Sercel VE432 DPG Installation and operating manual

VE432 DPG

Installation

& Reference

MANUAL

Documentation No. 0311385 Issue : April 1999

Software version 3.0

In no event shall SERCEL be liable for incidental or consequential

damages or related expenses resulting from the use of this product, or

arising out of or related to this manual or the information contained in it,

even if SERCEL has been advised, or knew or should have known of the

possibility of such damages.

The information in this manual is believed to be accurate and reliable.

However, SERCEL reserves the right to make changes to its products or

specifications at any time, without notice, in order to improve design or

performance and to supply the best possible product.

0311385 Issue : April 1999

i

Table Of Contents

INTRODUCTION--------------------------------------------------------------------------------------------------1-1

GENERAL DESCRIPTION------------------------------------------------------------------------------------1-1

SPECIFICATIONS-----------------------------------------------------------------------------------------------1-5

UNPACKING-------------------------------------------------------------------------------------------------------1-6

CONNECTING A DPG------------------------------------------------------------------------------------------2-1

DPG MOUNTING DIMENSIONS-----------------------------------------------------------------------------2-1

DPG STANDARD CONNECTIONS-------------------------------------------------------------------------2-2

1 APM, 1 DPG CONFIGURATION-------------------------------------------------------------------------------2-4

2 OR 3 APMS, 1 DPG CONFIGURATION----------------------------------------------------------------------2-5

CONFIGURATIONS WITH UP TO 8 APMS AND UP TO 4 DPGS--------------------------------------------2-6

CONNECTING A HUSKY TERMINAL TO A DPG--------------------------------------------------------------2-9

DPG MASTER/SLAVE CONFIGURATION---------------------------------------------------------------------2-10

OUTPUT SIGNAL SPECIFICATIONS--------------------------------------------------------------------2-14

RECORDER CABLE--------------------------------------------------------------------------------------------2-16

ANALOG PILOT CABLE---------------------------------------------------------------------------------------2-17

RADIO CABLE----------------------------------------------------------------------------------------------------2-18

DPG CONNECTORS------------------------------------------------------------------------------------------2-19

SOFTWARE INSTALLATION --------------------------------------------------------------------------------3-1

SOLARIS INSTALLATION OR RE-INSTALLATION ----------------------------------------------3-1

YEAR 2000 PATCH---------------------------------------------------------------------------------------------3-7

VE432 STANDALONE INSTALLATION-------------------------------------------------------------------3-8

VE432 SOFTWARE INSTALLATION FOR USE WITH SN388-------------------------------------3-8

GETTING STARTED--------------------------------------------------------------------------------------------3-9

CUSTOM SWEEPS----------------------------------------------------------------------------------------------4-1

ABOUT CUSTOM SWEEPS----------------------------------------------------------------------------------------4-1

LOADING A CUSTOM SWEEP FILE TO A DPG-----------------------------------------------------------------4-2

0311385 Issue : April 1999

ii

USING VE432 WITH A RECORDING SYSTEM OTHER THAN SERCEL-----------------------5-1

CONNECTION DIAGRAM-------------------------------------------------------------------------------------------5-1

DISTINCTIONS TO BE MADE --------------------------------------------------------------------------------------5-2

TOOLSVEHCI SOFTWARE LOADING UTILITY--------------------------------------------------------6-1

LOADING SOFTWARE TO A DPG OR DSD--------------------------------------------------------------------6-1

GROUND VISCOSITY AND STIFFNESS -----------------------------------------------------------------7-1

CONVERSION TO NORMALIZED UNITS ----------------------------------------------------------------7-1

VE432 STATUS --------------------------------------------------------------------------------------------------8-1

DPG ------------------------------------------------------------------------------------------------------------------8-1

DSD ------------------------------------------------------------------------------------------------------------------8-1

INTRODUCTION

GENERAL DESCRIPTION

0311385 Issue : April 1999

1-1

INTRODUCTION

GENERAL DESCRIPTION

General

The VE 432 is a new generation of Vibrator Digital Control System, using a fully auto-

adaptive servomechanism. It enables the use of all advanced Vibroseis techniques

such as :

- pseudo-random sweeps

- multiple simultaneous sources in flip-flop or slip-modes

- coded sweeps

- cascaded (*) sweeps

The VE 432 is fully compatible with most satellite DGPS and Glonass receivers, for

integrated tracking of source positions.

DPG DSD

(*) (Exxon Patent)

INTRODUCTION

GENERAL DESCRIPTION

0311385 Issue : April 1999

1-2

Digital Pilot Generator (DPG)

The DPG is connected to the data acquisition system through an Ethernet link and

acts as a master control unit for the VE 432 system.

The DPG can be :

-fully integrated with the SN 388 acquisition system,

-or connected to any other type of acquisition system, using its own graphic

user interface.

-or used as Slave unit to control acquisition start on a remote (slave)

acquisition system.

Digital Servo Drive (DSD)

Installed in each vibrator, the DSD performs real time control of the vibrator ground

force, computes and transmits a complete attribute set for a QC data base.

Maintenance modes are available that make it possible to easily check the

performance of the vibrator hardware and the GPS system.

VE432 Main features

•• Signal generation

Up to 4 different simultaneous pilot signals are generated by the DPG.

A pilot or a sweep signal is generated from an operator-defined library of 32 basic

signals combined with up/down, phase shift parameters.

Basic signals are defined by their frequency range, frequency vs. time law, time

duration, tapers and amplitude vs. time law.

A single DPG can handle up to 4 vibrator fleets with a total of 28 vibrators.

•• Digital vibrator control

By an automatic identification procedure, the VE432 digital model is adapted to any

type of vibrator without the need for manual adjustment.

The fully digital auto-adaptive servomechanism performs an optimal control which

minimizes the phase and distortion and maximizes the fundamental output.

Optimal digital control allows :

-fast sweep rate,

-combination of sweep segments with no dead time, used in cascaded (*)

-pseudo-random sweeps, for environmentally friendly vibration,

unlimited variety of user-defined sweeps (custom sweep type).

Exxon Patent

INTRODUCTION

GENERAL DESCRIPTION

0311385 Issue : April 1999

1-3

•• Enhanced real-time Quality Control

The DSD integrates a complete set of functions for automatic sensor tests. The check

for coherence between all the measurements contributes to quality assurance,

ensuring that the vibrator generates the proper sweep, without any risk of polarity

inversion.

A complete QC data base is generated for real-time or post-processing analysis

including :

- phase

- distortion

- fundamental ground force

In addition, the digital control identifies the ground viscosity and stiffness, which

regularly provides information on the ground absorption model and can be used to

enhance seismic data.

Real-time phase, distortion, fundamental ground force values versus time or

frequency, for each vibrator and each sweep, are available on request.

•• Bar-graph QC display

All the QC information is displayed within color bar-graphs with automatic threshold

detection. For each vibrator, current values and average values over the last 50

vibrations are shown.

•• Complete graphic display

In addition to the QC data base information, the VE 432 has the capability to

graphically display in real time, the Phase, Distortion and Force results vs. Time or

Frequency, for each vibrator.

•• QC Statistics

On request, statistics on QC data base can be performed, for daily or longer time

period analysis, to detect any drift in vibrator performance or to be used as a

preventive maintenance tool.

•• Slip-Sweep* capability

With a recording system from SERCEL, there is no need to wait until a sweep is

complete to start the next one. (* The Slip-sweep technique, developed by PDO,

allows substantial production increase to be achieved).

INTRODUCTION

GENERAL DESCRIPTION

0311385 Issue : April 1999

1-4

•• Recording system’s automatic start of acquisition

With a recording system from SERCEL, acquisition by the recording system can be

automatically started as soon as the vibrators are ready, using the DSD Ready signal

via radio.

DSD Network:

This feature allows the SN388 system to automatically start acquisition as

soon as all vibrators in a fleet are ready (with their pads down). There are no

delays to be adjusted any more. Everything is automatically started at

maximum speed.

Fleet navigation:

With the fleet navigation option, associated with the DSD Network option, the

geographical location of the fleet is relayed to the SN388 system, which

selects the corresponding VP (shot point) from its operation table and shoots

it automatically. VPs can be shot in any order by any fleet.

The navigation option is also supported in slip-sweep mode, allowing

acquisition to start as soon as any fleet is ready at any VP.

Fleet location feedback in Positioning window

When the shot sequence is controlled by the geographical location of the

fleet on the acquisition system, the fleet location is displayed in the

Positioning window before acquisition is launched. (With no DSD network,

the fleet location displayed is the location of the "leader" vibrator).

INTRODUCTION

SPECIFICATIONS

0311385 Issue : April 1999

1-5

SPECIFICATIONS

Signal length :up to 64 s in 1-s steps.

Frequency vs. time law :linear, logarithmic, pseudo-random, Tn, Pulse, user-

defined.

Frequency range :1 to 250 Hz in 1-Hz steps.

Amplitude vs time law :linear interpolation.

Tapers :up to 1/2 signal length, Blackman Law.

Max. Number of Vibrators :28.

“T0accuracy” :±20 µs typical.

Clock accuracy :1 ppm within temperature range and per year.

QC data base format Positioning data SPS file.

QC attributes APS file.

PHYSICAL (including mounting parts)

Size (W × D × H) Weight

DPG 255 × 389 × 411 mm 10 kg

DSD 278 × 443 × 421.5 mm 18 kg

Temperature range :Operating: 0°C to 45°C.

Storage : -40°C to 70°C.

Power supply :DPG : 110 V or 220 VAC / 40 W.

DSD : 10.5 to 28 VDC / 42 W without LIFT system

(add about 50 W with Lift system ON).

INTRODUCTION

UNPACKING

0311385 Issue : April 1999

1-6

UNPACKING

The VE432 system is composed of one or more of the following pieces of equipment

(depending on the configuration to be implemented):

- Digital Pilot Generator: DPG.

- Accessory set.

- Digital Servo Drive: DSD (See DSD Installation manual).

The VE432 DPG is composed of:

oa DPG unit (1717075017) including:

-a DVP board (1717074848)

-an SAPG board (1717074645)

-a DIO board (1717074678)

oa DPG Installation and Reference Manual (0311385)

oa DSD Installation and Reference Manual (0311378)

oan accessory kit (1717075235) including:

- a VE432DSD-E GROUND CABLE (1716075996)

- a VE432DPG-E RADIO CABLE (1717075948)

- a VE432DPG-E RECORDER CABLE (1717075949)

- a VE432DPG-E ANALOG PILOT CABLE (1717075950)

- a VE432 ETHERNET BNC/BNC CABLE (1717076385)

- an ATA & TRUE IDE MODE PC board (3120077)

- an R404011 coaxial load (3530117)

- a coaxial T adapter (5050210)

- a 50 OHM coaxial cord, 5 m long (5050212)

- two black banana plugs (5110051)

- ten 5X20 fuses, 2.5 A (5330119)

- a power cord, 2.5 m long (6050039)

- an RJ45 cable, 5 m long (6050047)

INTRODUCTION

UNPACKING

0311385 Issue : April 1999

1-7

The accessory set (1718075433) is composed of

-a CCU388 software package (1A11072510)

-a palmtop computer case (747076405)

-a HUSKY palmtop computer (317076033)

-a Husky/DSD cable (1718076053)

-a Husky/DSD extension cable (1718076123)

-a red banana jack (5110011)

-a black banana jack (5110065).

INTRODUCTION

UNPACKING

0311385 Issue : April 1999

1-8

CONNECTING A DPG

DPG MOUNTING DIMENSIONS

0311385 Issue : April 1999

2-1

CONNECTING A DPG

DPG MOUNTING DIMENSIONS

Approx. 20

All dimensions in mm

CONNECTING A DPG

DPG STANDARD CONNECTIONS

0311385 Issue : April 1999

2-2

DPG STANDARD CONNECTIONS

GROUND

wing nut

COM 1

(to palmtop computer)

ANALOG PILOTS

RETURN SWEEP

RETURN PILOT

TB

PILOT 2

PILOT 1

ETHERNET

RECORDER

(to recording system)

COM 2

Radio Fuse

AC

power

HI. LINE

CONNECTING A DPG

DPG STANDARD CONNECTIONS

0311385 Issue : April 1999

2-3

FO :Start order from recording system (either contact closure or voltage

pulse). Not used with the SN388 system (the FO is sent via the

LAN).

RDYOUT :Use only with SN388 system.

CLK :Use only with SN388 system to synchronize both systems (via

SN388 Master/Slave connector).

The palmtop computer is connected to the DPG to set up the output radio level or to

load a new software release to the DPG.

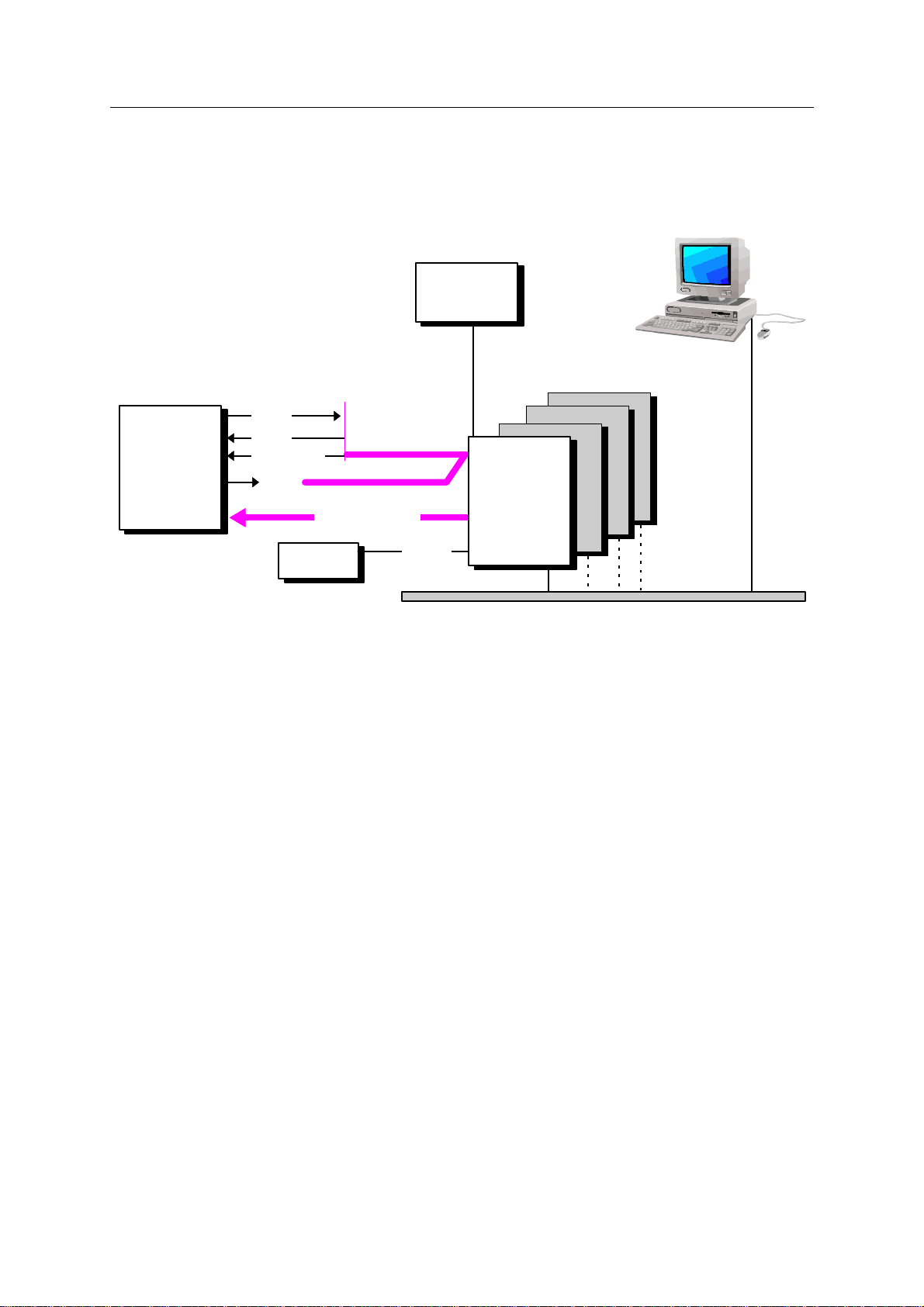

STANDARD CONNECTION DIAGRAM

TB

Ethernet

Palmtop

computer

Recording

System

Radio

(Up to 4 DPGs)

Analog Pilots

Radio

(Recorder)

VE432

DPG

CLK

(See examples

of possible

configurations

on next pages)

HCI

FO

RDYOUT

CONNECTING A DPG

1 APM, 1 DPG configuration

0311385 Issue : April 1999

2-4

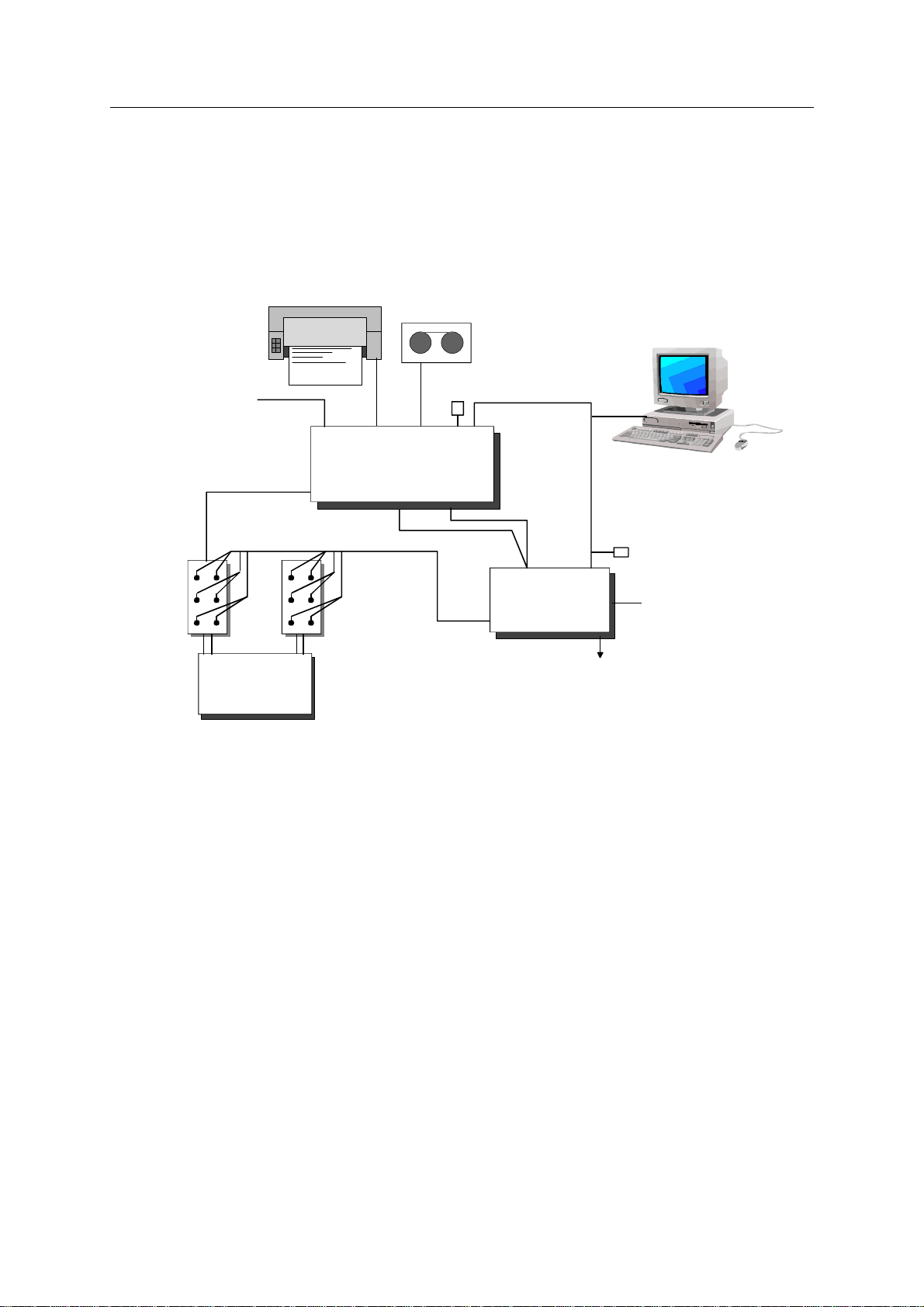

1 APM, 1 DPG configuration

READ CAMERA LAN

SN 388 APM

M / S

AUX

SU6

ACCB

POWER

(110/220 V)

SQC-Pro

CAMERA

DPG

RECORDER

ANALOG

Pilots RADIO

LAN

BLASTER

SCSI

HCI

50 Ω

50 Ω

ACCB

to RADIO

POWER

Analog Pilots: PILOTS 1 to 4 + Return Pilot + Return Sweep

(1)

(2)

(1) RECORDER cable (part No. 1717075949)

(2) ANALOG PILOT cable (part No. 1717075950)

CONNECTING A DPG

2 or 3 APMs, 1 DPG configuration

0311385 Issue : April 1999

2-5

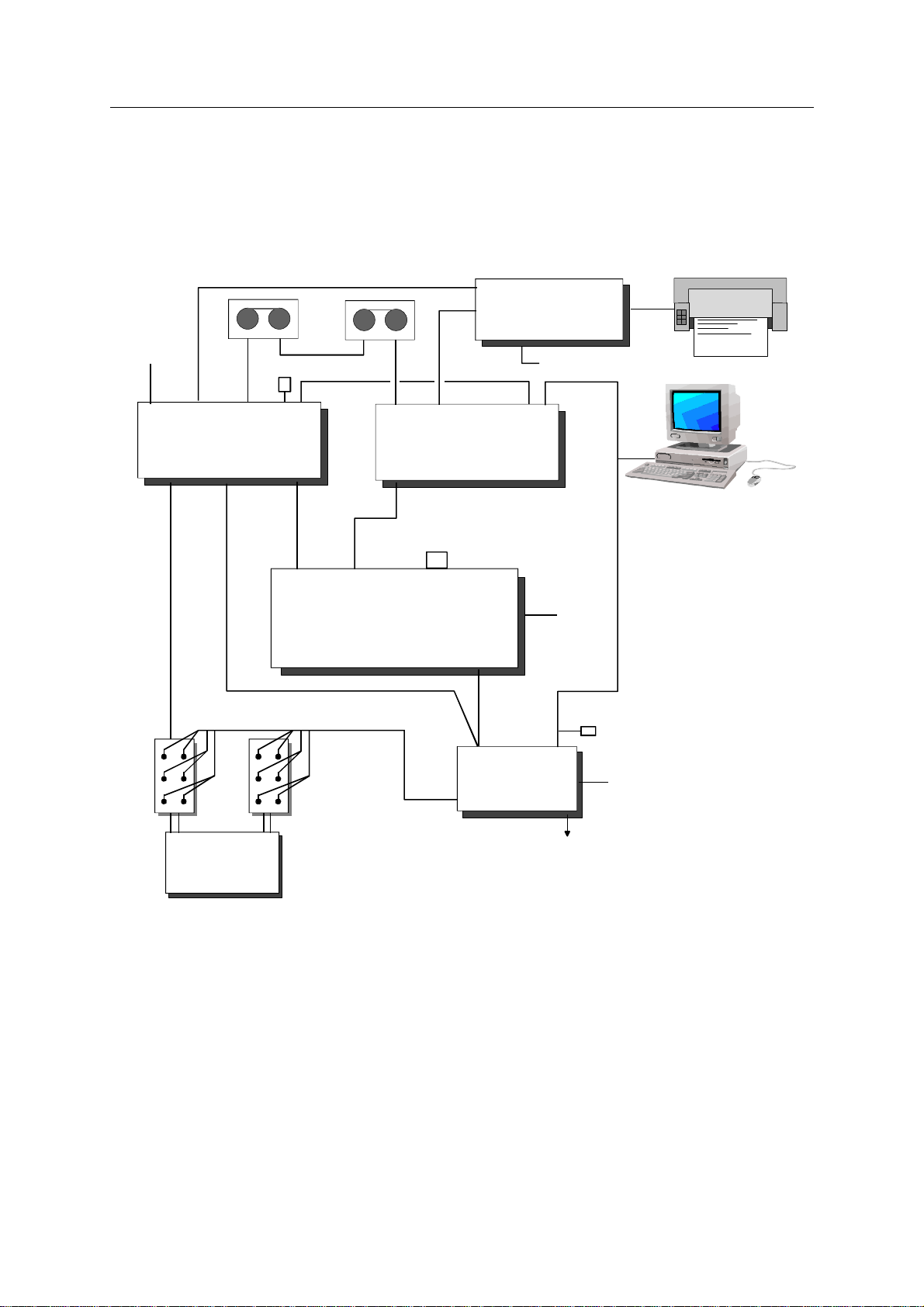

2 or 3 APMs, 1 DPG configuration

READ CAMERA LAN

APM1 (master)

M / SAUX

CAMERA

SCSI

APM2 (slave)

M / S AUX

MMCI4

IN

IN

IN

OUT

POWER

(12 VDC)

SQC-Pro

POWER (+12 V)

CAMERA

M/S

BLASTER

M/S

MMI-4

M/S

BLASTER

LAN

SCSI HCI

50 Ω

SU6

ACCB

POWER

(110/220 V)

DPG

RECORDER

ANALOG

Pilots RADIO

LAN

ACCB

to RADIO

POWER

Analog Pilots: PILOTS 1 to 4 + Return Pilot + Return Sweep

M/S

M/S terminator

(use this connector to connect

a third APM if required)

(1) RECORDER cable (part No. 1717075949)

(2) ANALOG PILOT cable (part No. 1717075950)

(3) M/S cable (part No. 1A13071930B)

(1)

(2)

(3) (3)

CONNECTING A DPG

Configurations with up to 8 APMs and up to 4 DPGs

0311385 Issue : April 1999

2-6

Configurations with up to 8 APMs and up to 4 DPGs

READ CAMERA LAN

APM1 (master)

M / SAUX

CAMERA

SCSI

APM2 (slave)

M / S AUX

MMCI4

IN

IN

IN

OUT

SU6

ACCB

ACCB

POWER

(110/220 V)

SQC-Pro

POWER (+12 V)

CAMERA

DPG1

RECORDER

ANALOG

Pilots RADIO

LAN DPG2

RECORDER

ANALOG

Pilots RADIO

LAN DPG3

RECORDER

ANALOG

Pilots RADIO

LAN

(6)

M/S8

(6)

M/S7

(6)

M/S6

(6)

M/S5

(6)

M/S4

(1) (6)

M/S3

BLASTER

M/S2

MMI-8

M/S1

BLASTER

BLASTER

(1)(3)

LAN

SCSI HCI

50 Ω

AUX1 AUX2 AUX3 DPG1 DPG2 DPG3 DPG4

(4) (4) (4)

50 Ω

ACCB

(2) (2) (2)

SU6

to RADIO 1 to RADIO 2 to RADIO 3

Part No.

(1) M/S cable 1A13071930B

(2) MMI-8 ACCB cable 1A13077600A

(3) APM BLASTER MMI-8 cable 1A13077599A

(4) DPG RECORDER MMI-8 cable 1A13077598A

(5) ANALOG PILOTS cable see VE432 DPG kit

(6) 14-19 plugs, M/S terminator 1A13072560

(with A wired to S, J wired to K)

(1), (2), (3), (4), and (6) contained in

Slip-Sweep option 1717077328B

(5) (5) (5)

This configuration should be used to connect either 4 or more APMs and 1 DPG, or

up to 8 APMs and up to 4 DPGs (Slip-sweep configuration).

Two pilots for each DPG are connected to the AUX line via ACCB interfaces. More

ACCB boxes can be used if more auxiliary channels need to be recorded.

CONNECTING A DPG

Configurations with up to 8 APMs and up to 4 DPGs

0311385 Issue : April 1999

2-7

Description of the links between the different modules

(when using an MMI-8 box)

(1) M/S cable (14-19S / 14-19S)

Used to connect the APM modules together. A plug with pin A wired to S, and J wired

to K (M/S terminator) needs to be connected to any unused M/S MMI-8 connector on

the MMI-8 box.

The TB signal on pins G and H is a logic OR of the TB signals from all the DPGs

connected.

(2) MMI-8 ACCB cable between MMI-8 and auxiliary line via ACCB box

(12-3S / banana plugs)

MMI-8

A, B TB connections from DPGs to AUX line

(A is wired to the red banana plug and B to the black one).

(3) APM BLASTER MMI-8 cable (16-26S / 12-10S)

MMI-8 BLASTER

C, D READY from DPGs to master APM via MMI-8. R, S

This signal is a logic “AND” of all connected DPGs, used to tell

the SN388 that VE432 is ready (used in normal mode only).

A, B FO from master APM (not used with VE432). A, B

G, H READY_IN from APM to DPG (not used). G, H

(4) DPG RECORDER MMI-8 cable between DPG and MMI-8 (14-19S / 12-14S)

RECORDER MMI-8

A, BCLOCK (from 17.920 MHz MMI-8 oscillator) A, B

all APMs and DPGs use the same clock from MMI_8 oscillator.

F, G READY from DPG to master APM via MMI-8 box F, G

(see APM BLASTER cable, C, D).

K, L TB from DPGnto AUXn(used in slip-sweep mode) and to master APM K, L

BLASTER plug (used in normal mode).

M, N FO from master APM (not used with VE432, this signal is sent by APM M, N

via the LAN in normal and slip-sweep modes).

P, R READY_IN from master APM to DPG (not used). P, R

The system will run in slip-sweep mode when the Slip-sweep option is enabled in the

OPERATION window, with the Continuous mode selected.

CONNECTING A DPG

Configurations with up to 8 APMs and up to 4 DPGs

0311385 Issue : April 1999

2-8

The sweeps then start automatically as soon as the vibrators are ready and a minimum

delay has elapsed after the start of the previous sweep. This minimum time is

“Slip time” + 2 s (when using 2 T0 parameters in the DPG radio transmission).

If no message is sent by the vibrators, the sweep starts at the end of a programmable

“Slip window” delay after the end of the previous sweep. Setting this delay to 99 s

amounts to setting an infinite delay (no start).

T: 0.5 s + FO-TB time (≈1.5 s with 2 T0 data) ≈2 s

Slip time

Slip time

Slip time

Slip time

Slip window

T

T

T

Fleet 1 sweep

Fleet 2 sweep

Fleet 3 sweep

Fleet 1 sweep

Fleet 2 sweep

fleet 2 Ready fleet 3 Ready fleet 2 Ready

Table of contents