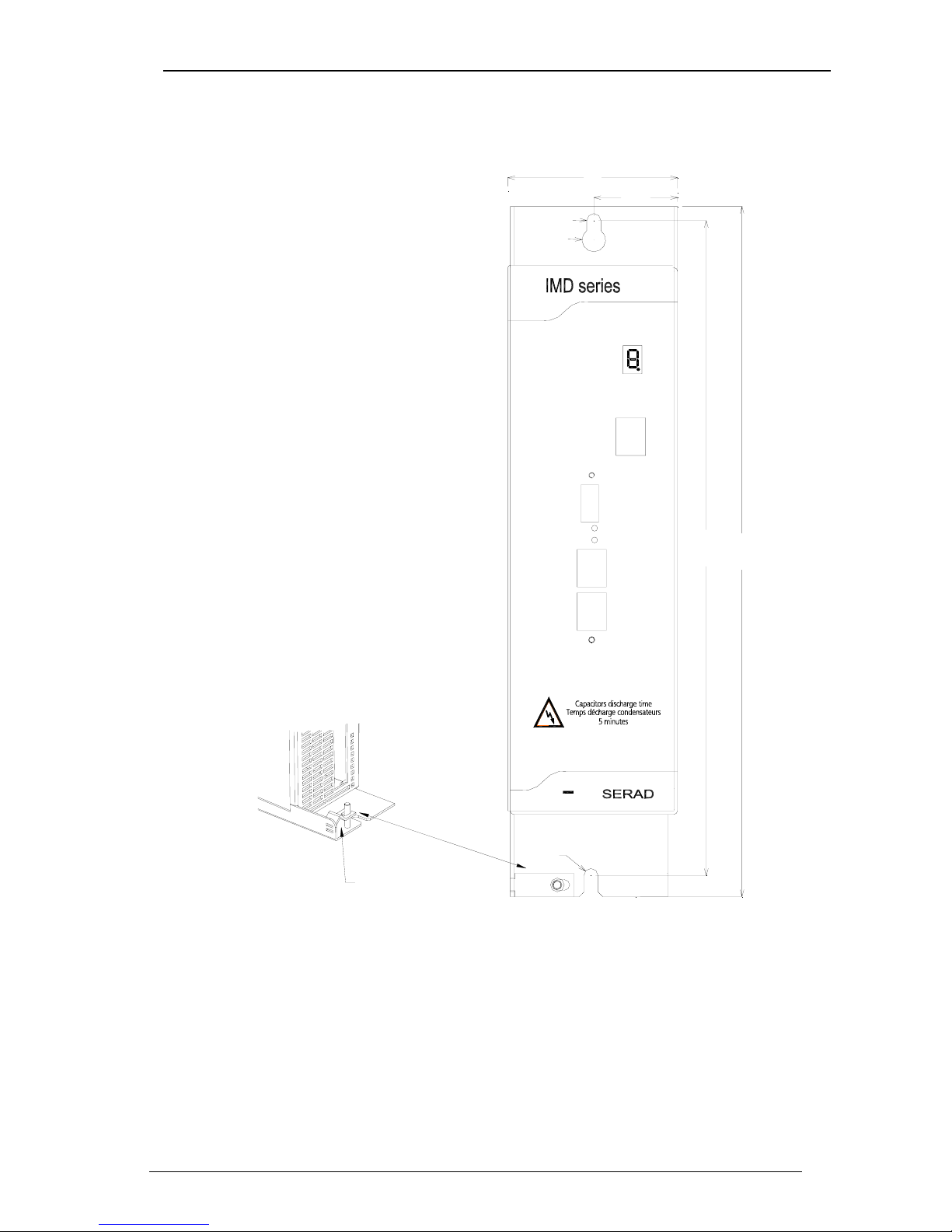

2-2- Front view

X1

COM

STATUS

X3

EXT2

X2

EXT1

NODE

CC

72

35.5

Ø6

Ø10

RX

TX

Ø6

278.5

Raccordement de la

tresse de blindage

du câble moteur

293.5

STATUS 7-segment diagnostic display

X1 COM RS-232 serial port for communication with a PC

X2 EXT1 Extension: Optional communications ports

X3 EXT2 Extension: Optional communications ports

IMD Drive installation guide

R722 - 9 - SERAD S.A

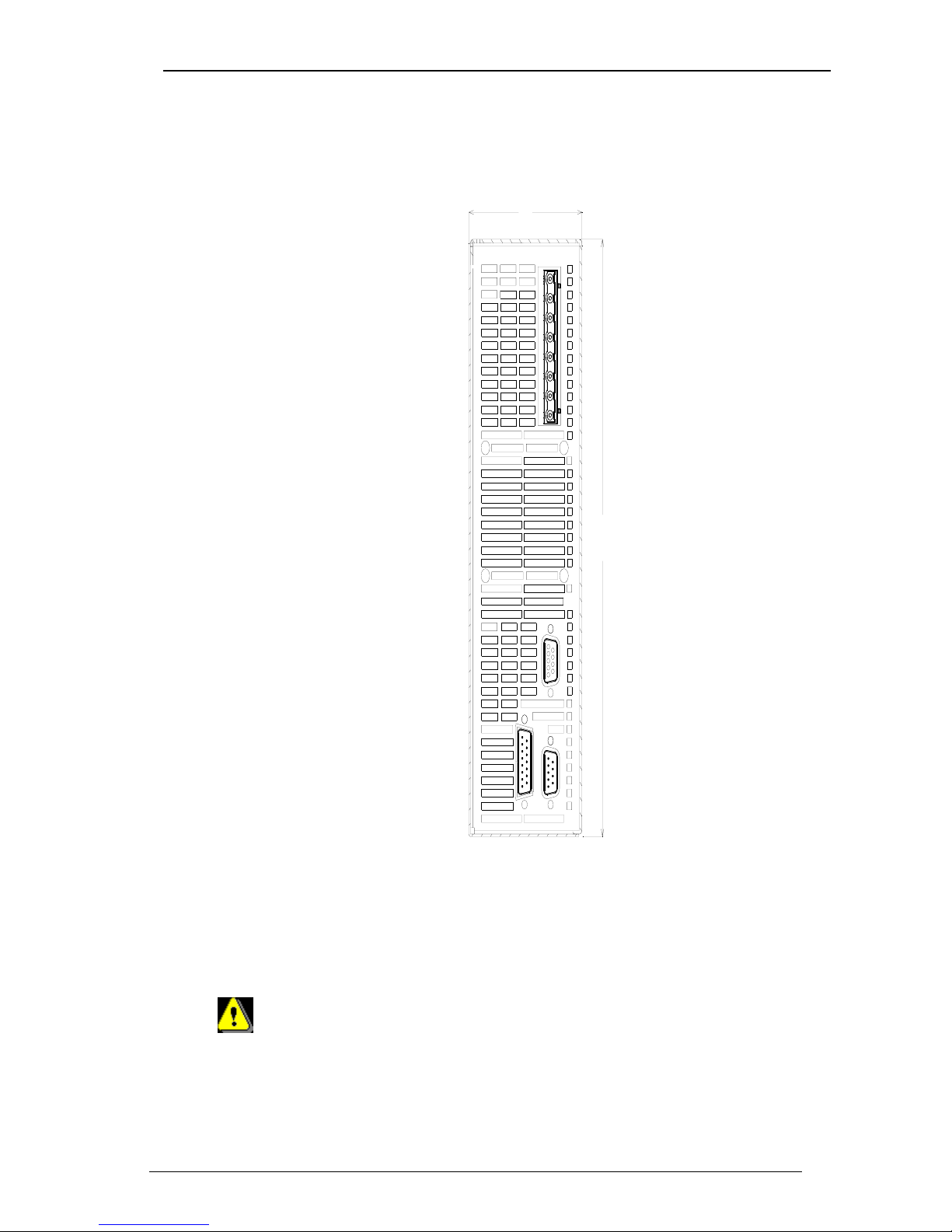

2-3- Top view

72

233.5

X8-POWER

SUPPLY

3X230.....480VAC

X7-DIGITAL

I/O

X6-

AUX.

SUPPLY

24VCC

X9-

EXTENDEDI/O

X5-

ENCODER

INPUT

X4-

ENCODER

OUTPUT

1

2

3

4

1

2

3

4

5

6

7

8

1

2+

X4 ENCODER OUTPUT Multifunction encoder output

X5 ENCODER INPUT Multifunction encoder input

X6 24Vdc Auxiliary 24V DC supply

X7 I/O Digital I/O

X8 POWER SUPPLY Single / Three-phase power supply

X9 EXT I/O Option: I/O expansion board

The voltage on connector X8 can reach 480V!

IMD Drive installation guide

R722 - 10 - SERAD S.A

2-4- Bottom view

72

233.5

X12

ANALOGI/OX11

RESOLVER

X13-SINCOS

X10-BALLAST/MOTOR

1

2

3

4

5

6

7

8

X10 RB / MOTOR External braking resistor and motor supply

X11 FEEDBACK Motor position feedback (resolver / encoder)

X12 ANALOG Analogues I/O

X 13 SINCOS Motor position feedbacks (if SINCOS encoder is used)

Care must be taken when making connection to connector X10. An incorrect

connection can seriously damage the drive. Dangerous voltages are present on

X10 (900V).

Wait at least 5 minutes to allow the capacitors to discharge before remove

connector.

IMD Drive installation guide

R722 - 11 - SERAD S.A

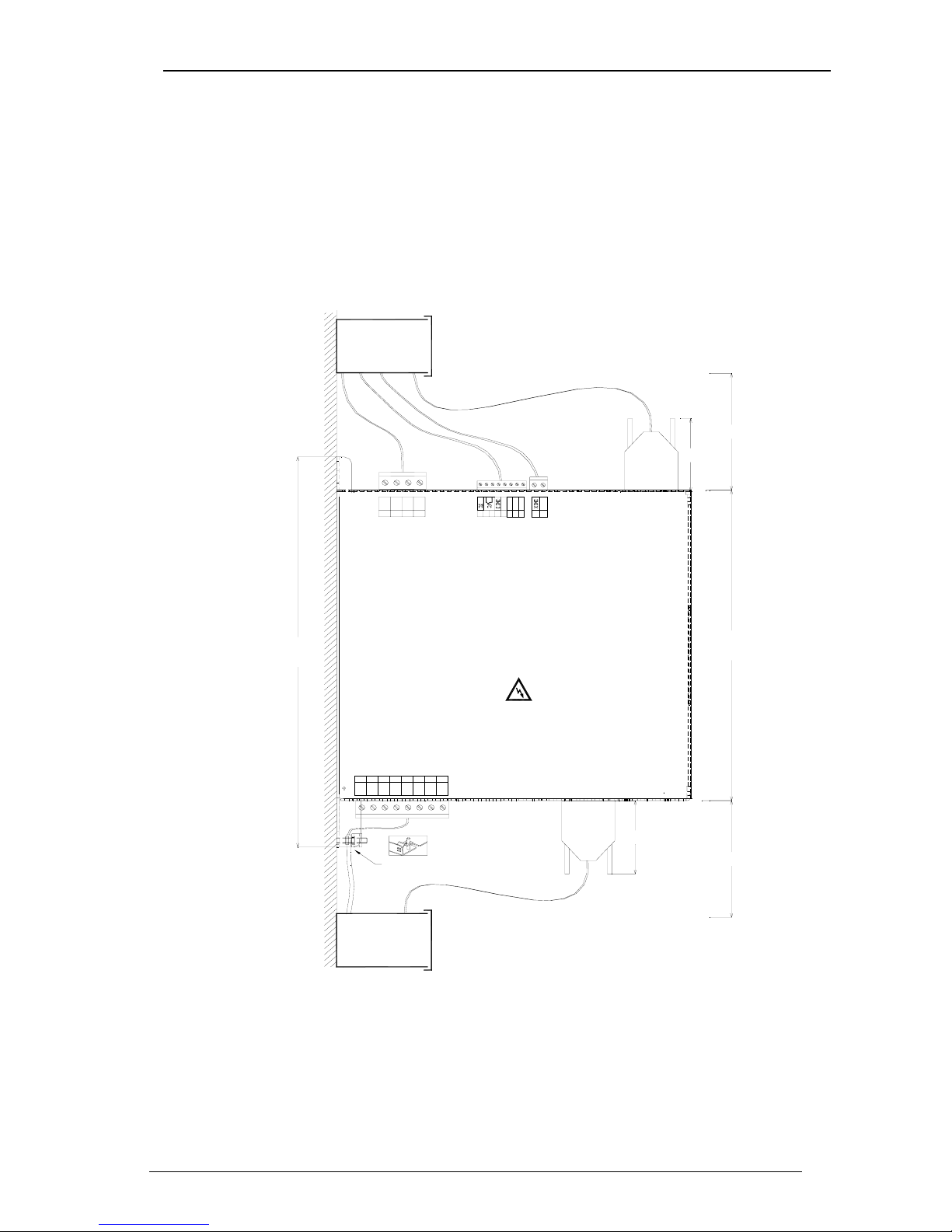

2-5- Mounting

Several drives can be mounted side-by-side provided that enough space (at least 20

mm) is left to ensure good natural convection. Let a space greater than 90 cm over and

under drives to allow for the various connectors and cables to be fitted

55

55

233.5

X10 - BALLAST / MOTOR

X11

RESOLVER

X12

ANALOG I/O

Capacitors discharge time : 5 minutes

High voltage on X8-X10 connectors

All the PE pins must be connected

Read manual before installing

Temps de décharge des condensateurs : 5 minutes

Haute tension sur les connecteurs X8-X10

Toutes les bornes PE doivent être raccordées

Lire le manuel avant l'utilisation

SERAD 271, route des crêtes 44440 T EILLE

www.serad.fr

Intelligent Motion Drive

I4

5

X7 - DIGITAL

I/O

X8- POWER

SUPPLY

3 X 230.....480V AC

For 1 x 230Vac connection, use L1 and L2

Pour une alimentation 230Vac m ono, utiliser L1 et L2

L3

4

2

1

3

L1

PE

L2

1

3

2

4

X5 - ENCODER

INPUT

X6 - AUX.

SUPPLY

7

6

8

1

2

I2

I3

I1

24V

X4 - ENCODER

OUTPUT

6

W

RB2

RI1

DC-4

DC+3

PE5

U8

V7

RACCORDEMENT

BLINDAGE MOTEUR

90

90

293.5

IMD Drive installation guide

R722 - 12 - SERAD S.A

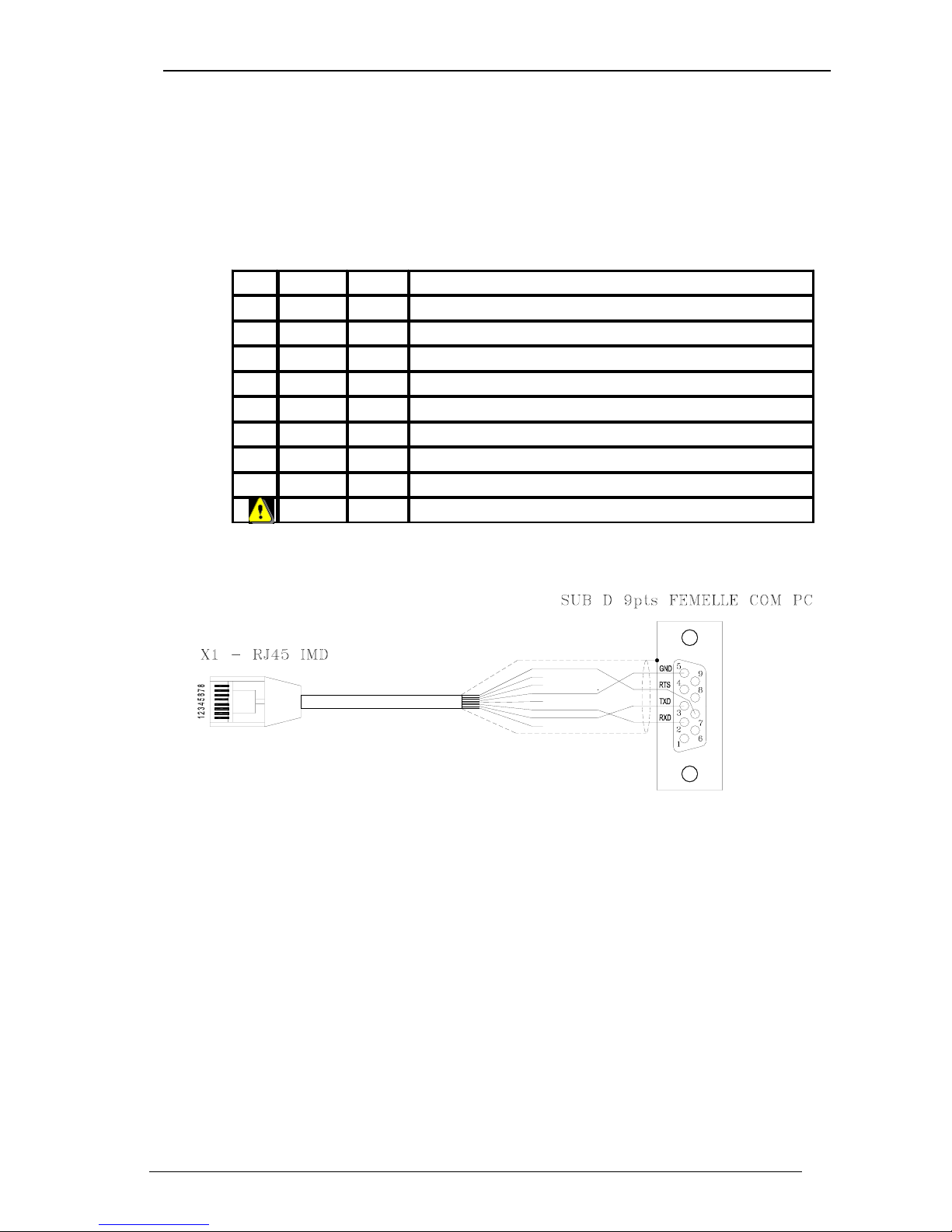

2-6- Connector pin assignments

X1: RJ45 serial port for downloading programs and parameters.

N° Name Type Description

1

2 RXD Inp Receive data

3 TXD Out Transmit data

4

5GND 0V

6

7

8 CTS Inp Cle ar to s en d

SHIELD Connect the shield to the shell of the connector

3-TXD

2-RXD

5-GND

7

8-CTS

6

4

1

IMD Drive installation guide

R722 - 13 - SERAD S.A

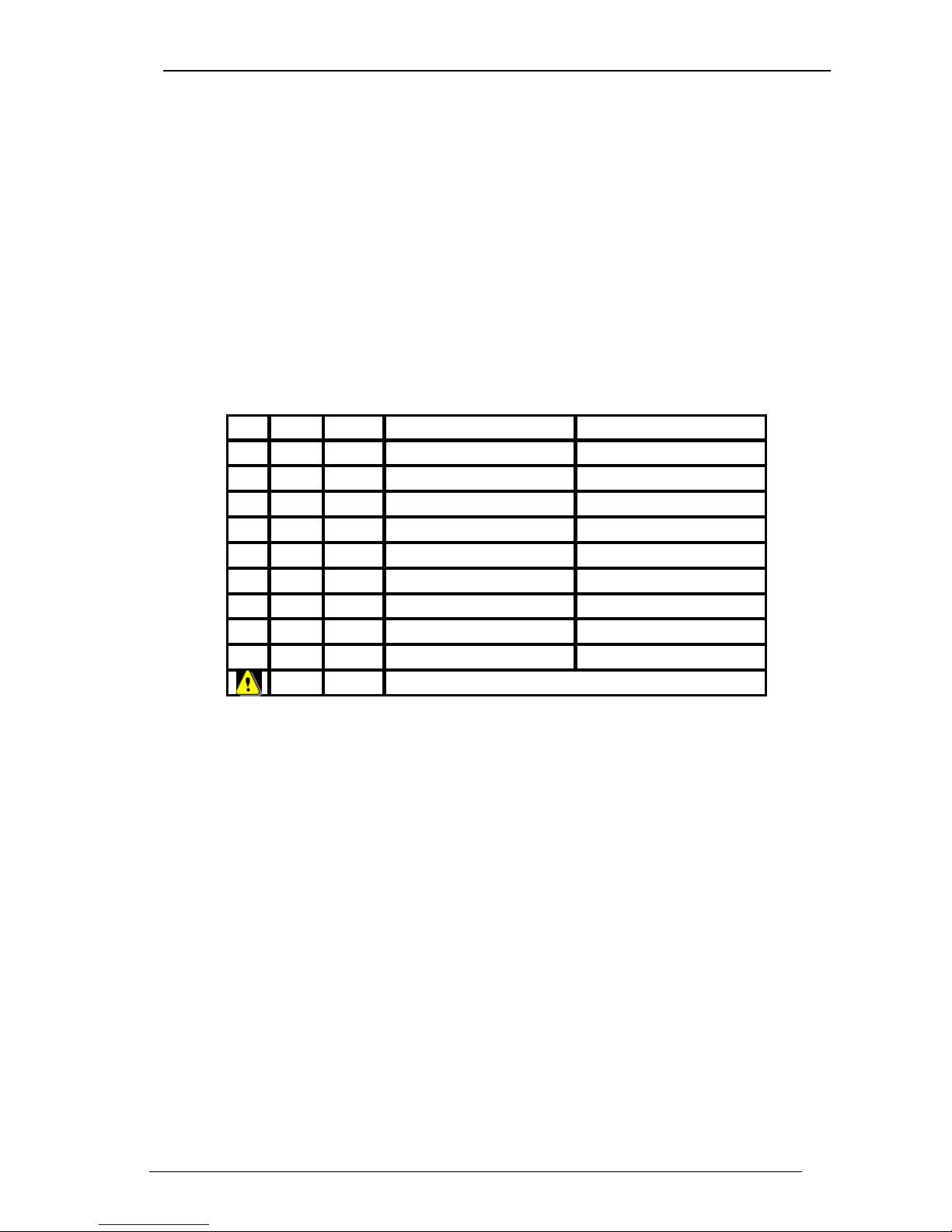

X2 & X3: Extension: Optional communications port

N° Module RS 232 Module RS 422 Module RS 485 Module CANopen

1

2RXD RX+

3TXD RX-

4

5GND GND GND GND

6

7 TX- TR X- C AN _ L

8 TX+ TR X+ C AN _ H

Connect the shield to the shell of the connector

•X2 and X3 are identical and have the same connection. They make easier drive

network connection.

•Node Address : For RS422, RS485 and CANopen, the NodeID corresponds to the

five firstly dipswitchs + 1

Ex: dipswitchs: 1 -> ON, 2 -> OFF, 3 -> ON, 4 -> OFF, 5 -> OFF

Dipswitchs value = 1 + 4 = 5

NodeID = 5 + 1 = 6

•Put on Dipswitch 6 to activate terminal resistor (120Ω).

RS232 communication allows communication with only 1 device (ex: 1 PLC

and 1 IMD drive).

IMD Drive installation guide

R722 - 14 - SERAD S.A

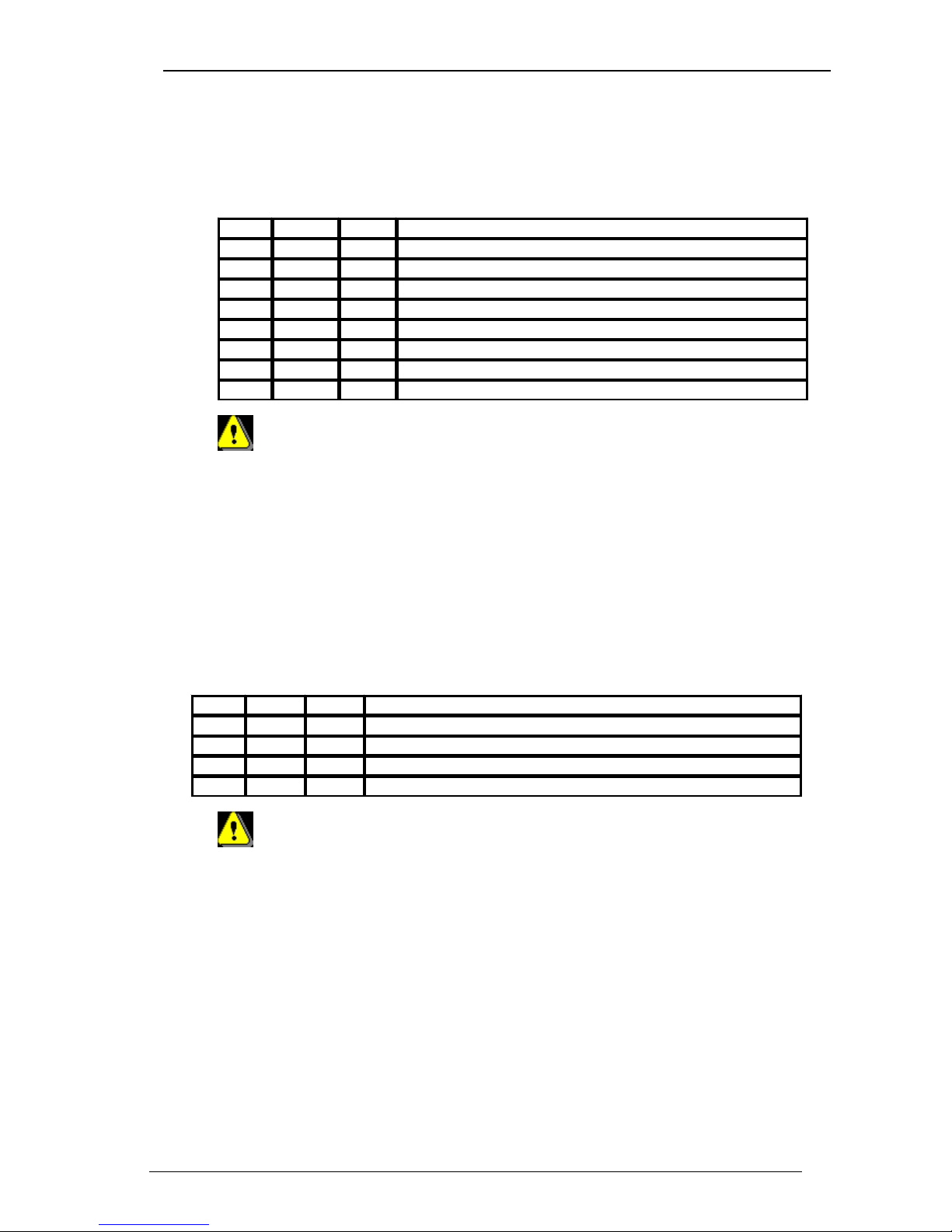

X4: Multifunction encoder output:

•Encoder emulation output

•IMDbus output

The choice of the output is made in iDPL software in the Multifunction encoder output

windows

Connector : SUBD 9 way female

N° Name Type Encoder emulation IMDbus

1AOut Channel A Data

2/A Out Channel A inverted /Data

3B Out Channel B Clock

4/B Out Channel B inverted /Clock

5Z Out Zero marker NC

6/Z Out Zero marker inverted NC

7

8GND 0V 0V

9

SHIELD Connect the shield to the shell of the connector

NC (Not connected): It is forbidden to connect this pins.

IMD Drive installation guide

R722 - 15 - SERAD S.A

X5: Multifunction encoder input:

•Incremental encoder input

•SSI encoder input

•Stepper input

•IMDbus input

The choice of the input is made in iDPL software in the Multifunction encoder input

windows

TTL 5V encoder (0-5V, differential)

Connector : SUBD 9 way male

* If the feedback is SINCOS then don’t use 5V powersupply (pin 7 of connector X5)

but an external powersupply.

NC (Not connected): It is forbidden to connect this pins.

X6: 24V dc supply

Connector: Removable 2 ways, 5.08mm pitch

N° Name Type Description

1XGND 0V

2 24Vdc Inp Control card supply, backup motor position

N° Name Type Incremental encoder Codeur SSI Stepper IMDbus

1A Inp Channel A Data Direction Data

2/A Inp Channel A inverted /Data /Direction /Data

3B Inp Channel B NC Pulse Clock

4/B Inp Channel B inverted NC /Pulse /Clock

5Z I/O Zero marker Clock NC NC

6/Z I/O Zero marker inverted /Clock NC NC

7 +5Vdc Out Supply for external

encoder, 100 mA max.* NC NC NC

8GND 0V 0V 0V 0V

9Inp NC

SSI selection : Connect

pins 8 and 9 NC NC

SHIELD Connect the shield to the shell of the connector

IMD Drive installation guide

R722 - 16 - SERAD S.A

X7: Digital I/O

Connector: Removable 8 ways, 3.81mm pitch

N° Name Type Description

1Q2Out

Output 2, programmable : type NPN, 24 Vdc, 100mA

2Q1Out

Output 1, programmable : standard function DRIVE READY

3Q1 Relay contact, N/O between terminals 2 and 3

4DGND 0V digital I/O

5I4Inp

Input 4, programmable

6I3Inp

Input 3, programmable

7I2Inp

Input 2, programmable

8I1Inp

Input 1, programmable:standard function ENABLE

The output Q2 is NPN open collector: the load must be connected between

Q2 and +24V DC.

X8: High voltage supply

Connector: Removable 4 ways, 7.62mm pitch

N° Nam e Type Description

1 PE Supply earth

2 L1 Inp Supply L1 for 230V and 400V

3 L2 Inp Neutral for 230V or supply L2 for 400V

4 L3 Inp Supply L3 for 400V

Care must be taken when making connection to connector X8.

Wait at least 5 minutes to allow the capacitors to discharge before remove connector.

The armoured motor cable must arrive directly on the terminals of the drive.

Connect the shield (on drive side) to the srew provided (see Front view of the drive).

IMD Drive installation guide

R722 - 17 - SERAD S.A

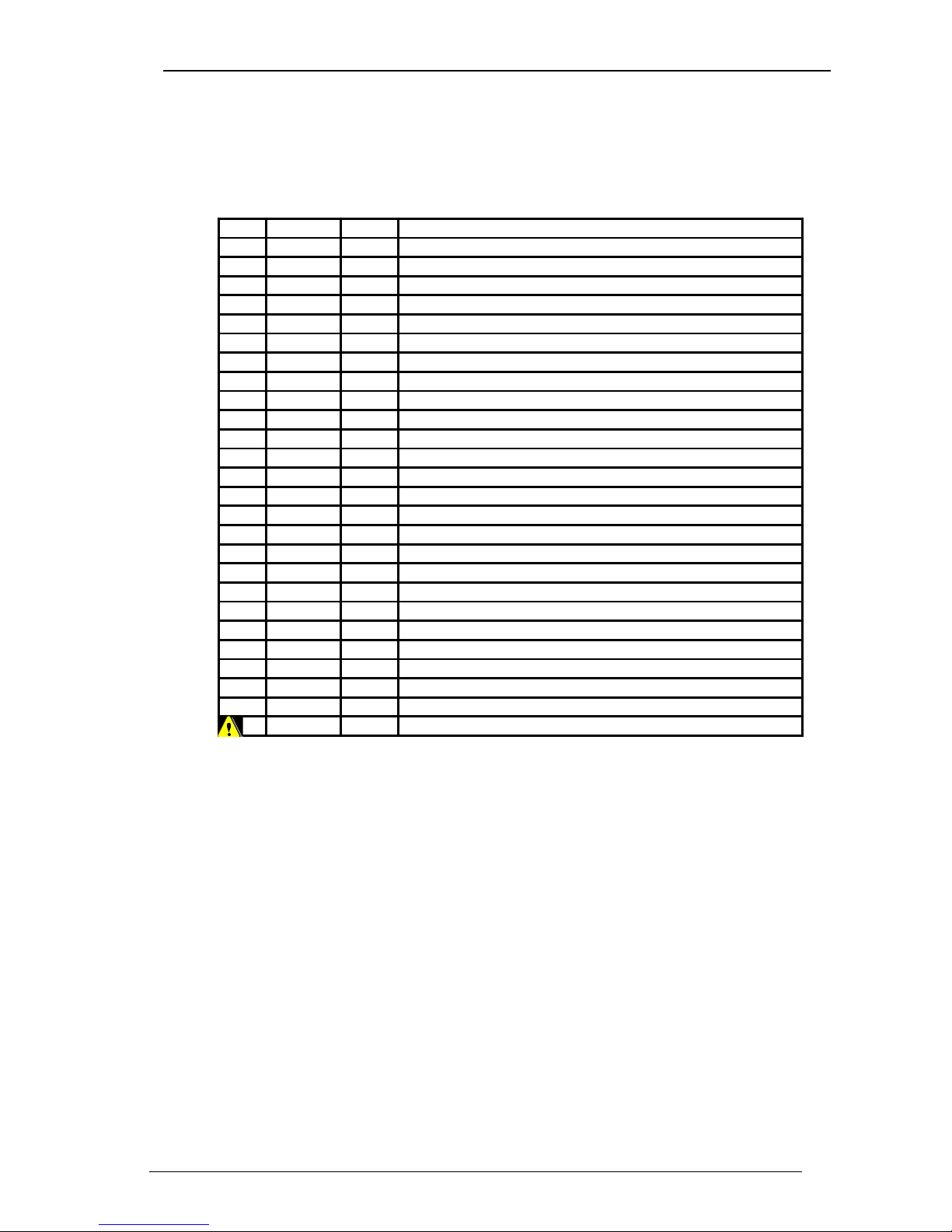

X9: Option: Expansion module, 12 inputs / 8 outputs

Connector: SUBD 25 way female

N° Nam e Type Description

1I5Inp

Input 5, programmable

2I6Inp

Input 6, programmable

3I7Inp

Input 7, programmable

4I8Inp

Input 8, programmable

5I9Inp

Input 9, programmable

6I10Inp

Input 10, programmable

7 IOGND* 0V digital I/O

8Q3Out

Output 3, programmable

9Q4Out

Output 4, programmable

10 Q5 Out Output 5, programmable

11 Q6 Out Output 6, programmable

12 IO 24Vdc** Inp External supply, 24 V dc

13 IO 24Vdc** Inp External supply, 24 V dc

14 I11 Inp Input 11, programmable

15 I12 Inp Input 12, programmable

16 I13 Inp Input 13, programmable

17 I14 Inp Input 14, programmable

18 I15 Inp Input 15, programmable

19 I16 Inp Input 16, programmable

20 Q7 Out Output 7, programmable

21 Q8 Out Output 8, programmable

22 Q9 Out Output 9, programmable

23 Q10 Out Output 10, programmable

24 IOGND* 0V digital I/O

25 IOGND* 0V digital I/O

SHIELD Connect the shield to the shell of the connector

* Pins 7, 24, 25: internal connection

** Pins 12, 13: internal connection

IMD Drive installation guide

R722 - 18 - SERAD S.A

X10: Motor armature

Connector: Removable 8 ways, 7.62mm pitch

N° Name Type Description

1RI Internal braking resistor *

2RB Braking resistor *

3 DC Bus + Out DC bus +

4 DC Bus - Out DC bus -

5PE Motor earth

6WOut

Motor phase W

7VOut

Motor phase V

8UOut

Motor phase U

The armoured motor cable must arrive directly on the terminals of the drive.

Connect the shield (on drive side) to the srew provided (see Front view of the drive).

*Selection of the braking resistor:

- Internal resistor: Fit a link between terminals 1 and 2

- External resistor: Remove the link between terminals 1 and 2

Connect the external resistor between terminals 2 and 3

Care must be taken when making connection to connector X10. An

incorrect connection can seriously damage the drive. Dangerous voltages are

present on X10.

SERAD MOTOR

C

A

1

4

B

D

3

Shield reverse

around the ring

1

4

3

2

C

Phase U

D

Phase V

Phase W

Earth

Break +

Break -

DESCRIPTION

IMD Drive installation guide

R722 - 19 - SERAD S.A

X11: Motor position feedback (resolver)

Connector: SUBD 9 way female

N° Name Type Description

1S2Inp

Sine Hi

2S1Inp

Cosine Hi

3AGND 0V analogue

4R1Out

Reference Hi

5°CM+Inp

Motor temperature sensor Hi

6S4Inp

Sine Lo

7S3Inp

Cosine Lo

8°CM-Inp

Motor temperature sensor Lo

9R2Out

Reference Lo

SHIELD Connect the shield to the shell of the connector

1

5

6

9

Resolver connector

SUB-D 9 way male

Metallic casing

Cable clamp

RESOLVER

SHIELD WIRE

2 TEMP -

SHIELD

5 REF +

6 TEMP +

9 REF -

4 SIN +

8 SIN -

7 COS -

3 COS +

CONNECTOR

Shield reverss

around the ring

connector M23

Resolver

4 twisted pairs (2 x 0.22mm)

Standard shield

DRIVE

SERAD

MOTOR

Shield clamp

IMD Drive installation guide

R722 - 20 - SERAD S.A

X12: Analogue I/O

Connector : SUBD 9 way male

N° Nam e Type Description

1IN2- Inp

Analogue input 2

2IN2+ Inp

Analogue input 2 : assigned to torque limit

3IN1- Inp

Analogue input 1

4IN1+ Inp

Analogue input 1 : assigned to speed or torque command

5AGND 0V analogue

6 -12V Out -12V, 20 mA output

7AGND 0V analogue

8+12VOut

+12V, 20 mA output

9OUTOut

Analogue output (function monitor)

SHIELD Connect the shield to the shell of the connector

X13: Option: SinCos encoder input

Connector: SUBD 15 way male

N° Name Type Description

1 °CM + Inp Motor temperature sensor Hi

2 AGND 0V analogue

3 /DATA I/O /DATA (EnDat*) /RS485 (HIPERFACE)

4 /CLK Out /CLOCK (EndDat*)

5 +5V Out +5V, 200 mA output (EnDat*)

6

7 REFCOS Inp Cosine Hi

8 REFSIN Inp Sine Hi

9 °CM- Inp Motor temperature sensor Lo

10 +8,3V Out +8.3V, 150 mA output(HIPERFACE)

11 DATA I/O DATA (EnDat*) RS485 (HIPERFACE)

12 CLK Out CLOCK (EndDat*)

13

14 COS Inp Cosine Lo

15 SIN Inp Sine Lo

SHIELD Connect the shield to the shell of the connector

* EnDat in develloping

This manual suits for next models

3

Table of contents

Other SERAD DC Drive manuals

Popular DC Drive manuals by other brands

Vicon

Vicon 239-03-00 Series Installation & configuration guide

Sanhua

Sanhua SD2 Series user manual

krispol

krispol STARCUS F35 installation manual

IMMOOS

IMMOOS SS1 Twin mGB Supplement to operating instructions

Danfoss

Danfoss VLT AutomationDrive FC 361 operating guide

New Japan Radio

New Japan Radio NJU6062 quick start guide