Servo Dynamics DigiDrive 2000 Series Quick setup guide

Servo Dynamics Corp.

28231 Avenue Crocker, Ste 10

Valencia, CA. 91355

PH: (818) 700-8600

DigiDrive

I

NFORMATION

M

ANUAL

2000

/

4000

DigiDrive Manual Series 2000 / 4000

Rev

.

A 10-99

Pg

2

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

CHAPTER A DESCRIPTION AND TECHNICAL DATA 6

1. INTRODUCTION 6

2. DESCRIPTION 6

3. TECHNICAL DATA 7

3.1

GENERAL DATA FOR ALL TYPES 7

3.2

ELECTRICAL DATA 8

3.3

SMALL DRIVE OUTLINES 10

3.4

MEDIUM DRIVE OUTLINES 11

3.5

LARGE DRIVE OUTLINES 12

3.6

SMALL AND MEDIUM WITH SPECIAL CLAMP TYPE PHOENIX (OPTION) 13

3.7

MOTORS 14

3.8

POSITION FEEDBACK 14

4. FUSES 15

5. OPTION LIST 15

6. ADD-ON BOARDS 16

7. EXTERNAL MODULES 17

Contents

DigiDrive Manual Series 2000 / 4000

Rev

.

A 10-99

Pg

3

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

CHAPTER B USER UTILITIES 19

1. DOS USERS 19

1.1

FPRGU.EXE : FLASH PROGRAMMING USER 19

1.2 2000U.EXE : 2000 USER 20

2. WINDOWS USERS 21

2.1

2000WU.EXE : 2000 WINDOWS USER 21

3. SERIAL LINK 23

3.1

DIALOGUE PROTOCOL 23

3.2

DIALOGUE EXAMPLES 25

CHAPTER C DRIVE PARAMETERS 26

1. PARAMETERS DESCRIPTION 26

1.1

GLOBAL LIST OF PARAMETERS 27

1.2

SCOPE PARAMETERS 34

CHAPTER D SETTING TO WORK 35

1. WIRING 35

1.1

CABLE LENGTHS AND CROSS-SECTIONS 35

1.2

GLOBAL WIRING PLAN 36

1.3

CONTROL UNIT WIRING 37

1.3.1 XRESOLVER 38

1.3.2 XCOMMAND 39

1.3.3 XENCODER 40

1.3.4 XSERIAL 232 AND XSERIAL 485 41

1.3.5 AXIS SELECTOR 43

DigiDrive Manual Series 2000 / 4000

Rev

.

A 10-99

Pg

4

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

1.4

XMOTOR CONNECTOR 43

1.4.1 DETERMINING THE MOTOR PHASES (WITHOUT DRIVE) 44

2. DISPLAY INDICATIONS 45

2.1

ALARMS 46

2.2

WARNINGS 47

3. PARAMETERS SETTINGS 48

3.1

MOTOR PARAMETERS 48

3.1.1 EXAMPLE OF MOTOR PARAMETERS 50

3.2

INSTALLATION PARAMETERS 51

3.2.1 ENCODER CONFIGURATION 52

3.2.2 END-SWITCH CONFIGURATION 54

3.2.3 SSI CONFIGURATION (OPTION) 54

3.2.4 GENERAL CONFIGURATION 55

3.3

REGULATION PARAMETERS 57

3.3.1 CONFIGURATION 57

3.3.2 CURRENT LOOP 58

3.3.3 SPEED LOOP 60

4. HOW TO SET THE PARAMETERS 61

4.1

HOW TO SET THE RESOLVER SHIFT ANGLE PARAMETER 63

4.2

HOW TO SET THE CURRENT LOOP PARAMETERS 65

4.3

HOW TO SET THE SPEED LOOP PARAMETERS 67

5. TROUBLE SHOOTING 69

CHAPTER E ASYNCHRONOUS MOTOR 73

1. CHANGE OF MOTOR AND FEEDBACK TYPE 73

2. SPECIAL PARAMETERS FOR ASYNCHRONOUS MOTORS 73

Pg

6

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

CHAPTER A DESCRIPTION AND TECHNICAL DATA

The servo-amplifiers series 2000 and 4000 are intended for the control of 3 phases brushless

servo-motors equipped with resolver and asynchronous servo-motors equipped with resolveror

encoder.

To avoid any confusion, the motors regulated by the series 2000 and 4000 servo-amplifiers

should have the following characteristics:

Rotor constructed with permanent magnets or winding cage arranged in 1, 2, 3, 4, 5 or

6 pole pairs, without commutator.

Stator constructed with 3 windings connected in star or delta.

Brushless motors : electronic commutation is only effected by means of a speed one

resolver (motors with Hall effect sensors and tachogenerator are not suitable).

Asynchronous motors : electronic commutation is only effected by means of a speed

one resolver or an incremental encoder.

The servo-amplifier series 2000 and 4000 are fully digital. High-performance torque, speedand

positioning control fulfils all requirements for rapid response and control accuracy.

Digital control allows comprehensive diagnostics, motor parameters tuning, data andfault

logging, etc.. using a PC based user program.

A wide range of firmware assures that it will meet the requirements of practically anyapplication.

The particular features of the servo-amplifiers series 2000 and 4000 are described there under:

Power supply

Single-Axis unit incorporating a braking module for connection to 3 phase power. The

drive also can be run from a common DC-bus voltage.

2. Description

1. Introduction

Pg

7

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

Series 2000: 230V three-phase power source.

Series 4000: Direct 400V three-phase main supply.

Option: Internal filters in power source reducing noise emission.

Power driver

Galvanic isolation between control and power electronics.

IGBT output stage.

Digital PWM current loop provides very low ripple motor currents and high motor

efficiency.

Digital controller

Full-digital servo-amplifier for Brushless motor with resolver.

Software updates are fully programmable through serial link RS232 or RS485.

Accepts customised network INTERFACE boards.

Energy managing system for fan-cooling.

Multi loop control (torque and speed).

Sinusoidal current output ensures smooth torque and optimal performance at low

speed.

7 segment status indicator for diagnostic display.

User's inputs

Analogue speed or current input command +/- 10V or digital input command.

RS232 serial port and RS485 serial port for multi axis controller system.

Limit switches for overrun protection in both directions.

External power supply to the Control and Interface boards to keep position data and

alarms in case of main power supply interruption.

User's outputs

Incremental encoder output simulation with adjustable resolution from 1 to 2048 ppr

and adjustable marker pulse. Differential line driver outputs.

Ready relay contact.

Protections

Protection and rugged construction for use in adverse conditions.

Power stage fully protected against short-circuit and over-temperature.

Motor protection by I2t limitation.

Detection of resolver fault, motor wiring failure, motor overheating.

3.1 General data for all types

Description

Unit

Series 2000

Series 4000

3. Technical data

Pg

8

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

Supply Voltage

VAC

3x230 +10% -20%

3x400 +10% -20%

Supply frequency

Hz

45 to 65

Operating temperature range

° C

0 to 60

Operating temperature range at full power

(from 45°C, reduce output current by

2% / °C to 60°C)

° C

0 to 45

Storage temperature range

°C

-25 to +55

PWM chopper frequency

kHz

7.5

Differential input reference

V

+ 10 to -10

Speed control range

1/32768

Speed loop bandwidth

Hz

max. 150

Current loop bandwidth

Hz

max. 2000

Max. output voltage tomotor

V

3 x 220

3 x 390

Output frequency to motor

Hz

0 to 500

Incremental encoder simulation

ppr

1 to 2048

Theoretical max. speed for motor with resolver

"speed one"

rpm

7500

ON-Switching threshold of brake module

VDC

385

670

OFF-Switching threshold of brake module

VDC

380

660

ON-Trip threshold of overvoltage

VDC

410

710

OFF-Trip threshold of overvoltage

VDC

400

690

OFF-Trip threshold of undervoltage

VDC

230

395

ON-Trip threshold of undervoltage

VDC

220

380

Serial link

Standard baud rate

Bd.

9600

Transmission

Full duplex

Format

1start bit, 8 data bits, no parity, 1 stopbit

International Protection

IP20

Indicative weight

kg

Small: 3.2, Medium: 6.1,Large:10.5

3.2 Electrical data

Driv

e

Size

Drive

Model

Number

Rated rms

Current

(I rms)

Rated pk.

Current

(I peak rated)

Max. rms

Current

(I rms max)

Max. peak

Current

(I peak max)

Rated

power

(P rated)

Max.

Power

(P max)

Pg

9

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

(A)

(A)

(A)

(A)

(kW)

(kW)

DSSA 0510-34

5

7

10

14

2

4

DSSA 1020-34

10

14

20

28

4

8

Small

DSSA 1836-34

18

25

36

50

7

14

DSSA 0306-56

3

4

6

8.5

2

4

DSSA 0510-56

5

7

10

14

3.5

7

DSSA 0918-56

9

13

18

25

6

12

Medium

DSSA 2040-56

20

28

40

56

13.5

27

Large

DSSA 2040-56

20

28

40

56

13.5

27

DSSA 3060-56

30

42

60

84

20

40

Note:

Irms = Ipeak / 1,41 Vrms = 220V or 390V

P = 1,73 x Irms x Vrms

or

P = 3 x Irms/phase x Vrms/phase

Braking power :

Driv

e

Size

Drive

Model

Number

R braking

()

Peak

braking

Power

(W)

Max.

continuous

braking power

(W)

Surge energy

(T=300K)

(J)

DSSA 0510-34

39

3’800

150

1’800

DSSA 1020-34

39

3’800

150

1’800

Small

DSSA 1836-34

39

3’800

150

1’800

DSSA 0306-56

56

8’000

250

2’600

DSSA 0510-56

56

8’000

250

2’600

DSSA 0918-56

56

8’000

250

2’600

Medium

DSSA 2040-56

20

22’000

500

5’200

Large

DSSA 2040-56

11

41’000

1’000

21’000

DSSA 3060-56

8

56’000

1’000

24’000

The surge energy rating is the maximum permitted dynamic brake application from cold. To a

first approximation, heat is then removed at the rate given by the continuous power figure : thus

about 20 seconds interval must be allowed between full energy stops.

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

Pg

10

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

Dis

position

Air f

low

3.3 Small drive outlines

Rear mounting Enclosure mounting

Installation, drill and cut out plan :

Rear mounting Enclosure mounting

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

Pg

11

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

3.4 MEDIUM DRIVE OUTLINE

Enclosure mounting

Installation, drill and cutout plan :

Rear mounting Enclosure mounting

Rear mounting

Dis

position

Air f

low

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

Pg

12

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

3.5 LARGE DRIVE OUTLINE

Rear mounting Enclosure mounting

Installation, drill and cutout plan :

Rear mounting Enclosure mounting

Dis

position

Air f

low

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

Pg

13

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

3.6 Small and Medium with special clamp type Phoenix (option)

Drill and cutout plan for enclosure mounting : Phoenix clamp

type SK8

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

Pg

14

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

3.7 Motors

D

Brushless3phasesservo-motors

D

Asynchronous,3phasesmotors

3.8 Position feedback

D

Resolver:

Characteristics :

Speed One (1 sine period and 1 cosine period per revolution)

Ratio 0.5

Reference frequency : 5..10 kHz

D Incremental encoder for asynchronous motor only.

D Absolute encoder Stegmann SinCos (HIPERFACE compatible).

D Absolute encoder Stegmann SinCoder (HIPERFACE compatible).

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

Pg

15

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

The following are the fuses equipped in the appropriate Drive Models.

Drive

Size / Model

DC-BUS (FBUS)

Braking module (FBR)

Internal Power Supply

(FDEC)

DSSA

0510-34

10A LF326

Littelfuse 6.3 x32

3.15A Wick.

19354

6.3 x 32

(Rbrak.=39)

1A WICKM.

19181

5 x 20

DSSA

1020-34

15A LF326Littelfuse

6.3 x 32

3.15A Wick.

19354

6.3 x 32

(Rbrak.=39)

1A WICKM.

19181

5 x 20

DSSA

1836-34

20A LF326

Littelfuse

6.3 x 32

3.15A Wick.

19354

6.3 x 32

(Rbrak.=39)

1A WICKM.

19181

5 x 20

Small

DSSA

0306-56

8A gG

Ferraz

10.3 x 38

500VFA 4A

Ferraz

6.3 x 32

(Rbrak.=56)

1A WICKM.

19181

5 x 20

DSSA

0510-56

8A gG

Ferraz

10.3 x 38

500VFA 4A

Ferraz

6.3 x 32

(Rbrak.=56)

1A WICKM.

19181

5 x 20

DSSA

0918-56

25A gRB

Ferraz

10.3 x 38

500VFA 4A

Ferraz

6.3 x 32

(Rbrak.=56)

1A WICKM.

19181

5 x 20

Medium

DSSA

2040-56

40A URGB

Ferraz

14 x 51

12.5A gRB

Ferraz

10.3 x 38

(Rbrak.=20)

1A WICKM.

19181

5 x 20

Large

DSSA

2040-56

40A URGB

Ferraz

14 x 51

25A URGB

Ferraz

14 x 51

(Rbrak.=11)

1.6A WICKM.

19354

6.3 x 32

DSSA

3060-56

50A URGA

Ferraz

22 x 58

32A URGB

Ferraz

14 x 51

(Rbrak.=8)

1.6A WICKM.

19354

6.3 x 32

Notes:

No replacement of any fuse should be carried out until the reason for it’s blowing has been

rectified.

5. Option list

4. Fuses

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

Pg

16

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

1. FILTER ON 3 PHASES INPUT SUPPLY

2. MECHANICAL MOTOR BRAKE RELAY

3. RS485 BUS

4. AUXILIARY 24V SUPPLY.

D

SDCPROFILE

Add-on board to perform simple movements and interfacing with 24V systems

(PLS).

Main characteristics :

24 V powered.

DC-DC conversion for drive power back-up

(the position value is kept when main supply of the drive is switched off).

14 Outputs potential free (24V 100 mA).

16 Inputs 24V potential free.

Windows Profile User software for easy setting.

To obtain more information about Profile board, contact your SDC distributor.

6. Add-on boards

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

Pg

17

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

D SDC IR115 / IR116 / IR117

Synchro-Control, positioning and CANopen interface modulefor

SERVO DYNAMICS Series 2000 and 4000 drives.

D

SDC SERVO net

Positioning control and SERVOnet (CAN-BUS type) interfacing module for

Servo Dynamics series 2000 and 4000 drives.

D

Future product :

Chip card module for parameters saving.

7. External modules

Chapter A - Descrip

tion

an

d

T

ech

ni

cal Data

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

Pg

18

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

D

SDC,RS232<->RS485converter

Main characteristics :

Connection of 1..15 drives to a RS232 interface (i.e. computer).

24 V powered.

RS232 header pinout same as drive XSERIAL232 header.

RS485 header pinout same as drive XSERIAL485 header.

Mounting on current DIN EN Profiles (Phoenix type UMK-FE).

To obtain more informations about

RS485-RS232 converter, contact

your SDC distributor.

Distributed by :

Official SDC distributors.

Pg

19

Servo Dynamics Corp. 21541-D Nordhoff

St.

Chatsw

orth,

CA 91311 www.servodynamics

.

com

Chapter B - User

utilities

Rev

.

A 10-99

DigiDrive Manual Series 2000 / 4000

CHAPTER B USER UTILITIES

This section of the manual describes the use of customer utilities. The software is for PC

compatible computer.

Two softwares are necessary for DOS users : FPRGU.EXE and 2000U.EXE

This software is used for updating FLASH memory, which contains the drive firmware.

For example, when a new firmware is developed, FPRGU.EXE is able to transfer it to the drive.

With this software, it is also possible to check the FLASH contentsintegrity.

Use of FPRGU.EXE

Connect RS232 Drive connector to the COM1 of the computer with a AT-Link cable. Verify that

the axis selector is on 0 and start the following sequence :

FPRGU <ENTER> Start software

M

Call Monitor function of the drive

T

Transfer

IRTxxxx.HEX <ENTER> Name of the file to transmit

Wait end of operation

I

Initialise (Reset command)

The drive is ready to work with new firmware

1.1

FPRGU.EXE

:

Flash

PRoGramming

User

1. DOS Users

This manual suits for next models

9

Table of contents

Popular DC Drive manuals by other brands

Delta Electronics

Delta Electronics Network Device VFD-S user manual

TeMec Drive

TeMec Drive AZ2 user manual

Sony

Sony DRU-880S operating instructions

GFA

GFA ELEKTROMAT SI 60.55 FU-55,00 installation instructions

Ewellix

Ewellix CLSM-92-T Installation, operation and maintenance manual

Arkel

Arkel ADrive VVVF user manual

Parker

Parker PDHX-E Series user guide

ABB

ABB ACQ580-31 Series Quick installation and start-up guide

Minarik

Minarik MM21036A installation guide

Danfoss

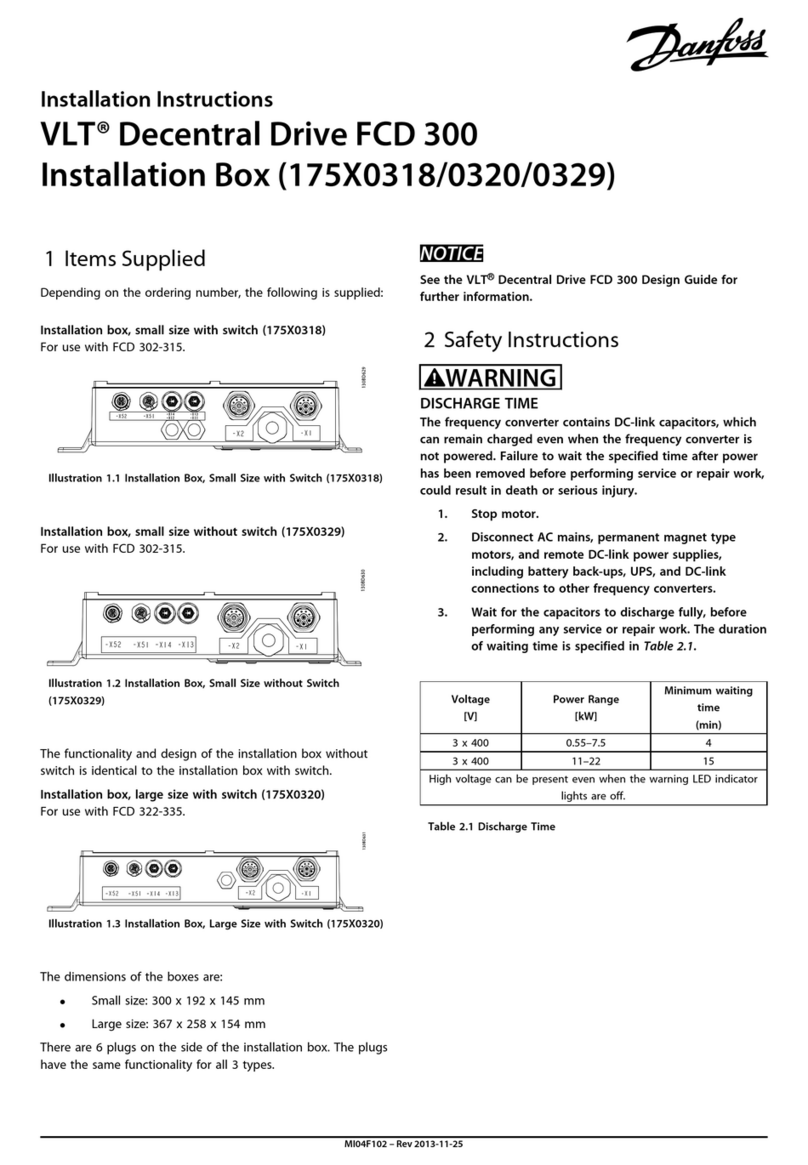

Danfoss VLT Decentral FCD 300 installation instructions

Aumuller

Aumuller ferralux KSA Series Mounting instructions

US drives

US drives PHOENIX Series instruction manual