Servpro 879 User manual

13/10 revised 11/11 Form No. 56041937

MODEL 879

EXTRACTOR

120V

INFORMATION

&

OPERATING

INSTRUCTIONS

CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ

ALL SECTIONS OF THIS INSTRUCTION MANUAL

IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

1. Always use a defoamer when foaming occurs to prevent vacuum motor damage.

2. Connect the machine to a properly grounded outlet.

3. Keep machine from rain, snow, and extremes in temperatures. Store the machine in a

heated location. Use the machine indoors. Do not use outdoors.

4. Use approved chemicals only. NO SOLVENTS.

5. Wear gloves or use rags when removing quick disconnects to prevent burns.

6. Never use water above 130° F/54° C in the solution tank.

7. Never turn on the solution pump without your solution line connected to both the

machine and the tool.

2

WARNING!

To reduce the risk of fire, electric shock, or injury:

•Do not leave the machine unattended when it is plugged in. Unplug the unit from the outlet when

not in use and before servicing.

•Never turn on the solution pump without first connecting either the priming hose or your solution

hose to your machine and to your tool.

•Always turn off the pump and release the pressure in the pump before disconnecting hoses

•Never add water over 130° F/54° C to the solution tank.

•Always use chemicals or water with a pH between 5 and 10.

•Extension cords must be 12/3 and no longer than 50 feet. Replace the cord or unplug immediately

if the ground prong becomes damaged.

•To avoid electric shock, do not expose to rain or snow. Use and store indoors.

•Do not allow to be used as a toy. Close attention is necessary when used near children.

•Use only as described in this manual. Use only the manufacturer’s recommended attachments.

•Do not use with damaged cord or plug. If the machine is not working as it should, has been dropped,

damaged, left outdoors or dropped into water, return it to a service center.

•Do not pull by the cord, use the cord as a handle, close a door on the cord, or pull the cord around

sharp edges or corners. Do not run the machine over the cord. Keep the cord away from heated

surfaces. To unplug, grasp the plug, not the cord.

•Do not handle the plug, the cord, or the machine with wet hands.

Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint,

hair, and anything that may reduce air flow.

•Keep loose clothing, hair, fingers, and all parts of body away from openings and moving parts.

•Do not pick up anything that is burning or smoking, such as cigarettes, matches, hot ashes, or any

health endangering dusts. Do not use to pick up flammable or combustible liquids such as gasoline

or use in areas where these liquids may be present.

•Turn off all controls before unplugging.

•Use extra care when cleaning on stairs.

•Connect to a properly grounded outlet only.

•Liquid ejected at the spray nozzle could be dangerous as a result of its temperature, pressure, or

chemical content.

IMPORTANT SAFETY INSTRUCTIONS

This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories, shops,

and offices. The Advantage 1200 is not intended for normal residential housekeeping purposes.

NOTE: Read all instructions before using this machine.

When using any electrical appliance, basic precautions should always be followed, including the following

warnings

FORM NO. 56041937 - SERVPRO 879

3

Serial Number: __________________

Model: #879 ADVANTAGE 1200

Purchase Date:_____________

Write the name and phone number of your

distributor: _____________________________

_______________________________________

INSPECTION:

Carefully unpack and inspect your 879 for shipping damage. Each machine is tested and inspected

before shipping. Any shipping damage incurred is the responsibility of the carrier. You should notify the

carrier immediately if you notice damage to the box, the machine, or its parts.

CLEANING SOLUTIONS:

We recommend liquid cleaning chemicals. Powder chemicals may be used, but unless mixed very thoroughly

they could cause a build-up in the pump, lines, and quick disconnects. Any problem caused by a chemical

build-up is not covered by warranty. Use a neutral cleaner with a pH between 5 and 10 to avoid premature

wear of the pump, seals, and/or other components. It is a good idea to test an inconspicuous area of

the floor.

MAINTENANCE:

For optimum performance flush the machine with clear water at the end of each working day. Once a

month, minimum, run a flushing compound through the machine to break up any mineral or chemical build-

up that may have formed. The vacuum motor and the pump do not require any scheduled maintenance;

however, the motor may require replacement brushes after 1000 - 1500 hours. Clean the body with an

all-purpose detergent, and protect it with an automobile interior polish. Lubricate the wheels, castors,

and quick disconnects with an all purpose silicone spray.

PARTS AND SERVICE:

Repairs, when required, should be performed by your Servpro distributor who maintains an inventory of

original replacement parts and accessories. Call the distributor from whom you purchased this machine if

you need parts and service. Be sure to specify the machine model. Have your serial number handy.

DANGER: DO NOT USE SOLVENTS, OR ANY CHEMICALS

THAT MAY BE FLAMMABLE, EXPLOSIVE, OR COMBUSTIBLE.

FORM NO. 56041937 - SERVPRO 879

4

AUTO PUMP OUT SWITCH (3):

This switch will turn on the automatic pump-out pump and it will illuminate when it is activated.

SOLUTION PUMP SWITCH (4):

The solution pump switch will turn on the solution pump and the switch will illuminate when it is

activated. The output pressure of this pump is adjustable through the unloader valve. Refer to the

drawing below, and to the Operation Instructions.

GREEN, TWO CIRCUIT INDICATOR (5):

This light will automatically turn on when you have plugged the two power cords into separate circuits.

If this light does not turn on, try other outlets with one of the cords until the light does turn on.

NOTE: All systems in the machine may operate if this light does not turn on, but you may trip a circuit

breaker in the wall.

SWITCH PLATE

Switches

12” Wheel

Castor

Recovery Tank

Lid

Vacuum Hose

Connection

Recovery

Tank

Drain

Solution Tank

Access

Solution

Output

YOUR MACHINE

MODEL (1):

This identifies the model of your

machine.

VACUUM SWITCH (2):

This push-button switch turns

on the vacuum. The switch will

illuminate when it is on.

III

MODEL

O

O

O

34

5

12

Power Cord

Pigtails

Pump-out Hose

Connection

Auto-fill

Hose Connection

Pressure

Adjustment Cap

Pressure Relief Valve

(inside base

compartment)

FORM NO. 56041937 - SERVPRO 879 revised 11/11

5

SET-UP & OPERATION

1. Before each use, inspect the machine, hoses, and cleaning tools for cleanliness and completeness.

Make sure hoses are in good condition and the spray nozzle(s) is tight.

2. If not using the auto-dump feature, just make sure the brass cap is on the drain hose connector on the

front of the base of the machine.

If you choose to use the auto-dump feature, remove the brass cover on the hose connector on the

front of base of the machine, attach a hose, and place the open end of the hose in a drain. Make sure

the recovery tank drain gate is closed, and the lid is tight on the recovery tank.

3. If you choose not to use the auto-fill feature, just fill the tank with water and cleaning

chemical. Follow chemical directions regarding dilution and mixing. Do not use harsh chemicals; they

may damage seals in pumps and valves, and cause the pump to wear prematurely. .

If you choose to use the auto-fill feature, connect the fill hose to the auto-fill connector (located over

the solution tank fill hole). Turn on the water source -- HIGH PRESSURE IS NOT NECESSARY -- and

allow the tank to fill with water. When using the auto-fill system, the auto-fill float will automatically

turn on and turn off as the tank empties and then fills.

NOTE: Never put water with a temperature exceeding 130 °F / 54 °C in the solution tank

4. Pre-spray the area to be cleaned, with a pump-up sprayer, while the tank is filling. Follow chemical

directions.

5. Plug in the two power cords. Do not connect both cords to the same outlet. The green, ‘separate

circuit locator light (1) on the switch plate should light up. If the locator light does not come on,

check the circuit breaker box in the wall, and/or try different outlets until it does turn on. Although all

systems in the machine may work correctly if you are not on two circuits, a circuit breaker in a wall

panel may trip. If you make sure the green light is turned on, you will prevent tripped circuit breakers.

6. Prime the 1200 psi pump: fill the solution tank with water, if not already done, and turn on the pump.

You may notice a ‘tone’ change in the sound of the pump (smoother, with less of a rattle).

CAUTION -- NEVER TURN ON THE SOLUTION PUMP BEFORE CONNECTING YOUR

SOLUTION LINE TO YOUR MACHINE AND TO YOUR TOOL. If the pump builds pressure

before you connect the hose and tool, you will not be able to connect them.

7. Use defoamer to prevent foam.

8. Attach the solution spray hose to the solution quick disconnect. Attach the vacuum hose to the hose

barb on the front of the recovery tank. Connect the other ends of the hoses to the tool.

9. Turn on the vacuum (2) and turn on the dump pump (3). Begin spraying.

10. When the job is finished, turn off the water source. Vacuum the remaining solution from the solution

tank into the recovery tank.

11. Run a few gallons of clean water through the system. Drain the recovery tank by opening the drain

gate over a bucket or drain. Disconnect the hoses from the cleaning tool.

12. Unplug the power cords.

13. Clean the machine and the tool. Never store your machine outside, and keep it from extremes in tem-

peratures.

NOTE: if the green, circuit locator light does not illuminate when the cords are plugged in, then both cords

are on

the same circuit. Try other outlets with one of the cords until you get the locator light to come on.

NOTE: if the heat switch is turned on when both cords are on the same circuit, the breaker in the wall may

trip.

FORM NO. 56041937 - SERVPRO 879

6

1 Operation:

•Attach a 3/4” garden hose to the auto-fill valve, and connect the other end of the hose to your water

source.

• Make sure the float that hangs from the auto-fill valve into the tank is free of obstruction and can

move freely.

• Turn the water supply on.

• The auto-fill float will automatically shut-off the flow of incoming water when the solution tank is

nearly full, and it will allow the valve to open again once the water level has dropped to a predeter

mined level.

AUTO-FILL

1 Operation:

•Before each use: if necessary, unscrew the stainless steel filter at the bottom of the recovery

tank and clean it. Also make sure the float in the recovery tank is clean.

•Attach a 3/4” garden hose to the dump pump outlet fitting on the back of the base of the

machine.

•Run the other end of the hose into a drain.

•Turn ON the dump pump switch (switch is located on the switch panel on the top of the machine).

•NOTE: the dump pump is ‘self-priming.’ You should see water start to flow within 30 seconds of

the pump turning on. If water does not begin to flow, check the filter to see if it is plugged with

debris.

•After each job: run clear water though the dump pump to wash out any chemical residue.

Remove and clean the stainless steel filter in the back of the tank. Reinstall the filter once it is

clean. Clean and empty the recovery tank.

AUTO-DUMP

CAUTION: Use care when handling hazardous chemicals.

CAUTION: Never leave the machine running when you are not actively using it.

CAUTION: always use a defoamer in the recovery tank to prevent water or foam

from entering the vacuum motor.

CAUTION: Always make sure the float cage is clean and the ball can

travel freely before turning on the machine.

AUTO VACUUM SHUTOFF:

When the recovery tank is full, the ball float will shut-off the suction to prevent the machine from

overflowing. NOTE: the float may not work if there is foam in the tank. Always use defoamer to

prevent overflow.

FORM NO. 56041937 - SERVPRO 879

7FORM NO. 56041937 - SERVPRO 879revised 11/11

120V

#879

39

40

40A

48

67

59

50

12

43

O

O

O

1

2

3

4

7

8

14

14A

15 16 17

18

52

29

32A

32

22

22A

25 24

23

33

55

28 34

35

36

37

38

34B

53 53A

34A

58

49

54

56

45 41

42 43

44

46

2169

57

47

61

62

63

64

60

65 28

28

68A

6

68

11

13

211

10B

10

10A

12

70

8

FORM NO. 56041937 - SERVPRO 879 revised 11/11

Item Ref. No. Qty Description

1#903USP 1 Drain Gate

2

#187USP 1 O-Ring

3 187B 2 Washer, rubber

4

#185USP 1 Nut, 1-1/2”

6 907 1 Hose Barb, vacuum inlet

7 1074 1 Gasket

8 2086A 1 Lid with Ring, 6”

56380968 1 O-Ring for 2086A Lid

10 929B 1 Ball Float, vac shut-off

10A 1154A 1 Adapter, ABS trap

10B 1154 1 Adapter, ABS

11#922USP 2 Elbow, PVC, FPT

12#156USP 2 Hose Clamp

13 430 25.5” Hose, vacuum, 2”ID X 25.5”

14 430A 1 Hose, vacuum, 2”ID X 13.5”

14A 4404C 1 Bar, vacuum hose hold-down

15 2167 1 Switchplate, Advantage

[ ] 2167-1200 1 Overlay

16 1623R 3 Switch, push-button, ON/OFF

17 227 1 Green light

18 2069B 1 Filter, inlet 30 mesh

21#31USP 1 Washer, brass

22 1184 1 Adaptor, garden hose

22A 1310A 1 Valve, water inlet

23 1533 1 Connector, hose adaptor

24 1534 1 Elbow, 1” 90º

25 1571 1 Bushing, 1” x 1/2” PVC

28#166USP 4 Hose Clamp

29 1557A 1 Screen, filter

32 2175 1 Lid, Solution tank

32A#805USP 1 Chain, 8”

33 TKC-11 1 Solution tank

34 946 1 Hose, pump inlet, 1/2” ID X 15”

34A 2176 1 Elbow, 1/2” ID, 90º

34B 2177 1 Grommet, rubber

35 925 1 Hose, pump bypass, 3/8” ID X 13”

36 408G 1 Vacuum, 3-stage

Item Ref. No. Qty Description

37 2013 1 Gasket, vacuum

38 MA-6 1 Manifold, vacuum

39#230USP 2 Retainer, cord pigtail

40 2154 2 Pigtail, power cord

40A 2155 2 Power cord, 25 ft

41 801 2 Hinge pin

42#910-1863 1 Axle rod, 18.63”

43 2092 2 Wheel, 12 inch

44#27AUSP 2 Axle cap

45 MPE-3 1 Base, complete

46#905USP 2 Castor

47#56471194 1 Latch

48 909A 1 Catch, for latch

49#459USP 1 Louver, 2-1/2”

50#45USP 1 Quick disconnect

52 VT-35 1 Recovery tank

53#2166 1 Pressure gauge

53A#219USP 1 Quick disconnect

54 FP228A 1 Gasket, 78.5”

55 1603 2 Strap, cord wrap

56 FP630 1 Hose assy, pump intake

57 237 1 Cap with chain, drain hose

58 2067 1 Pump, dump

59 1546 2 Hose barb, two per bag

60 FP636 1 Motor, no pump

61 FP657 1 Pump, complete, no motor

62 FP632 1 Hose, unloader to outlet

63 FP633 1 Unloader valve assembly

64 FP631 1 Hose, pump to gauge

65 946 1 Hose, dump pump inlet, 32”

67 4405A 1 Relay, 25 AMP

68 FP619 1 Pre-filter bag

68A 1140 1 Elbow, 90°, ABS

69#92AUSP 1 Nipple, s/s

70#2195 2 Label Servpro

[ ] 1093A 1 Label Warning

[ ] 4344 1 Label Gauge Priming Warning

* FP618 Pump and motor, complete

* 1160K Pump rebuild kit, valves & O-rings

* 1160A Pump rebuild kit, plunger and seals

* = Optional, Not Included

[ ] = Not Shown

#= Revised or new since last update

Model 879

9

MODEL #879

TROUBLE SHOOTING:

IF THIS OCCURS CHECK THIS

NO SPRAY

PUMP DOES NOT RUN

Solution tank is empty, or filter is plugged up.

Clogged spray tip.

Pump not running.

Valve on wand not operating.

Solution hose not completely connected to hose or to machine.

LOW SUCTION

NO SUCTION

This pump motor runs on DC voltage, and it should start running as soon as you

turn on the switch. If the pump motor does not start running, check the wiring to

the switch, to the bridge rectifier, and to the motor. Check the switch to see if it is

‘open.’ Measure the DC voltage out of the bridge rectifier (should be about 100V).

Debris is plugging cleaning tool or vacuum hose.

Drain gate is not completely closed, or seals are damaged.

Recovery Tank lid is not closed completely or is damaged.

Ball in the float is blocking air flow. Turn off the vacuum so the ball will drop down.

No power to motor. Does the switch light up? If not, the switch may be bad or

there may be no power getting to the switch. Check wiring connections.

Test the switch with a volt/ohm meter.

Test the vacuum motor by connecting it directly to AC.

MAINTENANCE SCHEDULE

CLEAN ALL FILTERS X

FLUSH OUT with DE SCALER

X

DAILY

WEEKLY

MONTHLY

OTHER

CHECK POWER CORD

REPLACE VAC MOTOR BRUSHES

YEARLY

X

Around 1500 hours

REPLACE PRESSURE REGULATOR XOr as needed

REBUILD PUMP Around 1500 hours

FORM NO. 56041937 - SERVPRO 879

SERVPRO INDUSTRIES, INC.

575 AIRPORT BLVD.,

GALLATIN, TN 37066

615-451-0200

NOTES:

MODEL #879

Table of contents

Other Servpro Scrubber manuals

Popular Scrubber manuals by other brands

Alto

Alto 7760 Operator's manual, instruction book and parts list

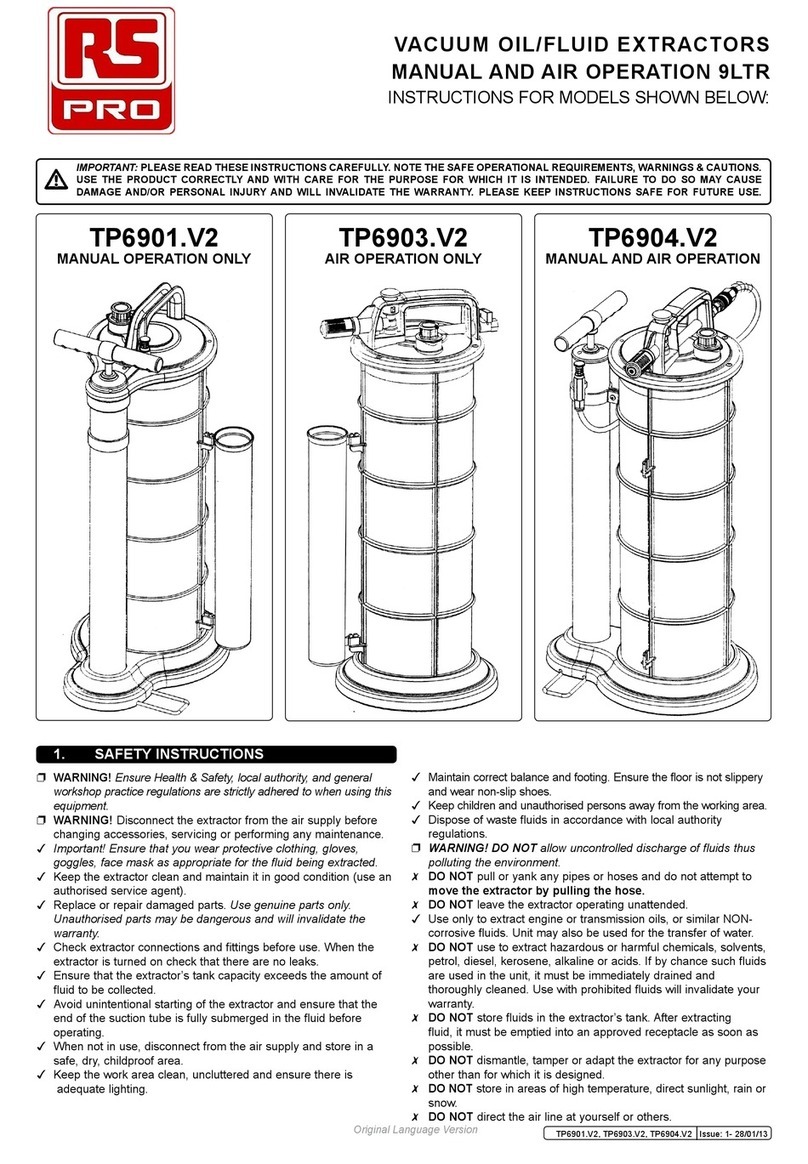

RS PRO

RS PRO TP6901.V2 instructions

Advance acoustic

Advance acoustic Hydro-Retriever 2067 Operator's manual

Kennedy

Kennedy FEP010 instruction manual

Tennant

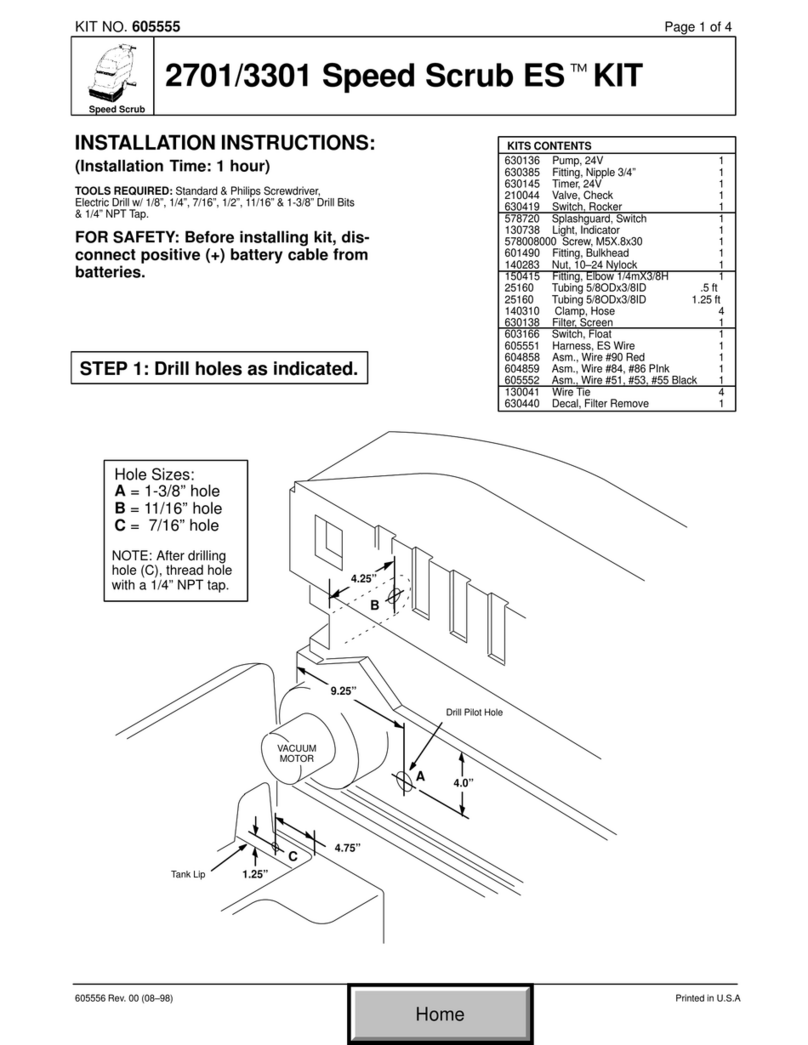

Tennant Speed Scrub ES KIT 2701 installation instructions

Clarke

Clarke CA60 20B Service manual

Dustbane

Dustbane Integra Scrub Parts & operation manual

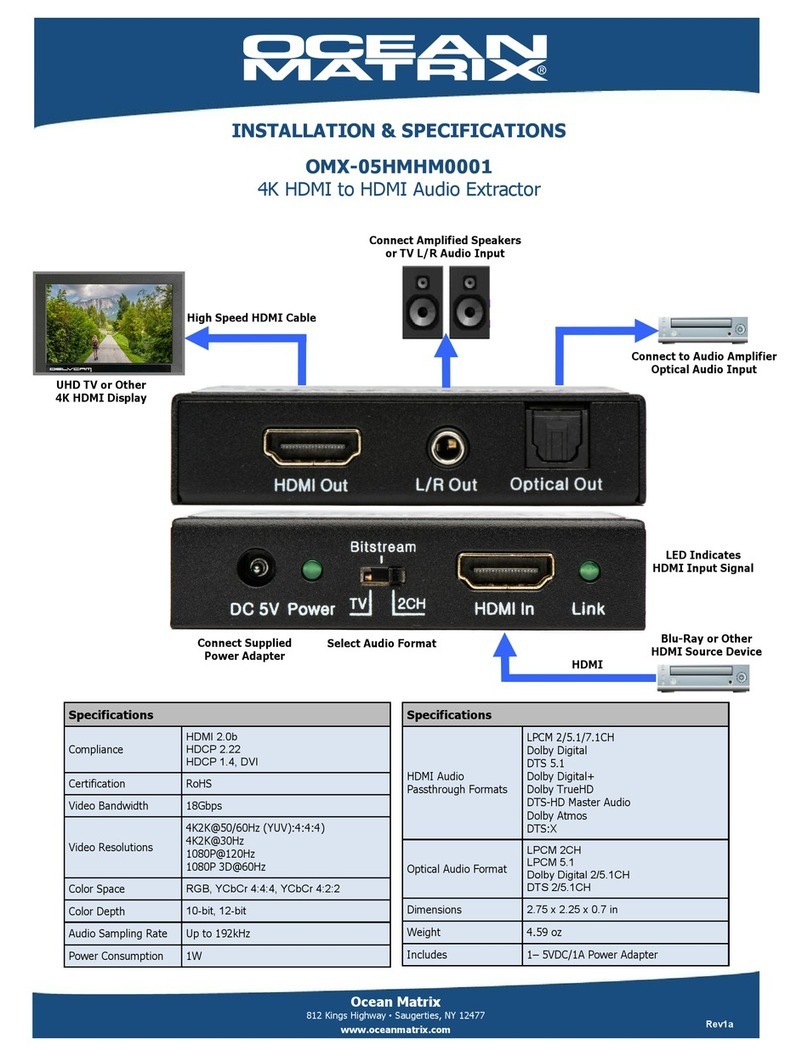

Ocean Matrix

Ocean Matrix OMX-05HMHM0001 INSTALLATION & SPECIFICATIONS

Tennant

Tennant M17 Series Operator's manual

PowerBoss

PowerBoss Scrubmaster B175 R operating manual

PowerBoss

PowerBoss CORE 50 owner's manual

Taski

Taski ergodisc 165 Instructions for use