Semacon S-1200 Series User manual

S-1200 Series Currency Counter

Operating Manual

Models S-1200, S-1215 and S-1225

i

CONTENTS

Copyright © 2011-2015 Semacon Business Machines, Inc. All Rights Reserved.

No part of this document may be copied or reproduced by any individual or entity for any reason without prior written permission

from Semacon.

(Revision O03)

Introduction 1

Front View Machine Diagram 2

Rear View Machine Diagram 3

Control Panel Overview 4

Control Panel Functions 5

Operating Instructions Overview

-Startup

-Basic Counting Process

-Error Codes During the Counting Process

6

Modes and Functions

-Add Mode

-Manual Mode

-Batching

7

Counterfeit Detection 8

Maintenance

-Clearing a Jam

-Cleaning

-Feed Tension Adjustment

9

Malfunction Code List 11

Error Code List 12

Technical Specifications 13

1

SEMACON S-1200 SERIES CURRENCY COUNTERS

This instruction manual serves as a general guide for operating your Semacon S-1200 Series

Currency Counter. This machine is a heavy duty bank grade currency counter designed to save

time and labor while counting banknotes in bulk. Before starting, please read the manual

thoroughly to become familiar with the operation and functions of the machine. Please follow the

operating instructions step by step and skip the functions that are not applicable to the model you

purchased. If you have any questions or suggestions, please contact your authorized distributor or

Semacon.

WA R N I N G S :

The machine should only be connected to a main AC socket with proper grounding and correct voltage.

Please turn off the power switch and unplug the power cable before you open the back cover or when the

machine will not be in use for an extended period of time.

Model Counting

Mode

Adding

Mode

Counting Speed

(Notes/Min)

UV Counterfeit

Detection

MG Counterfeit

Detection

S-1200 √√800/1200/1600 - -

S-1215 √√800/1200/1600 √-

S-1225 √√800/1200/1600 √ √

2

S-1200 SERIES CURRENCY COUNTER

FRONT VIEW

1) Carrying Handle

2) Sliding Hopper Guides

3) Separation Mechanism

4) Display

5) Left Side Cover

6) Stacker Rack

7) Feed Deck

8) Control Panel

9) Stacker Roller

10) Right Side Cover

11) Feed Tension Adjustment Knob

Figure 1

1

2

5

4

3

7

6

8

9

10

11

3

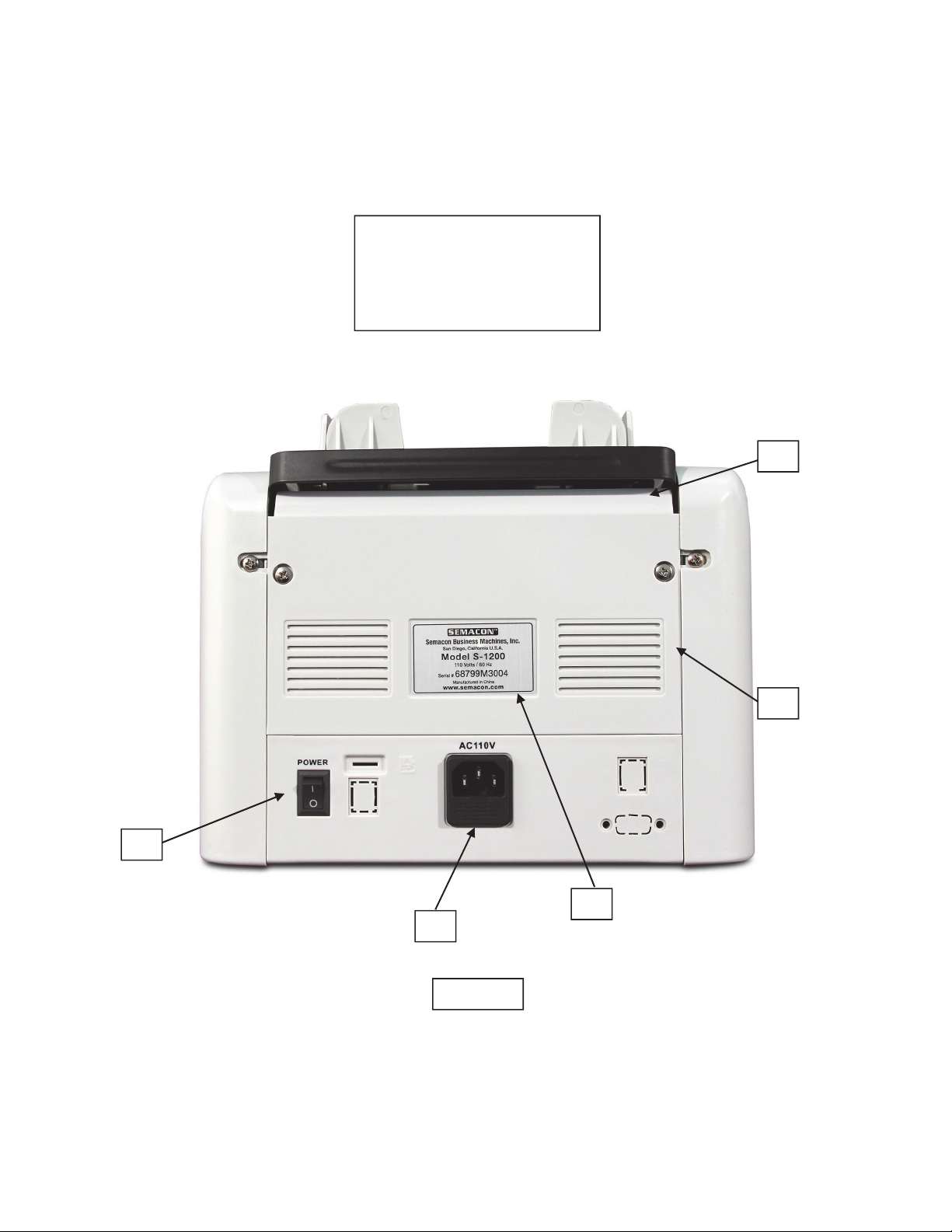

S-1200 SERIES CURRENCY COUNTER

REAR VIEW

12) Upper Cover

13) Power Switch

14) Power Socket

15) Serial Number Label

16) Upper Rear Cover

Figure 2

12

15

13

14

16

4

CONTROL PANEL OVERVIEW

KEY FUNCTION

START Starts the counting process

CLR Clears the counting number display

ADD Selects add mode or normal counting mode

SPD Changes the counting speed

MNL Selects auto or manual feed mode

0/C - 9 Number buttons for selecting the batch stop setting

0/C Clears the batch stop setting or functions as 0 when setting batch limit

UV Turns on/off UV counterfeit detection (models S-1215 and S-1225)

MG Turns on/off MG counterfeit detection (model S-1225 only)

Model S-1200

Model S-1215 with Ultraviolet Counterfeit Detection

Model S-1225 with Ultraviolet and Magnetic Counterfeit Detection

5

CONTROL PANEL FUNCTIONS

The START button is used to restart the counting process after the machine stops

during batch counting or after an error, and for manual feed mode.

THRU

The number buttons are used for selecting the batch stop setting. In this mode, the

counter will stop each time the batch stop setting is reached and the operator then

removes the batch from the stacker. Batch stop settings between 1 and 999 bills

can be entered. The batch stop setting will appear on the upper display. The

selected batch number can be cleared by pressing the 0/C button; this will remove

the batch setting and deactivate the batch stop mode.

The quantity of banknotes counted, which appears on the lower display, will be

reset to zero when the CLR button is pressed.

The ADD button switches between ADD mode and normal mode. When the

machine is in ADD mode, the machine will add the count for each stack of bills to

the previous total. In normal mode, the total is cleared each time a stack of bills

is removed from the stacker.

The UV button turns on/off Ultraviolet Counterfeit Detection. When Ultraviolet

Counterfeit Detection is activated, a green light will appear next to UV on the

control panel and the counter will scrutinize the paper of each banknote during the

counting process to determine if there are any suspect counterfeit notes. If a

suspect counterfeit banknote is detected, the counter will stop and alert the

operator. If you are experiencing too many false UV suspects, the UV detection

feature should be adjusted or deactivated.

(This feature applies to models S-1215 and S-1225 only)

The MG button turns on/off Magnetic Counterfeit Detection. When Magnetic

Counterfeit Detection is activated, a green light will appear next to MG on the

control panel and the counter will scrutinize the ink of each banknote during the

counting process to determine if there are any suspect counterfeit notes. If a

suspect counterfeit banknote is detected, the counter will stop and alert the

operator. If you are experiencing too many false MG suspects, the MG detection

feature should be adjusted or deactivated.

(This feature applies to model S-1225 only)

The SPD button adjusts the counting speed of the machine. When this button is

pressed, the green lights above the count display will switch between H(1600),

M(1200), and L(800), with 800 being the slowest counting speed and 1600 being

the fastest. The recommended setting is M(1200).

The MNL button switches between auto and manual feed mode. When the green

light is off the machine will start counting the bills as soon as they are placed in

the hopper. When the green light is on, the machine will not start counting until

the START button is pressed.

6

OPERATING INSTRUCTIONS OVERVIEW

Startup

1) Turn on the power switch located on the back of the counter near the power socket. The display

will read all 8’s, indicating that the unit is completing a self-check process and checking each

sensor.

2) 0will appear to indicate that the counter has successfully completed its self-diagnostic process

and is now in standby mode and ready to be used.

3) If the machine encounters a problem during the self-check startup process, an error message

will appear on the display. For example: E1

E6

Please refer to the Startup Malfunction Codes to determine what the error code represents.

Basic Counting Process

1) Place the banknotes in the hopper and the counter will auto-start the counting process. It will

count all the banknotes in the hopper and show the total count on the display.

2) To continue counting, remove all of the counted banknotes from the stacker and place the next

stack of banknotes in the hopper. The counter will begin counting from "0" again.

3) If the banknotes in the stacker are not removed before placing additional banknotes into the

hopper, the counter will restart automatically but will add the additional banknotes to the previous

total.

Error Codes During The Counting Process

During the counting process, if a suspect counterfeit banknote is detected or a feeding error occurs

(such as double note, chain note or half note), the counter will stop counting and the appropriate

error code will be displayed. Please see the Counting Error Code List to interpret the meaning

of any error codes.

NOTE: Avoid placing damp or wet banknotes into the machine. Always be sure to remove

any paper clips, rubber bands, staples or other items attached to the banknotes before counting.

If the banknotes are curled, folded or bent, flatten them before running them through the

machine.

7

MODES AND FUNCTIONS

Add Mode

Adding during count mode is performed by pressing the ADD button (green LED will light next

to the button when activated). With this mode turned on, the machine will add the count for each

stack of bills to the previous total.

Manual Start Mode

If you do not want the machine to start counting automatically when banknotes are placed in the

hopper, you can press the MNL button (green LED will light next to the button when activated).

This turns on the Manual Start Mode. In this mode, the machine will not start counting until the

START button is pressed.

Batching

1) To set a batch stop setting, enter any number from 1-999 using the numeric buttons and the

setting will appear in the upper display on the control panel. For example, to set the batch limit to

“50”, press the 5key and then press the 0/C key.

2) Place banknotes in the hopper. The machine will start counting and will stop once the counted

number reaches the preset batch number.

3) To repeat the batch counting, simply remove the banknotes from the stacker and the machine

will count the next batch.

4) To clear the batch stop setting, press the 0/C button until nothing appears above the count on

the display.

NOTE: Add mode can also be used when batching if the operator selects a batch stop setting

while Add mode is activated.

8

COUNTERFEIT DETECTION

Certain counter models contain a sophisticated counterfeit detection system (models S-1215 and

S-1225). While the counterfeit detection features are designed to be as accurate as possible, they

are specifically designed to pinpoint suspect banknotes that are believed to have a high probability

of being counterfeit. An alert to a suspect counterfeit banknote does not assure or guarantee that

the banknote is counterfeit. Additionally, while the counter is designed to detect potential

counterfeit banknotes, there is always the possibility that an actual counterfeit banknote may pass

through the screening process undetected.

The UV detection found in models S-1215 and S-1225 is designed to inspect and scrutinize the

banknote paper for potential counterfeit properties while the MG detection found in model S-1225

is designed to inspect and scrutinize the banknote ink for potential counterfeit properties. The

combination of UV and MG detection capabilities found in model S-1225 offers the greatest

protection and has the highest probability of catching a suspect counterfeit banknote.

9

MAINTENANCE

Clearing A Jam

With the machine off and the power cord unplugged, reach in and remove any jammed banknotes

if they are visible from either the top area of the machine near the feed rollers or the bottom area

of the machine near the stacker. If the obstruction is not visible, the operator can cut a bill-sized

piece from a file folder and use the feed wheels to manually roll it through the machine (with the

power off) in order to push the obstruction to a point where it is visible and within reach. If this

does not work, please contact your authorized Semacon service provider.

Cleaning

In order to properly maintain your counter, it should be cleaned on a regular basis. We suggest

regularly blowing any dust out of the counter with a can of compressed air which can be purchased

at most office supply stores. We also recommend placing a dust cover over the machine when it

is not in use and the power is off.

Depending on your usage level, your counter should be professionally cleaned and serviced on a

regular basis by your authorized Semacon distributor or it can be sent to the Semacon Service

Center for a general preventative cleaning & maintenance service. Contact your distributor to

determine the proper location for service.

WARNING: Never place your fingers inside the machine during operation.

WARNING: Always switch off the power and unplug the power cord when cleaning

the machine or before reaching into the counter to clear a jam.

WARNING: Do not use any wet cleaning cards in the machine.

10

Feed Tension Adjustment

You may need to occasionally adjust the feed tension to compensate for the normal wear that the

rubber feed wheels experience over time. The feed tension can be adjusted by turning the Feed

Tension Adjustment Knob on the top of the machine. The initial factory setting is with the dot at

the 0 position (in the center toward the back of the machine). Turning the knob clockwise (so the

dot on the knob is at +1 or +2) will loosen the feeding system, while turning the knob

counterclockwise (so the dot on the knob is at -1 or -2) will tighten the feeding system.

Most machines function best with the dot on the knob centered at 0, but if the machine is

experiencing frequent jam errors, the knob may need to be turned clockwise so that the dot is at

+1 or +2. Alternately, if the machine is experiencing frequent double note or chain note errors,

the knob should be turned counterclockwise so that the dot is at -1 or -2.

IMPORTANT! The dot on the knob should never be adjusted past +5 or -5.

Contact your authorized Semacon service provider if your machine still receives

error messages after the feed tension has been adjusted to either of these points.

11

MALFUNCTION CODE LIST

Malfunction

Code

Cause Solution

E1 The left count sensor pair is

dirty, out of alignment or needs

repair

Clean both sensors with a can of

compressed air and then use a cotton swab

dipped in alcohol or windex. If this does

not correct the problem, your counter

should be sent to an authorized Semacon

service center or Semacon for repair.

E2 The right count sensor pair is

dirty, out of alignment or needs

repair

Clean both sensors with a can of

compressed air and then use a cotton swab

dipped in alcohol or windex. If this does

not correct the problem, your counter

should be sent to an authorized Semacon

service center or Semacon for repair.

E3 The magnetic counterfeit

detection sensor needs repair

Your counter should be sent to an

authorized Semacon service center or

Semacon for repair

E4 The ultraviolet counterfeit

detection sensor needs repair

Your counter should be sent to an

authorized Semacon service center or

Semacon for repair

E5 The hopper sensor is dirty or

needs repair

Clean the sensor with a can of compressed

air and then use a cotton swab dipped in

alcohol or windex. If this does not correct

the problem, your counter should be sent

to an authorized Semacon service center

or Semacon for repair.

E6 The stacker sensor pair is dirty,

out of alignment or needs repair

Clean both sensors with a can of

compressed air and then use a cotton swab

dipped in alcohol or windex. If this does

not correct the problem, your counter

should be sent to an authorized Semacon

service center or Semacon for repair.

12

ERROR CODE LIST

Error Code Cause Solution

ECH Chain Note Detection Alert

Adjust Feed Tension Adjustment Knob

counterclockwise by one level (e.g.

from 0 to -1). Run a stack of bills

through the counter. If the machine still

receives error messages, repeat this step

until you reach -5.

If you reach -5 and the machine is still

receiving error messages, reverse the

process and run a stack of bills through

the machine after turning the Feed

Tension Adjustment Knob clockwise by

one level (e.g. from -4 to -3). This step

can be repeated until you reach +5.

If you reach +5 and your machine is still

receiving errors, please contact your

authorized Semacon service facility for

further assistance.

ECL Chain Note Detection Alert

(on the first bill in the stack)

dbH Double Note Detection Alert

dbL Double Note Detection Alert

(on the first bill in the stack)

EH Half Note Detection Alert

EJ Jam Detection Alert

Ob Skew Note Detection Alert

CF1

(models S-1215 and S-1225)

Suspect Counterfeit Note -

Ultraviolet Detection Alert

Inspect top banknote in stacker for

counterfeit qualities.

CF2

(model S-1225 only)

Suspect Counterfeit Note - Magnetic

Detection Alert

13

TECHNICAL SPECIFICATIONS

1) Ambient Temperature

32 - 104ºF

0 - 40ºC

2) Ambient Humidity

30 – 90%

3) Banknote Feeding System

SmartFeed™Friction Roller System

4) Counting Speed

800/1200/1600 Notes Per Minute

5) Note Size

115 x 50 mm to 175 x 85 mm

6) Hopper Capacity

200 – 300 Notes

7) Stacker Capacity

200 Notes

8) Display

4 Digit (LED)

9) Power Source

110 – 120VAC / 60Hz or 220 – 240VAC / 50Hz

10) Power Consumption

<50W

11) Stand-by Consumption

<20W

12) Unit Size

10.5”(W) x 9.75”(D) x 9.5”(H)

270mm(W) x 250mm(D) x 240mm(H)

13) Weight

15 lbs (6.8 kg)

Specifications are subject to change without notice.

7430 Trade Street

San Diego, CA 92121 USA

Tel: 858-638-0100

Fax: 858-638-0110

www.semacon.com

This manual suits for next models

3

Table of contents

Other Semacon Cash Counter manuals