SH Engines GF-6 User manual

自西元2009年,SH的研發團隊即開始著手研發小排氣量的汽油模型引擎。其目的與宗旨是為了因應模型用木精燃料日漸昂貴

與市面取得不易的難題,並突破現有的汽油模型車、飛機、船用汽油引擎體積龐大、價格昂貴與攜帶不便的問題。經過了多年的

經驗累積與突破,終於在2015年推出全球首創的1/8車用5.1cc高性能汽油引擎(GC31引擎)。

上述研發期間,SH研發團隊克服了所有現行市面上遙控模型用汽油引擎的最大通病...高溫及轉速低等各種問題,並且研發出

全球獨創的多項世界專利設計,結合現代高科技的加工技術,秉持著最完美的品質理念,成功量產出小排氣量的CDI點火汽油引擎。

雖然GC31系列CDI點火汽油引擎是達到預期的功能與成效,卻擺脫不了有CDI點火器而衍生的缺點:重量增加與佔用安裝空間,

以及高電壓的干擾與故障率難題。因此SH的研發團隊持續努力尋求突破,終於在2017年正式成功量產出免CDI點火器的"電熱式點

火汽油引擎"(GC31 SPEC2)。緊接著因應航模市場需求,2017年底推出了全球第一顆排氣量僅6cc的電熱式點火飛機用二行程汽油

引擎(GF-6)。

GF-6汽油引擎不但具有高馬力、高轉速、壽命長與運轉穩定特色,並具有易調整、散熱佳之卓越性能;以及降低燃料費用的

高經濟效益優勢,相信GF-6將會是遙控飛機玩家最新的最愛。

1.發動引擎時,請確實將引擎固定於飛機引擎座或試車台上,並把化油器

固定螺絲鎖緊,以防止鬆動造成引擎不能順暢運轉。

2.使用燃油:92無鉛汽油(另購)和SH專用二行程機油(另購)互相混合。

3.火星塞:引擎上附有一顆SH原廠的汽油專用火星塞,其點火電壓1.5V。

(與一般的木精引擎火星塞相同)。

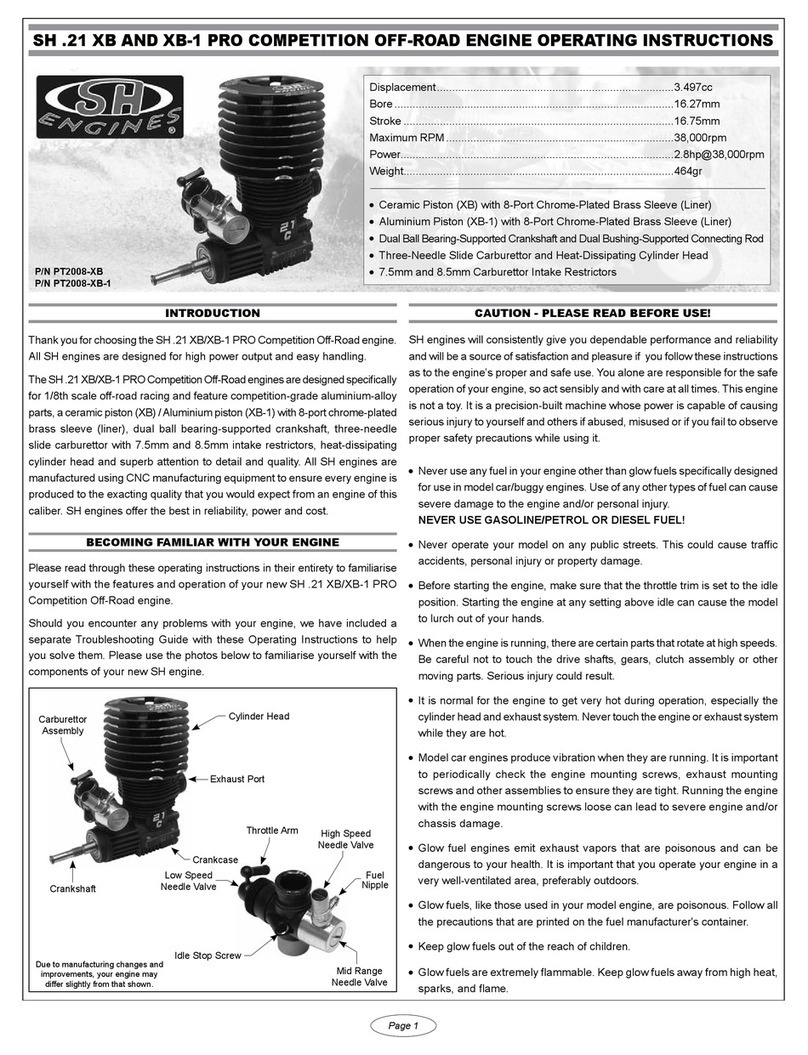

4.螺旋槳:建議使用10"x6"的螺旋槳,並依右圖(一)建議角度安裝

◎GF-6引擎,適用於二行程25~40級各廠各式機型。

◎為了能讓GF-6引擎充分發揮其最大馬力及最長的壽命,請確實做好飛行前的試車(磨合)工作。

/注意事項/

250ml機油,可混合5公升的汽油;或者是

80ml機油,可混合1.6公升汽油。(1600/80=20)

建議使用最佳機油混合比例為20:1,約4.76%

以下說明和設定,均是以出廠標準配備下,搭配10X6螺旋槳的設定,如果自行將消音器加裝諧振管,或者是更換加速管使用

時,則主油針需要大幅退出到4圈半~5圈後,再視使用情況進行微調。使用小於10"X6"的螺旋槳時,主油針也需要先大幅退出,避

免因為轉速過高,貧油潤滑不足而損壞引擎零件。

1. 首先請將節流閥怠速流量孔用遙控器調整至如背面附圖(二) 所示位置,

約2.0m/m處

。並將已經調好機油比例的燃油注入油

箱。油針細微調整時,以時鐘一圈等分12小時進行調整,一次只調1~2小時。

2. 第一階段磨合:主油針及副油針,於出廠時,就已大略設定好了。若您有轉動過,請將主油針如背面附圖(二) ,從完全關閉

開始

轉開4圈

,副油針調整時,請先將風門全開,之後再將副油針鎖到底

再轉出 圈

,然後再將化油器風門開到約一半位置,

用手堵住化油器進氣口,再以逆時間方向撥轉動引擎,目視燃油確認已吸入化油器中,讓燃油吸入引擎的內部,然後再插上電

夾,用馬達啟動器發動引擎,讓引擎保持中速運轉,然後可將電夾移開。

3. 此時先觀察引擎的轉速,如果引擎轉速太高時(RPM5000轉以上時),可將主油針以逆時針方向轉出,每次調整約轉動2小時,

直至引擎能穩定的富油運轉。若引擎因太過於富油而停止,可將主油針以順時針方向轉入,每次調整約轉動2小時, 直至引擎能

穩定富油運轉,此階段的初步磨合需經過約500cc的燃油磨合。 ※請注意此時排氣口的排煙必須是濃煙富油的。

4. 接著請調整設定遙控器,將節流閥的怠速關至預設的怠速孔位置,約2mm處,如背面附圖(二) ,以觀察怠速的運轉情形,如果

引擎轉速有持續升高的現象,即表示已經太貧油,副油針需反轉兩小時,如果引擎的怠速會因太富油而降慢,甚至是熄火,即表

示已經太富油,副油針需正轉兩小時,直到引擎能夠穩定的怠速運轉,此時的怠速應該是RPM3000轉為最佳。

(怠速時當移開電夾後,轉速會略微降低是屬於正常的。)

GF-6汽油引擎使用說明與介紹

GF-6汽油引擎使用說明與介紹

磨合時化油器調整設定與試車磨合步驟磨合時化油器調整設定與試車磨合步驟

45°

(圖一)

螺旋槳建議組裝角度:

將引擎主軸逆時鐘轉動,

轉到活塞要開始壓縮的角

度,然後在固定螺旋槳角

度約成45度。如圖一所示

使用與木精引擎相同電夾起動點火

→

磨合時建議使用

10”X6”螺旋槳

→

(背面接續說明)

3

※如果使用過大的螺旋槳,將會導致引擎過負載,因而造成引擎損壞

或是縮短引擎使用壽命。

※請確實鎖緊螺旋槳,以防止脫落造成人身意外傷害發生。

1

3

4

3

1

5. 第二階段磨合: 接著可試著將節流閥拉開至全開位置做加速動作,以便調整主油針,由於此時引擎尚在磨合階段,因此引擎必須是

處於富油狀態,此時排氣口會噴出豐沛的燃油及濃煙。如果引擎轉速太高時(高於RPM8000轉時),請立即將主油針以反時間方向轉

出,直至轉速低於RPM8000轉的狀態下做運轉。若引擎因太過於富油而停止時,請將主油針以順時針方向轉緊,一次轉約兩小時,

直至引擎能夠保持富油狀態下中速運轉,此第二階段高速磨合,需持續運轉約400cc燃油。

6.當完成上面的磨合步驟後:此引擎的磨合工作已經算是初步完成,不過引擎現在尚處於全新的狀態,因此接下來就是準備做實際的

首次飛行了。

首先確認接收電池電量充足,確認油箱燃油已加滿,確認伺服器正反動方向正確,然後再度啟動引擎讓引擎中速運轉2分鐘熱機

後,將飛機平放抓緊固定好再將油門全開,再次調整主油針的最終位置,請利用轉速表作量測,在飛機平放時引擎的最高轉速以RPM

10000轉為最佳設定,如果將飛機頭抬高約70~80度時,轉速會提昇至11500轉左右,然後再放平,轉速會降回10000轉為最佳

當飛行兩趟後再視情況些微的縮緊主油針,讓飛機在平放時的引擎轉速都調整在RPM10000轉以內做操作飛行。此時,引擎的磨

合終告完成了,期望此汽油引擎的誕生,能為你帶來更多的飛行樂趣,以及節省更多的燃料費用。

1. 若引擎有不順暢或化油器不易調整時,請檢查各部油路,是否有漏油或阻塞,建議你在油箱內加裝SH(SB001)汽油專用濾泡

器,以確保油路順暢。

2. 為了能使引擎正常的運轉,請務必使用原廠SH專用機油,以"20:1"的機油比例和92無鉛汽油做混合,約4.76%,並搭配

SH的GT4或GT5的汽油專用火星塞,能讓引擎更容易調整,發揮其最高的性能。建議使用10"x6"的螺旋槳,如果使用過大的

螺旋槳,將會導致引擎過負載,因而造成引擎損壞或是縮短引擎使用壽命。

3.當操作的飛行環境有了巨大的變化時,(熱/冷或高低海拔差異),必須重新設定化油器。

4.當引擎使用一加侖汽油後,請將火星塞與燃燒室拆下做細微的清理,如果火星塞已經嚴重積碳,或是燃燒室底部預熱網變形

了,請立即換新的零件(火星塞和燃燒室屬於消耗品,請依使用情形適時更換)。

5.燃油是危險的易燃品,請不要在附近有火源的地方發動引擎,並注意周邊安全。飛機不使用時,請務必將油箱燃油清空。使

用不完的燃油,請妥善收放,避免發生危險。

6.在試車期間,若有發生廠商疏忽之機件損壞,請轉交購買商店寄回原廠,SH定會給您合理及完善的售後服務。

7.當引擎放置長時間沒有使用時,剛開始準備發動會有化油器吸不到油的情形,此時請檢查所有油管油路是否順暢,並檢查油

箱內濾心是否阻塞,化油器部分請將主油針和副油針拆下,將油針上累積的油垢清洗乾淨,再將油針依建議設定鎖回去化油

器,以上檢查完畢後再重新安裝相關零件和油管,重新發動引擎。

/注意事項/

1.此SH汽油引擎只能適用SH的汽油專用火星塞,才能夠正常運轉及發揮優異的馬力性能。

2.此引擎所使用的油箱,油管都必須是耐汽油專用的材質。

3.此引擎禁止使用含有硝基甲皖的木精燃料。

專

利

證

號

NO. 申請國家 專利證號 NO. 申請國家 專利證號 NO. 申請國家 專利證號

1

2

3

4

5

6

M441718

ZL201220334172.9

202012102665.1

8985078

M477016

9169776

台灣

大陸

德國

美國

台灣

美國

!

注意

※請隨時注意引擎轉速及油量,避免讓引擎轉速高於RPM8000轉以上。

※新引擎如果轉速設定高於RPM10500時,將會導致引擎過熱容易熄火的問題產生

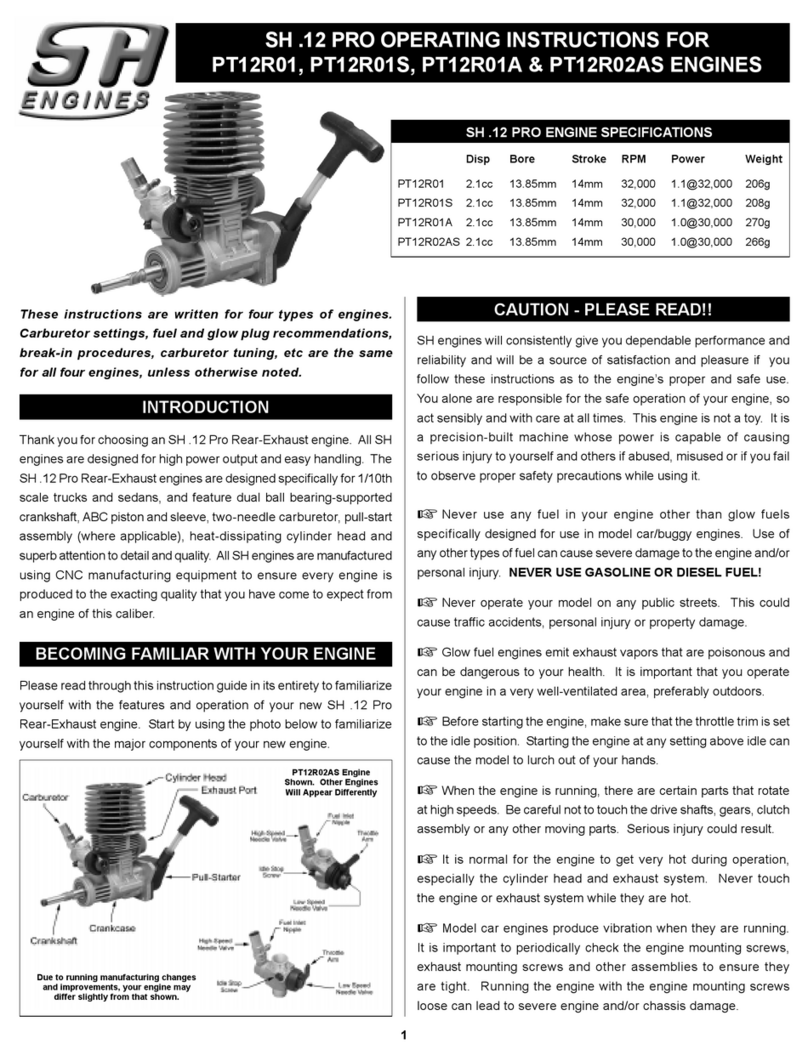

(圖二)

怠速調整螺絲 主油針鎖到底退4圈

怠速孔以遙控器控制到關閉約2mm

副油針鎖到底退 圈

(鎖到底前請先將風門全開)

入油嘴組裝角度不

要高於水平線,避

免氣泡囤積油管中

排不掉,導致引擎運轉不順暢而熄火

1

2

3

→

→

→

→

附圖二所示的油針位置,僅適用於新引擎

磨合時,以出廠標準配備下,搭配10x6螺

旋槳的設定。當引擎已經磨合完成,主油

針建議位置2圈半左右,副油針位置1

圈左右,發動先熱機後,再視情況微調油

針,當怠速容易熄火的時,請檢查怠速孔

是否關太小,請用遙控器將怠速孔調到大

約2mm,飛機平放時,全油門轉速在10000

轉以內。然後飛行一趟後再視情況調整主

油針,一次調整1小時。更換使用小於

10"x6"螺旋槳時,主油針需要先大幅退

出,避免因為轉速過高,而貧油潤滑不足,

損壞引擎零件。

2019/04/01 修訂

34

1

34

GF-6 2-Stroke Electric Ignition Gasoline Engine Manual

(for .30 size Aircraft)

The SH R&D team started developing the mini gasoline engine back in 2009. The purpose was to respond to

the challengebetween high nitro fuel costs and the difficulty of obtaining it in the market. The goal was also to

improve the inconvenience of carrying bigger size engines for car, aircraft and boat applications. SH finally

launched the world’s first 5.1cc (GC31) high performance gasoline engine for 1/8 scale use in 2015, after

years of experience and major breakthroughs.

The SH Team overcame the common problems plaguing existing gasoline engine in the RC market; including

high temperature, low speed and so on, during the research and development period. Not only were exclusive

designs from world patents applied, but SH also combined CNC high-tech processing. Here SH has

successfully produced a small displacement CDI ignition gasoline engine with their persistent efforts and

continuous improvements.

Although the GC31 CDI ignition gasoline engine series achieves the performances and effects as expected,

it still couldn’t get rid of the defects from the CDI igniter; such as increasing weight, space limitations during

installation and high voltage interference, with some other trouble challenges. Therefore, SH continuously

tested and finally made a breakthrough, officially releasing the electric ignition gasoline engine (GC31 SPEC2)

in 2017. According to the demand of the aircraft market, the world’s first 6cc 2-stroke electric ignition gasoline

engine (GF-6) was produced in the same year, at the end of 2017.

GF-6 gasoline engine comes with great power, high speed, lasting life, operational stability, easy

adjustment, excellent cooling and economic fuel consumption! That’s why we strongly believe it will be the best

choice for all the aircraft pilots.

●Suitable for all 2-stroke .25-.40 size model aircrafts on the market

●Proper run-in (break-in) of the engine is a very important step in ensuring that you get the

highest performance and lifetime of your engine.

drawing(1)

45°

→

→

The igniter spec as same as the standard

nitro engine

Propeller size of

10”x6” as

suggestion

45 degree installation angle

of propeller recommend as

above picture showed

(spin the engine shaft counter

clockwise direction to the piston

compression angle, and fixed the

propeller angle at 45 degree)

ATTENTION

●An inappropriate (too big) propeller may cause the engine to become overloading, and

potentially shorten its life.

●Please make sure the propeller is tightly locked in case of any issues occurred by an

accident.

250ml engine oil can be mixed with 5

liters of gasoline or 80ml engine oil mixed

with 1.6 liters of gasoline. (1600/80=20)

1. Please make sure the engine is mounted to your model securely and that the fixed screw is locked

tightly to the carburetor in case of any issues causing unsmooth performance.

2. Use a mixture of 92 Octane gasoline and SH

specified 2-cycle oil.

Suggestion: the best gasoline and engine

oil is 20:1, roughly around 4.76%

3. Plug: The engine is equipped with an SH factory

specified manufacture plug, with a 1.5A voltage

applied.

(the plug spec as same as the standard nitro engine).

4. Propeller: We suggest a propeller size of 10"x6" and

the installation angle recommend as the below

drawing (1) showed

Carburetor Setting and Run-In Procedure

Following setting all based on the factory standard; comply with the propeller size of 10”x6” as setting.

If replace others muffler, the main speed needle need to adjust at 4 1/2 turns to 5 turns from the bottom and

make slight adjustments accordingly to the condition. If use propellers size smaller than 10”X6”, the main

speed needle need to turns much more at rich condition to avoiding any damages to engine due to high RPM

or too lean condition.

1. First, adjust the idling screw to the position showed in figure (2) of mark , fully closed from the bottom

and open approx. 2.0mm. Then add the 28.5:1 fuel/oil mixture into the fuel tank. For needle adjustments,

image the slot in the needle is the hour band on a clock and only adjust the needle from 1-2 hour increments

each change.

2. First stage of run-in:

The main needle and low speed needle are preset from the factory. Please turn the main needle see back

side attached figure (2) of mark , Set the main needle at 4 turns from the bottom and low speed needle

at 134turns from the bottom. After that, open the carburetor about half position. block the carburetor inlet by

hand and spin the engine counter-clockwise direction to help push fuel into the carburetorand inside the

engine. Connect the plug igniter and apply an electric starter to start the engine; keeping the engine staying

in mid-range running, and then you can remove the plug igniter.

3. Engine RPM observation:

You can turn the main speed needle counter clockwise 2 hours if the engine reaches over more than 5000

RPM’s. Adjust in 2 hour increments at a time until the engine is running rich. You can turn the main needle

clockwise 2 hours if the engine is too rich and stops running. Adjust in 2 hour increments at a time, until

the engine returns to a rich and smooth-running condition. At this stage roughly required 500cc of

fuel running through

3

1

※

The exhaust should emit lots of dark blue smoke, indicating that the engine is in

rich condition.

4. Low speed needle adjustment:

Adjust the idling screw to the position showed in figure (2) of mark , fully closed from the bottom and

open approx. 2.0mm.If the engine idle speed is high and continues to increase and not slow down, it’s too

lean, and the low speed needle needs to be turned counter clockwise 2 hours until idle is stable.If the

engine at idle speed is too low and leads to stalling, it’s too rich and the low speed needle needs to be

turned clockwise about 2 hours until the idle is stable. Stay at 3000 RPM for best idle speed of this time.

(RPM going a little lower is normal once you remove the plug igniter during idling)

3

1

2

3

→

→

→

→

Idling screw set the main speed

needle at 4 turns

from the bottom

Set the low speed

needle at 134turns

from the bottom

set the low speed needle

at 2mm from the bottom

Fuel inlet mounted

angle

(no excess to the horizontal

line to avoid any air flow bubble

stock into the fuel line caused

unsmooth running or stalling.

figure(2)

In Figure (2) the needle position showed is only for

the new engine during the run-in, comply with

propeller size of 10”x6” as suggestion. Once the

run-in is completed, we suggest setting the

main needle at 212turn from the bottom,

low speed needle at 134turn from the bottom.

Make slight needle adjustments according to the

condition after the engine warms up. Please check

if the idle hole is too small and set the throttle

allowance about 2mm by radio when at idling

condition but stalls easily. Also open the throttle

fully and maintain around 10,000 RPM when the

aircraft model is on a flat surface. Make main speed

needle adjustments 1 hour increments each time

after each flight. The main speed needle will need

to be adjusted when switching to a different size

propeller due to the loading difference or will cause

the damages to the engine.

NOTES

6. After the first and second stage run-in procedure, preliminary engine run-in is complete, but the

engine is still new. At this stage, we can proceed to our first initial flight.

Make sure the receiver battery is fully charged, fuel tank is full and the servos have the

correct forward and reverse direction. Then start the engine and allow a 2-minute warm up in the mid

speed range of running. Put the aircraft model on a flat surface, holding tight and set the throttle

position to fully open to adjust the main needle. The idle engine RPM setting is around 10,000 RPM

when the aircraft is on flat ground. When set the nose wheel around 70-80 degree, the RPM will

increasing to 11,500 then put back to a flat surface the RPM will returning to 10,000.

After 2 flights, make slight main needle adjustments when the aircraft model is on a flat

surface, and set the engine to maintain 10,000 RPM operation during flying. Finally, we have completed

the run-in procedure. We hope this engine brings more flying fun and saves as much as fuel costs.

1.Kindly check the fuel lines to ensure there is no leaking or clogged issue when the engine is

running unsmooth or when you have needle setting difficulties. Installing a SH specified fuel

filter SB001 into the fuel tank is suggested.

2.Please use the SH specified 2 cycle engine oil to maintain proper engine operation. Use 92

gasoline and SH specified 2 cycle oil mixed up; Gasoline and engine oil ratio is 20:1,

roughly around 4.76% SH specified plug of GT4 or GT5 plug is recommended and we also

suggest the propeller with size 10"x6" to obtain the best performances.

(The engine may be overloaded, leading to shorten life if you use an inappropriate,

or bigger, propeller size)

3.The needles may need to be reset if there are any big changes to the operating flight environment.

(Hot/cold or any differences of the high altitude and low altitude)

4.Please clean the spark plug and burn room after 1 gallon of fuel has run through the engine.

If the heating screen of burn room has serious carbonated damage or the plug bottom is

carbonated, Please replace with a new one (Both plug and burn room are consumables,

please replace according to the use situation)

5.The fuel is flammable and dangerous; always stay away from sparks, heat or any other ignition

source. Don’t store the fuel in the gas tank after you have finished flying your aircraft model.

Store your fuel, gasoline or mixed fuel safely in a cool, dry location.

6. Provided warranty conditions have been met, your product will be repaired or replaced free of

charge. Repair or replacement decision is as the sole discretion of SH.

7. If the engine hasn’t been used for a long time, the fuel may not get through the fuel line into

the engine or carburetor. Please go check whether the fuel filter in the fuel tank is clogged,

disassemble the carburetor and clean up. Adjust the needle setting as recommended and

assembled the relative parts back. Then restart the engine.

※The new engine will flame out due to overheating if RPM exceeds 10,500 RPM

A. Only use with SH specified gasoline spark plug to ensure the engine runs

properly and has great performance.

B. The fuel tank and fuel line need to be made from gasoline resistance material

C. It is prohibited to use any nitro fuel which contains methane!

※

Always watch out for the engine speed and how much fuel is running through; make

sure engine speed stays under 8000 RPM

5. Second stage of run-in:

Set the throttle to fully open position for accelerating, to set the main needle adjustment. The engine needs

to stay in a rich condition during the run-in procedure and the exhaust should emit a lot of fuel and white/blue

smoke at the same time.You can turn the main speed needle counter clockwise 2 hours if the engine reaches

over more than 8000RPM. Adjust in 2 hour increments at a time, until engine returns to stable running

under 8000 RPM. You can turn the main needle clockwise 2 hours if the engine is too rich, leading to

stalling. Make adjustment in 2 hour increments at a time until the engine is back to a rich condition in

mid-range running. The run-in procedure at this second stage required at least 400cc of fuel running

through.

Table of contents

Other SH Engines Engine manuals

Popular Engine manuals by other brands

Tecumseh

Tecumseh OHV110 Operator's manual

KCFA

KCFA SV-X3 Series Installation and Wiring

RADEMACHER

RADEMACHER RolloTube Basic 2160 20 90 installation instructions

Advanced Micro Controls Inc.

Advanced Micro Controls Inc. SMD23E2 user manual

Becker

Becker L120-11-C16 Assembly and operating instructions

Siemens

Siemens SIMOTICS FD 1MN1 operating instructions

Nice

Nice NEOSTAR T Series Installation and use instructions and warnings

MINN KOTA

MINN KOTA ULTERRA installation instructions

HE PARAMOTORES

HE PARAMOTORES R 220 Installation and operator's manual

SOMFY

SOMFY GOME MOTION Roll Up 28 WT instructions

Mitsubishi

Mitsubishi 4G9 series Workshop manual

Rail King

Rail King Y6b 2-8-8-2 operating instructions