Chopin QUATUOR User manual

20, avenue Marcellin Berthelot - Z.I. du Val de Seine

92396 Villeneuve La Garenne cedex - France

www.chopin.fr

www.chopinservice.com

QUATUOR

User’s manual

10/2016

Phone: +33 1 41 47 50 33

Fax: +33 1 47 47 17 13 (SAV)

E-mail: [email protected]

QUATUOR

2 User’s manual

10/2016

QUATUOR

3

User’s manual

10/2016

IMPORTANT

The technical elements that constitute this manual (text and illustrations) are not contractual,

their only target being to bring assistance for using the Quatuor.

Use, duplication or disclosure of subject data, for any purpose other than relating to the use or

servicing of the equipment, is strictly prohibited without the written authorisation of Chopin

Technologies.

QUATUOR

4 User’s manual

10/2016

QUATUOR

5

User’s manual

10/2016

Siège de Chopin Technologies

20 avenue Marcellin Berthelot, 92396 Villeneuve-la-Garenne Cedex, France

Tél. : +33 1 41 47 50 90 – Fax. : +33 1 47 92 02 44

S.A. au capital de 1 821 700 Euros – R.C.S. Nanterre – Siret 403 156 441 00020 – APE 332 B – TVA FR 03 403 156 441

DECLARATION OF CONFORMITY

We Chopin Technologies, address as below,

declare under our sole responsibility that the following Apparatus :

Quatuor

When installed and used in accordance with the instructions in the Product Manual,

is in conformity with the following standards :

the EEC directive “Low Voltage“ 2006/95/CE.

the EEC directive “Electromagnetic compatibility“ 2004/108/CE

Emmanuel LECOMTE

Conformance officer

Chopin Technologies

Daniel VILHIES

Technical director

Chopin Technologies

Date :

10/2010

QUATUOR

6 User’s manual

10/2016

QUATUOR

7

User’s manual

10/2016

Table of contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Section 1 Installation and setup . . . . . . . . . . . . . . . . . . . . . . . 11

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2. Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4. Connection of other units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5. IElectric connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6. Powering up the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Section 2 Normal use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1. Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2. Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3. The touch screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4. Test cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5. Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Section 3 Operation and configuration . . . . . . . . . . . . . . . . . 31

1. Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2. Safety recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3. Screens of the QUATUOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Section 4 Making adjustments and calibrations . . . . . . . . . . 49

1. Choosing the sieves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2. Case of the sunflower sieve with cover (FADT-65) . . . . . . . . . . . . . 55

3. Creating or modifying a calibration . . . . . . . . . . . . . . . . . . . . . . . . . 57

Section 5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1. Periodic maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2. Problem solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3. Changing fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4. Calibrating the screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5. Calibrating the scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6. Replacement recommended frequency of parts having

an influence on the result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Appendix keyboard shortcuts . . . . . . . . . . . . . . . . . . . . . . . . 71

QUATUOR

8 User’s manual

10/2016

QUATUOR

9

User’s manual

10/2016

INTRODUCTION

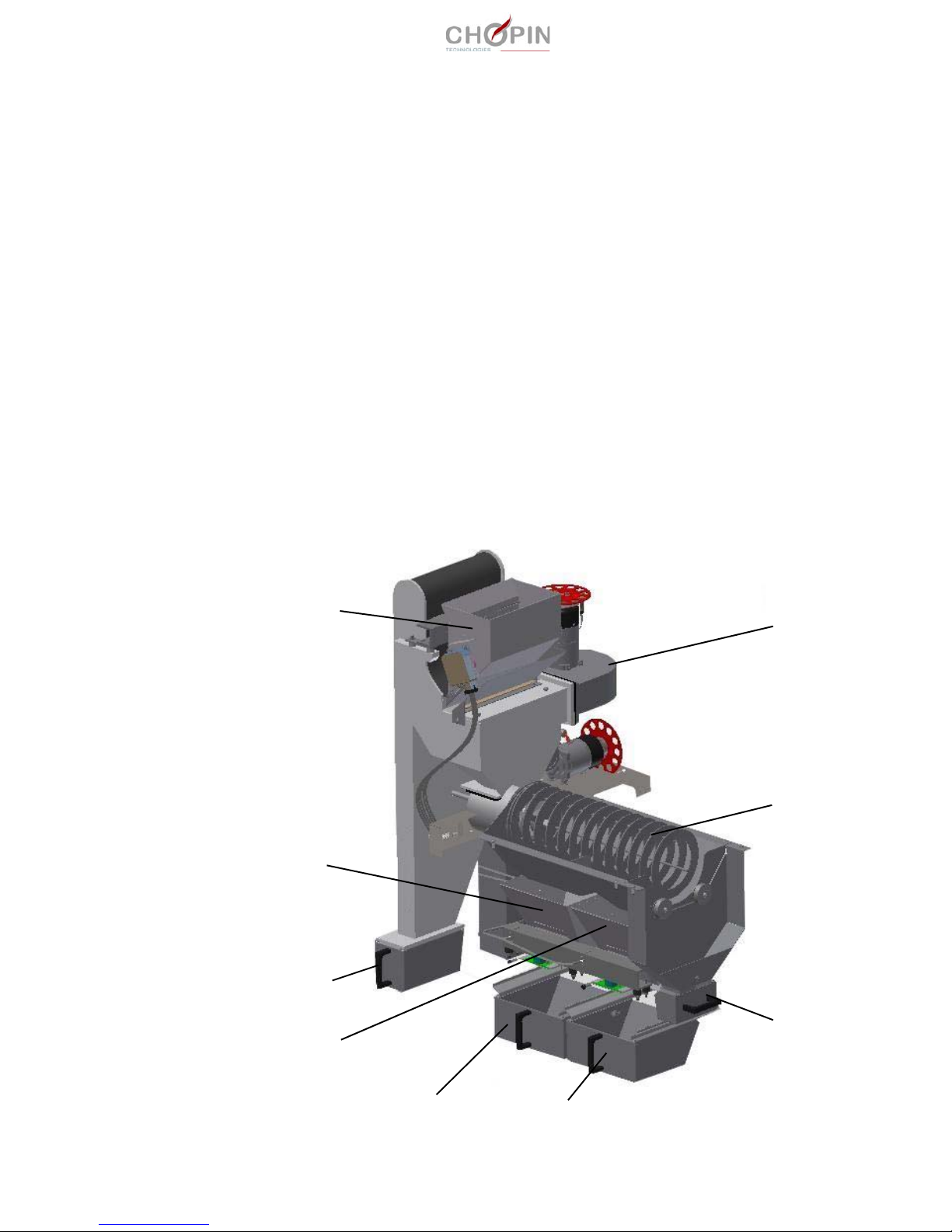

■ Principle :

■ The function of the Quatuor is to provide the percentage of good

grain, impurities and broken grain from a given sample.

■ The test cycle starts with a debearding (optional module), and the

sample weighing (scale B1).

■ The apparatus proceeds then to the elimination of lightest parti-

cles (dust).

■ The rest of the sample falls then into cylindrical sieves and is

sorted into 3 categories:

❏ broken grain,

❏ good grain,

❏ big impurities.

■ Good grain and broken grain are weighed separately by scales

B2 and B3 respectiveley.

blower

sieves

weighing

hopper B1

scale B3

light impurities

broken grain good grain

big

impurities

scale B2

QUATUOR

10 User’s manual

10/2016

■ Within 1 mn 30 sec, the QUATUOR:

❏ sorts the sample into 4 categories (light impurities, broken grain,

good grain, big impurities),

❏ calculates the percentage of good grain, broken grain and impuri-

ties + broken grain.

■ Overall characteristics:

❏ The QUATUOR has a memory able to contain 21 user-program-

mable calibrations.

❏ A parallel output allows the connection of a printer with a Cen-

tronics interface.

❏ An RS232 serial interface allows the connection of a PC compati-

ble.

❏ A mini DIN port allows the connection of a standard keyboard.

❏ Power supply: 230 V - 50/60 Hz - 210 W

❏ Noise level: < 70 dB

❏ Dimensions:

Length = 500 mm; Depth = 730 mm; Height = 940 mm

❏ Net weight: 50 kg

■ Environment:

❏ Inside use.

❏ Storage temperature: — 20°C to + 60° C

❏ Operating temperature: 2°C to 45° C

❏ Hygrometry: HR 85% at 40°C

❏ Supply voltage tolerance: < ± 10%

❏ Pollution level according to EN 61010: 2

❏ Installation class according to EN 61010: II

(for transitional over voltage)

❏ Utilisation area (dust hazard risk): all areas except areas rated

20, 21 and 22.

■ Fuse :

Fuse 5x20 T 2A 250V

QUATUOR

11

User’s manual

10/2016

Section 1 INSTALLATION AND SETUP

QUATUOR

12 User’s manual

10/2016

QUATUOR

Section 1 Installation and setup 13

User’s manual

10/2016

Section 1. Installation and setup

1. Unpacking ■ The apparatus is packed in a dedicated packing, that we recom-

mend you to keep for future use (transfer from one location to

another one, periodic service, etc.).

This packing contains the QUATUOR with accessories and the

user’s manual.

■ The QUATUOR shall be handled by two persons. See handling

areas on figure below.

QUATUOR

14 Section 1 Installation and setup User’s manual

10/2016

2. Composition The QUATUOR (1) is supplied with:

■ 1 pen for touch-screen (2),

■ 1 one-litre container (3),

■ 1 power cord (4),

■ a distribution screw (5), with an optional sieve (see installation

page 53),

■ a brush (6), to be installed before the first use.

1

4

3

5

2

6

QUATUOR

Section 1 Installation and setup 15

User’s manual

10/2016

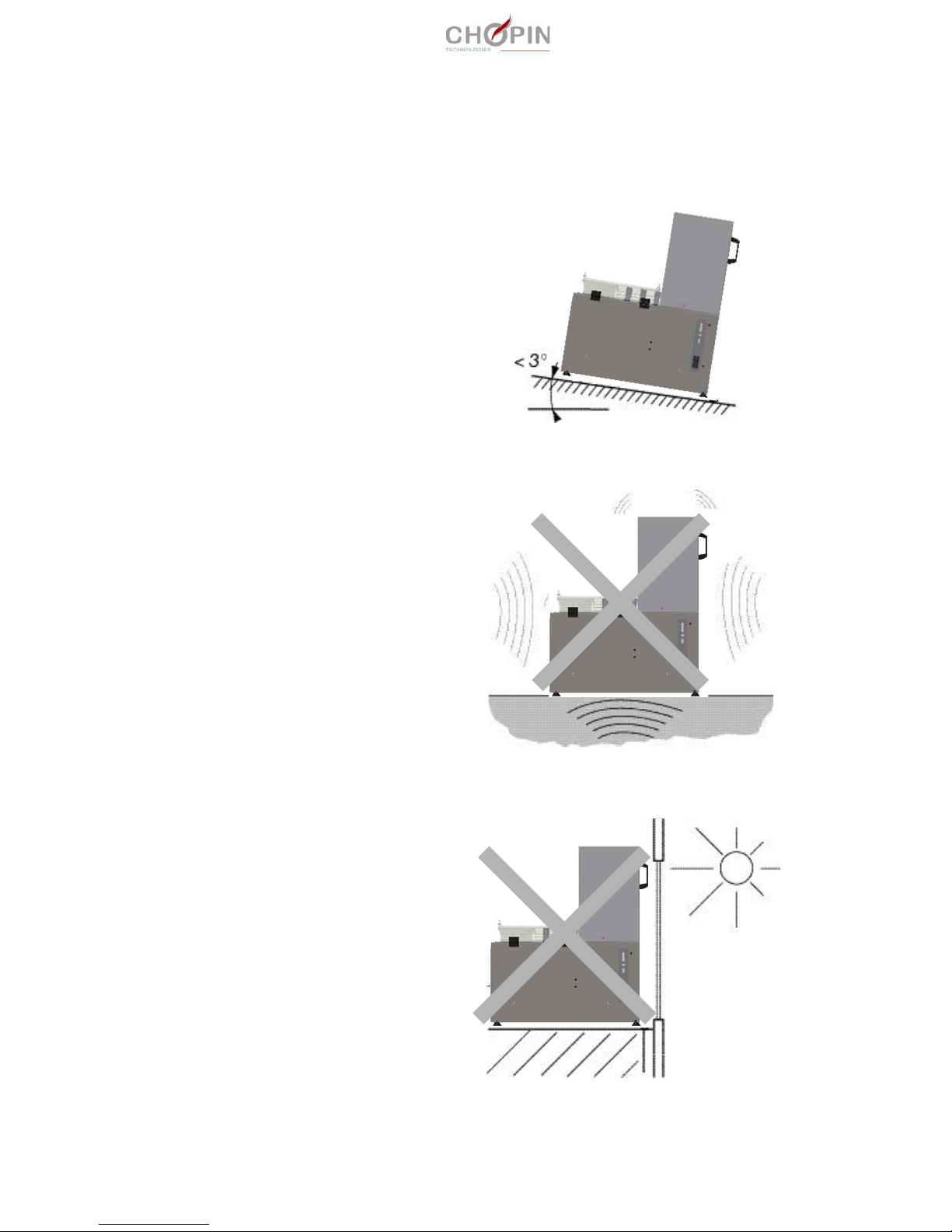

3. Installation 3.1 Generalities

■ Install the QUATUOR on a stable and horizontal surface. Maxi-

mum tilt angle: 3°.

■ Avoid locations subjected to vibrations (machines, trains, trucks,

etc.): this may cause wrong weight measurements.

■ Avoid placing the QUATUOR behind a window pane exposed to

sunshine during several hours.

QUATUOR

16 Section 1 Installation and setup User’s manual

10/2016

3.2 Installing the brush

1. Open the cover.

2. Insert the brush on the first spring.

3. Push the second spring with the hand and insert the brush on

the second spring.

QUATUOR

Section 1 Installation and setup 17

User’s manual

10/2016

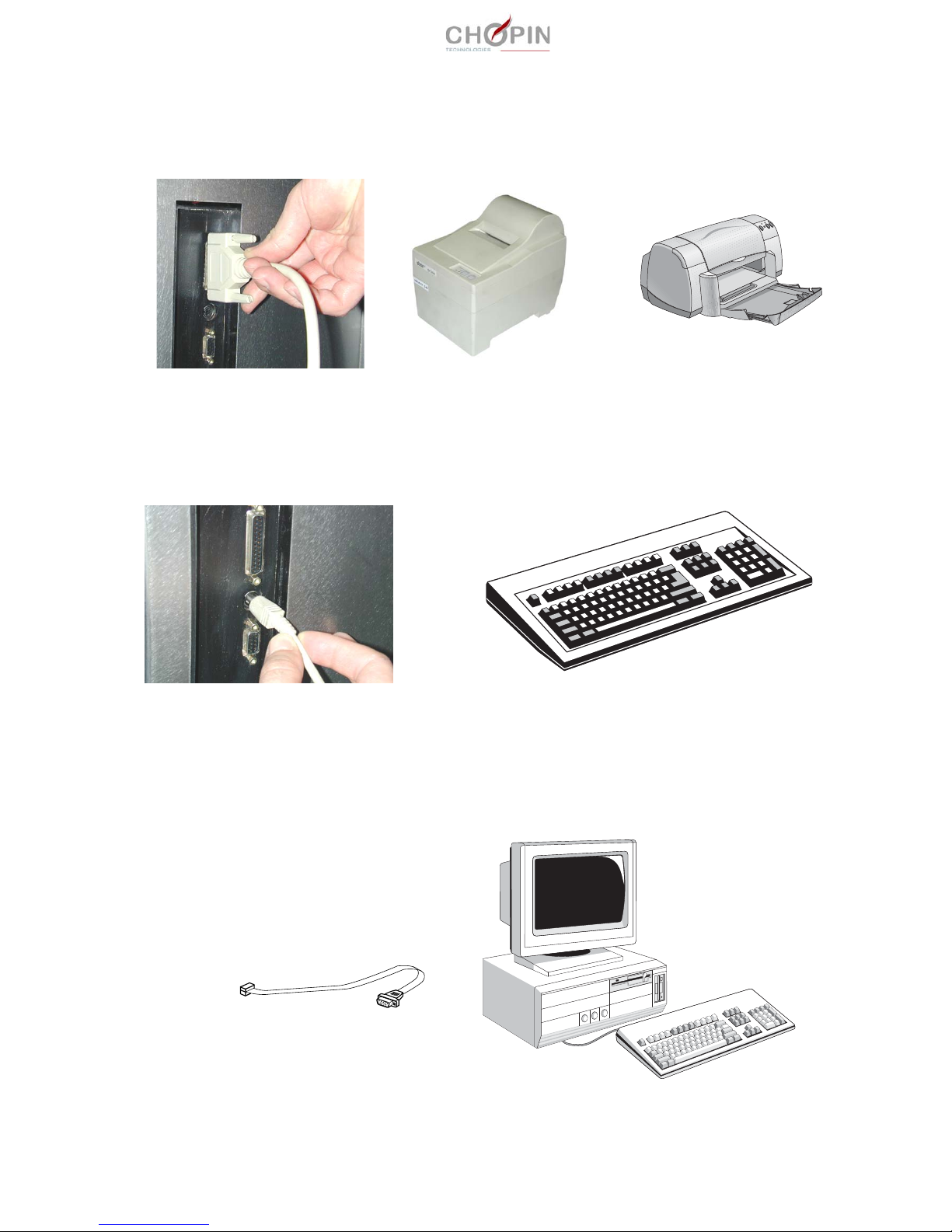

4. Connection of other

units

■ The printer

A standard or ticket-type printer can be connected to the QUATUOR

through the Centronics parallel port.

■ The keyboard

A keyboard can be connected to the QUATUOR through the mini

DIN serial port.

This will enable the entering of alphanumeric characters in certain

menus.

■ A computer

A computer can be connected on the RS232 port of the QUATUOR.

Contact Chopin Technologies.

or

QUATUOR

18 Section 1 Installation and setup User’s manual

10/2016

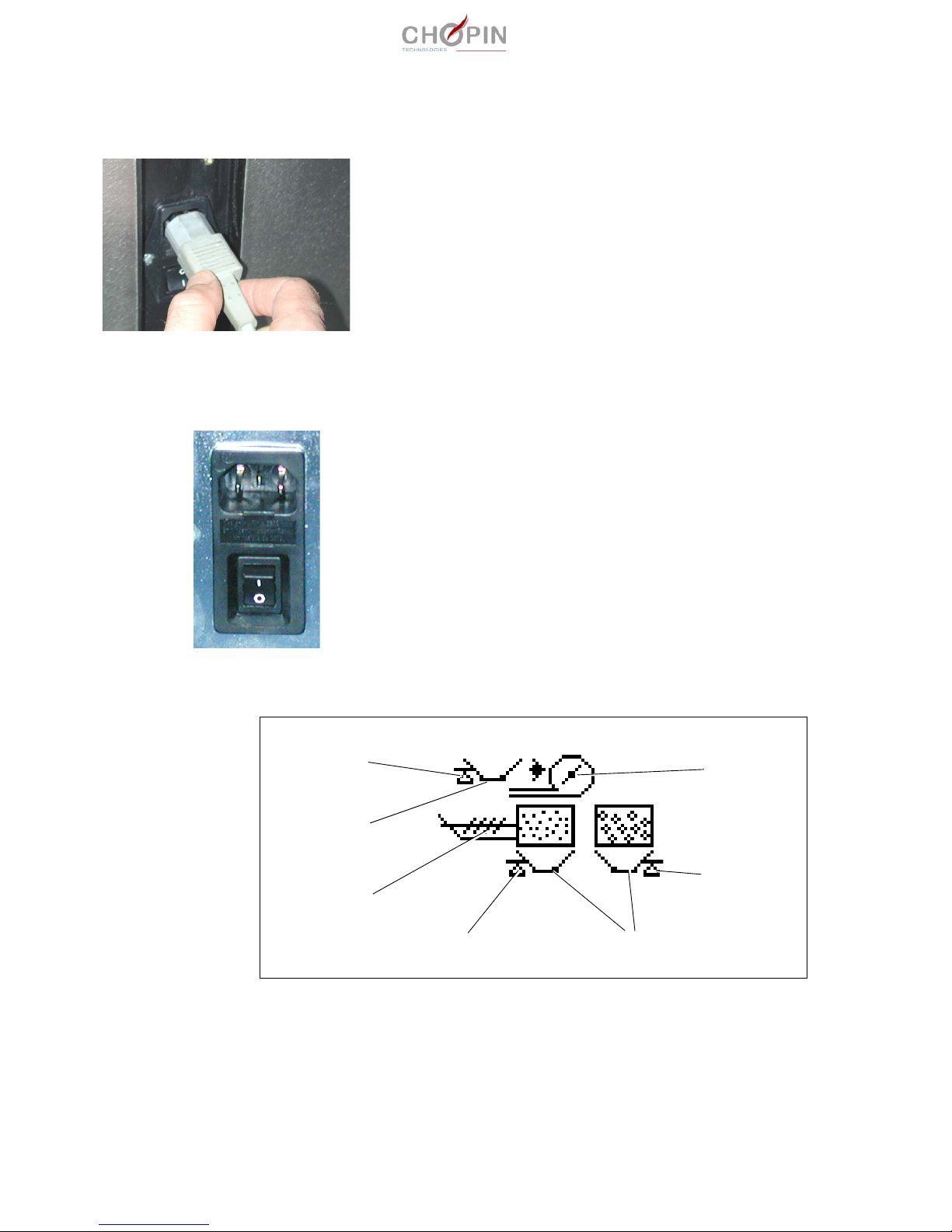

5. IElectric connection The QUATUOR is an electronic apparatus which must be connected

to an electrical network equipped with an Earth terminal. Above all,

verify the condition of this connection.

In addition, the electrical network must be equipped with an RDD

(Residual Differential Device) of the AC grade with a sensitivity

30 mA.

For the connection to the network, use the power cord provided with

the QUATUOR.

The mains plug and the I/O switch are located at back of the appa-

ratus.

6. Powering up the unit ■ Turn the On/Off switch to ON. The QUATUOR runs a self-test

sequence, checking most of its functions (memories, INIT parame-

ters, motors, scales, etc.); during this sequence, which lasts 1 min

approx., all commands (by means of the touch screen or a key-

board) are inactive.

■ During this self-test sequence are displayed:

❏ the name of the apparatus,

❏ the software version,

❏ successively the different test phases described in table below

.

blower

sieve control

M4

B1

B3

M1

B2

QUATUOR

Section 1 Installation and setup 19

User’s manual

10/2016

■ If an anomaly is detected during this sequence, an error message

is displayed. In this case switch the apparatus Off then On. If the

message is still present, refer to chapter "Problem solving"

page 62.

■ After this initialization sequence, the QUATUOR is ready, and the

the main menu is displayed; it mentions the name of the last grain

selected before apparatus power-off, and allows to choose the oper-

ation to initiate by simply selecting the corresponding touch icon.

■ The user may so :

❏ modify the selected grain,

❏ initiate a test sequence of a grain sample,

❏ access to other menus whose content is detailed in chapter "The

maintenance menu" page 41.

Phase Meaning

1 Tare on scale B1

2Functional test of M1 (grain feeding trap door) with

position reading of stops

3 Functional test of M2

4Functional test of the debearder, then functional

test of M3

5 Tare on scale B1

6 Functional test of the blower

7If tare B1 phase 1 <> tare B1 phase 5, then open-

ing of M1

8Functional test of sieve control, and if tare B1

phase 1 <> tare B1 phase 5, then waiting 180sec

9 Functional test of M4 (emptying trap doors)

10 Tare on scales B2 and B3

QUATUOR

20 Section 1 Installation and setup User’s manual

10/2016

Table of contents

Other Chopin Test Equipment manuals

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started