STS DME04 User manual

1 Operating Instructions: DME04

Section I –Correct Use and Application ............................................................................................2

Section II –Unit Description .................................................................................................................5

Application ....................................................................................................................................................................................5

Section III –Unit Operation ..................................................................................................................6

Positioning the Mixer.....................................................................................................................................................................6

Loading the Drum.........................................................................................................................................................................6

Operating the Mixer .....................................................................................................................................................................7

Setting the Operation Timer ........................................................................................................................................................8

Safety Features..............................................................................................................................................................................8

Troubleshooting.............................................................................................................................................................................9

Section IV –Unit Maintenance ..........................................................................................................10

Maintenance Checklist............................................................................................................................................................. 10

Consumables.............................................................................................................................................................................. 10

Technical Specification ............................................................................................................................................................ 11

Decommissioning the Mixer ..................................................................................................................................................... 12

Final De-commissioning, Disposal............................................................................................................................................ 12

Safety Tests to be performed at Intervals and after Unusual Incidents............................................................................. 12

2 Operating Instructions: DME04

Section I –Correct Use and Application

General

The unit described in the present operating instructions is designed for mixing load units. It must be used, operated and serviced in accordance

with the present instructions. Any other type of use is beyond the scope of application and can result in damage to personnel, the unit or

property.

Correct Application

NOTE:

The maximum load must not be exceeded.

The load must be mixed by the attachment provided by the manufacturer.

Correct applications of this unit are as follows:

-Mixing of loads

Approved Application Conditions

-Operation in industrial and commercial environments

-Permissible temperature range 5°C to 40°C

Proprietor Responsibilities

For the purposes of the present operating instructions the “proprietor” is defined as any natural or legal person who either uses the unit himself,

or on whose behalf it is used. In special cases (e.g. leasing or renting) the proprietor i s considered the person who, in accordance with existing

contractual agreements between the owner and user of the unit, is charged with operational duties. The proprietor must ensure that the unit is

used only for the purpose for which it is intended and that there is no danger to life and limb of the user and third parties. Furthermore,

accident prevention regulations, safety regulations and operating, servicing and repair guidelines must be followed. The proprietor must ensure

that all users have read and understood these operating instructions.

NOTE:

Failure to comply with the operating instructions shall invalidate the warranty. The same applies if improper work is carried out on the unit by

the customer or third parties without the permission of the ma nufacturer.

Adding Attachments and/or Accessories

The mounting or installation of additional equipment which affects or enhances the performance of the unit requires written p ermission of the

manufacturer. Local authority approval may also need to be obtained. Local authority approval does not however constitute the

manufacturer’s approval.

S a fe t y Re g u l a ti o n s fo r t h e O p e r at i o n of t h e Un i t

Operator authorisation

The unit may only be used by suitably trained personnel, who have demonstrated to the proprietor, or his representative that they can drive

and handle the loads and have been authorised to operate the unit by the proprietor or his representative.

Operator’s rights, obligations and responsibilities

The operator must be informed of his duties and responsibilities and be instructed in the operation of the unit and shall be familiar with the

operating instructions. The operator shall be afforded all due rights.

Unauthorised use of unit

The operator is responsible for the unit during the time it is in use. The operator must prevent unauthorised persons from operating the unit.

Damage and faults

The supervisor must be immediately informed of any damage or faults to the unit or attachment. Units which are unsafe for operation must not

be used until they have been rectified.

Repairs

The operator must not carry out any repairs or alterations to the unit without the necessary training and authorisation to do so. The operator

must never disable or adjust safety mechanisms or switches.

Safety devices and warning labels

Safety devices, warning signs and warning instructions in the present operating instructions must be strictly observed.

Type of loads to be mixed

The operator must make sure that the Drum is in a satisfactory condition. Drums must always be positioned safely. Use suitable precautions to prevent liquids

from spilling.

Mixer Checks

Checks and operations to be performed before starting daily operation.

WARNING!

Damage and other mixer defects can result in accidents.

If damage or other mixer defects are discovered during the following checks, the mixer must be taken out of service until it has been repaired.

-Report any defects immediately to your supervisor

-Tag out and decommission a faulty mixer

-Only return the mixer to service when you have identified and rectified the fault

Pre-start inspections

Procedure

-Check the whole of the mixer for signs of damage

-Check that the markings and labels are present, clean and legible

3 Operating Instructions: DME04

Safety Regulations for Operation

Types of loads to be mixed

The operator must make sure that the load is in a satisfactory condition. Loads must always be positioned safely and carefully. Only mix loads

as specified for the unit.

WARNING!

Unsecured and incorrectly positioned loads can cause accidents

Before mixing a load unit the operator must make sure that it has been correctly positioned and does not exceed the mixer’s c apacity.

-Only mix loads that have been correctly positioned. Use suitable precautions to prevent parts of the load from tipping or falling

down

-Damaged drums must not be rotated

-Never exceed the maximum load capacity of the m ixer

-Do not stand on the unit

Unit Operation

W A R N I N G !

Unsecured and incorrectly positioned loads can cause accidents

Before mixing a load unit the operator must make sure that it has been correctly positioned and does not exceed the unit’s capacity.

-Instruct other people to move out of hazardous area of the unit. Stop working with the unit if people do not leave the hazardous

area

-Never exceed the maximum load capacity of the unit

WARNING!

Risk of accidents and damage to components

All modifications to the unit, in particular safety mechanisms, are prohibited. The operating speeds of the unit must not be increased under any

circumstances.

Hazardous area

Warning! Risk of accidents / injury in the hazardous area of the mixer.

The hazardous area is defined as the area in which a person is at risk due to mixer movement, rotating operations or the load itself.

Instruct unauthorised people to move hands away from the hazardous area.

The doors are fitted with a safety switch which prevents the mixer from operating until the doors are closed, even so the operator

should never try to start the mixer with the doors open.

With the doors shut the hazardous area is protected, the controls of the mixer should be used to stop the rotation before the doors

are opened.

If a door is opened whilst the unit is mixing will stop. There is a small amount of time where the rollers will still be slowing down after

the doors have been so care should be taken.

Do not operate the mixer with the covers off .

NOTE: Only original spare parts have been certified by the manufacturer. To ensure safe and reliable operation of the unit, use only the

manufacturer’s spare parts.

Operational Safety and Environmental Protection

The checks and servicing operations contained in this chapter must be performed in accordance with the intervals as indicated in the

servicing checklists.

WARNING!

Risk of accidents and damage to components

All modifications to the mixer, in particular safety mechanisms, are prohibited. The operating speeds of the mixer must not b e increased under

any circumstances.

NOTE:

Only original spare parts have been certified by the manufacturer. To ensure safe and reliable operation of the mixer, use only the

manufacturer’s spare parts.

Maintenance Safety Regulations

Maintenance Personnel

The unit should only be serviced and repaired by a competent individual as selected by the company the equipment is intended for use with.

Cleaning

CAUTION!

Fire Hazard

Do not use flammable liquids to clean the mixer.

CAUTION!

Risk of component damage when cleaning the mixer

Do not clean with pressurised water.

Consumables and used parts

CAUTION!

Consumables and used parts are an environmental hazard

Used parts, oils and fuels must be disposed of in accordance with the relevant environmental protection regulations.

-Note the safety regulations when handling these materials

Servicing and Inspection

Thorough and expert servicing is one of the most important requirements for the safe operation of the unit. Failure to perform regular servicing

can lead to unit failure and poses a potential hazard to personnel and equipment.

WARNING!

The application conditions of a unit have considerable impact on the wear of the service components.

4 Operating Instructions: DME04

L i ft i n g t h e U n i t

WARNING!

Accidental movement during transport

Improper fastening of the mixer during transport can result in serious accidents.

-Loading must be carried out by special trained staff in accordance with recommendations contained in Guidelines BS EN

12640:2001. In each case correct measurements must be made and appropriate safety measures adopted

-The unit must be securely fastened when transported on a lorry or trailer

-The lorry/trailer must have fastening rings

-Use only tension belts or tie-down straps or with sufficient strength

Lifting the Unit

Requirements

-Gearbox cover removed

Tools and Material Required

-Fork Lift

Procedure

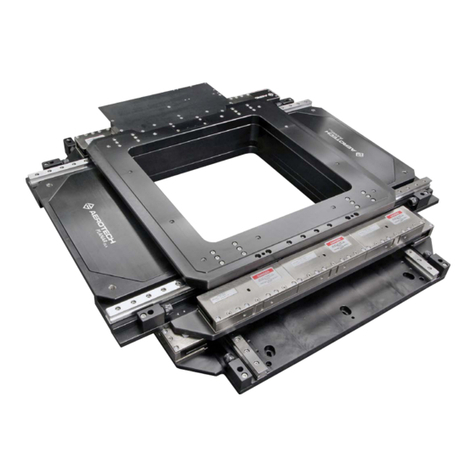

-There are 4 lifting eyes to attach lifting strops

-Ensure the unit is kept as low as possible whilst being lifted

Securing the unit for transport

Tools and Material Required

-Tension belts/tie down straps

Procedure

-Move the unit onto the transporting truck

-Park the unit securely

-Strap the belts around the unit and tension them sufficiently

The unit can now be transported.

4 Lifting Eyes, 1 at each corner

5 Operating Instructions: DME04

Section II –Unit Description

Application

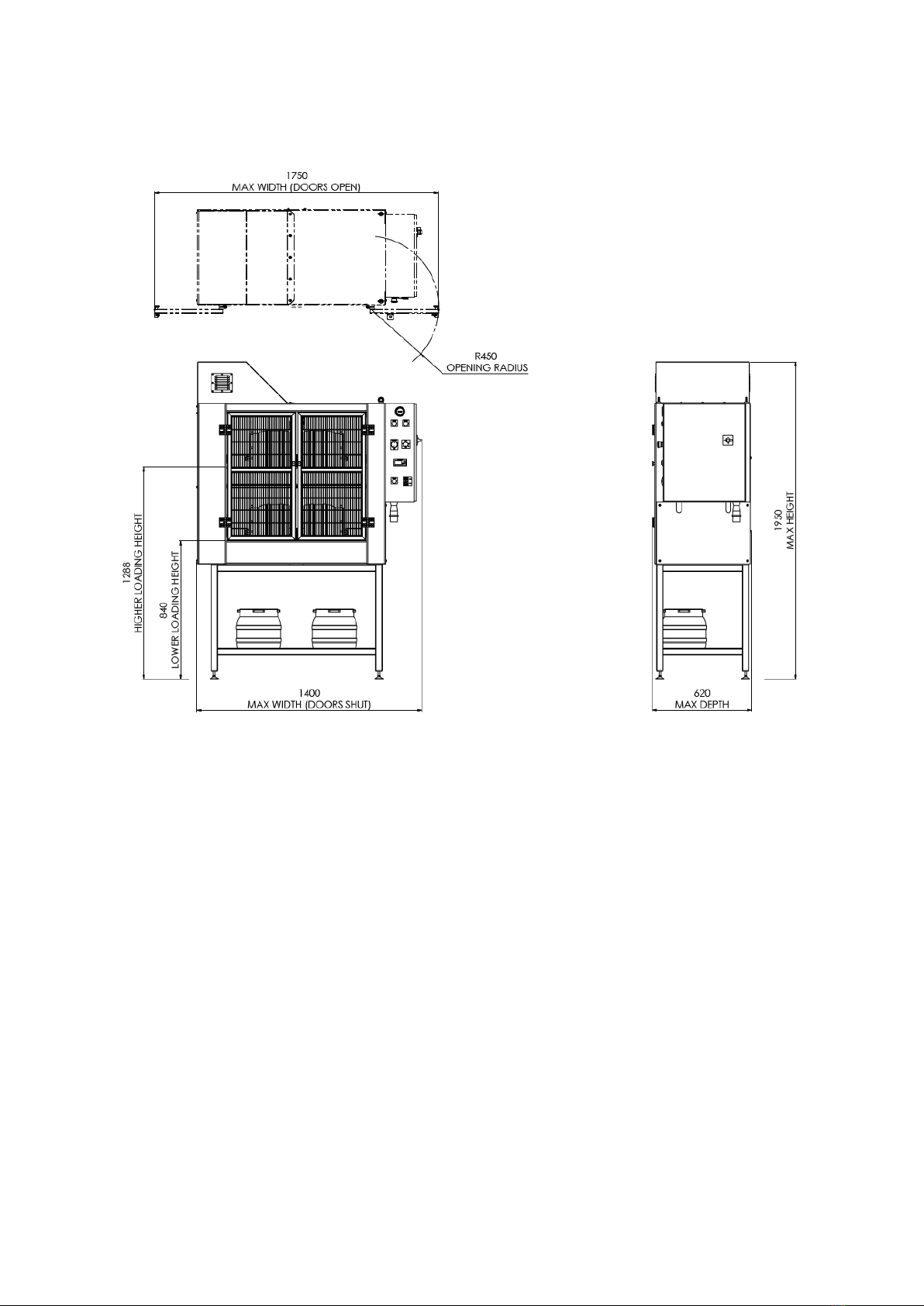

The DME04 is a static electric drum mixer with an electric rotating function

designed for mixing 10 litre drums, up to 4 at a time. This is the only drum type

that should be used with this unit. The intended purpose of this unit is to be

able to accept, rotate and mix drums at various speeds which can be

adjusted via the side mounted controls.

An emergency stop button has been incorporated which will rapidly cut out

all the electrical functions when pressed. If the doors are opened whilst the

unit is operating, the mixer will stop to ensure the safety of the operator and

other personnel. The mixer will not start unless the doors are shut.

The unit has been designed with smooth geometry including rounded edges.

The rotating wheels are fully enclosed within the housing which is compliant

with BS EN 13857 2008 to ensure safe handling of the mixer. The digital timer

displays the remaining mixing time which can be set by the operator.

THE RATED CAPACITY OF THIS MIXER IS 80KG SWL (4 X 20 KG)

6 Operating Instructions: DME04

Section III –Unit Operation

IMPORTANT

Before using the mixer, operators must read and understand this instruction

manual. Failure to observe the instructions in this manual will invalidate the

warranty.

The unit is delivered fully assembled but should be inspected for transit

damage. Any damage should be reported to STS and the equipment should

not be used.

Never allow any part of your body or anyone else’s to be put in a position

where it might cause injury. Always operate the unit in accordance with the

instructions.

Positioning the Mixer

-Position the mixing unit in a position close to a 230V mains power point

and ensure that the doors can be opened fully for drum loading.

-The unit is fitted with 4 screw feet. The lock nut can be tightened to lock

the feet in place.

-Ensure that the mixing unit is level before use.

-Plug the mains lead into a suitable 230V power supply. Ensure that the

cable is positioned away from any areas that would cause the cable

to be a trip hazard.

Loading the Drum

-Drum handles must be removed prior to loading the drums into the

mixer.

-Open the two doors fully at the front of the unit. Each drum can then

be individually placed on to the inside shelf of the unit before being

positioned on to the rollers. Note. The drum orientation should align with

the yellow instruction stickers.

-The weighted wheels will move up and out of the way as a drum is

pushed into position.

-Once all the drums have been loaded into the unit, close the doors so

they are held by the magnetic catches. Closing the doors activates

the safety switches which allows the unit to operate.

7 Operating Instructions: DME04

Operating the Mixer

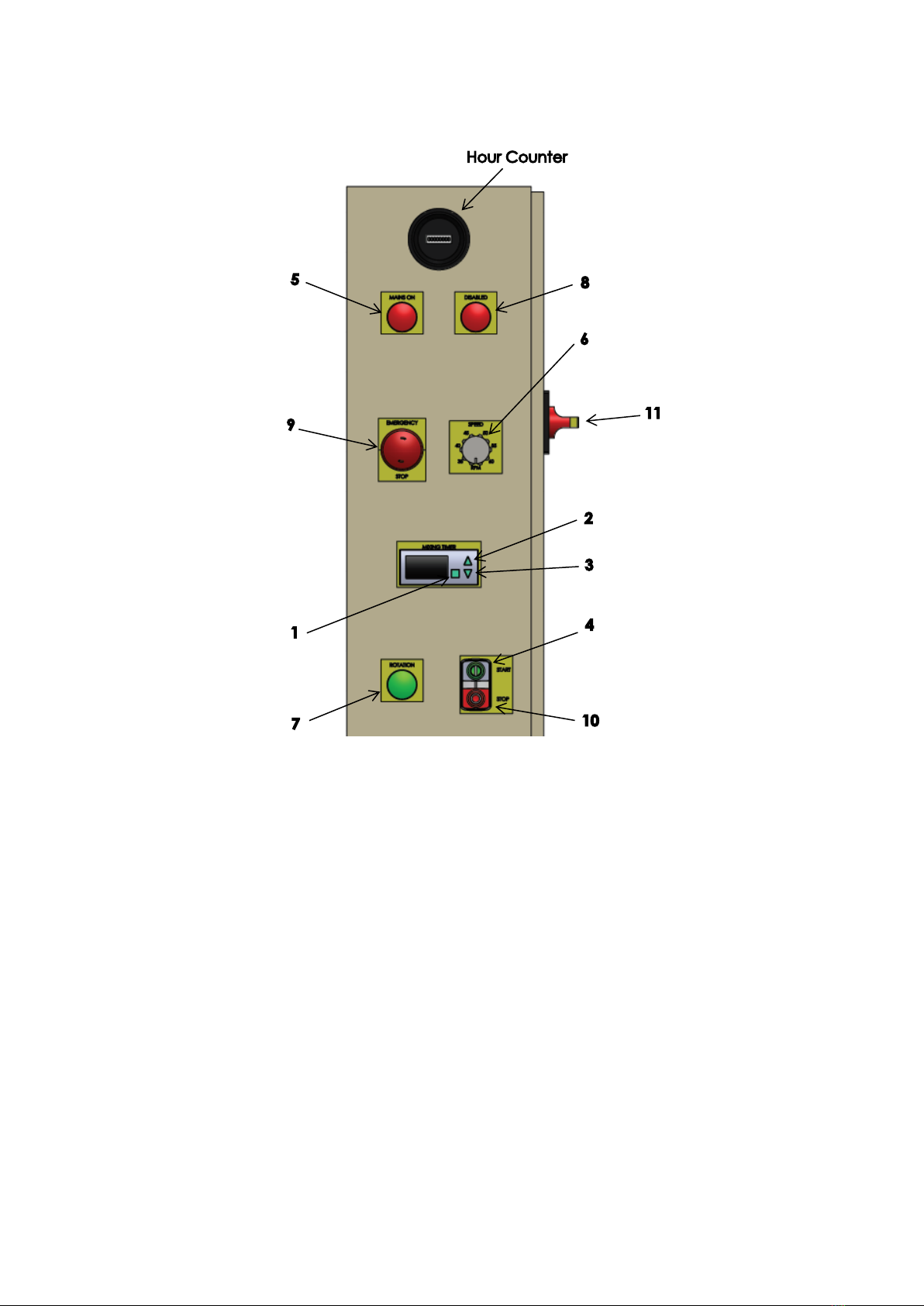

-Turn the power switch on (11). The mains on light (5) should be

illuminated.

-Turn the rotation speed control (6) to the desired rotation speed. The

speed can be adjusted between 35-60 rpm.

-Press the green start button (4) on the main panel to start the mixing

cycle. The mixer timer is initially set for 30 minutes if you wish to adjust

the mix time follow the instructions for “Setting the Operation Timer”.

-The green rotation light (7) will illuminate whilst mixing.

-The timer will count down until the set time has elapsed.

-To stop the mixing process before the timer counts down, press the red

stop button (10).

-Once mixing is complete the doors can be opened and the drum

removed in reverse order of the drum loading procedure.

-The disabled light (8) will illuminate when the doors are open.

8 Operating Instructions: DME04

Setting the Operation Timer

-To set the mixing time, first press the set button (1) once. The display will

start flashing. Use the up (2) and down (3) arrows to set the desired

mixing time in hours and minutes.

-Press the set button (1) to confirm the mixing time. The mixing time

figures should now stop flashing.

Safety Features

-There is an emergency stop button (9) on top of the panel. If this is

pressed the rotation will stop. To re-set the button, twist the button

clockwise. The button will then pop up and reset.

-If the door is opened whist the unit is operating the unit will stop.

9 Operating Instructions: DME04

Troubleshooting

When trying to locate a fault, proceed in the order shown in the table.

NOTE:

Troubleshooting must only be performed by competent personnel. If after

carrying out the following remedial action the unit cannot be restored to

operation, contact the manufacturer’s technical helpline listed at the end of

this manual.

In order for STS to be able to react quickly and specifically to the fault, the

follow information is essential:

-Mixer serial number

-Description of error

-Mixer product name

-Current location / Company

Mixer does not rotate

Possible Cause

Action

Emergency stop engaged

Ensure emergency stop is in the

correct position (twist clockwise to

release)

Doors are not closed

Close the doors at the front of the

unit

Doors do not hold fully closed

Ensure the magnetic strips and

contact plates are clean

Isolator switch (11) is not engaged

Turn the isolator switch to the On

position

10 Operating Instructions: DME04

Section IV –Unit Maintenance

The following servicing checklist indicates the operations to be performed

and the respective intervals to be observed. Maintenance intervals are

defined as:

W = Every 50 service hours, at least weekly

A = Every 1000 service hours, at least annually

● = Standard maintenance interval

Maintenance Checklist

Chassis and Superstructure

W

A

1

Check labels are legible and complete

●

●

2

Inspect the unit for damage and that it is in good condition

●

●

3

Check chassis and screw connections for damage

●

4

Check guarding

●

●

Rotation

W

A

1

Check gearbox for wear and damage

●

2

Check drive belts for wear and damage

●

3

Check bearings for wear and damage

●

4

Check drive wheels for wear and damage

●

Agreed Performance Level

W

A

1

Carry out a test run with rated load, if necessary with customer

specified load

●

Electrical System

W

A

1

Check electric wiring for damage (insulation damage,

connections). Make sure wire connections are secure

●

2

Check emergency stop and control box controls

●

●

3

Check contactors and/or relays

●

4

Check operation of door switches

●

●

OPERATORS SHOULD REPORT ANY DEFECTS ON THE MIXER TO THE

APPROPRIATE PERSON

Consumables

If the belts show excessive wear they should be replaced. Replacement parts

are available from STS.

11 Operating Instructions: DME04

Technical Specification

SWL. 4 x 20kg Net Mass. 260kg

System Voltage. 230VNominal Power. 550W

Max Noise Level. 79dbA Drum Range. 4 x 10L Drums

12 Operating Instructions: DME04

Decommissioning the Mixer

If the mixer is to be out of service for more than a month, e.g. for commercial

reasons, it must be stored in a frost-free and dry room. All necessary measures

must be taken before, during and after decommissioning as described

hereafter.

Prior to decommissioning

-Thoroughly clean the mixer

-Check for wear and damage on the chassis and any components

Final De-commissioning, Disposal

Final de-commissioning or disposal of the mixer must be performed in

accordance with the regulations of the country of use. In particular,

regulations governing the disposal of batteries, fuels and electronic and

electrical systems must be observed.

The mixer must only be disassembled by trained personnel.

Safety Tests to be performed at Intervals and after Unusual Incidents

Perform a safety check in accordance with national regulations.

The mixer must be inspected at least annually or after any unusual event by a

qualified inspector. The inspector shall assess the condition of the mixer from

purely a safety viewpoint, without regard to operational or economic

circumstances.

For further help contact the Bespoke Handling Equipment:

Technical Support Line: 44 (0) 1736 851050

In the interest of all concerned it is essential that equipment of our

manufacture is used only for the purposes for which it has been designed and

it must be used in accordance with the instructions which are supplied.

Table of contents

Other STS Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

AxleTech

AxleTech PRC 416-P Maintenance manual

SCHUNK

SCHUNK PGN-plus 40 Assembly and operating manual

GF

GF JRG Coral force 5000 Installation and operating instructions

Diamatic

Diamatic ULTRA BMG-780 RS operating instructions

ABB

ABB HT574226 Operation manual

Eriez

Eriez 36C Installation, operation and maintenance instructions