SG 6128 A Series User manual

Installation Instructions

Model 6128 A-Series

Electronic Safe Lock

• FürAnweisungenaufDeutschbesuchenSiebittediefolgendeWebsite:

• Paraobtenerinstruccionesenespañol,visitelasiguientepáginaweb:

• Pourobtenirlesinstructionsenfrançais,veuillezconsulterlesiteci-dessous:

• Peristruzioniinlinguaitaliana,visitareilsitowebseguente:

• ForinstructionsontheChineseversion,pleasevisitthefollowingURL:

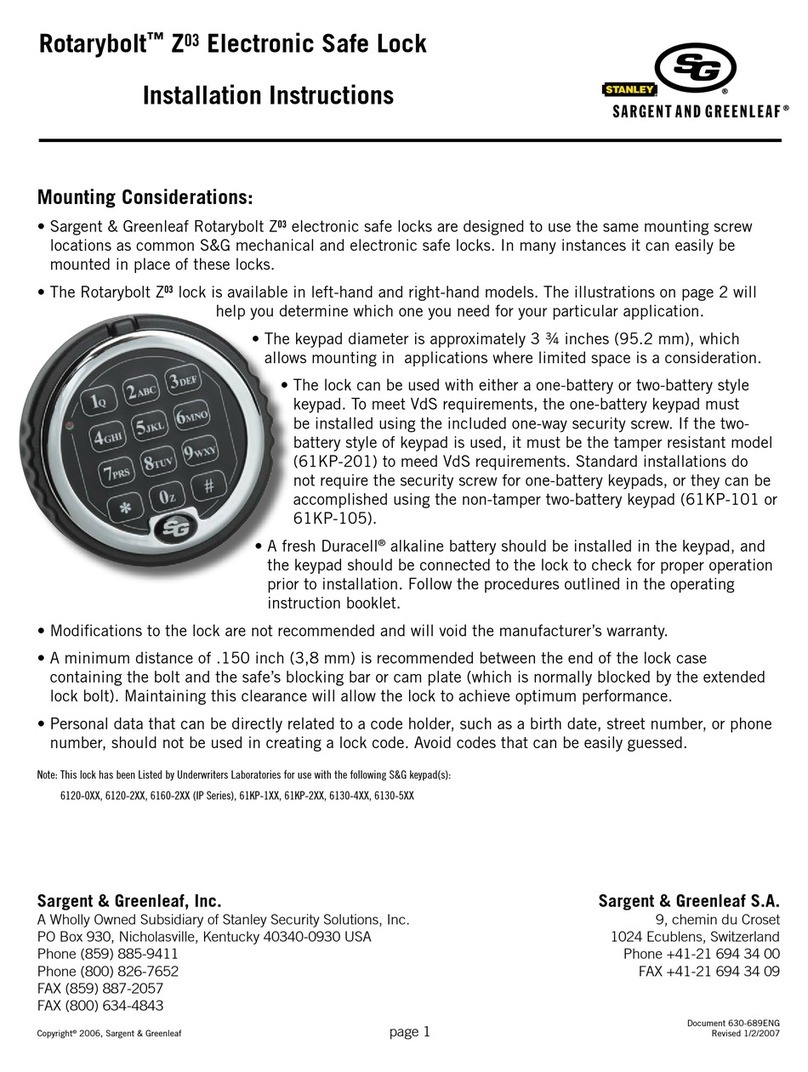

Mounting Considerations

• Sargent&Greenleaf6100seriesMotorizedElectronicCombinationLockshave

beendesignedtousethesamemountingscrewlocationsandoccupythesame

spaceasmostotherS&Glocks,bothmechanicalandelectronic.

• Modicationstothelock(includinglockboltattachments)arenotrecommended,

andwillvoidtheyourwarranty.

• Aminimumdistanceof.150”(3,8mm)isrequiredbetweentheendofthelockcasecontainingthebolt

andtheclosestapproachofthesafe’sblockingbarorcamplatewhichisnormallyblockedbytheextended

lockbolt.Donotallowthesafe’sblockingbarorcamplatetodepresstheelectroniclock’sboltfartherthanit

retractsduringnormalmotoroperation.iscanleadtoinconsistentlockoperation.

• e6100seriesrequirestwo9-voltalkalinebatteries(mayormaynotbeincludedwithyourlockdepending

onthespecickitordered).WerecommendDuracell®batteries.Donotuseoldorpartiallydrainedbatteries.

Attaching Screws: Useonlythescrewsprovidedwiththelock.Lockbodymountingscrewswillbe

either¼-20orM6,dependingontheapplication.eymustengagethemountingplatebyatleastfour

fullthreads.Donotuselockwashersorthreadsealingcompoundsunlessspecicallydirectedtodoso

inthefullinstallationinstructions

Recommended Attaching Screw Torque: 30to40inch-pounds(3.4to4.5Nm)forthelockbody.No

morethan15inch-pounds(1.695Nm)forthekeypadattachingscrews.

Minimum Lock Cable (Spindle) Hole Diameter: 0.312”(7,9mm)MaximumLockCable(Spindle)

HoleDiameter:0.406”(10,3mm)LockisDesignedtoMove:0.0lbs.(0Newtons)

Lock Bolt Maximum Free Movement: 0.352”(8,95mm)Atleast0.109”(2,77mm)ofthelockbolt

remainsoutsidetheedgeofthelockcasewhenboltisfullyretracted.

Maximum Bolt End Pressure:Lockisdesignedtowithstandatleast225lbs.(1000Newtons)

MaximumBoltSidePressure:Safeandcontainerboltworkorlockingcamdesignsmustneverapply

morethan225lbs.(1000Newtons)ofsidepressureonthelockbolt.

Interface with Boltwork:islockisnotintendedfordirectboltworkattachment.Beforeinstalling

thelock,operatethesafeopeningmechanismandverifythattheinstalledpositionwilleectively

securetheboltworkswhenthelockislocked.Aerinstallation,checkthatthereiaclearancebetween

thecombinationlockboltandtheboltworks;aspressureontheboltcouldaectthelock’sabilityto

functionproperly.

Mounting Environment:elockbodyisdesignedtobemountedinsideasecurecontainer.e

containermustbeconstructedtooerprotectionagainstphysicalattackdirectedatthelock.e

amountofprotectionisdependentonthedesiredlevelofsecurityforthesystemasawhole.Lock

protectionmayincludebarriermaterials,relockdevices,thermalbarriers,thermalthese.Relockdevice

attachingscrewsmustNOTbelongerthanthedepthofthetappedattachingscrewholeprovidedin

thelockcase.Aminimumdistanceof.150inch(3,8mm)isrecommendedbetweentheendofthelock

caseandtheclosestapproachofthesafe’sblockingbarorcamplate(whichisnormallyblockedbythe

extendedlockbolt).Maintainingthisclearancewillallowthelocktodeliveroptimumperfor-mance.

econtainershouldbeconstructedtopreventaccesstothecombinationlockwithouttheuseoftools

whenthecontainerdoorordrawerisleopen.

Code Restrictions:Personaldatathatcanberelatedtoacodeholder,suchasabirthdate,streetnumber,orphonenumber,shouldnot

beusedincreatingalockcode.Avoidcodesthatcanbeeasilyguessed.

Note: Everyinstallationofthisproductmustcomplywiththeserequirementsandthoseintheproductinstallationinstructionsto

qualifyforthemanufacturer’swarrantyandtocomplywithEN1300requirements.

3.320"(84,3mm)

2.624"(66,6mm)

1.624"(41,2mm)

1.000"(25,4mm)

Bolt extension:

Locked=.461"

(11,71mm)

Unlocked=.125"

(3,18mm)

2.400"(61,0mm)

.312"

7,9mm

.281"

7,1mm

1.165"(30mm)

Before You Install

Your6128A-SeriesLockwasmostlikelyshippedwiththekeypadandkeypadextensionconnectedtothelock

cablestoallowforpre-installationtesting.Ifyourlockdoesnothavecablesalreadyconnectedtothekeypad

andkeypadextension,temporarilyconnectthemnowasshownintheseinstructions.Youshouldinstallfresh

batteriesinthekeypad(S&GrecommendsDuracell®alkalinebatteries)andcheckthefunctionofthelockprior

toinstallationbypressing10101010#andobservingthelockboltretract,thenextend6secondslater.Aer

thischeck,disconnectthecablesfromtheextensionbaseandkeypadbypullingontheconnectors(NOTon

thecablesthemselves).einstallershouldwearaproperlygroundedESDwriststrapwhileworkingwithlock

cablesandcomponentstoavoidESDdamage.

1. Removetheexistinglock(ifpresent).emountingplateshouldbesmoothand

at,with¼-20(M6)mountingscrewholes.ewirechannel(spindlehole)must

haveadiameterofatleast0.312inch(7,9mm).e6100seriescanbemounted

right-hand,le-hand,vertical-up,orvertical-downwithoutanymodicationsor

adjustments.

2. Useareamerorroundletoremoveanysharpedgesfromthewirechannel(spindle

hole)thatmightdamagethewirecable.Gentlypulltheconnectorstoeasethecables

throughthehole.Pull6”to8”(15to20cm)ofcabletothefrontofthesafedoor.

Laterintheinstallation,excesskeypadextensioncablewillbepulledbackinsidethe

safedoor.Makesurecablesarenotcrimpedorstressedatanypoint.

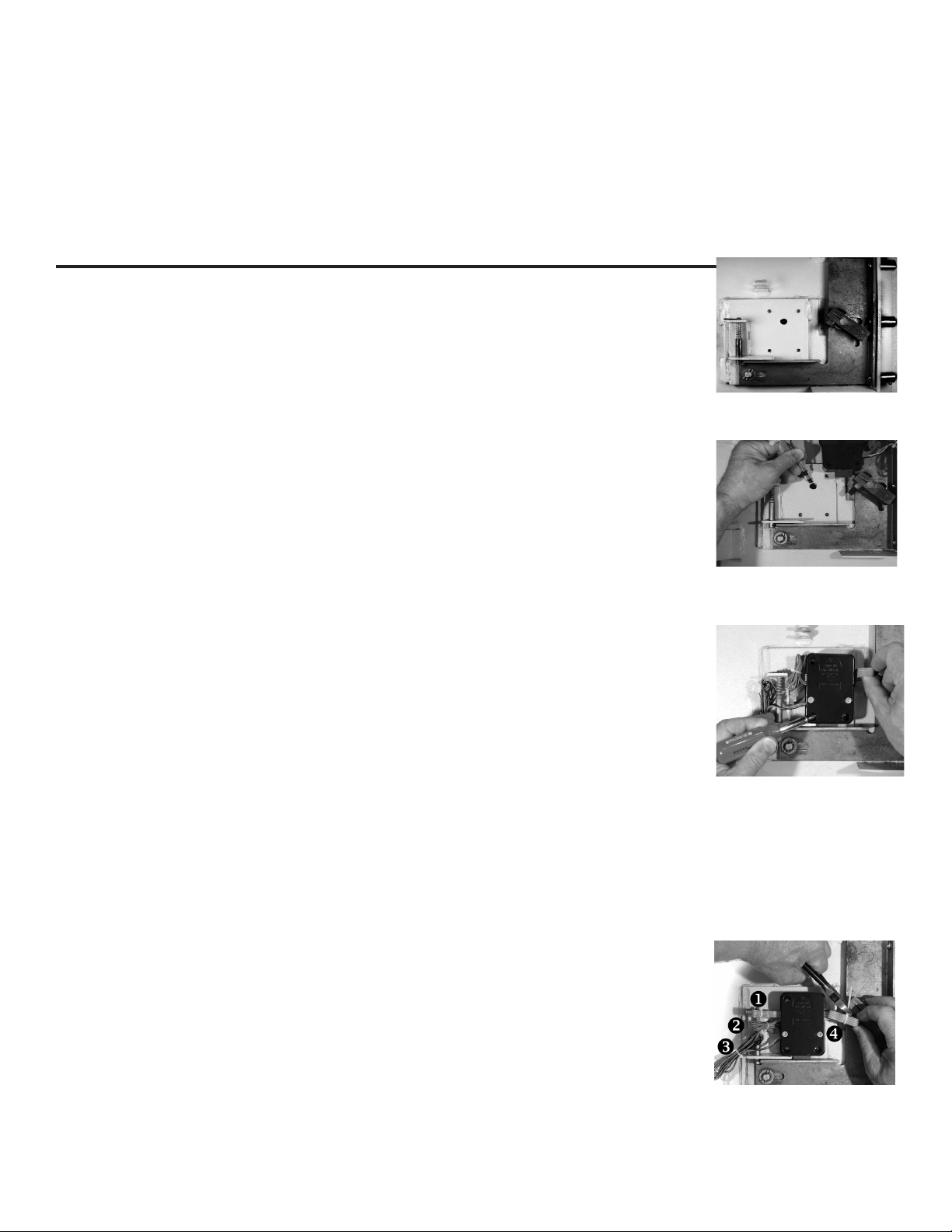

3. Usingtwoofthe¼-20(orM6)screwsinthekit,looselyattachthelockbodytothe

safe’smountingplate.isisjusttoholditinplaceduringcableattachmentstothe

keypadandkeypadextension.Beverycarefultoavoidcrushingorcrimpingthe

cables.Notetheblack/red/greenwirebundle.isisfortheboltpositionindicator,

adrycontactswitch(200VDC,0.5ampmax.)eblackwireiscommon,thegreen

wirecompletesacircuittotheblackwirewhenthelockboltisretracted,andthered

wirecompletesacircuittotheblackwirewhenthelockboltisextended.eBPI

canbeusedtotriggeranyswitch-activateddevice.

Notethebluewireloop.isisthesecureloop,aclosedcircuitthatmaybeusedin

applicationsrequiringswitchesorotherdevicestosignalthelockthatboltworkis

thrown,thedoorisclosed,orsomeotheractionhastakenplace.elockboltwill

NOTretractifthecircuitformedbythebluewireloopisopen.Bothsetsofwires

shouldbebundledandplacedwheretheywillnotinterferewithmovingboltwork

componentsifnotused.

4. Removethelockmountingscrewssoyoucancarefullypulltheexcessextension

basecableinside.Itisimportanttomakesurethekeypadandextensioncablesare

withintherecessedchannelsunderneaththelockcasebeforethecaseissecurely

attachedbythethreemountingscrews.Onceplacedinthemostconvenientchannel,

eachcableshouldbeprotectedunderneaththecasebyaself-adhesivefoamorvinyl

pad.Itisveryimportantthatcablesarenotfolded,crimped,orcrushedbeneaththe

lockcase.erearefoursetsofwiresthatmustbecarefullyplacedwheretheywill

notinterferewithorbedamagedbymovingboltwork.eseare:

• excesskeypadcable(4-conductor)

• secureloop(1-conductorbluewire)

• boltpositionindicator(BPI)wires

• excesskeypadextensioncable(5-conductor) 2

A. Makesurethelockboltdoesn’tbindagainstthesafe’sboltwork.etopphotoshowsbindingoftheedgeof

thecutoutinthesafe’sblockingbar,eventhoughtheboltworkisfullythrowntothelockedposition.Inthe

bottomphoto,thebindinghasbeenrelievedbyremovingasmallamountofmaterialfromthesideofthe

blockingbarcutout.Itisimportantthatthereisclearanceonallsidesofthelock’sboltwhentheboltworkis

inthefullylockedposition.Bindingwillimpairthelock’sperformance.Anynecessarymodicationsshould

bemadetotheboltwork,notthelock.

B. Ifyoursafeincorporatesarelockdevice,youwillneedtoattachtheplatethatnormallyholdsitincheckto

thelockbody.isisusuallydoneatthelock’scoverscrewlocations.Removethecoverscrews.DONOT

REMOVETHELOCKCOVER,asthiswillvoidtheproductwarranty.Typically,thecoverscrewswillbe

replacedwithslightlylonger8-32machinescrews.Yourreplacementscrewsmustengagethethreadedholes

inthelockbodybyatleastfourthreads.Relockdevicedesignsvaryfromsafetosafe.Youmustmakesure

thereplacementcoverscrewsholdthelockcoverrmlyagainstthelockbody,andthattherelockdevice

plateholdsthedevicesecurelyincheck.Otherwise,thereisriskofalockout.Aertheplateisinstalled,once

againchecktomakesurewiresandcablesaresecuredsothattheywillnotcomeintocontactwithmoving

boltworkoranythingelsethatcandamagethem.

Lock installation Considerations

IncorrrectCorrrect

3

Keypad and Keypad Extension Installation with Escutcheon

1. Cleanthefrontsurfaceofthesafedoorsothenumberplatewilladhere.Removetheclearprotective

lmfromthefrontoftheplate,andaxtheincludedserialnumberlabelasshown.Next,remove

theprotectivepaperbackingontheundersideoftheplate,thenrunbothcablesthroughthecenter

holeoftheplate.Placetheplateonthefrontofthesafe,carefullyliningupthemountingscrewholes

inthesafedoor.eplatewillstickinplacewhenpressedagainstthedoor.

2.

3. Placethekeypadbaseoverthekeypadextension,pullallexcesscablethroughthecenterhole(as

shown),lineupthekeypadbasemountingscrewholeswiththoseinthedoor,andusetheincluded

8-32(orM4)machinescrewstosecurelyfastenthemountingbasetothedoor.Itwillalsoholdthe

keypadextensionandnumberplate(ifused)rmlyinplace.eraised,circularpostneartheedge

ofthebasewillbeverynearthebottomofthekeypad.Usethisfeatureasareferencetohelpyou

orientthebasecorrectlybeforeyoufastenitintoplace.

4.

5. Placethekeypadoverthebase.Makesurethekeypadcableisclearofthepad’stwospringclips

asyoupushthekeypadrmlyontothebase.Itshouldsnapintoplace.Ifyouneedtoremovethe

keypad,pullthebottom(areanearesttheS&Glogo)awayfromthemountingbaserst.Neverallow

thekeypadtohangbytheattachedcable.einstallationiscomplete,butdonotclosethesafedoor

untilsuccessfullycompletingthefollowinglocktest.

einstallationiscomplete,butdonotclosethesafedooruntilsuccessfullycompleting

thefollowinglocktest.

efollowingcheckshouldbeperformedthreetimeswiththedoorremainingOPEN.

Atthekeypad,enter10101010#.elockwillBEEPthreetimesanditsboltwillretract.

Turnthesafehandletoverifythatthelockisunlocked.Turnthesafehandletothelocked

position.egreenSTATUS1LEDonthekeypadextensionwilllightbriey.e safe

door should remain open for the three operational checks.Youcanclosethesafedoor

andturnthehandletothelockedpositionaerthethirdoperationalcheck.elockbolt

willextend,andthelockwillBEEPthreetimes.Inaddition,thegreenSTATUS1LEDon

thekeypadextensionwilllightbriey.Testthesafe’shandletomakesureitissecure.

Lock Test

Fromthefrontofthesafe,connecttheve-conductorcable(thelarger

one)tothekeypadextensionbase.econnectorandreceptacleare

“keyed,”sotheconnectorwillonlyseatwhenorientedcorrectly.Route

thecableasshownhere.Makesuretheconnectorisfullyseatedinthe

keypadextensionreceptacle.Notetheself-adhesivepadtotherightofthe

cablereceptacle.Oncetheconnectorispluggedin,removetheprotective

backingfromthispad.Pullallexcesscablethroughthecenteropening

tothefrontoftheextensionbase.enlineupthebase’smountingscrew

holeswiththoseinthedoor,andpresstheextensionagainstthedoor.e

extensioncanbemountedinfourdierentorientations.Picktheonethat

bestsuitsyourparticularapplication.

Atthefrontofthesafe,installanew9-voltbatteryineachofthekeypad’s

twobatteryholders.Duracell®brandbatteriesarerecommended.Support

thetopofeachholderwithathumborngeraseachbatteryisinserted.

iswillhelppreventbendingorbreakingtheholderposts.ekeypad

cableconnectorisshapedsothatitwilltintothekeypadreceptacle

onlywhenalignedcorrectly.Inserttheconnectorintothereceptaclein

theundersideofthekeypad.Ifitdoesnotseateasily,donotforceit.is

meansyouneedtoturnit1800beforeattemptingtoinsertitagain.

4

Sargent & Greenleaf, Inc.

One Security Dr.

Nicholasville, KY 40340-0930 USA

Phone: (800)-826-7652

Fax: (800)-634-4843 5

Sargent & Greenleaf S.A.

9, Chemin du Croset

1024 Ecublens, Switzerland

Phone: +41-21 694 34 00

Fax: +41-21 694 34 09

Document 630-821

Revised 03/18/2019

Placethekeypadbaseoverthekeypadextension,pullallexcesscable

throughthecenterhole(asshown),lineupthekeypadbasemountingscrew

holeswiththoseinthedoor,andusetheincluded8-32(orM4)machinescrews

tosecurelyfastenthemountingbasetothedoor.Itwillalsoholdthekeypad

extensionandnumberplate(ifused)rmlyinplace.eraised,circularpost

neartheedgeofthebasewillbeverynearthebottomofthekeypad.Usethis

featureasareferencetohelpyouorientthebasecorrectlybeforeyoufastenit

intoplace.eextensioncanbemountedinfourdierentorientations.Pickthe

onethatbestsuitsyourparticularapplication.

efollowingcheckshouldbeperformedthreetimeswiththedoorremainingOPEN.

Atthekeypad,enter10101010#.elockwillBEEPthreetimesanditsboltwillretract.Turnthesafehandletoverifythatthelockisunlocked.Turn

thesafehandletothelockedposition.egreenSTATUS1LEDonthekeypadextensionwilllightbriey.esafedoorshouldremainopenforthe

threeoperationalchecks.Youcanclosethesafedoorandturnthehandletothelockedpositionaerthethirdoperationalcheck.elockboltwill

extend,andthelockwillBEEPthreetimes.Inaddition,thegreenSTATUS1LEDonthekeypadextensionwilllightbriey.Testthesafe’shandleto

makesureitissecurely

1. Fromthefrontofthesafe,connecttheve-conductorcable(thelargerone)tothekeypadextensionbase.

econnectorandreceptacleare“keyed,”sotheconnectorwillonlyseatwhenorientedcorrectly.Routethe

cableasshownhere.Makesuretheconnectorisfullyseatedinthekeypadextensionreceptacle.Notethe

self-adhesivepadtotherightofthecablereceptacle.Oncetheconnectorispluggedin,removetheprotec-

tivebackingfromthispad.Pullallexcesscablethroughthecenteropeningtothefrontoftheextension

base.enlineupthebase’smountingscrewholeswiththoseinthedoor,andpresstheextensionagainst

thedoor.

2.

3. Atthefrontofthesafe,installanew9-voltbatteryineachofthekeypad’stwobatteryholders.Duracell®

brandbatteriesarerecommended.Supportthetopofeachholderwithathumborngeraseachbatteryis

inserted.iswillhelppreventbendingorbreakingtheholderposts.

4. ekeypadcableconnectorisshapedsothatitwilltintothekeypadreceptacleonlywhenalignedcor-

rectly.Inserttheconnectorintothereceptacleintheundersideofthekeypad.Ifitdoesnotseateasily,do

notforceit.ismeansyouneedtoturnit1800beforeattemptingtoinsertitagain.

5. Placethekeypadoverthebase.Makesurethekeypadcableisclearofthepad’stwospringclipsasyoupush

thekeypadrmlyontothebase.Itshouldsnapintoplace.Ifyouneedtoremovethekeypad,pullthebottom

(areanearesttheS&Glogo)awayfromthemountingbaserst.Neverallowthekeypadtohangbytheat-

tachedcable.

6. AttachthelockSerialnumbertotheKeypadExtensionplate.

Keypad and Keypad Extension Installation

einstallationiscomplete,butdonotclosethesafedooruntil

successfullycompletingthefollowinglocktest.

Lock Test

Table of contents

Other SG Lock manuals

Popular Lock manuals by other brands

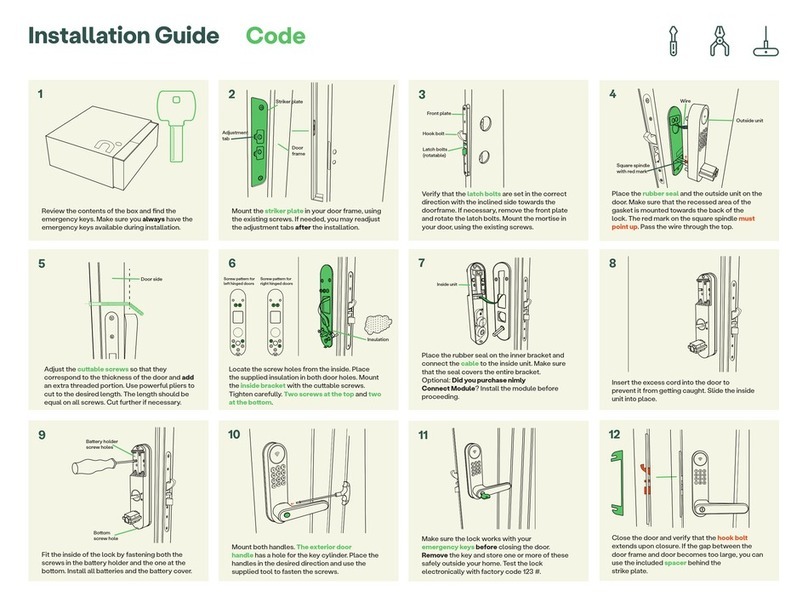

nimly

nimly Code installation guide

Abus

Abus FTS 3003 Fitting and operating instruction

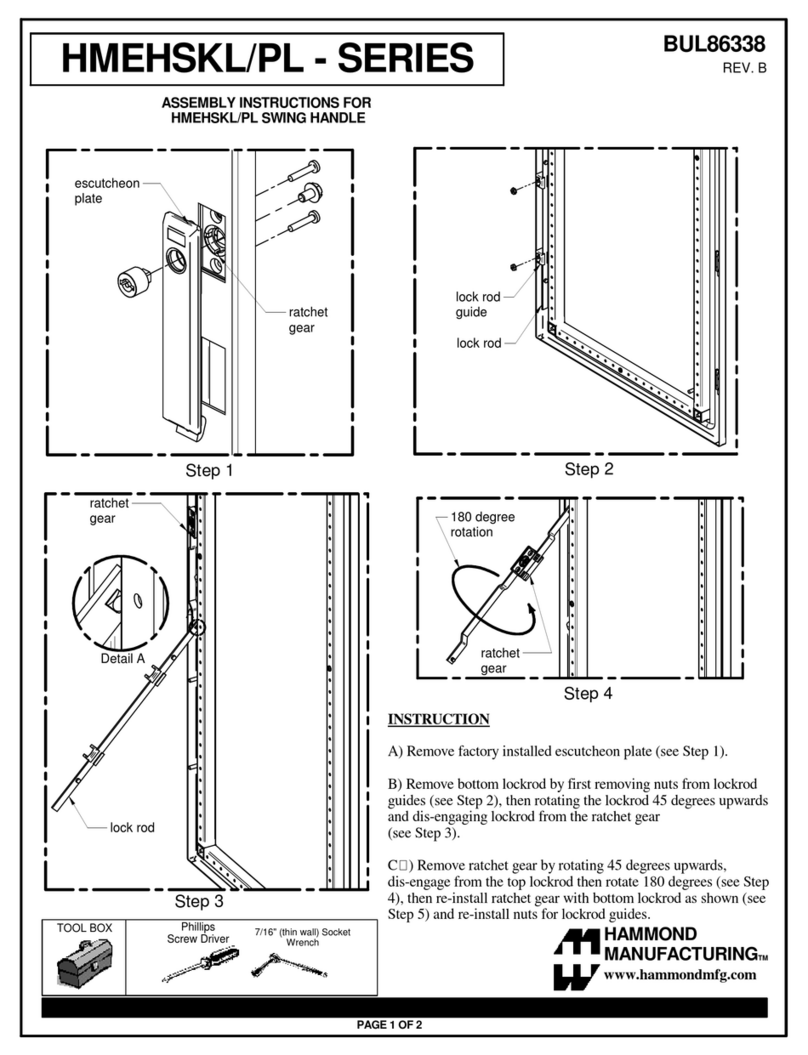

Hammond Manufacturing

Hammond Manufacturing HMEHSKL Series Assembly instructions

Spectrum Brands

Spectrum Brands Kwikset 258SQT 11P SMT installation guide

Kaba Mas

Kaba Mas Unicon CL20 installation instructions

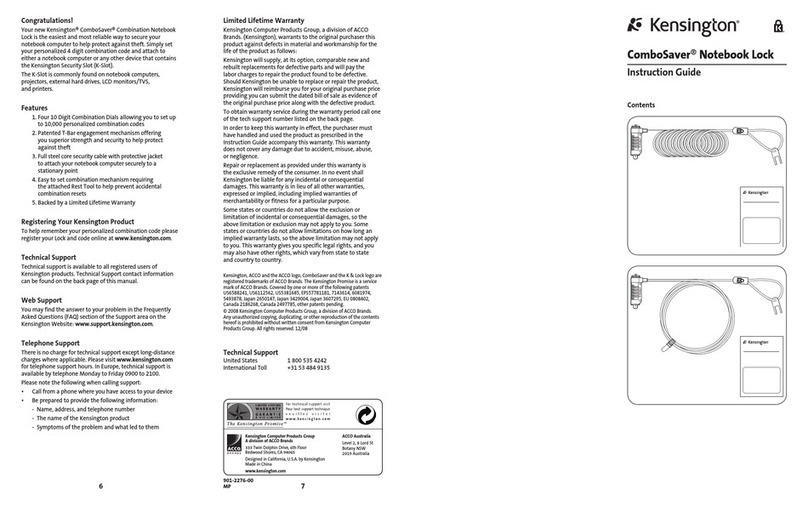

Kensington

Kensington ComboSaver Instruction guide