Seres OL TOC Evolution VUV User manual

TOC Evolution VUV

Operator’s Manual

TOC Evolution VUV

SOL-96.120.031 / 060223

© 2023, Seres OL SAS, France, all rights reserved.

The information contained in this document is subject to change without notice.

Customer Support

Seres OL and its representatives maintain a fully trained staff of technical specialists

around the world. For any technical question, contact your nearest Seres OL representa-

tive, or the manufacturer:

Seres OL SAS

ZA de la Sipière

219, Avenue de Provence

FR-13730 Saint-Victoret

France

Internet: www.seres-ol.com

E-mail: [email protected]

Document Status

Title: TOC Evolution VUV Operator’s Manual

ID: SOL-96.120.031

Revision Issue

00 February 2023 First edition

SOL-96.120.031 / 060223

TOC Evolution VUV

1

Table of Contents

1. Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1. Warning Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2. General Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3. Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4. International Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2. Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1. Instrument Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2. Instrument Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1. Before Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2. Mounting the Wall Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3. Hydraulic Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4. Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.1 Connections on I/O Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4.2 Cable Thicknesses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.3 Cable Cross-Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.4 AC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.5 Jbus via RS485 (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.6 Jbus via TCP/IP (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4. Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1. Installing the Reagent Bottles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2. Filling the Liquid Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.3. Starting Sample Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4. Preliminary Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5. Run-in Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.6. Manual Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.7. Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.8. Jbus Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1. Access Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.2. User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.1. Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2. Stop of Operation for Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3. Replacing Reagents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4. Replacing Peristaltic Pump Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.4.1 Reagent Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SOL-96.120.031 / 060223

TOC Evolution VUV

2

6.4.2 Sample Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.5. Replacing Soda Lime and Activated Charcoal. . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.6. Replacing Silica Gel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.7. Replacing UV Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.8. Manual Measurement and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.8.1 Manual Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.8.2 Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.8.3 Standard Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.9. Longer Stop of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7. Configuration of the Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8. Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.1. What To Do If... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.2. Saving Diagnostic Data to USB Stick. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.3. Replacing Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.3.1 NDIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.3.2 Glassware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.3.3 Reagent Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9. Fluidic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

SOL-96.120.031 / 060223

TOC Evolution VUV

Safety Instructions

3

Operator’s Manual

This document describes the main steps for instrument setup,

operation and maintenance.

1. Safety Instructions

General The instructions included in this chapter explain the potential risks

associated with instrument operation and provide important safety

practices designed to minimize these risks.

If you carefully follow the information contained in this chapter, you

can protect yourself from hazards and create a safer work environ-

ment.

More safety instructions are given throughout this manual, at the

respective locations where observation is most important. Strictly

follow all safety instructions in this publication.

Target

audience

Operator: Qualified person who uses the equipment for its intended

purpose.

Instrument operation requires thorough knowledge of applications,

instrument functions and software as well as all applicable safety

rules and regulations.

OM location Keep the Operator’s Manual in proximity of the instrument.

Qualification,

training

To be qualified for instrument installation and operation, you must:

read and understand the instructions in this manual as well as

the Material Safety Data Sheets and

know the relevant safety rules and regulations.

SOL-96.120.031 / 060223

TOC Evolution VUV

Safety Instructions

4

1.1. Warning Notices

The signal words and symbols used for safety-related notices have

the following meaning:

DANGER

Your life or physical wellbeing are in serious danger if such

warnings are ignored.

Follow the prevention instructions carefully.

WARNING

Severe injuries or damage to the equipment can occur if such

warnings are ignored.

Follow the prevention instructions carefully.

CAUTION

Damage to the equipment, minor injury, malfunctions or incorrect

process values can be the consequence if such warnings are

ignored.

Follow the prevention instructions carefully.

Mandatory

signs

The mandatory signs in this manual have the following meaning:

Safety goggles

Safety gloves

SOL-96.120.031 / 060223

TOC Evolution VUV

Safety Instructions

5

Warning signs The warning signs in this manual have the following meaning:

Electrical shock hazard

Corrosive

Harmful to health

Flammable

Hot surface

UV radiation

General warning

SOL-96.120.031 / 060223

TOC Evolution VUV

Safety Instructions

6

1.2. General Safety Regulations

Spare parts

and

disposables

Use only official Seres OL spare parts and consumables. If other

parts are used during the normal warranty period, the manufacturer’s

warranty is voided.

Modifications Modifications and instrument upgrades shall only be carried out by

an authorized service technician. Seres OL will not accept responsi-

bility for any claim resulting from unauthorized modification or alter-

ation.

Local

regulations

All wiring and connections (electrical, hydraulic) may only be carried

out by qualified personnel and in accordance with the local regula-

tions of the respective country.

WARNING

Electrical shock hazard

If proper operation is no longer possible, the instrument must

be disconnected from all power lines, and measures must be

taken to prevent inadvertent operation.

To prevent from electrical shock, always make sure that the

protective earth wire is connected.

Service shall be performed by authorized personnel only.

Whenever electronic service is required, disconnect the

instrument from power.

WARNING

Chemical exposure hazard

When handling chemicals or performing maintenance work

on hydraulic parts of the analyzer, wear suitable protective

equipment.

Read the Material Safety Datasheets (MSDS) of the chemicals

carefully.

SOL-96.120.031 / 060223

TOC Evolution VUV

Safety Instructions

7

WARNING

Do not use this instrument in presence of flammable liquids or

vapors as this may pose a safety hazard.

WARNING

If it is necessary to carry out maintenance work with the UV lamp

switched on, wear UV protective goggles.

1.3. Handling Precautions

Position the box correctly (up/down). Carefully unpack the analyzer

and check it for visible damage. If the analyzer shows any visible

damage, do not connect it to power and contact customer service

immediately.

SOL-96.120.031 / 060223

TOC Evolution VUV

Safety Instructions

8

1.4. International Symbols Used

The symbols found on the instrument have the following meaning:

Electrical fuse

Ground

Equipotentiality

Alternating current

Hot surface

General attention

Electrical hazard

UV radiation

SOL-96.120.031 / 060223

TOC Evolution VUV

Product Description

9

2. Product Description

Application

range

The TOC Evolution VUV is a complete monitoring system for the

automatic, continuous measurement of total organic carbon (TOC) in

potable water and return condensate.

Measuring

principle

Advanced oxidation process with UV/VUV light and persulfate: By

purging the sample after adding acid, the inorganic carbon is con-

verted to CO2 and completely extracted from the sample. The sam-

ple is injected into the oxidation reactor. UV directly oxidizes the

organic matter which turns into CO2. The CO2 produced is then de-

tected by an NDIR (non-dispersive infrared) detector.

COD

correlation

Optionally, the measured TOC value can be correlated with the

chemical oxygen demand (COD). The COD is calculated using the

following equation:

COD = A * TOC + B

with A = COD correlation coefficient, B = COD offset.

The correlation has to be configured at the factory. Fill the equation

with the appropriate values for your sample and include them when

ordering the analyzer.

Note: The correlation is only valid if the customer's process

is stable and the customer is able to determine the correlation

equation.

Configurations The instrument is available in the following configurations:

Three measuring ranges:

– 0 to 2 ppm

– 0 to 10 ppm

– 0 to 100 ppm

available with one or two measuring channels (common

measuring range)

tangential filtration as an option (available with one measuring

channel only)

automatic calibration as an option

SOL-96.120.031 / 060223

TOC Evolution VUV

Product Description

10

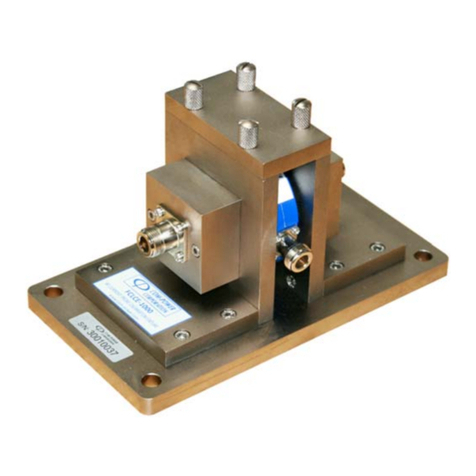

Tangential

filtration

(option)

The sample is pumped through a tangentially positioned membrane

filter with a mesh size of 100 μm. Only a small amount, approximately

1%, is drawn through the membrane filter and used by the analyzer.

A sample flow of 500 l/h results in a velocity of 1.75 m/s. At the point

where the membrane filter is located, the cross-sectional area of the

sample line is reduced to double the sample velocity. The higher ve-

locity helps to keep the membrane filter clean.

In addition, the membrane filter is cleaned by compressed air back-

flushing at 2.5 bar (air supply with 7 bar provided by customer). The

frequency and duration are automatically controlled by the analyzer.

Input On request:

One input for dry (potential-free) contact to stop measurement at the

end of the measurement cycle.

Signal

outputs

Two signal outputs per measuring channel.

Current loop: 4–20 mA

A

B

Sample inlet

100 µm membrane filter

C

D

Filtered sample

Compressed air inlet

3.5 m/s

2.5 bar

0.5 l/h

500 l/h

1.75 m/s

A B DC

SOL-96.120.031 / 060223

TOC Evolution VUV

Product Description

11

Relays Three potential-free contacts per measuring channel with the follow-

ing functions:

two thresholds (high/low)

sample flow alarm

On request, one of the following functions can be configured ex-

works for relay 2 (replaces threshold 2):

“end of cycle indication” of the active sample stream for each

channel

maintenance/calibration indication

Maximum load: 1 A/24 V

Alarm relay One summary alarm for “analyzer failure”.

Maximum load: 1 A/24 V

SOL-96.120.031 / 060223

TOC Evolution VUV

Product Description

12

2.1. Instrument Specifications

Power supply Voltage:

Power consumption:

110 (configuration) or 230 VAC

50/60 Hz

300 VA maximum

Environmental

conditions

Temperature:

Relative humidity:

Pollution level:

Installation category:

Maximum altitude:

5–40 °C

5% to 95%

2

II

2000 m

Do not use this instrument in presence of flammable liquids or gases.

Protect it from bad weather, humidity, corrosive substances and dust.

Process

connections

Sample inlet:

Sample inlet with

tangential filtration:

Sample outlet:

Sample outlet (fast loop):

Sample outlet waste:

Sample outlet

(multi-channel):

1/4” BSP F

D 12 pipe

soft tubing D INT 9

soft tubing D INT 18

soft tubing D INT 12

soft tubing D INT 19

Sample

requirements

Flow rate:

Temperature:

Inlet pressure:

Outlet pressure:

Particle size:

min. 40 l/h (opt. 50 l/h)

5–50 °C

0.1–3 bar

pressure-free

<100 µm

Additional requirements for analyzer with tangential filter:

Flow rate:

Inlet pressure:

Air supply:

min. 200–500 l/h

0.5 to 1 bar

7 bar, clean and dry air

Cycle time 5 to 10 minutes, programmable interval

SOL-96.120.031 / 060223

TOC Evolution VUV

Product Description

13

FS = full scale

Measuring

range

Low-range variant:

Limit of detection:

Repeatability:

Accuracy:

0–2 ppm

0.01 ppm

±2% FS

±3% FS

Middle-range variant:

Limit of detection:

Repeatability:

Accuracy:

0–10 ppm

0.1 ppm

±2% FS

±3% FS

High-range variant:

Limit of detection:

Repeatability:

Accuracy:

0–100 ppm

0.5 ppm

±2.5% FS

±3% FS

SOL-96.120.031 / 060223

TOC Evolution VUV

Product Description

14

1-channel instrument with optional reagent shelf:

Wall cabinet Material:

Screws:

Weight:

Protection degree:

Stainless steel SS316

4x M8

80 kg

IP55

Reagent shelf made of SS316 available as an option.

551 mm / 21.69"

600 mm / 23.62"

780 mm / 30.71"

920 mm / 36.22"

993 mm / 39.09"

348 mm /

13.70"

422 mm /

16.61"

490 mm /

19.29"

273 mm /

10.75"

408 mm /

16.06"

SOL-96.120.031 / 060223

TOC Evolution VUV

Product Description

15

1-channel instrument with tangential filtration:

2-channel instrument:

920 mm / 36.22"

993 mm / 39.09"

422 mm /

16.61"

408 mm /

16.06"

551 mm / 21.69"

600 mm / 23.62"

913 mm / 35.94"

920 mm / 36.22"

993 mm / 39.09"

551 mm / 21.69"

600 mm / 23.62"

734 mm / 28.90"

422 mm /

16.61"

408 mm /

16.06"

SOL-96.120.031 / 060223

TOC Evolution VUV

Product Description

16

2.2. Instrument Overview

1-channel

instrument A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

Power switch

Touchscreen

Cable glands

Fan

Activated charcoal

and soda lime

cartridges

Silica gel cartridge

Peristaltic pump

(sample)

Peristaltic pumps

(reagents)

Analyzed air outlet

Liquid seal

UV protective cover

Fast loop

Sample inlet tap

Air filter

Reagent tubes

H

G

A

B

C

D

E

F

J

I

K

O

N

L

M

SOL-96.120.031 / 060223

TOC Evolution VUV

Product Description

18

2-channel

instrument A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

Power switch

Touchscreen

Cable glands

Fan

Activated charcoal

and soda lime

cartridges

Silica gel cartridge

Peristaltic pump

(sample)

Peristaltic pumps

(reagents)

Analyzed air outlet

Pressure reducing

device

Sample inlet taps

Liquid seal

UV protective cover

Air filter

Reagent tubes

J

K

I

L

M

O

N

H

G

A

B

C

D

E

F

Table of contents

Other Seres OL Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

CARLO GAVAZZI

CARLO GAVAZZI WM3-96 - PROGRAMMING instruction manual

COM-power corporation

COM-power corporation CLCE-400 instruction manual

Thermo Scientific

Thermo Scientific SPECTRONIC 200 user guide

Anaheim Scientific

Anaheim Scientific P771 user manual

Factair

Factair SAFEGUARD operating instructions

HEIDENHAIN

HEIDENHAIN MSE 1201 installation instructions