Setra Systems SPC3000 Series User manual

SPC3000 Series

Particle Counters

User's Manual

Version 2.0

2

Copyright 2021 by Setra Systems, Inc., All Rights Reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise,

without the prior written permission of Setra Systems, Inc. The information contained in this document constitutes proprietary

trade secrets of Setra Systems. You are not allowed to disclose or allow to be disclosed such information except as allowed

by Setra Systems in writing. No patent liability is assumed with respect to the use of the information contained herein. While

every precaution has been taken in the preparation of this manual, Setra Systems, Inc. assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein.

Neither Setra Systems, Inc. nor its affiliates shall be liable to the purchaser of this product or third parties for damages, losses,

costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse, or abuse of this product or

unauthorized modifications, repairs, or alterations to this product, or failure to strictly comply with Setra Systems operating and

maintenance instructions.

Setra Systems, Inc. shall not be liable against any damages or problems arising from the use of any options or any products

or accessories other than those designated as Original Setra Systems Products or Setra Systems approved.

Products by Setra Systems, Inc. - SPC3000 Series

Setra Systems, is a registered trademark of Setra Systems, Inc.

MODBUS is a registered trademark of Schneider Automation Inc.

Microsoft™, Windows™ and Excel™ are trademarks of Microsoft Corporation

NOTICE: The contents of this manual are subject to change without notice.

Product Name: Setra Systems. Inc. SPC3000 Series Remote Particle Counter

Model Numbers: SPC33014M3NWNNS, SPC33014M3PWNNS, SPC35014M3NWNNS, SPC35014M3PWNNS,

SPC35102M3NWNNS, SPC35104M3NWNNS

The following standards are applied only to the particle counters that are so labeled. EMC is tested using Setra Systems

power supplies.

North America: EMI: FCC/ICES-003 Class A

FCC Compliance Statement for American Users

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case the user will be required

to correct the interference at their own expense.

3

Table of Contents

Contents

1-1

Overview.................................................................................................................................................4

1-2

Specifications ........................................................................................................................................5

1-3

Included Accessories............................................................................................................................7

1-4

Optional Accessories............................................................................................................................8

1-5

Product Views........................................................................................................................................9

2-1

Unpacking and inspecting the Instrument........................................................................................10

2-2

Registering Your Product...................................................................................................................10

2-3

Contacting Setra Systems..................................................................................................................10

2-4

Storing and Shipping the Instrument................................................................................................10

2-5

Power Considerations and Connecting to AC Power......................................................................10

2-6

Turning the Unit On.............................................................................................................................10

2-7

Laser Safety Information ....................................................................................................................11

2-8

Electrostatic Safety Information ........................................................................................................11

3-1

Interpreting Indicators.........................................................................................................................12

3-2

Connections.........................................................................................................................................13

3-3

Installation............................................................................................................................................14

3-4

Data Port...............................................................................................................................................15

3-5

Single Sensor Installation...................................................................................................................15

3-6

Multiple Sensor Installation................................................................................................................16

3-7

Cautions During Setup........................................................................................................................16

5-1 Maintenance/Calibration.....................................................................................................................17

Appendix –A..............................................................................................................................................19

4

1-1

Overview

Thank you for purchasing a Setra Systems particle counter, the world’s smallest, remote particle counter

sensor available for measuring and monitoring particle counts in clean room and controlled

environments for the Aerospace, Life Science, Data Storage, IAQ and Industrial Hygiene Markets.

This user manual will provide the detailed explanation and instructions for the proper use and operation

of this feature-rich particle counter.

The Setra Systems particle counters provide a range of particle size measurement from 0.3 µm to 10.0

µm for both 0.1 and 1.0 CFM flow. These sensors allow for efficient particle counting with high accuracy

and resolution that meets ISO 21501-4 for the calibration of a particle sensor.

These particle counters are configured with 2 or 4 particle size channel versions. The output of these

sensors can be accessed through the use of external software, a PLC, SCADA or facility monitoring

system that communicates via MODBUS ASCII or RTU protocols over an RS-485 connection.

Thank you,

5

1-2

Specifications

Size Channels:

SPC35102M3NWNNS

Factory calibrated at 0.5 & 5.0 μm

Size Channels:

SPC35104M3NWNNS

Factory calibrated at 0.5, 1.0, 2.5 & 5.0 μm

Size Range

0.5 to 5.0 μm

Flow rates

1.0 CFM (28.3 LPM)

Counting Efficiency

50% @ 0.5 μm; 100% for particles >0.75 μm per JIS

Size Channels:

SPC33014M3NWNNS

Factory calibrated at 0.3, 0.5, 1.0, & 5.0 μm

Size Range

0.3 to 25 μm

Flow rates

0.1 CFM (2.83 LPM)

Counting Efficiency

50% @ 0.3 μm; 100% for particles >0.45 μm per JIS

Size Channels:

SPC35014M3NWNNS

Factory calibrated at 0.5, 1.0, 2.5 & 5.0 μm

Size Range

0.5 to 25 μm

Flow rates

0.1 CFM (2.83 LPM)

Counting Efficiency

50% @ 0.5 μm; 100% for particles >0.75 μm per JIS

Size Channels:

SPC33014M3PWNNS

Factory calibrated at 0.3, 0.5, 1.0, 2.5 & 5.0 μm

Size Range

0.3 to 25 μm

Flow rates

0.1 CFM (2.83 LPM)

Counting Efficiency

50% @ 0.3 μm; 100% for particles >0.45 μm per JIS

6

Size Channels:

SPC35014M3NWNNS

Factory calibrated at 0.5, 1.0, 2.5 & 5.0 μm

Size Range

0.5 to 10 μm

Flow rates

0.1 CFM (2.83 LPM)

Counting Efficiency

50% @ 0.5 μm; 100% for particles >0.75 μm per JIS

7

Zero Count

<1 count / 5 minutes (<2 particles / ft³) (per ISO 21501-4 & JIS)

Calibration

NIST traceable

Vacuum Requirements

External vacuum >15” (38.1 cm) of Hg

Communication Modes

MODBUS™ RTU or ASCII outputs (specified upon order)

Connections

RS-485

LED Indicators

User-settable LED Ring

Green: Solid or blinking based on Modbus register value

Red: Solid or blinking based on Modbus register value

Power LED

Green: Solid = Power, Blinking = Counting

Service LED

Red: Off = No Faults, Blinking = Fault(s)

Standards

ISO 21501-4 and JIS B9921

Calibration

Recommended minimum once per year

External Surface

Stainless Steel

Dimensions (L x W x H)

1.85” x 3.58”x 3.37” (4.7 cm x 9.1 cm x 8.6 cm)

Not including probes or connectors

Weight

1.07 lb. (0.485 kg)

Accessories

Wiring connector

Optional Accessories

Isokinetic probes, purge filter assembly

Power

9-24 VDC

Operating Conditions

41º to 104ºF (5º to 40ºC) / 20% to 95% non-condensing

Storage Conditions

32º to 122ºF (0º to 50ºC) / Up to 98% non-condensing

Warranty

2 Years. Extended warranties available.

Please note that specifications are subject to change without notice.

8

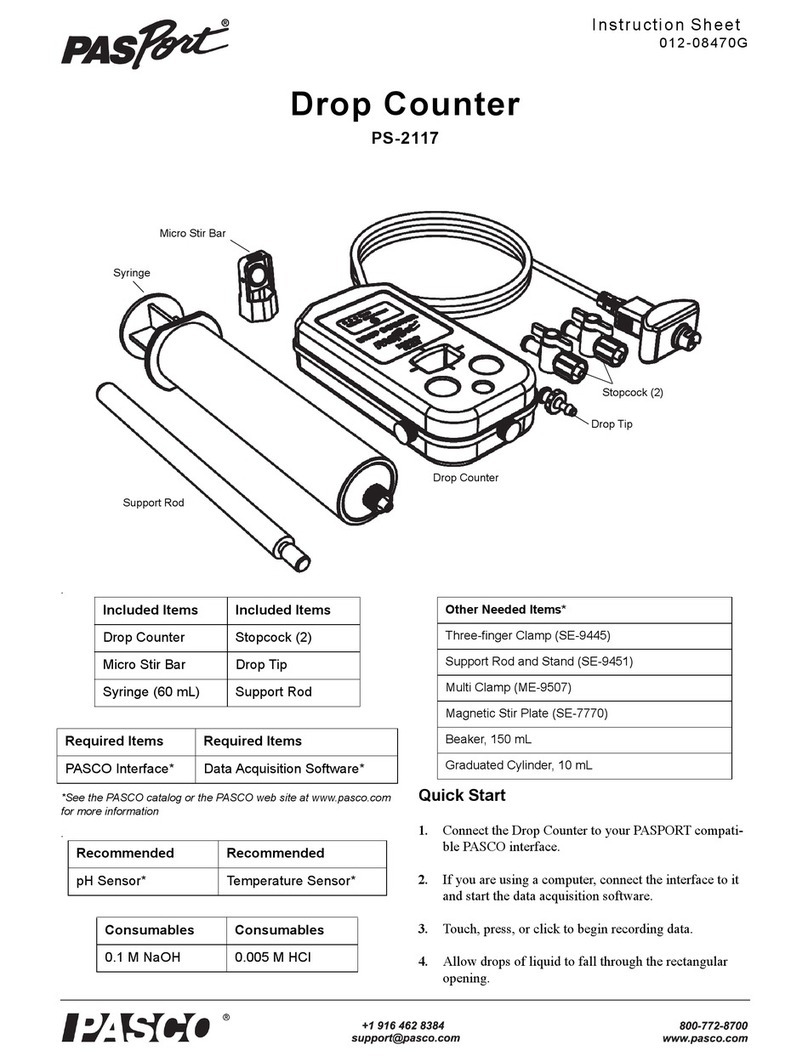

1-3

Included Accessories

Description

Part Number

Image

Wiring Connector

AS-99086

3000 Series User Manual

(USB Key –One per order)

MN-24028

9

1-4

Optional Accessories

Description

Part Number

Image

Isoprobe 0.1 CFM (2.83 LPM) Stainless Steel

PS-12041

Isoprobe 1.0 CFM (28.3 LPM) Stainless Steel

AT-2101

Purge Filter Assembly 0.1 CFM (2.83 LPM)

AS-99002A

Purge Filter Assembly 1.0 CFM (28.3 LPM)

AS-99041A

10

1-5

Product Views

11

2-1

Unpacking and inspecting the Instrument

Careful consideration was given to our packing material to ensure that your Setra

Systems Instrument will reach you in perfect condition. If the Instrument has been

subject to excessive handling during shipping, there may be visible damage to the

shipping carton. In the event of damage, keep the shipping container and packing

material for the carrier’s inspection. Carefully unpack the Instrument from its shipping

container and inspect the contents for damaged or missing items. If the Unit appears

damaged or something is missing, contact the carrier and Setra Systems immediately.

Please save the container and packing material in case you must return the

Instrument.

2-2

Registering Your Product

All Setra Systems Instruments are automatically registered upon sale for the warranty

period and tracked by Serial number.

2-3

Contacting Setra Systems

To order accessories, receive technical assistance, report damaged or missing items

from your shipment, or get contact information for your nearest Setra Systems

authorized reseller, call +1-800-257-3872 or +1-978-264-0292

2-4

Storing and Shipping the Instrument

If the unit needs to be packed and shipped for annual calibration or service, it is

recommended to use the original packing materials. If they are not available, please

insure that the instrument is packaged in a box that is sturdy and that the unit is well

protected with proper packing materials to cushion and protect it from harm during

transit.

To store the instrument, place it in a box, under cover, in an environment as stated in

our specifications.

2-5

Power Considerations and Connecting to AC Power

The Setra Systems 3000 Series Instrument is powered from a customer provided

external DC power source between 9 –24 VDC.

2-6

Turning the Unit On

The 3000 Series instruments are designed to operate as fixed installed instruments, and

automatically power on when power is applied to the external power connector. The

instrument can be powered down if the power connection is removed.

12

2-7

Laser Safety Information

The Remote Particle Sensor is a Class 1 laser-based instrument.

•During normal operation, you will not be exposed to laser radiation.

•Precaution should be taken to avoid exposure to hazardous radiation in the

form of intense, focused, invisible light.

•Exposure to this light may cause blindness.

Take these precautions:

•DO NOT remove any parts from the particle sensor unless you are specifically

told to do so in this manual.

•DO NOT remove the housing or covers. There are no user-serviceable

components inside the housing.

DANGER

◆

Any use of controls, adjustments, or procedures other than those

specified in this manual may result in exposure to hazardous optical radiation.

WARNING

2-8

Electrostatic Safety Information

Please complete all service and maintenance work at a static-safe work station.

If you fail to do so, electrostatic discharge (ESD) may result in damaging

electronic components. Please consider the following for creating a static-safe

work station:

•Make sure all the test instruments are earth-grounded.

•Use a resistor-isolated wrist strap as well as a grounded conductive table mat.

13

3-1

Interpreting Indicators

Figure 3-1 Front Panel LEDs

LED Indicators

User-settable LED Ring

Green: Solid or blinking based on Modbus register value

Red: Solid or blinking based on Modbus register value

Power LED

Green: Solid = Power, Blinking = Counting

Service LED

Red: Off = No Faults, Blinking = Fault(s)

Power

Indicator (Green)

Service

Indicator (Red)

LED Ring

Indicator (Red/Green)

14

3-2

Connections

Figure 3-2 Connections on Top of Instrument (inlet)

Figure 3-3 Connections on Bottom Right of Instrument (vacuum connection)

15

3-3

Installation

Please follow the steps below to prepare the instrument.

1. Locate where instrument(s) are going to be mounted.

2. Attach the Optional Isokinetic Inlet Joint Tube to the top of the inlet.

Figure 3-5 Attach Optional Isokinetic Inlet to Joint Tube

3. Attach the Optional Isokinetic Inlet to Joint Tube.

Figure 3-6 Attach Optional Isokinetic Inlet to Joint Tube to Inlet

16

4. Please refer to section 3.4 and 3.5 for communication and wiring details.

5. Attached the sensor to an external vacuum pump system with a tube at the bottom

of the instrument. Add a negative pressure gauge to the other end of the tube. If the

pressure is more than -15 in.Hg (-50kPa) vacuum. The flow rate of a 3000 series is

controlled to maintain proper flow (There is a critical orifice inside of the unit, which

controls the flow rate when the negative pressure is equal to our greater than -15

in. Hg (-50kPa) vacuum. After checking the negative pressure, remove the negative

pressure gauge, and then attach the tube to the outlet on the bottom of the sensor.

There is flow sensor in the unit. When the flow value is below the target threshold (e.g.

the tube is bent, vacuum pump is not functioning, etc.), the sensor status register

during sampling (see Modbus register map) will indicate a flow error. The Modbus Last

record flow rate register (see Modbus register map) can be used to monitor flow rate.

3-4

Data Port

The connector on the bottom of the instrument is used to communicate with your facility

monitoring system, Cleanroom Monitoring System, SCADA, or PLC.

Table 3-4 Connector Pin-outs

3-5

Single Sensor Installation

Figure 3-6 illustrates how to wire the connector for a whole system.

Figure 3-5 Application for a Single Sensor

17

3-6

Multiple Sensor Installation

Figure 3-6 Typical Multiple Sensor Installation Diagram

In a multiple instrument configuration, the wires should be connected from adjacent instruments at the

terminal block connector in order to create a bus and keep stub lengths to a minimum.

3-7

Cautions During Setup

1. Factory default address for the unit is 247. The default Baud Rate is 115200 bps, but the

following baud rates are possible: 9600, 14400, 57600 bps. Communication is 8 data bits, at least 1

stop bit and no parity. The default Modbus protocol is Modbus-RTU.

2. The length of optional sampling tubing can have a length of up to 1 meter with an inside

diameter of 5 or 6 mm. If longer or thinner tubing is used it could create head loss and reduce

the flow rate. Please select the tube made of antistatic materials and deploy as straight as

possible.

18

4-1 Communication Protocol

The remote particle sensor can be communicated with using the Modbus-RTU

or Modbus- ASCII protocol. Facility/Cleanroom Monitoring software can be

used as the monitoring system. If you would like to use your own monitoring

system, please contact Setra Systems, Inc.

5-1

Maintenance/Calibration

•Please do not open the enclosure of the unit. If you need to open the

enclosure, please contact Setra Systems for consultation.

•ISO 21501-4 states that the recommended calibration interval of an LSAPC

(light scattering airborne particle counter) is one year or less. For calibration,

please contact Setra Systems or an authorized distributor.

•Please check the negative pressure at the tube (where it connects to the

outlet of the unit) to ensure that the vacuum pump is providing enough

negative pressure to the unit.

See Section 3.3, line 5 for more details.

•Before cleaning / disinfecting the environment, please turn off the unit, stop

the vacuum pump, and then put the included red cap on the inlet nozzle.

For cleaning (fumigation) please be sure to follow this procedure:

[Before fumigation]

1. Turn off the Power of the unit.

2. Turn off the vacuum pump.

3. Put the red inlet cap on the isokinetic probe to protect the optical block

from the agent.

[After fumigation]

4. Please make sure the air ventilation is completed (If agent is left in the

environment and gets into the optical block, it will cause a malfunction).

5. Turn on vacuum pump and power.

19

Appendix

–

A

The MODBUS Register Map can be found on the USB memory stick as

a separate PDF document file

Setra Systems, Inc.

159 Swanson Road

Boxborough, MA 01719, USA

Phone: +1-978-264-0292

www.setra.com

Table of contents

Other Setra Systems Cash Counter manuals

Popular Cash Counter manuals by other brands

Stuart

Stuart SC6 Plus Instructions for use

Autonics

Autonics LA8N Series quick start guide

Yoosol Electronics

Yoosol Electronics PRIMO-P2 Operation manual

GeoVision

GeoVision GV-3D People Counter V2 user manual

Royal Sovereign

Royal Sovereign RBC-1000 Series owner's manual

logos biosystems

logos biosystems Luna-FL user manual