Cencal Out 4Modbus

• Serial line / output 4

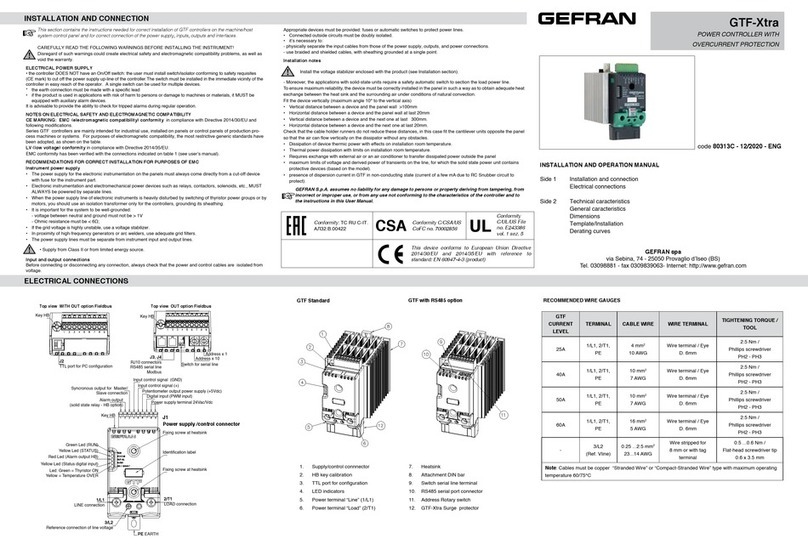

Advice for Correct Installation for EMC

Instrument power supply

• The power supply to the electronic equipment on the

switchboards must always come directly from an isolation

devicewithafusefortheinstrumentpart.

• The electronic instruments and electromechanical power

devicessuchasrelays,contactors,solenoidvalves,etc.,must

alwaysbepoweredbyseparatelines.

• When the electronic instrument power supply is strongly

disturbed by the commutation of transistor or power units

or motors, an isolation transformer should be used for the

controllersonly,earthingthescreen.

• Itisessentialthattheplanthasagoodearthconnection:

-thevoltagebetweenneutralandearthmustnotbe>1V

-theOhmicresistancemustbe<6W;

• Ifthemainsvoltagefluctuatesstrongly,useavoltagestabilizer.

• In the proximity of high frequency generators or arc welders,

useadequatemainsfilters.

• The power supply lines must be separate from the instrument

inputandoutputones.

Inputs and outputs connection

• Theexternallyconnectedcircuitsmustbedoublyisolated.

• To connect the analogue inputs (TC, RTD) the following is

necessary:

-physicallyseparatetheinputcablesfromthoseofthepower

supply,theoutputsandthepowerconnections.

-usewovenandscreenedcables,withthescreenearthedin

onepointonly

• To connect the regulating and alarm outputs (contactors,

solenoid valves, motors, fans, etc.), fit RC groups (resistance

andcondensersinseries)inparalleltotheinductiveloadsthat

operateinAlternatingCurrent.

(Note: all the condensers must conform to VDE (class X2)

standards and withstand a voltage of at least 220V AC. The

resistancesmustbeatleast2W).

• Fit a 1N4007 diode in parallel with the coil of this can be

removedinductiveloadsthatoperateinDirectCurrent.

GEFRAN S.p.A. declines all responsibility for any

damage to persons or property caused by tampering,

neglect, improper use or any use which does not

conform to the characteristics of the controller and to

the indica tions given in these Instructions for Use.

Warnings and instructions for mounting to the panel

Instructions for installation category II, pollution

level 2, double isolation.

• onlyfor lowpower supply:supply fromClass 2or lowvoltage

limitedenergysource.

• the power supply lines must be separate from the controller

inputandoutputones

• grouptheinstrumentstogetherkeepingthemseparatefromthe

poweredpartoftherelay

• do not install high-power remote switches, contactors, relays,

thyristor power units (especially the “phase angle” type),

motors,etc.inthesameswitchboard

• avoiddust,humidity,corrosivegassesandheatsources

• do not block the ventilation holes: the working temperature

mustbebetween0...50°C

• surroundingair:50°C

• use60/75°Ccopper(Cu)conductoronly,wiresizerange2xNo

22-14AWG,Solid/Stranded

• useterminaltighteningtorque0.5Nm

Nominal ambient conditions

Before supplying the Controller with power, make

sure that the mains voltage is the same as that

shown in the last number of the order code.

600

ouT1 ouT2 ouT3

SV

ouT4

L1

L2

L3

F

8888

8888

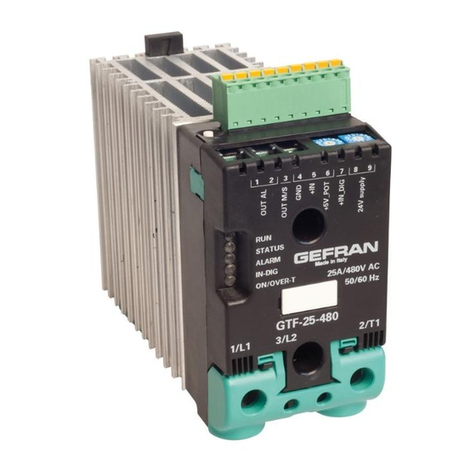

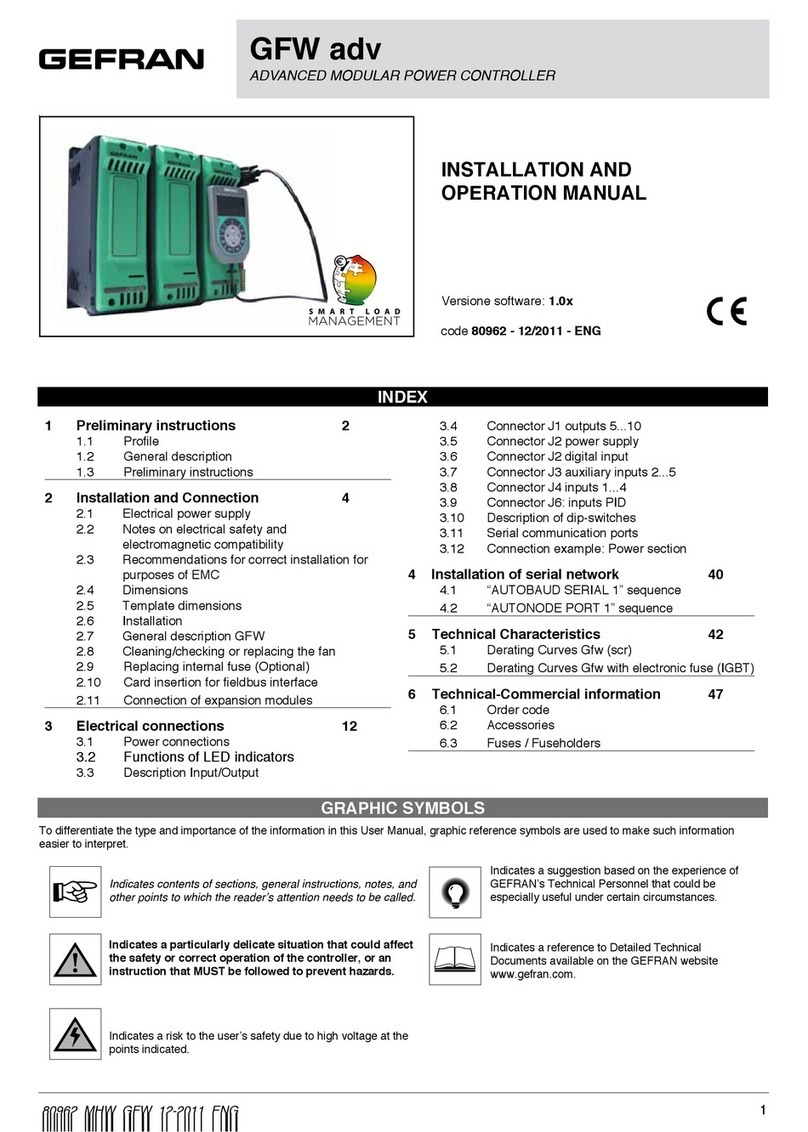

This section contains the instructions necessary for correct

installation of the 600 controllers into the machine control

panel or the host system and for correct connection of the

controller power supply, inputs, outputs and interfaces.

Before proceeding with installation read the following

warnings carefully!

Remember that lack of observation of these warnings

could lead to problems of electrical safety and

electromagnetic compatibility, as well as invalidating

the warranty.

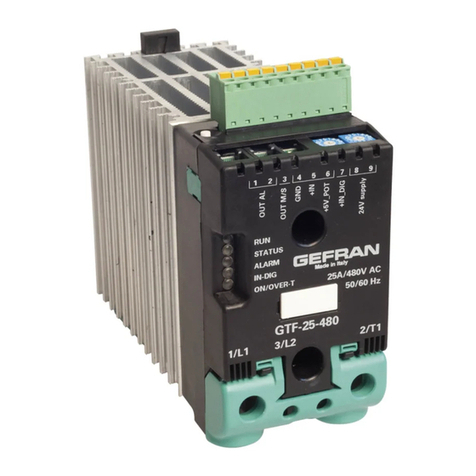

Electrical power supply

• the controller is NOT equipped with an On/Off switch: the user

mustprovideatwo-phasedisconnecting switch thatconformsto

the required safety standard (CE marking), to cut off the power

supplyupstreamofthecontroller.

The switch must be located in the immediate vicinity of the

controller and must be within easy reach of the operator. One

switchmaycontrolmorethanonecontroller.

• ifthecontrollerisconnectedtoNOTisolatedelectricalequipment

(e.g.thermocouples),theearthconnectionmustbemadewitha

specific conductor to prevent the connection itself from coming

directlythroughthemachinestructure.

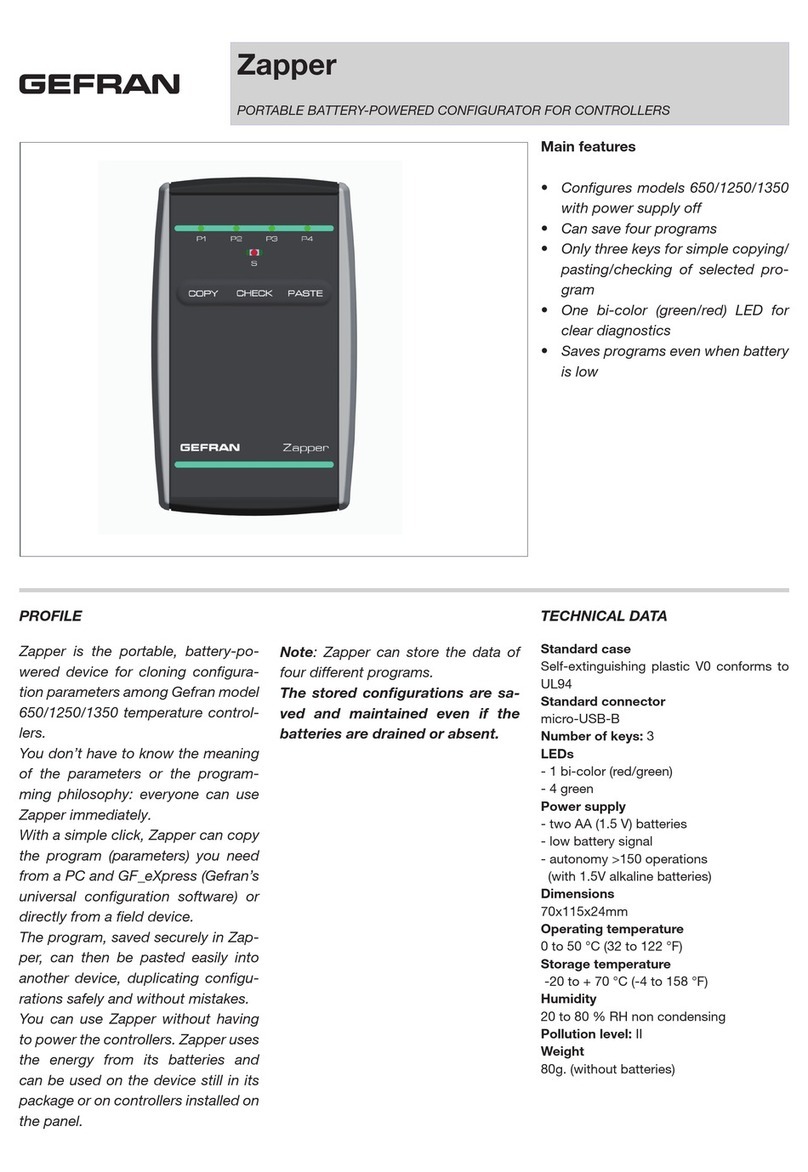

600

CONTROLLER

INSTALLATION AND OPERATION MANUAL

Side1 1Dimensionsandcut-out;panelmounting

2Installationandconnection

3Descriptionoffaceplate

4Connections

Side2 5Technicalspecifications

6“Easy”programmingandconfiguration

7Quickstartguide

The complete manual is available for download from the

website www.gefran.com

GEFRANspareservestherighttomakeanyaestheticor

functionalchangeatanytimeandwithoutnotice.

cod.80311 - 11/2012 - ENG

1 • DIMENSIONS AND CUT-OUT;

PANEL MOUNTING

99

10

45

45

48

70

70

63

48

Forcorrectandsafeinstallation,

followtheinstructionsand

observethewarningscontained

inthismanual.

Panel mounting:

Tofixtheunit,insertthebracketsprovidedintotheseatsoneither

sideofthecase.

Tomounttwoormoreunitssidebyside,respectthecut-out

dimensionsshowninthedrawing.

2 • INSTALLATION AND CONNECTION

3 • DESCRIPTION OF FACEPLATE

Automatic/ManualadjustmentselectionActiveonlywhenPV

displayvisualisestheprocessvariable

Function indicators

Indicatesmodesofoperation

MAN/AUTO= OFF(automaticcontrol)

ON(manualcontrol)

SETPONT1/2= OFF(IN1=OFF-localSetpoint1)

ON(IN1=ON-localSetpoint2)

SELFTUNING=ON(enabledSelf)

OFF(disabledSelf)

“Inc” and “Dec” key

Presstoincrement(decrement)anynumericalparameter••Increment(decrement)speedisproportionaltotimekeystays

pressed••Theoperationisnotcyclic:oncethemaximum(minimum)valueofafieldisreached,thevaluewillnotchangeevenif

thekeyremainspressed.

PV Display:Indicationofprocessvariable

ErrorIndication:LO,HI,Sbr,Err

LO=thevalueofprocessvariableis<diLO_S

HI=thevalueofprocessvariableis>diHI_S

Sbr=faultysensororinputvalueshigherthanmax.limits

Err=PT100thirdwireopenedforPT100,PTCorinput

valueslowerthanmin.limits(i.e.:TCwrongconnection)

Function key

Givesaccesstothevariousconfigurationphases••

Confirmschangeofsetparametersandbrowsesnextor

previousparameter(ifAuto/Mankeyispressed)

SV display:Indicationofsetpoint

Indication of output states

OUT1(AL1);OUT2(Main);OUT3(HB);OUT4(HB)

5Aat

250Vac/30Vdc

relay

Standard:

100...240Vac±10%

Optional:

11...27Vac/dc±10%

Max.power10VA;50/60Hz

4 • CONNECTIONS

• Ammeter outputs/input

6

5

4

3

2

1

7

8

9

10

11

12

18

17

16

15

14

13

19

20

21

22

23

24

19

21

20

22

-

+

Out2

Out1

• Power Supply

23

24

~

~

TOP

6

5

-

+

Out3(Al2)

Ing.T.A.

PWR

Standard

configuration

4...20mA

Connectat20mAinput

Usewiresof

adequatediameter

(min.1mm2)

PT100,JPT100,

PTC,NTC

• Pt100 / PTC / NTC

• Device structure • Identification of boards

3

1

2

Pt1003wires

PTC/NTC

/Pt1002wires

Availablethermocouples:

J,K,R,S,T

(B,E,N,L,U,G,D,Ccustomlinearization

isavailable)

-Observepolarities

-Forextensions,usethecorrect

compensatingcableforthetypeofTCused +

-

• TC Input

2

1

4

2

3

1

+ 24Vo15V

VT

-

+

+

S

-

Ri=50Ω

4

2

3

1

+24Vo15V

VT

-

+

+

-

Ri=50Ω

T

T

• Linear input with 3-wire transmitter

• Inputs

• Input 1 linear with transmitter 2 wires

9

10

11

+

-

TX

A

(Data+)

RX

-

+

12

9

10

11

12

DISPLAY

POWER

SERIALINTERFACE/OUT4

Selectsignalat

contact3

CPUboard-Componentside

CPU

PT100

+VT

Linearinput

indccurrent

20mA,

Ri=50Ω

Linearinputin

dcvoltage

60mV,1VRi>1MΩ

5V,10VRi>10KΩ

2

1+

-

• Linear input (I)

4

1

2

-

+

• Linear input (V)

RS485isolatedserialline

SeeserialcarddatasheetforCencalconfiguration

-5Aat250Vac/30Vdcrelay

-24V,10Vat20mAlogic

-triac20...240Vac,1A±10%

-Digitalinsulated24Vac/dc

-5A/250Vacrelayonly

-5Aat250Vac/30vdcrelay

-24V,10Vat20mAlogic

-continuous0…10V,0/4…20mA

-analog0…10V,0/4…20mAfor

transmission,resolution12bit

-inputfromcurrenttransformer

50mAac,10Ω50/60Hz

-logicinput24V,5mAorfrom

no-voltagecontact

-Digitalinsulated24Vac/dc

Userconfigurablegenericoutput

11

B

(Data-)

24V

15V

10V

5V

1,23V

R20

S2

NB.:youcankeeptheOUT1relayenergizedatpower-upby

insertingjumperS2andremovingresistanceR20.

IN/OUTboards

(seeappendix)

Powerboard-Solderside

Selecttransmitter

voltage

Altitude Upto2000m

Working/storage

temperature 0..50°C/-20...70°C

Noncondensing

relativehumidity 20...85%

GEFRAN spaviaSebina,74-25050Provagliod’Iseo(BS)

Tel.03098881-fax0309839063Internet:http://www.gefran.com

PV

• if the controller is used in applications with risk of damage to

persons,machineryormaterials,itisessentialtoconnectitup

toauxiliary alarmequipment. Itis advisableto makesure that

alarmsignalsarealsotriggeredduringnormaloperation.

ThecontrollermustNOTbeinstalledinflammableorexplosive

environments; it may be connected to equipment operating

in such atmospheres only by means of appropriate and

adequatetypesofinterface,conformingtotheapplicablesafety

standards.

Notes Concerning Electrical Safety and

Electromagnetic Compatibility:

CE MARKING:

The instrument conforms to the European Directives 2004/108/

CEand2006/95/CEwithreferencetothegenericstandards:

EN 61000-6-2(immunityinindustrialenvironment)EN 61000-6-3

(emissioninresidentialenvironment)EN 61010-1(safety).

Series 600 temperature controllers are mainly designed to

operateinindustrial environments, installedonthe switchboards

orcontrolpanelsofproductiveprocessmachinesorplants.