Serma EVA4201 User manual

Documentation

EVA4201/4301 – User Guide

Evaluation Board for

80W

Power Factor Corrected (PFC) Supply

Featured Products: PE4201/PE4301

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 2 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

Table of Contents

1.

Revision History ....................................................................................................................... 2

2.

Safety Instructions.................................................................................................................... 3

3.

Introduction .............................................................................................................................. 3

3.1

Features ................................................................................................................................... 3

3.2

IC`s General Description.......................................................................................................... 3

4

How to design an application ................................................................................................... 4

4.1

Given board specification......................................................................................................... 4

4.2

Calculating the Current ............................................................................................................ 4

4.3

Inductor .................................................................................................................................... 6

4.4

Current Sense Resistor............................................................................................................ 7

4.5

Error Amplifier Compensations .............................................................................................. 10

4.6

Self Biasing .............................................................................................................................11

4.7

EMI and Driver SlewRate....................................................................................................... 12

4.8

Start-Up Bypass Rectifier ....................................................................................................... 12

5

Description ............................................................................................................................. 13

5.1

Evaluation Board Specifications............................................................................................. 14

5.2

Wire bridges ........................................................................................................................... 14

5.3

Schematic .............................................................................................................................. 15

5.4

Component Placement........................................................................................................... 16

5.5

Board Picture and Layout ...................................................................................................... 17

5.6

Bill of Material......................................................................................................................... 18

6

Operating ............................................................................................................................... 19

6.1

Caution................................................................................................................................... 19

6.2

Load ....................................................................................................................................... 19

6.3

AC-Input ................................................................................................................................. 19

6.4

Power-up Sequence............................................................................................................... 19

7.

List of Abbreviations ............................................................................................................... 20

8.

Notes ...................................................................................................................................... 21

9.

Contact Addresses ................................................................................................................. 22

1. Revision History

Version Date Changes Page

Initial Version V1.0 12/2008

V1.1 04/2013 Formula (2) 4

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 3 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

2. Safety Instructions

Please take caution - the board operates at 405V DC and is directly plugged into the power

network. Operating this Board requires an isolated transformer!

The EVA4201/4301 was designed to help understand and evaluate the features of two Power Factor

Correction IC`s. Used external devices are standard components chosen for safe operation and do not

represent a completely fine-tuned OEM application. The BOM (bill of material) for a final application may

look slightly different.

The board can also be used with PEs high precision PFC ICs, the PE4202 and the PE4302.

3. Introduction

3.1 Features

The board is designed to support applications of our two PFC-IC’s PE4201 and PE4301

PE4201 PE4301

- Low Total Harmonic Distortion (THD) - Wide Range Input

- Low StartUp Current (<5µA) - Low Total Harmonic Distortion (THD)

- Low Operating Current (<450µA) - Low Operating Current (<550µA)

- Disable Function (<170µA) - Disable Function (<100µA)

- Under-Voltage Lockout with >8V Hysteresis - Under-Voltage Lockout with >8V Hysteresis

- Over voltage and Over current protection with - Over voltage protection, Peak current

separate Reference protection and Open loop protection with

- Reduced operating Frequency at low Output separate Reference

Power - low Peak current protection threshold

- High Efficiency at high and low Output Power - Operating Frequency between 40 kHz and

- Internal Clamping Resistor at G 250 kHz dependent upon load

- fast Driver turn ‘off’ - High Efficiency at high and low Output Power

- very fast Driver ‘off’ at over current sense - Internal Clamping Resistor at Driver

- Driver load up to 5nF - Soft start

- fast Driver Switch ‘off’

Application with PE4201/PE4301

•Active power factor correction

•Switch mode power supplies

3.2 IC`s General Description

The PE4201 and PE4301 are wide input range controller ICs for active power factor correction

converters. Both ICs provide many protection functions, such over voltage protection, open loop

protection, supply under voltage lockout, output under voltage protection and peak current limit

protection. These protection functions are working with separate reference.

The PE4201 operates in the CRM with voltage mode PWM control and in DCM under light load

condition. The maximum switching frequency is clamped with an internal delay circuit. Compensations

for voltage loop are external.

The PE4301 IC operates in the CCM with average current control. The switching frequency depends upon

load. At high output load the frequency is low and with low load the frequency is high. The Compensation

for voltage loop and soft start is external.

For more information refer to the datasheets.

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 4 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

4 How to design an application

4.1 Given board specification

PE4201/PE4301

The board setup in the original state has the following specification parameters. The following chapters

show, what has to be changed to design an active PFC supply towards different parameters. Please

take caution when calculating. Wrong device parameter calculation can damage the Evaluation board or

other devices.

AC Line Input voltage 85 VAC ... 265 VAC

AC Line Frequency 47 ... 63Hz

Switching Frequency 40 ... 250 kHz

Output voltage 340 -405V DC (adjustable)

Output Load max 80W

Over Voltage Threshold 416V DC

4.2 Calculating the Current

PE4201

The input power:

86,96W=

92%

80W

=

η

out

P

=

in

P(1)

The input current:

A0,52=

110V

0,66*86,96W

=

AC

V

in

P

=

ACin_LL

ID∗

(2)

A=

265V

86,96W

=

AC

V

in

P

=

ACin_HL

I

0,33

(3)

D… Duty Cycle at 110V

The peak current:

A=0,52A22=

ACin_LL

I22=

pk_LL

I

1,48

∗∗∗∗

(4)

A0,93=A33,022=

ACin_HL

I22=

pk_HL

I∗∗∗∗

(5)

This peak current affects the component selection on the current sense resistor, Power-MOSFET, diode

and inductor.

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 5 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

0,11A0,40A20,220,2

ACin_LLLL

==I=∆I∗∗∗∗

0,093A0,33A20,220,2

ACin_HLHL

==I=∆I∗∗∗∗

,61A0

2

0,22

A40,02

2

2

LL

ACin_LLpk_LL

=+=

∆I

+I=I ∗∗

,51A0

2

0,22

A33,02

2

2

LL

ACin_HLpk_HL

=+=

∆I

+I=I ∗∗

PE4301

The input power:

86,96W

92%

80W

out

in

==

η

P

=P

(6)

The input current:

0,40A

110V

86,96W

AC

in

ACin_LL

==

V

P

=I

(7)

0,33A

265V

86,96W

AC

in

ACin_HL

==

V

P

=I

(8)

The ripple current ∆I

is set to 20%

(9)

(10)

The peak current:

(11)

(12)

This peak current affects the component selection on the current sense resistor, MOSFET,

diode and inductor.

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 6 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

out

inout

V

VV

=D

−

0,615V

405

110V2405V

LL ==D

∗−

0,074V

405

265V2405V

HL ==D

∗−

4.3 Inductor

PE4201

For CRM operation, the maximum 'on' time and the maximum 'off' time control the lowest frequency.

The minimum CRM inductance L

(CRM)

at low and high line input voltage can be calculated as follows:

f

1

pk

I

in

V

out

V

in

V

out

V

=

(CRM)

L∗∗

−

(13)

µH=

40kHz

1

1,48A

V2

405V

V2405V

=

(CRM)

L

1623

110110

∗

∗

∗

∗−

(14)

µH=

40kHz

1

0,93A

265V2

405V

265V2405V

=

(CRM)

L

754

∗

∗

∗

∗−

(15)

For high line voltage and high output power the inductor has to have a nominal inductance of 400µH.

The switching frequency at low line voltage can be calculated according to equation (16):

(CRM)

L

1

pk

I

in

V

out

V

in

V

out

V

=f ∗∗

−

(16)

39,9kHz=

1623µH

1

1,48A

110V2

405V

110V2405V

=f ∗

∗

∗

∗−

(17)

PE4301

For CCM operation, the maximum 'on' time and the maximum 'off' time control are the lowest

frequencies. The minimum CCM inductance L

(CCM)

at low and high line input voltage can be calculated

as follows:

Duty Cycle

(18)

(19)

(20)

CCM Inductor

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 7 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

∆If

DV

=L

∗

∗∗

in

CCM

2

(21)

µH21425

A11,040kHz

0,615110V2

CCM_LL

==L

∗

∗∗

(22)

µH7536

0,093A40kHz

0,074265V2

CCM_HL

==L

∗

∗∗

(23)

For high line voltage and high output power the inductor set to 8000µH.

The switching frequency at low line voltage obtains as:

∆IL

DV

=f

∗

∗∗

CCM

in

2

(24)

kHz6,109

A11,08000µH

0,62110V2 ==f

∗

∗∗

(25)

4.4 Current Sense Resistor

PE4201

The current sense resistor provides the threshold voltage for the over-current protection function. The

maximum inductor peak current is set to 1,48 A.

0,15Ω=

1,48A

0,22V

=

OCP

I

SHPCP

V

=

s

R

(26)

R

sense

=0,15

Ω

PE4301

1,55Ω=

0,61A

0,95V

=

OCP

I

CSPCP

V

=

s

R

(27)

R

sense

=1,55

Ω

For higher/lower output power the resistor RS has to be reduced/increased and the inductor has to be

re-calculated.

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 8 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

2.5 Output Bypass Capacitor

PE4201/PE4301

The bypass capacitor on the output of the circuit has to be able to suppress the ripple of the switching

frequency and the residues of the full-wave rectified input frequency (2 * f

in

).

f

1

out

∆V

1

out

V

out

P

=

out

C∗∗

(28)

It is recommended to use 4 * f

in

to suppress the sine wave residues of the input voltage for calculation.

The ripple shall be assumed to be at 5% of the output voltage.

at 40W :

34,2µF=

50Hz4

1

405V0.05

1

405V

40W2

=

out

C

∗

∗

∗

∗

∗

(29)

at 80W :

68,7µF=

50Hz4

1

405V0.05

1

405V

80W2

=

out

C

∗

∗

∗

∗

∗

(30)

A capacitor with at least 47µF (C13) should be used. It has to withstand the maximum output voltage.

The equivalent series resistance (ESR) of the capacitor shall not build up a voltage higher than half the

ripple amplitude (2,5% of V

out-max

) at peak-current.

16

Ω

=

0,61A

405V0,025

=

peak

I

out

∆

V

=

C

R

∗

(31)

To reduce the ESR it is recommend to place a capacitor with small ESR in parallel to the high

capacitance device. For 2% ripple at minimum switching frequencies the parallel capacitance can be

calculated according to equation (23):

0,61µF=

40kHz

1

405V0.02

1

405V

80W

=

out2

C∗

∗

∗

(32)

The capacitor on the board is C12=100n/400V.

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 9 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

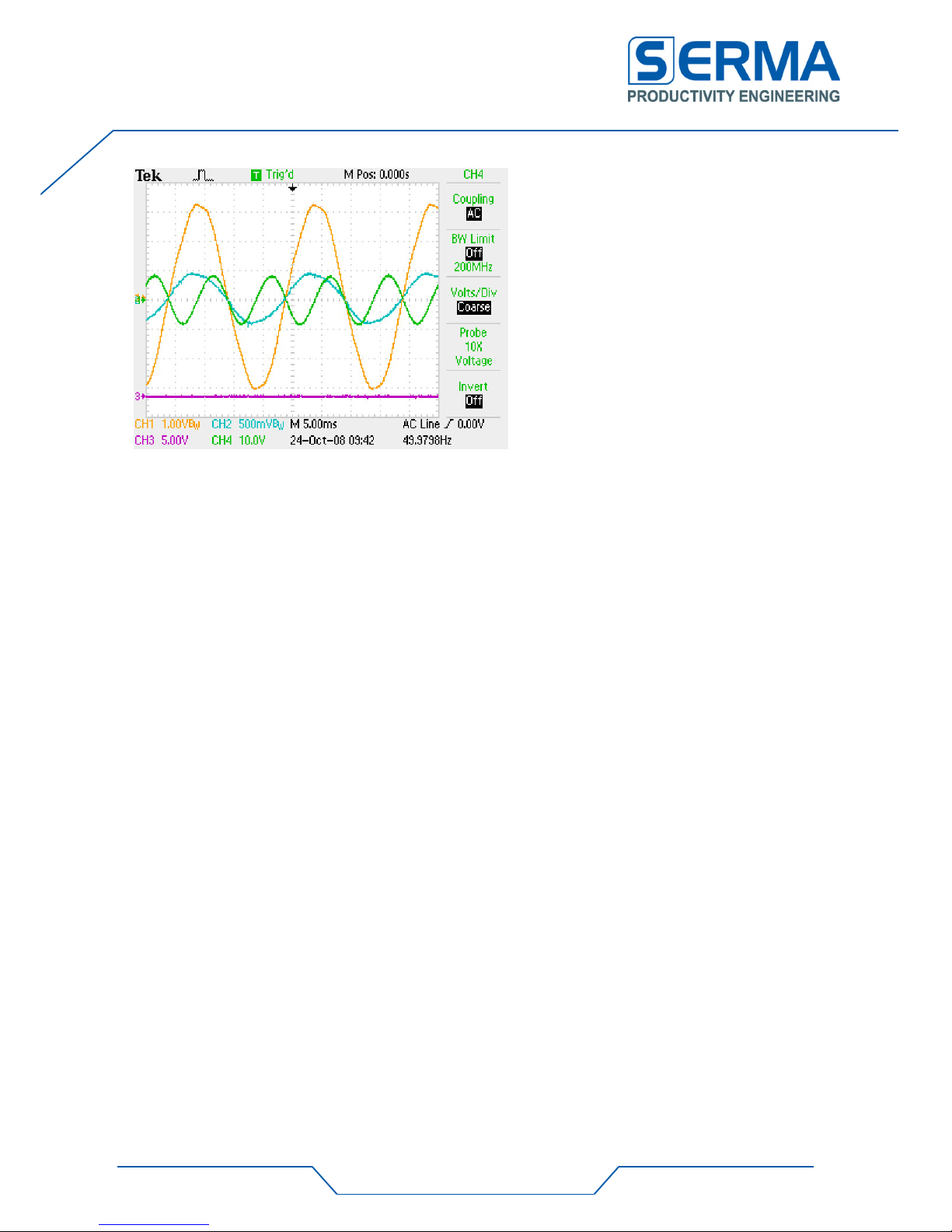

The figure shows the input voltage (230V~) in orange color, the current (I

out

=0.20A) in blue color and

the ripple of the output voltage in green color (only AC, C13=47µ, C6=0.1µ). The ripple is lower than

20V peak-to-peak (<5%).

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 10 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

Input Filter

PE4201/PE4301

A high-frequency has to be applied in the primary AC input to reduce reflections from and to the power

grid.

Figure 1: Input Filter

The capacitor C

HF

following the bridge rectifier provides the peak current and reduces the voltage ripple.

This is typical for a 330nF or for a 470nF capacitor. A high capacitance here will decrease the power

factor (C1).

The L-C filter before the bridge rectifier has to suppress the switching frequency by about 20dB. The

cut-off frequency shall be below 10kHz.

4.5 Error Amplifier Compensations

PE4201/PE4301

The output of the integrated error amplifier has to be filtered by means of an RC filter for frequency

compensation.

Figure 2: Error Amplifier Compensation

At the same time the capacitor C

SP

ensures a soft start function. Capacitance can be calculated

according to equation (33). The soft start time is set up at 30ms.

237nF=

2,53V

20µA30ms

=

RREF

V

VCOmax

i

ss

t

=

z

C

∗

∗

(33)

C8=220nF shall be chosen here.

The frequency response should have a second pole slightly above twice the power grid frequency.

This is set up by R

SP

and C

Z

.

C

HF

C

EMI

2

C

EMI

1

L

EMI

AC

Lin

e

V

IN

VCO

IN

RRE

F

R

SP

C

Z

C

SP

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 11 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

6,028k=

220nF100Hz2

π

1

=

z

C

z

f2

π

1

=

SP

R

∗∗∗∗

(34)

R4=5,6kOhm shall be chosen here.

The frequency of the second pole shall be at about 1/7 of the switching frequency. This defines the

capacitance of C

SP

.

4,6nF=

6k5,7kHz2

π

1

=

SP

R

z

f2

π

1

=

SP

C

∗∗∗∗

(35)

C9=4,7nF shall be chosen here.

4.6 Self Biasing

PE4201/PE4301

Power supply of the PE4201/PE4301 during start up is provided through a high resistance resistor from

the power grid input voltage. The maximum resistance has to be calculated resulting from the minimum

input voltage and the required supply voltage of the PE4301 as well as the minimum required start up

current.

20MegΩ=

5µA

20V85V2

=

ST

I

ST

V

in

V2

=

STUP

R

−∗

−∗

(36)

To reduce start up time and account for leakage currents in the external diode the resistor is chosen to

be 4MOhm. This is an experimental trade-off. Make sure the chosen resistor type has the proper power

dissipation. Also, relatively high voltage over the resistor is to be accounted for (245V). It is

recommended to use two 2MOhm resistors is series.

The capacitor on VDD has to provide power until the switching of the power-MOSFET has started and

power will be provided from the help winding on the transformer. That can only happen after start-up

and when the input voltage is at maximum level. At 50Hz this time t

VDD

is about 10ms.

Current consumption calculates from the IC supply current and the loss in the power-MOSFET when

switching.

Power consumption of the IC is <450µA. Power-MOSFET switching consumption consists of an ohmic

part (resistor on ‘G’) and the dynamical part in the MOSFET. This is a charge changing process at the

gate capacitance in the device.

Switching frequency will not be constant over an input frequency period. It can be assumed to be 150

kHz on average. Also the duty cycle factor will not be constant. For simplicity it can be assumed to be

50%.

A simplified but sufficient equation to calculate the dynamic and ohmic portion is given in equation (37)

and (38) respectively.

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 12 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

1,275mA=8,5V150kHz1nF=

Gmax

Uf

G

C=

Gdyn

I∗∗∗∗

(37)

0,2125mA=0,5

20kΩ

8,5V

=T

G

R

Gmax

U

=

Gohm

I∗∗

(38)

Total current consumption calculates according to equation (39).

1,9375mA=0,2125mA+1,275mA+0,45mA=

Gohm

I+

Gdyn

I+

stat

I=

VDD

I

(39)

From that the capacitance of C

VVD

can be calculated:

1,38µF=

8V22V

10ms1,94mA

=

LO

V

ST

V

VDD

t

VDD

I

=

VDD

C

−

∗

−

∗

(40)

The help winding on the transformer has to provide between 20 ... 25V DC.

The Transformation Ration (TR) can be calculated according to equation (41):

18,4=

22V

405V

=

VDD

V

out

V

=TR

(41)

4.7 EMI and Driver SlewRate

PE4201/PE4301

The driver slew rate can be influenced a network according to figure 3.

Figure 3: Network for Driver Slew Rate

R

tFALL

determines the Slew Rate of the falling edge (in practice 4.7 to 6.8Ω). The diode should be a fast

recovery Si-diode (MMSD914T1G).

R

tRISE

determines the Slew Rate of the rising edge (to optimize to gate capacity of the used FET, 18 to

56 Ω). Caution has to be taken to meet EMI regulations.

4.8 Start-Up Bypass Rectifier

PE4201/PE4301

A diode (D

BYPASS

) in parallel to the coil and the boost diode (D

BOOST

) reduces the current through the coil

during start-up. It also pre-charges the bypass capacitor on the output to the peak input voltage.

This reduces over voltage peaks and currents in the coil and so improves EMI parameters. It also

protects the power-MOSFET from over voltage damage. To reduce the current through the diode a

series resistor shall be used.

G

R

tFALL

R

tRISE

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 13 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

In the range up to 80W, there is no need to use a bypass diode; the current depends on C

out

in addition

with possible start current on the load. In case of C

out=

47µF there is a max. current about 9A in a time

window of 4ms. The rectifier, inductors and boost- diode (R

sense

– PE4301) can handle it for such a

short time.

Figure 4: Bypass Rectifier

5 Description

The EVA4301-80 was designed to help understand and evaluate the features of the PE4201/PE4301

Power Factor Correction IC. Used external devices are standard components chosen for safe operation

and do not represent a completely fine-tuned OEM application. The BOM (bill of material) for a final

application may look slightly different.

The PE4201 is a wide input range controller IC for active power factor correction converters in CRMode

with voltage mode PWM control.

The PE4301 is a wide input range controller IC for active power factor correction converters in CCMode

with voltage mode frequency and PWM control.

Please take caution since the board operates at 405V DC.

V

IN

V

OUT

D

BYPAS

D

BOOST

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 14 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

5.1 Evaluation Board Specifications

AC Line Input voltage ...................................... 85 Vac - 265 VAC

AC Line Frequency .......................................... 47 – 65 Hz

Switching Frequency in the middle .................. 40 – 170 kHz

Output voltage .................................................. 340- 405V DC

Output Load ..................................................... max. 80W

Over Voltage Threshold ................................... 416V DC

Efficiency (@230V / 80W) ................................ 92%

Power Factor (@110V / 80W).......................... 0.965

Power Factor (@230V / 80W).......................... 0.990 (PE4301),

......................................................................... 0.988 (PE4201)

Operating Ambient Temp Range ...................... 0 – +40 °C

5.2 Wire bridges

The board has been designed to provide evaluation support for the PE4301 as well as the PE4201 PFC

ICs. For that reason the following wire bridges and components will have to be set properly.

PE4201 PE4301

JP1 2_3 1_2

JP2 1_3 1_2

R2*, R11*, C12* on Board open

R7**, C11**, R23** Open on Board

R

Sense

4x1.0Ώ/0.1W 3x4.7Ώ/0.5W

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 15 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

5.3 Schematic

Figure 5: Board Schematic

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 16 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

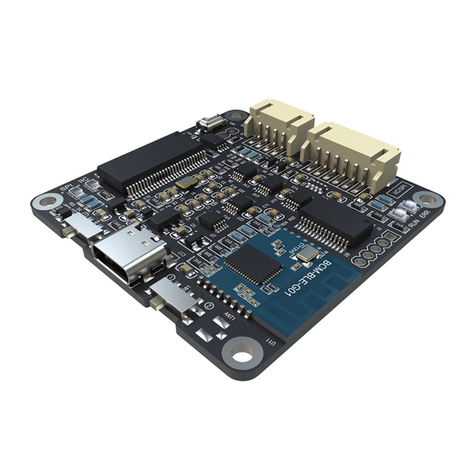

5.4 Component Placement

Figure 6: Board device population

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 17 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

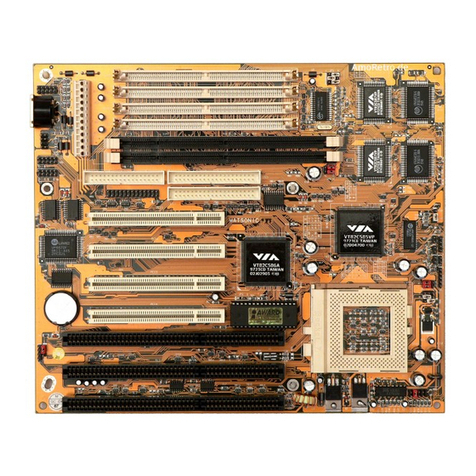

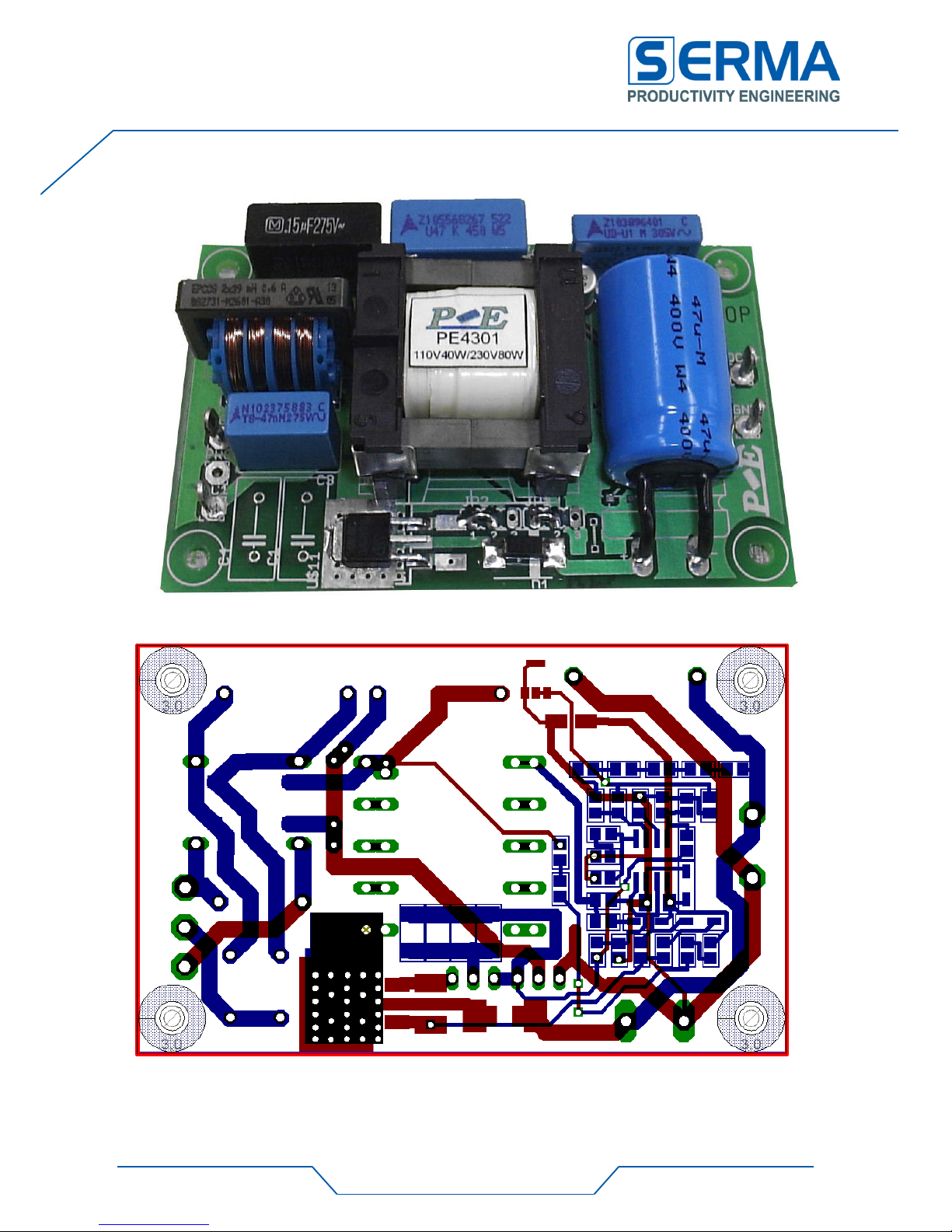

5.5 Board Picture and Layout

Figure 7: Board photograph (8cm x 5cm)

Figure 8: PCB Layout

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 18 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

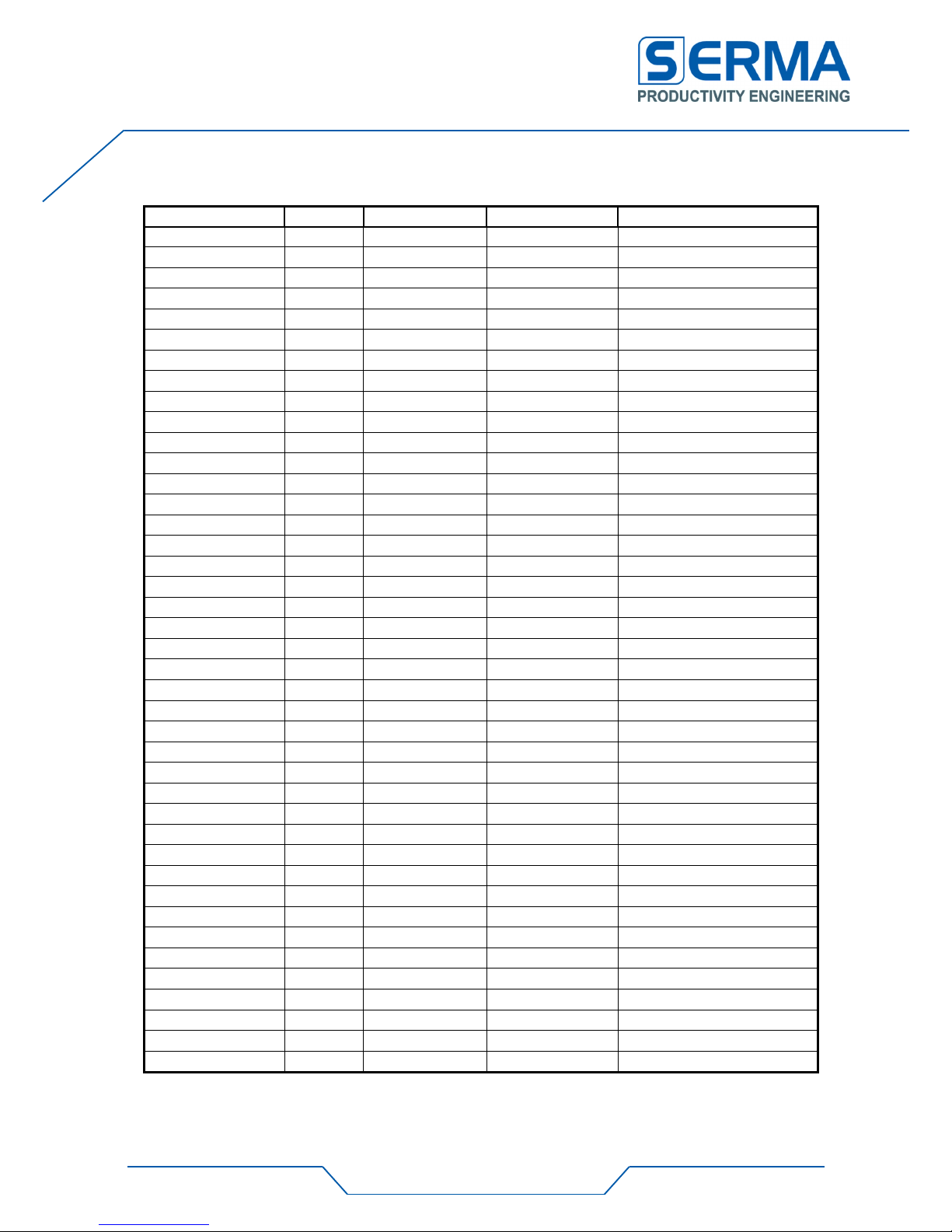

5.6 Bill of Material

Nr.

Reference

Used

Description

/Package

Vendor

IC

1

PE4X01_SO08

PE4X01_SO08

PE

4201

or

PE

4301

C1,C4

2

2.2n/3kV

C2N2

Res. f. Prot. Earth

C2

1

150n/250V~

C150

-

084X183

C3

1

47n/250V~

C102

-

064X133

C5

1

470n/400V

C150

-

084X183

C6

1

100n/630V

C15B6

C7

1

100n

C1206K

C8

1

10µ/35V

153CLV

-

0405

C9

1

4,7n

C0805

C10

1

220n

C0805

C11

**

1

100p

C0805

not for

PE

4201

C12*

1

100p

C0805

not for

PE

4301

C13

1

47µ/400V

VRH

horizontal

D1

1

ES1H

SMC

D2,

D3

2

MMSD914T1G

SOD123

D4

1

Res ZD 25V

SOD123

R1

1

4.7

Ω

R0805

R2, R3, R4, R5, R10, R14

6

330k

R0805

R2*

1

2k

R0805

not for

PE

4301

R6, R7, R8, R9

4

470k

R0805

R7**

1

10k

R0805

not

for

PE

4201

R11, R19

2

10k

R0805

R12

1

4.7

-

6.8

Ω

R0805

optimi

ze for

FET

R13

1

18

-

56

Ω

R0805

optimize for FET

R1

1

, R1

5

, R

16

, R2

0

,

4

1

Ω

/4.7

Ω

R0805

/

R

2010(

PE

4301

)

dep. on max. power

R17

1

100k/180k

R0805

PE

4201

/

PE

4301

R18

1

5.6k

R0805

R21

1

Res (5k adjustable r.)

PC25

adjust DC

-

OUT

R23

1

100k

R0805

R24

1

Re

s (tbd)

R0805

alternativ for R21

fixed

U$1

1

B40S

B40S

rect. 1A/400V

U$2

1

B82731S

B82731S

39mH filter

EPCOS®™

U$3

1

E_25 (EPCOS)

E25L

AL=91nH/n²

U$4

1

N2881

N2881AL

Coilcraft®™

only for 110V

U$5

1

SPD07N60S5

DPAK

U$11

1

IRF840

D2PAK

$2

1

47µ/400

V

VRH

horizontal

$0000

1

PE4X01_SO08

PE4X01_SO08

PE

4201

or

PE

4301

C1,C4

2

2.2n/3kV

C2N2

Res. f. Prot. Earth

C2

1

150n/250V~

C150

-

084X183

C3

1

47n/250V~

C102

-

064X133

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 19 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

6 Operating

6.1 Caution

The Evaluation board has been designed to operate between 40VAC and 80VAC input power grid

voltages and 405VDC output voltage.

Powering the board outside specified operating conditions will destroy devices and might cause severe

damage and harm people.

The board has been designed for a maximum load of 80VA. Overloading the output will cause

overheating and destruction of devices.

Devices can heat up to 50°C in normal operation mode. Take caution to not burn your fingers.

Security measures for high voltage operation have to be taken.

6.2 Load

Resistive and electronic continuous loads up to 80VA at 450VDC can be applied on the output. The load

can be applied on the DC-OUT terminal. Pay attention to the polarity and wire diameter.

6.3 AC-Input

The Input voltage has to be applied on the AC-IN terminal. An isolation transformer is required,

especially when other power grid supplied measurement devices (oscilloscope, voltmeter) are being

used to prevent from electrical shock or device damage. Avoid personal contact with the board when

powered. Be aware that capacitors hold charges even when power will be turned off. Discharge the

output capacitor through the load or a high ohmic load resistor after power off.

6.4 Power-up Sequence

Before input voltage will be turned on, all measurement devices should be connected. It is

recommended to slowly turn up the input voltage with a regulation transformer, usually in combination

with a separation transformer. Be aware that capacitors hold charges even when power will be turned

off. Make sure they will be discharged before disconnecting the measurement devices.

The board has no explicit measuring points. You can measure on the IC.

Pin of IC

7 GND: Ground, reference potential for all measuring points

5 VDD: supply voltage for PE4201/4301, 0..30VZC

8 AC (PE4201): help winding voltage through 2kOhm, -50..25V

8 CS (PE4301): negative voltage of current sensor (-0,9.. -1,2V)

3 RG (PE4201): voltage on RG, 1,03V (internal reverence)

3 FQ (PE4301): voltage on FQ, 1,03V (internal reverence)

1 VCO: voltage on output of regulation amplifier, 0 ... 5,5V

4 SH (PE4201): voltage over Shunt resistor, 0 ... 0,5V

4 RV (PE4301): adjust slew rate of the duty cycle

2 IN: voltage in loop back, V

OUT

/160, 2,50 ... 2,65V

6 G: voltage at IC-Pin G, power-MOSFET Gate driver voltage, typical 0 ...

8,5V

Vout: DCout +

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 20 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

7. List of Abbreviations

Abbreviation

Explanation

AC

-

IN

Input Voltage

AC

Lin

Input Current

BOM

Bill of material

CCM

C

on

tinuous

Conduction Mode

C

EMI

Capacitor for EMI

C

G

Capacity of the gate (M

O

SFET)

C

HF

Capacitor for

reduction of HF

-

tran

smitting

C

out

Output Capacitor

C

out2

Output Capacitor

C

SP

Cap. For

C

VVD

Cap. On Pin VDD

C

Z

Cap. On Current Sense

CRM

Critical Conduction Mode

D

BOOST

Boost

-

Diode

D

BYPASS

Bypass

-

Diode

DCM

Discontinuous

Conduction Mode

DC

-

OUT

Output Voltage

EMI

Electromagnetic Interferences

ESR

Equivalent series resistance

G

Output to Gate

(MOSFET)

IN

Feedback

-

Input for Output

-

Voltage

I

OCP

Max. Current for switching of MOSFET

I

VCOmax

Max. VCO

-

Voltage

I

VDD

IC

-

Current

L

(CCM)

Inductivity in CCM

L

(CRM)

In

ductivity in CRM

L

EMI

Inductor to reduce EMI

PFC

Powerfactor

-

Correction

P

in

Input

-

Power

P

out

Output

-

Power

PWM

Puls

e

-

Width

-

Modulation

R

G

Clamping Resistor

R

STUP

Start

-

Up Resistor

R

tFALL

Fall

-

Time of Voltage on Gate

R

tRISE

Rise

-

Time of Voltage

on Gate

THD

Total Harmonic Distortion

TR

Transformation Ration

t

VDD

Time for Starting the

IC

U

Gmax

Max. Voltage on Gate

VCO

Voltage Controlled

Oscillator

V

CSPCP

Voltage of

Peak

-

Current

-

Protection

VDD

Operating Voltage of the IC

V

in

Voltage on Pi

n “IN”

V

LO

Lock Out Voltage

V

out

Output Voltage

V

RREF

Internal Reference

of the IC

V

SHPCP

Max. Voltage on Input Current Protection

V

ST

Start UP Voltage

This manual suits for next models

1

Table of contents