Setra Systems MicroCal User manual

User Manual

MicroCal™

Advanced Modular Pressure Calibrator

800.257.3872

setra.com

3

Table of Contents

1.0 SAFETY INSTRUCTIONS...................................................................................5

2.0 INTRODUCTION...............................................................................................6

3.0 STANDARD EQUIPMENT BREAKOUT..................................................................7

4.0 OPERATING FEATURES

4.1 MICROCAL............................................................................................8

4.2 PORTABILITY.........................................................................................8

4.3 CALIBRATOR SCREEN OVERVIEW..........................................................9

5.0. CALIBRATOR SETUP

5.1 USER INTERFACE PANEL.....................................................................11

5.2 BATTERY CHARGING...........................................................................11

5.3 REPLACE & INSTALL BATTERY..............................................................12

5.4 REFERENCE INSTALLATION.................................................................14

5.5 GETTING STARTED..............................................................................14

6.0 MICROCAL INTERFACE SCREENS

6.1 APPLICATION DEFINITIONS................................................................16

6.2 REAL TIME: GENERAL.........................................................................16

6.21 REAL TIME: DIAL GAUGE..............................................................17

6.22 REAL TIME: PSWITCH .................................................................17

6.23 REAL TIME: EXPERT SYSTEM........................................................17

6.3 RUN TEST: GENERAL...........................................................................18

6.31 RUNTEST: DIAL GAUGE................................................................19

6.32 RUNTEST: PSWITCH ...................................................................19

6.33 RUNTEST: DITHER CONTROL PAGE...............................................20

6.34 RUN TEST: EXPERT SYSTEM...........................................................21

6.4 TEST SETUP: GENERAL.......................................................................22

6.41 TEST SETUP: DIAL GAUGE .............................................................23

6.42 TEST SETUP: PRESSURE SWITCH...................................................23

6.5 UUT UNIT UNDER TEST SETUP: GENERAL.......................................24

6.51 UUT SETUP: DIAL GAUGE..............................................................28

6.52 UUT SETUP: PSWITCH .................................................................28

6.53 UUT SETUP: EXPERT SYSTEM........................................................29

6.6 SYSTEM .............................................................................................30

4

7.0 UNIT UNDERTEST CONNECTION.....................................................................35

8.0 CALIBRATING/TESTING ATRANSDUCER/TRANSMITTER .................................35

9.0 MICROCAL MANAGER INTERFACE

9.1 SETUP FOR MICROCAL CONNECTION ................................................38

9.2 GRAPHICAL USER INTERFACE SETUP ...............................................39

9.3 TEST RESULTS DATA...........................................................................43

10.0 MICROCAL SPECIFICATIONS

10.1 MEASUREMENT................................................................................46

10.2 CONTROL..........................................................................................46

10.3 GENERAL SPECIFICATIONS...............................................................46

11.0 ADDITIONAL RESOURCES

11.1 GLOSSARY OF TERMS........................................................................47

11.2 INTERPRETING PRESSURETRANSDUCER SPECIFICATIONS..............48

12.0 SPARE PARTS & ACCESSORIES....................................................................52

13.0 RECALIBRATION &WARRANTY INFORMATION..........................................53

5

1.0 SAFETY INSTRUCTIONS

Use the calibrator only as specied in the manual, otherwise the protection provided

may be impaired.

Do not operate the calibrator in explosive gas, vapor or dust environments.

The calibrator is designed to operate from 14.4VDC removable Lithium Ion battery

source or from the AC adaptor that is included. Do not use AC adapters, chargers or

batteries other than those supplied by Setra.

If supplying external excitation to the Unit UnderTest in a measure mode, do not exceed

30VDC.

There are no user serviceable parts internally, removing the internal cover will void

warranty. Return the unit to the factory for re-certication or repair.

BEST PRACTICES FOR CALIBRATOR OPERATION:

Use the shortest length of tubing from the calibrator to the Unit UnderTest, during

pressure testing avoid vibration of the tubing.

Avoid movement of the calibrator during operation, avoid locating in a high vibration

environment.

Keep reference door closed when not changing modules.

Allow the calibrator to warm-up for 30 minutes before use. The calibrator can be turned

on during transport.

6

2.0 INTRODUCTION

DOCUMENTING PROCESS CALIBRATOR:

The Setra MicroCal is a pressure generating, modular pressure documenting calibrator.

The calibrator has been designed and optimized to meet the needs of our customers for

a capable system for the calibration, troubleshooting and documentation of very low

pressure measuring information.

The design of the MicroCal exploits years of experience in the calibration of Setra trans-

ducers, as well as NASA patented and Setra exclusive licensed technology.

Major Features:

• 7”Touchscreen Display, capable of storing thousands of Units Under

Test (UUT) data les.

• Portable, battery powered system, capable of full operation throughout

a typical work day.

• Closed loop pressure control which is immune to the eects of ambient

pressure perturbations, (doors closing, people moving around).

• Very low internal reference pressure standards, which are selectable to

match customer needs.

• Auto zero pressure“tare”function.

• Ability to source power to the UUT, or use external power supply.

• High resolution pressure control capable of precise generation and

pressure control in the micro inch of water column pressure ranges.

• Leak testing

• High accuracy MCPM modular pressure references give exibility and

accuracy to the end customer.

• Modular battery to ensure all your calibrations are able to be completed.

Diagram 1

High Pressure Port

Electrical Connections

for Unit UnderTest

Low Pressure Port

Reference

Modules

7

3.0 STANDARD EQUIPMENT BREAKOUT

THE ITEMS BELOW ARE INCLUDED INYOUR CALIBRATOR:

Diagram 2

AC Power Adapter

Pneumatic Fittings

&Tubing

ElectronicTest Lead Kit

Calibration Certicate

User Manual

Calibrator

Rechargeable

Battery

Diagram 3

Pressure Module Box

What’s Included:

Up to 4 Pressure Reference

Modules Per Box

Accessory Box

What’s Included:

User Manual

Rechargeable Battery

AC Power Adapter

ElectronicTest Kit

Pneumatic Fittings &Tubing

8

4.0 OPERATING FEATURES

4.1 THE MICROCAL PERFORMSTHE FOLLOWING MAJOR FUNCTIONS

• User interface for setups, display and storage.

• Data transfer to and from MicroCal Manager Database.

• Monitors battery voltage

• Stores data for UUT, test proles and test results.

• ISO Certication

4.2 PORTABILITY - CALIBRATOR IS FULLY PORTABLE AND POWERED BY

• 24VDC external, 120/240 power adapter included

• Using the removable battery which has been designed for operation

throughout a typical workday after a full charging cycle. The Li-Ion battery israted at

14.4VDC, 6.6 Amp hour (AH).

9

4.3 CALIBRATOR SCREEN OVERVIEW

Real-Time Screen

• Displays installed references

• Actively read Applied Pressure, UUT Output & %

Error

• Apply user selectable pressure, for manual cali-

bration

• Enable either Control (apply pressure) or Monitor

(read pressure from system)

• Select UUT proles

Run Test Screen

• Select UUT Proles

• Select Test Setup

• Automatically run pressure test based on UUT and

test setup selections

• Store and recall“As-Found”&“As-Left”test results

Test Setup Screen

• Create unique test proles; Ascending, Descend-

ing, Both or Custom

• Dene number of test points

10

UUT Setup Screen

• Create unique site specic UUT ID’s

• Select a“Test Setup”to associate to UUT

• Dene the parameters of a UUT that will be tested

• The UUT setup/selection is utilized across multiple

screen functions

System Screen

• Communications software revisions of the

MicroCal

• Visual indication of battery level

• Set default settings for the unit

• Select engineering units to be used across all

functions

11

5.0 CALIBRATOR SETUP

5.1 USER INTERFACE PANEL

The user interface panel includes the pressure and electrical connections to the unit

under test. (See Diagram 4)

5.2 BATTERY CHARGING

The MicroCal is assembled, calibrated and tested at the factory. The battery, as received,

will be in a partially charged state. Before operation please be sure to fully charge the

battery to get maximum portable use of the device.

TO CHARGE THE BATTERY:

• Connect the AC power adapter (AC adapter is shipped in Accessory Box, see Diagram

3) to AC supply connector on back of unit or use optional desktop charger (869974-G)

• Initial battery charging will take approximately 2-4 hours.

Diagram 4

User Interface Panel

12

5.3 REPLACE & INSTALL BATTERY

Open Battery Door: Rotate the black knob counter-clockwise and pull up on the battery

door.

Remove Installed Battery: Pull tab and lift out battery.

Install Charged Battery: Align pins inside the battery compartment with the receptacle

on charged battery. Place battery into compartment unit the battery is fully seated.

Close Battery Door: Rotate the black knob counter-clockwise, rotate the door to the

closed position, and release knob to lock into position.

Battery Door

Reference Door

Diagram 5

13

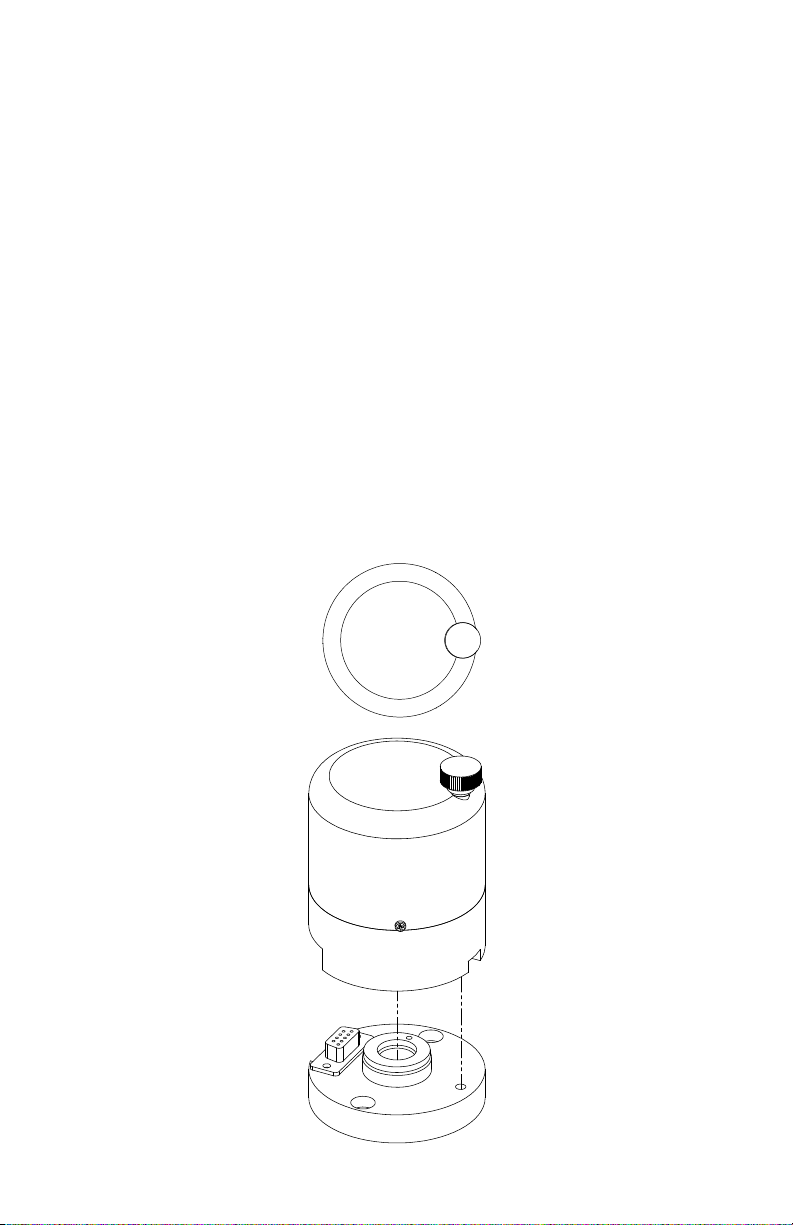

5.4 REFERENCE INSTALLATION: CHANGING MICROCAL PRESSURE MODULE (MCPM)

(Diagram 6)

The MicroCal is designed with 2 pressure reference bases. These MCPM reference mod-

ules can be added in eld into either base. Software will automatically detect installed

reference.

Open Reference Door (See Diagram 6): Rotate the black knob counterclockwise and pull

up on the reference door.

Remove Installed Reference: Loosen black thumbscrew (3 o’clock position) by rotating

counter-clockwise.

Install New Reference: Align the MCPM reference so the knob is in the 3 o’clock position.

Press down on the MCPM housing until fully seated. Tighten black thumbscrew by

rotation clockwise.

Close Reference Door: Pull the reference door down and rotate the black knob counter

clockwise.

Diagram 6

14

5.5 GETTING STARTED

1. Open calibrator top.

2.Turn on calibrator power by toggling the power button towards the back of the unit

(power switch on left side of the calibrator see Diagram 7).

3. Once calibrator is powered up, re-zero function begins automatically. Please wait for

completion. (User will hear operation of solenoid valves and stepper motor).

4. Software will startup with Real-Time Page. Select desired UUT from drop-down to

begin performing calibrations. (See Section 6.5 to setup new UUT proles)

Diagram 7

Power

Switch

RS232

Expert System Interface

15

Diagram 8: Real-Time Screen

Applied

Pressure

UUT

Output

Terminal

Based Error

Installed

Pressure References

Navigation Buttons

Bar Graph of Error

% FS

Excitation to Unit

UnderTest

Access Stored UUT

Proles

Vents Pressure to Atmosphere

Snapshot of Data

TARES Internal Pressure

Standards

Enable Monitor Only

Mode ( No Pressure Control)

Enables Pressure

Control

Go to Pressure

Macro Buttons

16

6.0 MICROCAL INTERFACE SCREENS

The MicroCal Interface is tab-based, split into 5 major sections at the bottom of the

screen.

6.1 APPLICATION DEFINITIONS

General:This describes operation for the broadest range of applications.

Dial Gauge: Departures from general operation for Dial Gauge calibration.

P-Switch: Departures from general operation for Pressure Switch calibration.

Expert System: Departures from general operation for Expert System calibration.

6.2 REALTIME: GENERAL

Screen Instructions (Diagram 9):

RealTime page is constantly updating and is used to see the output and pressure being

applied for calibration purposes and test purposes (acts as a digital indicator).

APPLIED PRESSUREWINDOW: Displays system pressure.When a new pressure set point

is selected, the text will turn yellow while pressure is outside of target control band (Re-

quired control stability for UUT). Text will turn green when target pressure is reached.

SETPOINT: The go to pressure macro buttons are congured by the selected UUT pressure

range. These can be used to manually step through pressure setpoints for calibration or

when making manual adjustments. For all units, the top most button will display the

UUT’s -FS PressureValue.The bottom-most button will display the UUT’s +FS Pressure

Value. Pressing any of the buttons enters the pressure value on the button into the

target pressure window and calls the“Go to Pressure”function.

VENT: Opens both positive and negative pressure ports to each other and atmosphere.

TARE: Zeros out internal pressure standard and re-zero’s mechanical components in

controller.

GOTO PRESSURE: Calls controller to generate pressure point set in pressure target box.

HOLD: Stops any process in action.

MONITOR: Switches calibrator into monitoring mode. This allows calibrator to be used

as pressure measurement device.

CONTROL: Switches calibrator into control mode. This allows the calibrator to be used for

pressure control and as a measurement device.

Error Graph is an auto-scaling display of the present error of the UUT’s output as com-

pared to the applied pressure.The red bars on the graph represent the UUT’s accuracy

specication limits.The labels will display the present range of the graph. The arrow

showing the error will turn red when the error is outside of tolerance.

17

6.21 REALTIME: DIAL GAUGE

Dierences from General (Diagram 9):

-Output and Error windows hidden.

-Bar Graph of Error is hidden.

6.22 REAL TIME: PSWITCH

Dierences from General (Diagram 9):

-Output window changes to OPEN/CLOSE indicator/capture window

-Error window changes to OPEN/CLOSE indicator/capture window

-Bar Graph of Error is hidden.

6.23 REAL TIME: EXPERT SYSTEM

Dierences from General (Diagram 9):

-Monitor Only/Control button locked out, automatically controlled by the process head

connection/disconnection.

Diagram 9

Applied

Pressure

UUT

Output

Terminal

Based Error

Installed

Pressure References

Navigation Buttons

Error Graph

Excitation to Unit

UnderTest

Access Stored UUT

Proles

Vents Pressure to

Atmosphere

Stops Pressure Control

TARES Internal

Pressure Standards

Enables Pressure

Control

Enable Monitor Only

Mode ( No Pressure

Control)

Go to Pressure

Macro Buttons

18

6.3 RUNTEST: GENERAL

Screen Instructions (Diagram 10):

1. Tap the RUN TEST tab at the bottom of the page.

2. Select desired UUT from the drop down box at the top of the page. If desired UUT is not

there, see Page 24 for creating a new UUT.

3. View the TEST drop down box and conrm that prole selected is the desired pressure

test prole, if not, select desired prole from drop down list or if desired test prole is

not there, see Page 22 for creating a new test setup.

4. Select AS FOUND or AS LEFT radio button.

5. Tap TARE and wait until completed. This zeroes the ref. unit.

6. Tap RUN button.

7. To stop a test in process, tap the STOP button. This will stop and

cancel the test.

8. Target pressure will be generated and data will be automatically

recorded at each pressure point. Note: If the DisplayTest Results in Graph Option is selected (see

Edit Defaults page) - a graph will appear displaying pressure vs. error after the pressure sequence

has been completed (Diagram 11).

9. To record data -Tap RECORDTEST RESULTS button

Note: RecordTest Results Button has 3 states indicating the save status of test results. When no test

results are available to save, the button reads“No Results To Save.” When results on screen have

been saved, the button will change to“Test Results Saved.” After a test is complete and before the

data is saved, the button will read“RecordTest Results.”

10. To review data - Tap REVIEW TEST RESULTS button

11. To expand/collapse theTest Prole/Results window, double tap anywhere insideTest Results

list.

Diagram 10

Record Data

Target Pressure

Prole ID

TestTab

Review Data

Do Test

Unit UnderTest

(UUT) Identity

Re-Zero

Stop

As Found/As Left

Test Selection

Test Prole/

ResultsWindow

19

6.31 RUNTEST: Dial Gauge

Dierences from General (Diagrams 10 & 11):

-Pressing RUN button brings up separate test page with dither control (Diagram 12).

-Output columns removed fromTest Prole/Results window.

6.32 RUNTEST: PSWITCH

Dierences from General (Diagrams 10 & 11):

-Pressing RUN button brings up separate test page with dither control (Diagram 12).

-Output columns removed fromTest Prole/Results window.

-O/C column added to indicate the state of the pressure switch.

O - Open

C - Closed

Diagram 11

20

6.33 RUNTEST: DITHER CONTROL PAGE (Manual Pressure Incrementing)

Screen Instructions (Diagram 12):

Test Point Indicator: Displays present test point number.

Target Pressure: Displays present test point target pressure.

Eng Units Display: Displays pressure units.

Pressure Display Window: Displays present pressure during test.

OPEN/CLOSE Indicator: Available only with P-Switch, indicates open/closed status of

switch.

Take Data Button: Forces data collection for Dial Gauge. Tells software that the UUT is

indicating the present target pressure.

Target Pressure Button: Set pressure target to original target dened by test prole for

present test point.

Vent Button: Stops the test in progress and vents MicroCal pressure ports to atmosphere.

Halt: Pauses pressure control. Leaves system closed to allow for quick re-acquisition of

target pressure.

Set PointWindow: Displays present set point for the MicroCal pressure controller.

Updates when test point number is changed, or when +/- dither controls are used. Also,

allows user entry.

GO Button: Updates pressure target within MicroCal to that displayed in the set point

window. Starts pressure control.

- FINE Button: Decreases pressure set point by 0.1% of UUT span.

+ FINE Button: Increases pressure set point by 0.1% of UUT span.

- COARSE: Decreases pressure set point by 1% of UUT span.

+ COARSE: Increases pressure set point by 1% of UUT span.

Cancel Button: Stops test in progress and erases any data taken. Leaves unit in vented

state.

Diagram 12

Take Data Button

Vent Button

Cancel Button

Pressure

Display

Window

OPEN/CLOSED

Indicator

(P-Switch Only)

Set PointWindow

Halt Button

GO Button

+ FINE Button- FINE Button

+ COURSE Button- COURSE Button

Target

Pressure

Test Point

Indicator Eng. Units

Display

Table of contents