Sfere WDH-31-531 User manual

Motor Protection Controller

User Manual

Applied to:

WDH-31-531

JIANGSU SFERE ELECTRIC CO., LTD.

CONTENT

1 Introduction ...................................................................................................... 1

1.1 Product Overview ..................................................................................1

1.2 Application scenario ..............................................................................3

1.3 Overview of functions ...........................................................................5

1.3.1 Monitoring functions ................................................................. 5

1.3.2 Protection functions ...................................................................6

1.3.3 Control functions ........................................................................7

1.3.4 Communication .......................................................................... 7

1.3.6 Management functions ..............................................................9

1.4 Overview of system components ....................................................... 11

1.5 Order codes ......................................................................................... 13

2. Installation ..................................................................................................... 15

2.1 Size ....................................................................................................... 15

2.1.1 Controller main body installation(5A/25A hole type)......15

2.1.2 Controller main body installation(100A hole type)..........15

2.2 Terminal Wiring ................................................................................... 17

2.2.1 Diagram of connection between main body and display panel

............................................................................................................17

2.2.2 External residual current transformer wiring .........................18

2.3.3 Voltage input wiring .................................................................18

3. Motor protection ...........................................................................................19

3.1Thermal Overload ................................................................................ 19

3.2 Stall ...................................................................................................... 21

3.3 Current imbalance ...............................................................................21

3.4 Phase Loss ............................................................................................22

3.5 Under Load .......................................................................................... 22

3.6 Jam Protection .....................................................................................23

3.7 Short-Circuit .........................................................................................24

3.8 Ground Fault ........................................................................................24

3.9 Residual Current ..................................................................................25

3.10 Start Overtime ...................................................................................26

3.11 Phase sequence .................................................................................27

3.12 Under Voltage ....................................................................................27

3.13 Over Voltage ...................................................................................... 28

3.14 Voltage Imbalance .............................................................................29

3.15 PT Breaking ........................................................................................29

3.16 External Fault .....................................................................................30

3.17 Time tE ( Increased Safety Motor ) ...................................................31

3.18 Thermistor ......................................................................................... 32

4. Motor control ................................................................................................ 33

4.1 Start/stop control logic ....................................................................... 33

4.1.1 Command start and stop ......................................................... 33

4.1.2 External bypass start/stop .......................................................34

4.2 Control authority .................................................................................35

4.3 Power on self-starting .........................................................................36

4.4 Under voltage restart .......................................................................... 37

4.4.1 Instant restart ...........................................................................37

4.4.2 Under voltage restart ...............................................................37

4.5 Analog Output ..................................................................................... 38

4.6 Start mode ........................................................................................... 39

4.6.1 Thermal relay ........................................................................... 39

4.6.2 Direct start ................................................................................40

4.6.3 Reversing .................................................................................. 41

4.6.4 Two speed start ........................................................................42

4.6.5 Star Delta start ......................................................................... 43

5. Communication ............................................................................................. 44

5.1 RS485 network .................................................................................... 44

5.1.1 Network topology .................................................................... 44

5.1.2 Interface definition .................................................................. 44

5.1.3 Related parameters ..................................................................44

5.1.4 Modbus instruction sets .......................................................... 45

6. Operation panel .............................................................................................46

6.1 Panel .................................................................................................... 46

6.2 Control interface ..................................................................................47

6.3 Query interface ....................................................................................48

6.3.1 Running data ............................................................................ 49

6.3.2 Alarm ........................................................................................ 50

6.3.3 Record .......................................................................................50

6.3.4 Maintenance information ........................................................51

6.4 Setting interface .................................................................................. 52

6.4.1 Basic setup ................................................................................53

6.4.2 System Setup ............................................................................ 53

6.4.3 Start control ..............................................................................54

6.4.4 Protection Setup ...................................................................... 55

6.4.5 Self-start Setup .........................................................................56

6.4.6 Restart Setup ............................................................................56

6.4.7 Analog output Setup ................................................................56

6.4.8 Communication Setup ............................................................. 57

6.4.9 Digital input Setup ................................................................... 57

6.4.10 Digital output Setup ...............................................................58

6.4.11 System clock .......................................................................... 59

7. Fault detail ..................................................................................................... 61

8. Technical data ................................................................................................ 63

9. Appendix ........................................................................................................65

9.1Overload protection time characteristic table ................................... 65

9.2 tE Time Protection Characteristic Table ............................................. 65

Version

number

Date

Description

V1.0

2022.04.22

Initial version

V1.1

2022.06.15

Correct some errors

Precautions

This instruction is intended for use by professionals who are trained and familiar with

standards in electrical installation and control and automation engineering.

The responsible person must ensure that the application or use of the product meets all

safety requirements.

Abbreviation

DCS

Distributed Control System

PLC

Programmable Logic Controller

NO/NC

Normal Open / Normal close

DI

Digital input

DO

Digital output

AI

Analog input

AO

Analog output

PTC/ NTC

Thermal resistance input

MC

Main module

SCT

Current transformer module

Related document

WDH-31-530 Modbus-RTU protocol manual

1

1 Introduction

1.1 Product Overview

WDH-31-531 motor protection controller (hereinafter referred to as controller or WDH) is

applicable to the application sites of three-phase low-voltage AC motor with rated

frequency of 50/60hz, rated voltage of 690V AC and rated current of 800A. The product has

the functions of monitoring, control, protection and communication, and provides perfect

protection and control for the motor.

Application

·Low voltage three phase AC motor

·Motor independent control box or MCC cabinet

·Reversing and Reduced voltage applications

·Industrial automation, such as belt-transportation, mixing system etc.

·Fire pumps and fans

Advantages

- A variety of protection functions are built in, and the on / off, alarm or trip functions of the

protection function are programmable

- Rich starting control, single-step starting (direct / two-way, etc.); Two step starting (star

delta / soft start coordination, etc.)

- Under voltage hoisting, power on and self starting function ensure the uninterrupted

operation of the motor

- With residual current transformer, additional residual current transformer and external

wiring can be avoided

- 1-way PTC / NTC thermistor input for motor temperature monitoring and protection

- 5-way programmable switching value input and 4-way programmable relay output

- 2 Channel Programmable 4 ~ 20mA analog output

- Rich SOE event records, tripping, alarm, start stop, input displacement, etc

- Standard RS485 communication interface, optional Modbus RTU or PROFIBUS DP protocol

- Optional Ethernet communication interface with switch function, Modbus TCP protocol

- Optional black-and-white or color Chinese LCD module to visually display and indicate

various parameters, information and status

2

- Equipped with upper computer management software to realize parameter configuration,

debugging and monitoring

- Modular structure design, flexible combination of main body, transformer, display module

and optional function

- The installation method is flexible and the overall size is reasonable. It can be installed in 1

/ 4 drawer cabinet

3

1.2 Application scenario

MOTOR

LOAD

Contator

Phase CT 3

Residual CT1

BUS

Breaker

Fuse

Voltage inputs

METERING

V,A,W,Var,VA,pf,Hz,Wh,Varh

27

27

47 59

51R 49 66 37 46

50G 51G

RS485-Modbus RTU

Voltage

Communication

Digital

inputs

50P

48

68

Relay outputs

HMI

Current inputs

Residual inputs

Thermistor inputs 49

Figure 1 WDH-31-531 Function block diagram

4

131211

UcUbUa

~ 3 M

KM FU3 FU4 FU5

QF

N

L3

L2

L1

T1

L1 L2

T2 T3

L3

14

Un

PTC/NTC

6665

2

1

N

L

1815

1DO

2019

3DO

2221

4DO

FU1

N

L

KM

KM

SB1

QF

QF

Main circuit

Stop Start Run Alarm Fault

START

A

START

B

STOP

RESET

2x2 PIN

5958

B1A1

70 71 72 73 74 75

KM

QF

DIC DI1 DI2 DI3 DI4 DI5

ON

OFF

Panel

Monitoring + Protection

Control circuit

Start/Stop + Monitoring

Automation

Remote control + Monitoring

Modbus-RTU

AO1-

30

AO1+

31

17

2DO

16

PTC/NTC

Figure2 WDH-31-531 Typical application diagram

5

1.3 Overview of functions

1.3.1 Monitoring functions

The controller completes the measurement of important electrical parameters (voltage,

current, power, power factor, electric energy, etc.) of the motor circuit through the main

module.

*Direct input line voltage up to 690V

*Direct input current up to 100A (hole type)

* Full wave or fundamental wave measurement mode can be selected

* Residual current can be measured

* Optional measurement of 1-way thermistor

Measuring parameter

Range

Accuracy/Defenition

Voltage

Voltage RMS ( U )

Imbalance ( imb U )

Frequency ( F )

5% ~120%Ue

0% ~100%

45 ~65Hz

1.0% / 0.1V

--- / 0.1%

0.5% / 0.01Hz

Current

Current RMS ( I )

Ground current ( Ig )

Residual current ( Ir )

Sequence current

( I1/I2 )

Imbalance ( unb I )

Thermal capacity ( Cc )

2% ~1000%Ie

2% ~1000%Ie

2%~400%I△n

2% ~120%Ie

0% ~100%

0% ~100%

1.0% / 0.1A

1.0% / 0.1A

1.0% / 1mA

1.0% / 0.1%

--- / 0.1%

--- / 1%

Power

Active Power ( P )

Reactive Power ( Q )

Power Factor ( PF)

Active energy ( EP )

Reactive energy ( EQ )

0% ~120%Pe

0% ~120%Pe

0~±1

---

---

1.0% / 0.01kW

1.0% / 0.01kvar

1.0% / 0.001

2.0% / 0.01kWh

---/ 0.01kvarh

Motor

temperature

Thermistors (PTC / NTC)

0~10kΩ

3.0% / 0.01 kΩ

Table 1. WDH-31-531 Measuring parameter

6

1.3.2 Protection functions

* support multiple ANSI standard protection functions

* Each protection could be selected as drop in or drop out respectively

* Each protection could be configure as alarm/ trip stage respectively

* The protection object could be setting as the circuit breaker for the large current

protection

Protection

ANSI code

Current

Thermal Overload

Under Load (current or power)

Stall

Jam

Current imbalance

Phase loss

Short Circuit

Ground Fault

Residual Current

Start overtime

time tE

49

37

51LR/50S

51R

46

46

50/51

50N/51N

50G/51G

48

Voltage

Under voltage

Over voltage

Phase sequence

Voltage imbalance

PT breaking

27/27P

59

47

46

50P

Non-

electric

Thermistor

External fault

49

68

Table 2.WDH-31-531 Protection overview & ANSI code

7

1.3.3 Control functions

* WDH-31-531 by the main control module to achieve the control of the motor stop/start.

*Main module contains 5 DI, 4 relay output and 2 analog ouput

*By simple programming to achieve the logical control as following:

Motor start type

Uncontrolled :·Overload relay

Single step starting:

·Direct start

·Reversing

·Two speed

·Electro valve

Double-step starting:

·Star/Delta start

Control authority

·Panel Position

·Local terminal Position

·Remote terminal Position

·Communication control Position

Uninterrupted operation

·Under voltage restart

·On-power self-start

Table 3. WDH-31-531 control functions overview

1.3.4 Communication

RS485

Protocol

Interface

Slave address

Baud rate

Data format

Networking capacity

Modbus-RTU

3-pin terminal

1~247

4800bps~9600bps

N.8.1、0.8.1、E.8.1、N.8.2

< 32

8

1.3.5 I/O interface

DI

·Main control module contains 5 DI

·DI dry contact (internal DC24V)

·Each DI function could be customized

DI:Setting descriptions

Function

Descriptions

Contactor state

Local Start

Local Stop

Local STA/STP

Remote Start

Remote Stop

Remote STA/STP

Emergency Stop

Interlock Stop

External Fault

L/R Switch

Contactor auxiliary contact feedback signal for monitoring

Local terminal start signal input

Local terminal stop signal input

Local terminal start, stop signal input

Remote terminal start signal input (connected to DCS output signal)

Remote terminal stop signal input (connected to DCS output signal)

Remote terminal start, stop signal input (connected to DCS output signal)

Emergency stop signal input (no control permission limit)

Interlocking stop signal input (no control permission limit)

External fault signal input, can be connected to non-electrical sensors, relays,

etc.

Local, remote control permission switching signal input, generally connected

to the switch

Table 5. WDH-31-531 DI common functions

9

Relay output

·Main control module contains 4 relay output(1NC/3NO)

·Functions of each relay output could be customized

Relay output:Function customized

Function

Descriptions

start A

start B

protection trip

Short circuit fault

Self-diagnostic output

Device ready output

Running signal output

Total alarm signal

Total trip signal

Start control relay A output for single step start

Start control relay B output for double step start

Trip relay or stop relay output

Large current overflow fault relay output, connected to circuit

breaker OFF coil

Device equipment fault diagnosis relay output

Device ready relay output (no fault + no stop signal + circuit

breaker in position)

Motor running status signal output

Motor alarm status signal output

Motor fault status signal output

Table 6. WDH-31-531 Relay common functions

1.3.6 Management functions

The data management of the motor protector is accomplished by the main control module

and could be record the relative data by the display module or the communication interface.

Motor running data management

·Current maximum current during a starting process

·Maximum current during historical starting process

·The maximum current of the current running process

·Maximum current during historical operation

·current running time

·Accumulated running time

·Current stop time

·Total stop time

·Start and stop operations

·Contactor ON/OFF times

·The total number of alarms & trips

·The latest modification of parameter information

SOE record

·12 times Trip Record

·12 times Alarm Record

·12 times Start Record

·12 times Stop Record

10

·12 times DI Switch Record

·12 times Reset Record

Table 7. WDH-31-531 Management functions overview

11

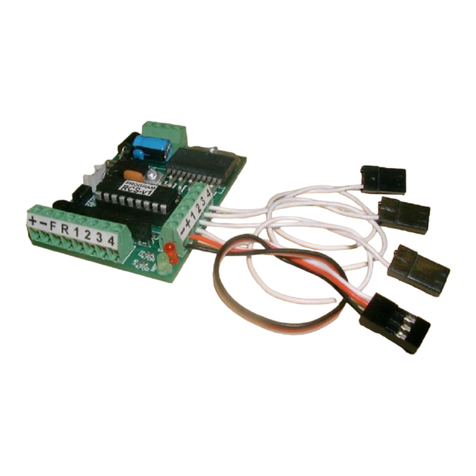

1.4 Overview of system components

Components

Image

Descriptions

Special protective type current transformer

Hole type(25A)

5A (0.2A~5A)

25A (2.5A~25A)

-Three phase current

measurement access

-It must be installed integrally

with the main body

(splicing type)

-100A current perforated

access

-If the circuit current exceeds

100A, an external primary

transformer is required

Hole type(100A)

100A (10A~100A)

Main control module

Main control module

(RS485)

· din rail mounted

(Integrated with the

transformer)

·Three phase current

measurement

·Three phase voltage

measurement

·Residual current

measurement

·1 circuit thermistor input

·5-way switching value input

·4-way relay output

·1 channel analog output

·1 channel RS485

communication interface

External CT

SHI-ZT40

(core size: 40mm)

·External CT is inevitable for

the current of the main loop is

over 100A

·SHI-ZT40 (300A:5A)

·SHI-ZT40 (500A:5A)

·SHI-ZT40 (800A:5A)

12

SHI-ZT60

(core size: 60mm)

··External CT is inevitable for

the current of the main loop is

over 100A

·SHI-ZT60 (300A:5A)

·SHI-ZT60 (500A:5A)

·SHI-ZT60 (800A:5A)

13

1.5 Order codes

WDH-31-531

Rated current:

Rated voltage:

AC380V

AC660V

5A

300A

AC100V

25A

100A

500A

800A

Type selection by rated current

Code

Range

Motor Power(380VSystem)

Hole size

5A

25A

100A

250A

500A

800A

0.2A~5A

5A~25A

25A~100A

100A~250A

200A~500A

500A~800A

0.13~2kW

2~11kW

11~55kW

45~115kW( External CT 300A:5A)

90~280kW( External CT 500A:5A)

280~400kW( External CT 800A:5A)

Φ10.5mm

Φ10.5mm

Φ18mm

Φ10.5mm

Φ10.5mm

Φ10.5mm

External CT: SHI-ZT40/ZT60

When the rated current of the motor is over 100A, the current of the measuring module

should be at 5A, the external CT is inevitable. The transform ratio should be 500A:5A,

800A:5A etc. The protection accuracy of the CT is 5P10, the measurement accuracy is 0.5

class, 3pcs as 1 set.

SHI-ZT40 (300A:5A)

SHI-ZT40 (500A:5A)

SHI-ZT40 (800A:5A)

SHI-ZT60 (800A:5A)

SHI-ZT60 (500A:5A)

Cable diameter Φ40mm

Cable diameter Φ40mm

Cable diameter Φ40mm

Cable diameter Φ60mm

Cable diameter Φ60mm

Add-on feature (choose one only)

Functions

Type

Descriptions

Analog output

M2

2-way analog output function (transmission

output)

Temperature input

T

1-way thermistor input (0 ~ 10 kΩ)

14

Mode Selection Example

WDH-31-531 -25A/380V

WDH-31-531 -100A/660V + T

Protocol

rated current

rated voltage

DI

Additional function

1*Modbus

25A (5A~25A)

AC380V

DC24V(Passive contact point)

None

1*Modbus

100A (25A~100A)

AC660V

DC24V(Passive contact point)

1*thermistor input

Table of contents