Contents

Operating Manual PNOZ m3p (ETH)

1001352-EN-09 | 3

1 Introduction ............................................................................................................................ 5

1.1 Validity of documentation.......................................................................................................... 5

1.2 Using the documentation .......................................................................................................... 5

1.3 Definition of symbols................................................................................................................. 5

2 Overview ................................................................................................................................. 7

2.1 Range ....................................................................................................................................... 7

2.2 Unit features ............................................................................................................................. 7

2.3 Chip card .................................................................................................................................. 8

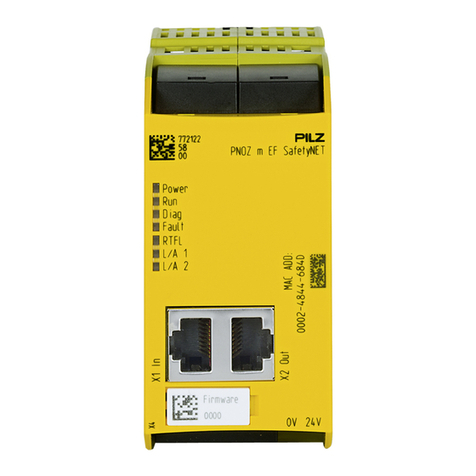

2.4 Front view ................................................................................................................................. 8

3 Safety ...................................................................................................................................... 11

3.1 Intended use ............................................................................................................................. 11

3.2 System requirements................................................................................................................ 12

3.3 Safety regulations ..................................................................................................................... 12

3.3.1 Safety assessment ................................................................................................................... 12

3.3.2 Use of qualified personnel ........................................................................................................ 13

3.3.3 Warranty and liability ................................................................................................................ 13

3.3.4 Disposal .................................................................................................................................... 13

3.3.5 For your safety.......................................................................................................................... 13

4 Function description ............................................................................................................. 14

4.1 Integrated protection mechanisms............................................................................................ 14

4.2 Functions .................................................................................................................................. 14

4.3 Application for furnaces ............................................................................................................ 14

4.4 Block diagram ........................................................................................................................... 15

4.5 Diagnostics ............................................................................................................................... 15

4.6 Cascading................................................................................................................................. 15

4.7 Safety mat, muting.................................................................................................................... 16

4.8 Interfaces ................................................................................................................................. 16

5 Installation .............................................................................................................................. 17

5.1 Control cabinet installation........................................................................................................ 17

5.2 Dimensions ............................................................................................................................... 18

5.3 Install base unit without expansion module ............................................................................. 18

5.4 Connecting the base unit and expansion modules ................................................................... 19

6 Commissioning ...................................................................................................................... 20

6.1 General wiring guidelines ......................................................................................................... 20

6.2 Ethernet interfaces (ETH version only)..................................................................................... 21

6.2.1 RJ45 interfaces ("Ethernet") ..................................................................................................... 21

6.2.2 Requirements of the connection cable and connector.............................................................. 21

6.2.3 Interface configuration .............................................................................................................. 21

6.2.4 RJ45 connection cable ............................................................................................................. 22

6.2.5 Process data exchange ............................................................................................................ 23

6.3 Function test during commissioning ......................................................................................... 23

6.4 Commissioning the PNOZmulti control system for the first time............................................... 24

6.4.1 Load project from chip card ...................................................................................................... 24