ShadeFX Freestanding Canopy User manual

Freestanding Canopy

Assembly Guide

ShadeFX Installation Guide 2

REV. 03/2021

Table of Contents

Introduction

How it Works 3

The Importance of Proper Assembly 3

Proper Handling 3

System Components

Base Assemblies 4

Structure Assembly 5

Track and Canopy Assemblies 5

Recommended Tools 6

Hardware 7

Assembly

Step 1: Locating, Securing, and Leveling the Base 10

Step 2: Assembling the Structure 14

Step 3: Attaching the Canopy 18

Post-installation

Rotating the Canopy 20

Winter Storage 21

Wind 21

Improper Uses of the Product 21

Lubricants 21

ShadeFX Installation Guide 3

REV. 03/2021

Introduction

How it Works

All ShadeFX systems utilize the patented single-track drive system. Fabric panels of the canopy assembly are

extended or retracted as the lead carrier and wing travel along the drive beam.

The Importance of Proper Assembly

Proper assembly will preserve the life of your ShadeFX Retractable Freestanding Canopy. Inadequate assembly

may result in avoidable and expedited wear on the system’s components. The assembly instructions outlined in

this guide are intended to assist with the successful deployment of your Freestanding Canopy.

It is recommended that a complete review of the assembly guide be conducted prior to assembly. If there are

questions regarding assembly that are not addressed in the guide, please contact ShadeFX before continuing.

Proper Handling

Proper care must be taken when handling the product during assembly as contact with hard, sharp or abrasive

surfaces could result in deformation, scratches or rips in the fabric and components of the system.

It is important to handle your canopy assembly with care, especially when lifting the canopy onto the structure. It

is recommended to work in a group of at least two people.

Questions

ShadeFX Retractable Freestanding Canopies are a unique product with limited comparable oerings. Whether you

are an experienced contractor or homeowner assembling the system for the rst time, questions may arise.

ShadeFX Canopies: (855) 509-5509

ShadeFX Installation Guide4

REV. 03/2021

System Components

Each ShadeFX Freestanding Canopy will include a base assembly, structure assembly, track assembly and a

canopy assembly. The nal product will resemble the following image.

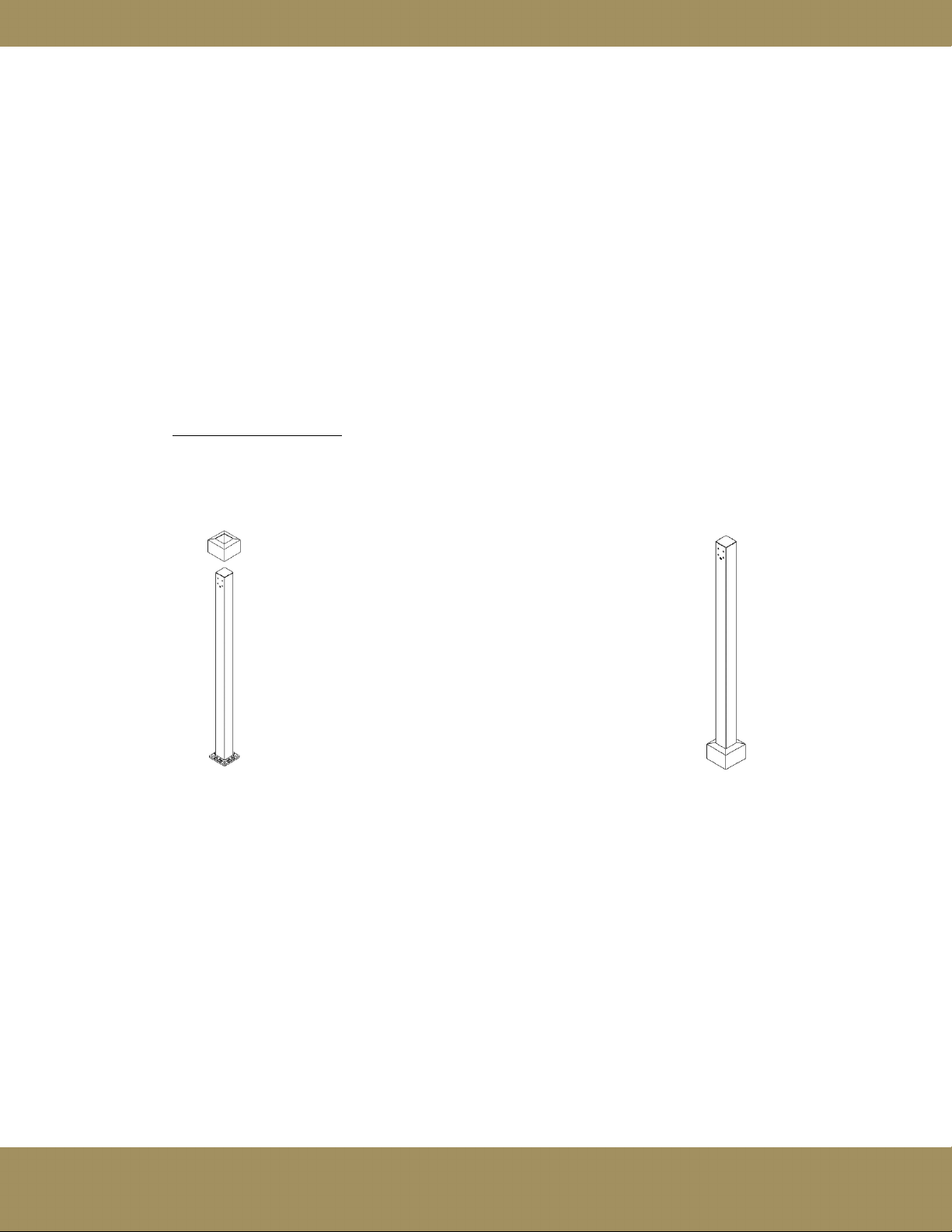

Base Assemblies

Concrete Base Wood Base

ShadeFX Installation Guide 5

REV. 03/2021

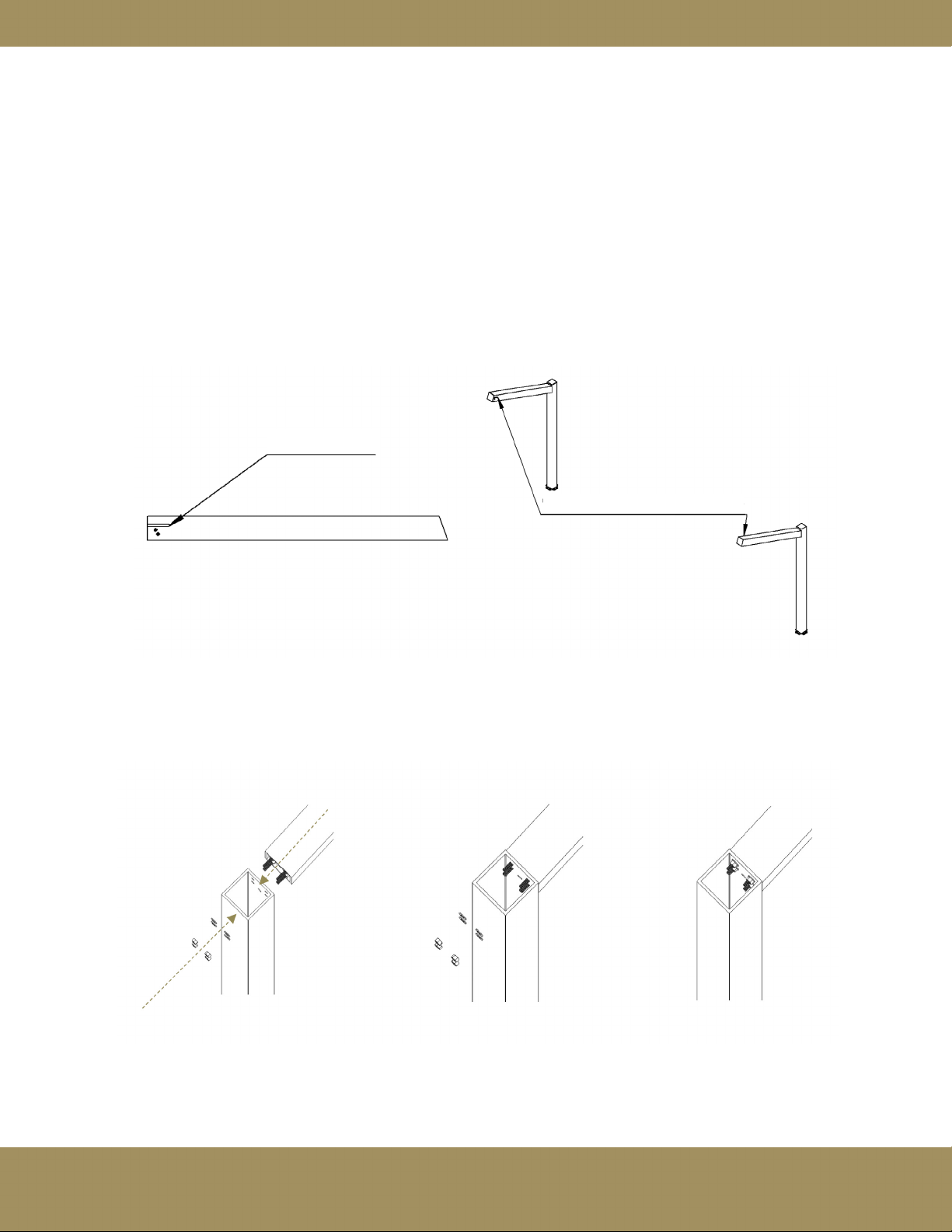

Structure Assembly

Track and Canopy Assemblies

ShadeFX Installation Guide6

REV. 03/2021

Recommended Tools

The tools listed below are recommended to facilitate an ecient and eective assembly. Certain tools may be

substituted.

• Stepladder (x2)

• Tape or laser measure

• Level

• Pencil, marker (for base plate location marking)

• 9/16” Wrench

• 7/32” Socket Head Bit or Allen Key

• Rubber Mallet

• Chalk or string line

• If Wood Base Option: Drill and #2 Robertson (Square) drive

• If Concrete Base Option: Concrete drill, 9/16” socket drive, and 5/16” concrete drill bit

ShadeFX Installation Guide 7

REV. 03/2021

Hardware

Hardware is dependent on the number of units and base option selected. Hardware is categorized into four

groupings: general hardware, base assembly hardware, structure assembly hardware and track assembly

hardware.

General Hardware

A Removable Canopy Handle to extend and retract the canopy is included with each order. Gravity Clips “G-Clips”

are also included with every canopy to attach the canopy assembly to the track assembly. The number of G-Clips

is dependent on track length. Quantities listed below are on a per canopy basis.

Item Quantity Per Canopy Drawing

Removable Canopy Handle* x1

Gravity Clip “G-Clip”

x10 (8’ Track Length)

x12 (10’ Track Length)

x16 (12’ Track Length)

x18 (14’ Track Length)

x20 (16’ Track Length)

*Only one handle will be provided per order

Base Assembly Hardware

Base assembly hardware is dependent on the type of base selected and number of canopies purchased.

Quantities listed below are on a per post basis.

Concrete Base Hardware

Item Quantity Per Canopy Drawing

3/8” x 5” LDT Screw Anchor x4

3/8”x16 x 1” Flat Socket Cap

Screw x8

ShadeFX Installation Guide8

REV. 03/2021

Wood Base Hardware

Item Quantity Per Canopy Drawing

#10-8 x 4” Wood Screw x16

3/8”x16 x 1” Flat Socket Cap

Screw x8

Structure Assembly Hardware

Structure assembly hardware quantity is dependent on the number of canopies purchased. Quantities listed

below are on a per post basis.

Item Quantity Per Post Drawing

3/8” Washer x4

3/8”-16 Hex Nut x4

ShadeFX Installation Guide 9

REV. 03/2021

Track Assembly Hardware

Track assembly hardware quantity is dependent on the number of units purchased. Quantities listed below are on

a per canopy basis.

Item Quantity Per Canopy Drawing

Rotation Plate x2

3/8”-16 x 1-1/2” Flat Socket Cap

Screw x8

3/8”-16 x 1-1/2” Hex Bolt x4

3/8”-16 Hex Nut x2

3/8” Washer x4

ShadeFX Installation Guide10

REV. 03/2021

Assembly

The following instructions are intended to assist with the assembly of the Retractable Freestanding Canopy.

Please contact ShadeFX if you require clarication of any of the steps listed below.

The assembly of the Freestanding Canopy consists of three major steps:

1. Locating, Securing and Leveling the Base

2. Assembling the Structure

3. Attaching the Canopy

The steps of Locating, Securing and Leveling the Base will vary depending on the base type selected

(Concrete/Wood). Assembling the Structure and Attaching the Canopy remain constant across both base

options.

Step 1: Locating, Securing and Leveling the Base

In Step 1 you will connect the post to the base, locate & align the bases to each other and level & secure the

bases to the mounting surface.

Concrete Base / Wood Base

Concrete and wood bases follow the same set of steps. If wood base is selected, the deck must be reinforced

at base locations to ensure all screws are engaged in structural wood. Contact ShadeFX if deck reinforcement

recommendations are needed.

Connecting the Post to the Base

i. Connect post to base using 3/8”-16 x 1” at head socket screws (x8). The post plate aligns with

the recessed cutout in the base. Repeat for other post(s).

ShadeFX Installation Guide 11

REV. 03/2021

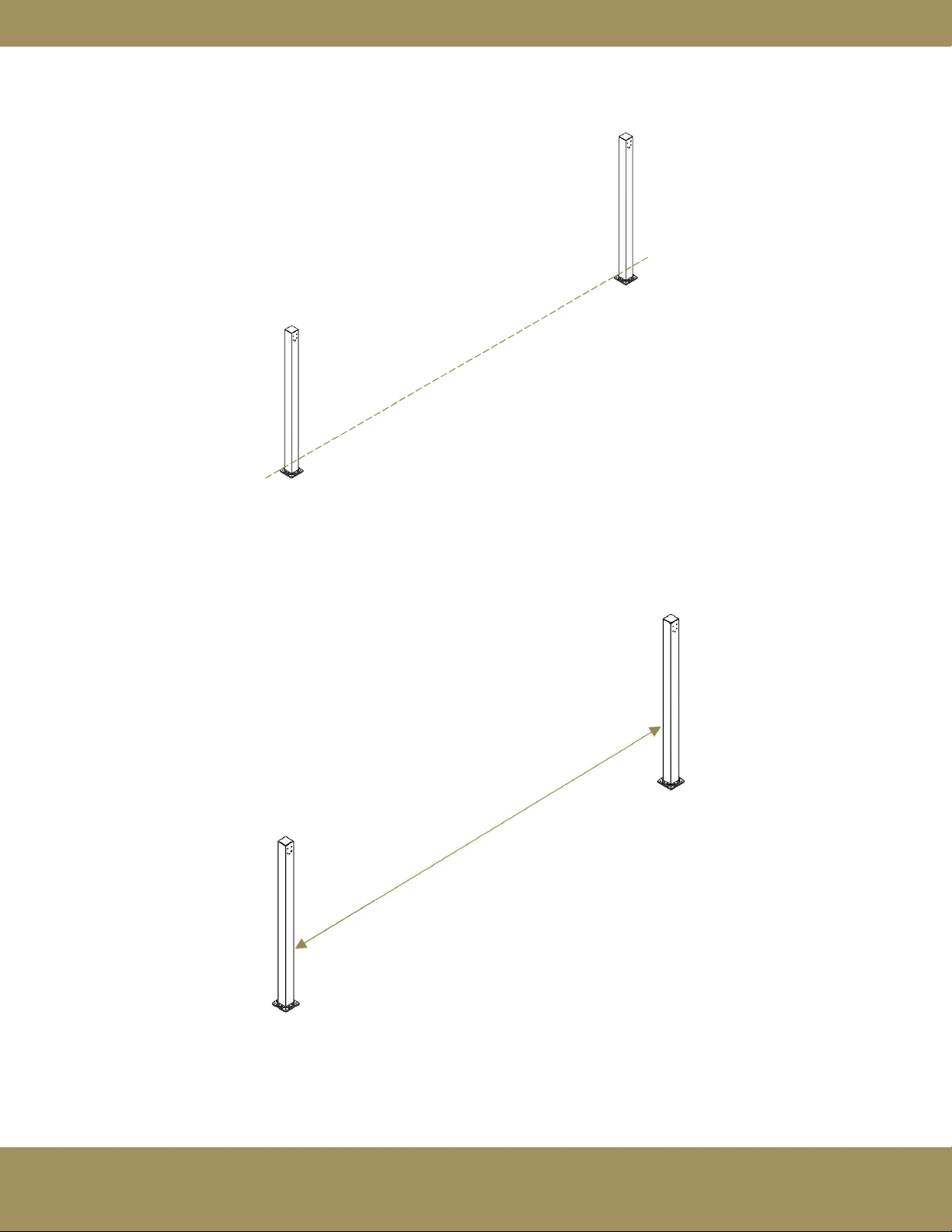

Locating and Aligning the Bases

i. Ensure the front face of the post is facing forward.

ii. Determine the required distance between the bases for CONCRETE mounting by subtracting

2-3/4” from the total track supporting beam length (track supporting beam + rotation plate).

Ex: for a 16’ track the required distance between bases is 189-1/4” (192”-2-3/4”)

Determine the required distance between the bases for WOOD mounting by subtracting 5-3/4” from

the total track supporting beam length (track supporting beam + rotation plate).

Ex: for a 16’ track the required distance between wood bases is 186-1/4” (192”-5-3/4”)

Ensure the back (or front) of the bases are co-linear by dropping a chalk line.

Front Face of Post

Inside Back Distance

Inside Front Distance

ShadeFX Installation Guide12

REV. 03/2021

iii. Once the bases are aligned the distance between the inside of the posts should equal the total track

supporting beam length (track supporting beam + rotation plate) +1/4”.

Ex: for a 16’ track the inside to inside post distance should be 192-1/4” (192”+1/4”)

iv. Using a marker or pencil, mark the hole locations through the base plate onto the surface below.

Inside Post-to-Inside Post Distance

ShadeFX Installation Guide 13

REV. 03/2021

v. Pre-drill holes on marked locations:

Concrete: use concrete drill and 5/16” concrete drill bit

Wood: use regular drill and #2 Robertson (Square) drive

vi. Mount base plate/post assembly to the ground using the predrilled holes and the provided fasteners.

Concrete: use a high torque drill and a 7/16” socket bit

If the fasteners are too dicult for the drill to tighten use a socket wrench and

the 7/16” socket bit and tighten the fasteners manually.

Wood: use a regular drill and #2 Robertson (square) bit

vii. For Concrete Base only:

Slide the post skirts over the posts so that they cover the baseplates.

ShadeFX Installation Guide14

REV. 03/2021

Step 2: Assembling the structure

In Step 2, you will assemble the structure that supports the canopy by attaching the arm to the post, attaching the rotation

plate to the track supporting beam and mounting the track supporting beam to the posts. Step 2 is constant across all

three base options.

Attaching the Arms to the Post

i. The cut faces (see below) should be facing each other when installed on posts. Ensure the arms are

angled upwards when installing.

Secure arms in place by installing washers (x4 per arm) and 3/8”-16 hex nuts (x4 per arm) from inside

the posts.

“Cut face”

“Cut face” facing inwards

ShadeFX Installation Guide 15

REV. 03/2021

Attaching the Rotation Plate to the Track Supporting Beam

ii. Attach rotation plate onto the track supporting beam by rst inserting the 3/8”-16 x 1-1/2” hex bolt

through the slot hole.

Then, secure the rotation plate onto the track supporting beam using 3/8”-16 x 1-1/2” at socket

cap screws (x4). Add a 3/8” washer and loosely thread a 3/16” nut until the nut is just on the

protruding thread. Repeat on the other side of the track supporting beam.

Ensure protruding threads on both rotation plates are adjacent to the same face. Ex: Protruding

threads adjacent to Face “A”

Face “A”

ShadeFX Installation Guide16

REV. 03/2021

Mounting the Track Supporting Beam to the Posts

iii. With two ladders set up in front of each arm, two laborers are to simultaneously raise the track

supporting beam to align the protruding threads with the slot in the arms. Slide the protruding thread

into the arm slots such that the existing threads (with nuts) protruding from the plates are

inserted rst. Refer to the image below for insertion direction.

iv. Set desired track angle (at orientation shown below). This orientation can be changed at any time

(see ‘Post Assembly’). Insert 3/8”-16 x 1-1/2” hex bolt with 3/8” washer into the plate hole when

the appropriate hole in the post is aligned. Repeat on other side of the track supporting beam.

20º from Horizontal

(Tilted Backwards)

Horizontal

20º from Horizontal

(Tilted Backwards)

ShadeFX Installation Guide 17

REV. 03/2021

v. Ensure both the bolt inserted in Step 2-iv as well as the nut fastened onto the protruding thread in

Step 2-ii are tightened fully and is done on both ends of the track supporting beam.

vi. Press post caps into top of arms and top of posts. Use a rubber mallet if required.

ShadeFX Installation Guide18

REV. 03/2021

Step 3: Attaching the Canopy

In Step 3 you will connect your canopy to the structure. Each wing is to be inserted into a carrier assembly and

secured using gravity clips (G-clips) (x2). Start with a lead carrier (has a protruding eye bolt), then all of the normal

carriers, then end with the other lead carrier. Ensure that the rst wing (lead wing) inserted into a lead carrier is the

rst wing on the fabric.

Note: Do not dispose of the packaging bag as it can be used for winter storage of the canopy.

i. Raise wing into carrier assembly. Align holes in wing with holes in carrier assembly.

Lead Wing

Lead Carrier

ShadeFX Installation Guide 19

REV. 03/2021

ii. Once holes are aligned, insert G-clips.

iii. Rotate G-clips downward until they lock into position.

Notice the direction of the G-clips on each side of the drive beam are dierent.

ShadeFX Installation Guide20

REV. 03/2021

Post-installation

Rotating the Canopy

Changing the canopy orientation requires the removal of the post caps on the arms. This can be done by inserting

a at screwdriver into the small slot in the post cap to pry the cap o.

Completely remove the hex bolt while being careful not to drop the washer

Hold the track supporting beam and slowly release the nut on the protruding thread until rotation is possible

Tighten nut and bolt to secure in place (Canopy Tilted Forward position shown above)

Rotation can be done with the canopy still attached but it is recommended that it be retracted in the middle of the

track supporting beam.

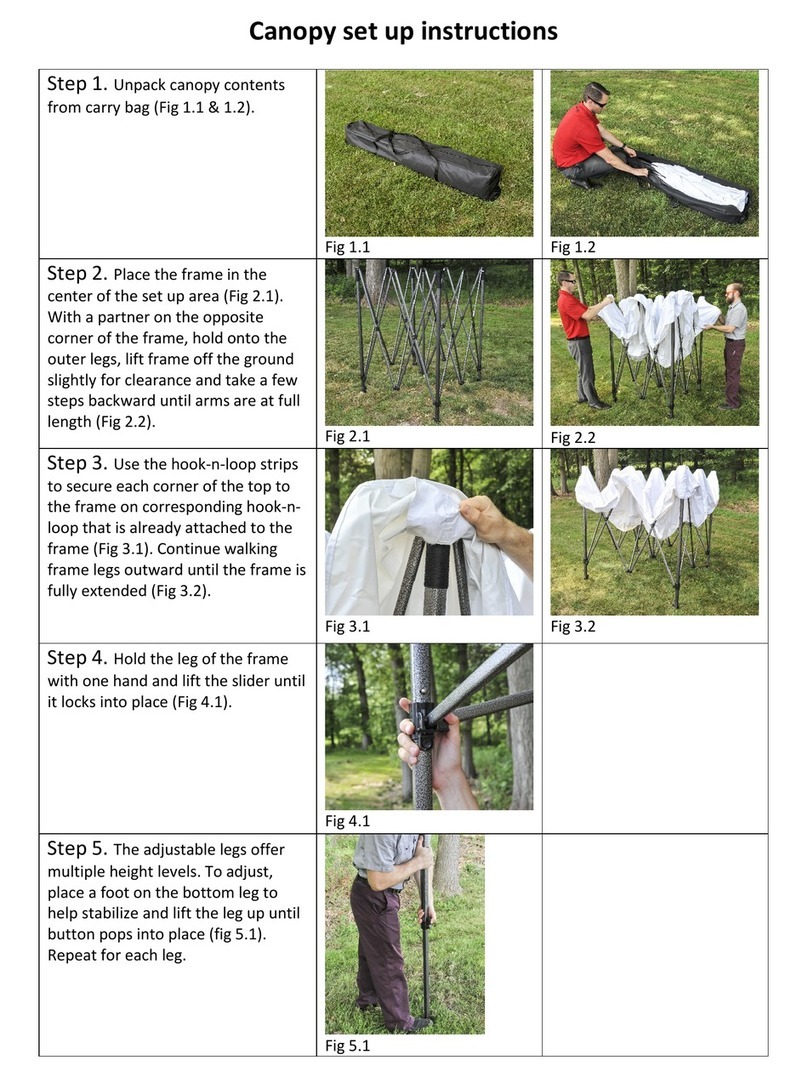

Table of contents

Popular Tent manuals by other brands

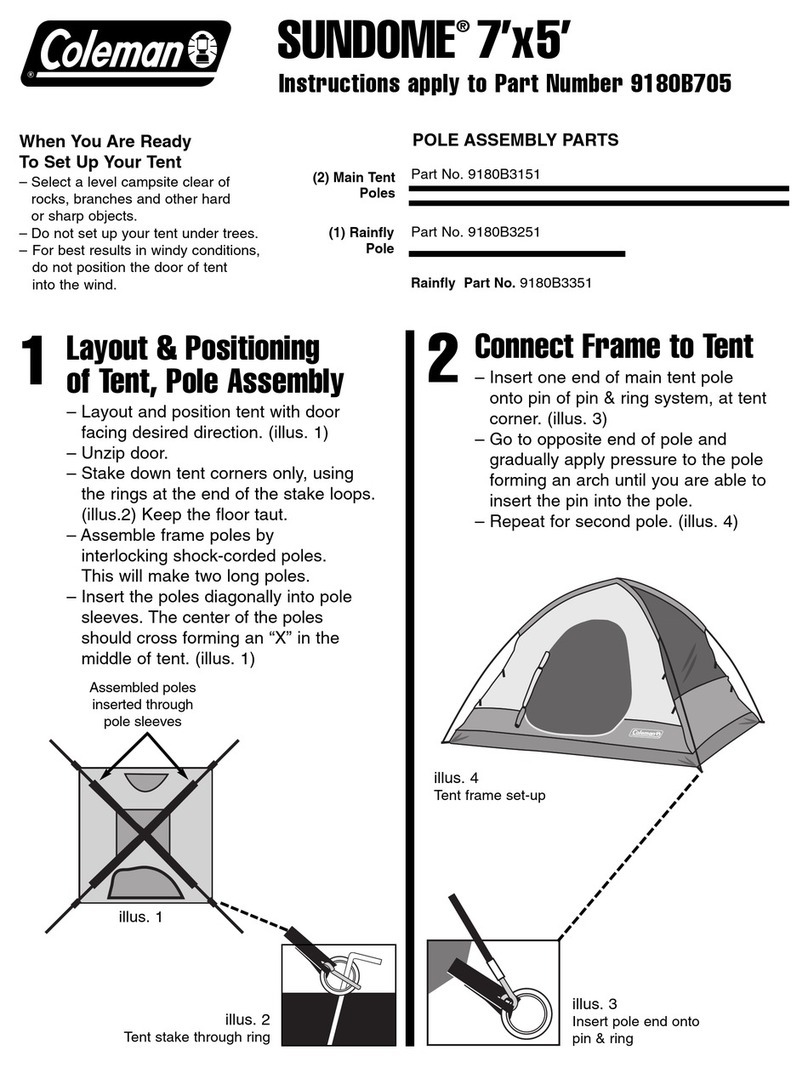

Coleman

Coleman Sundome 9180B705 instructions

Vortex

Vortex 3300 Louvre Pergola owner's manual

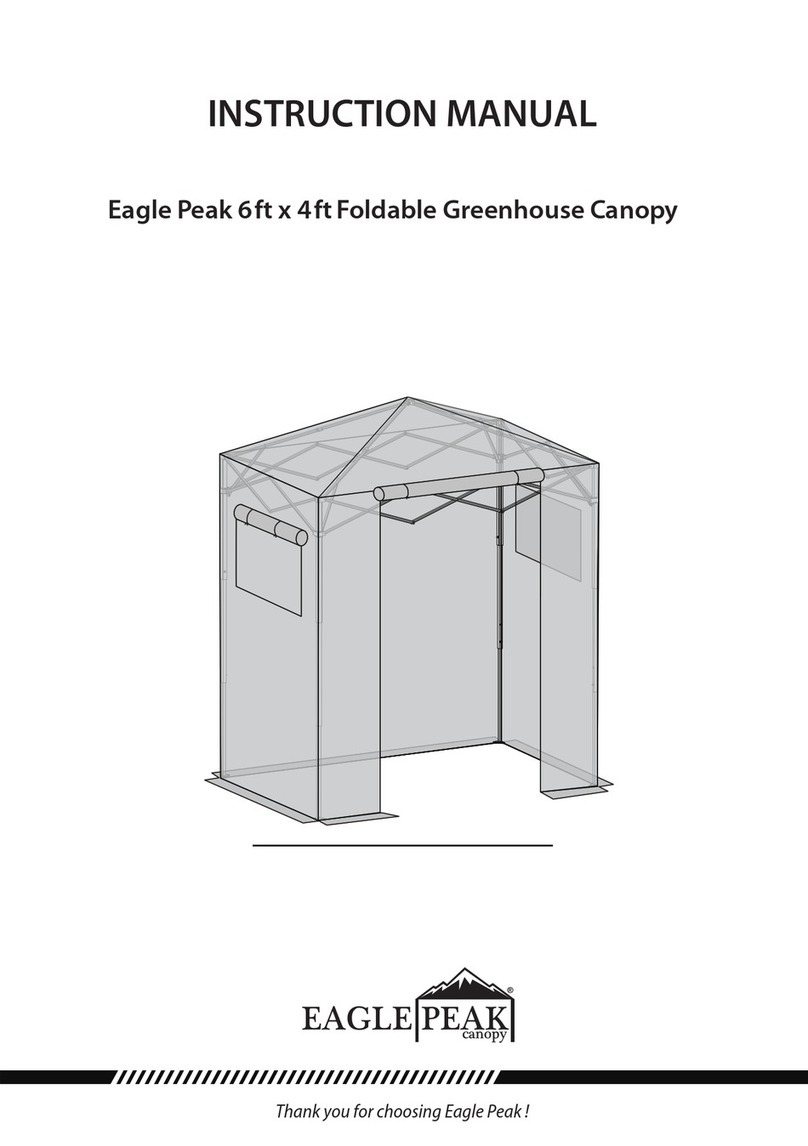

Eagle Peak

Eagle Peak 6ftx4ft Foldable Greenhouse Canopy instruction manual

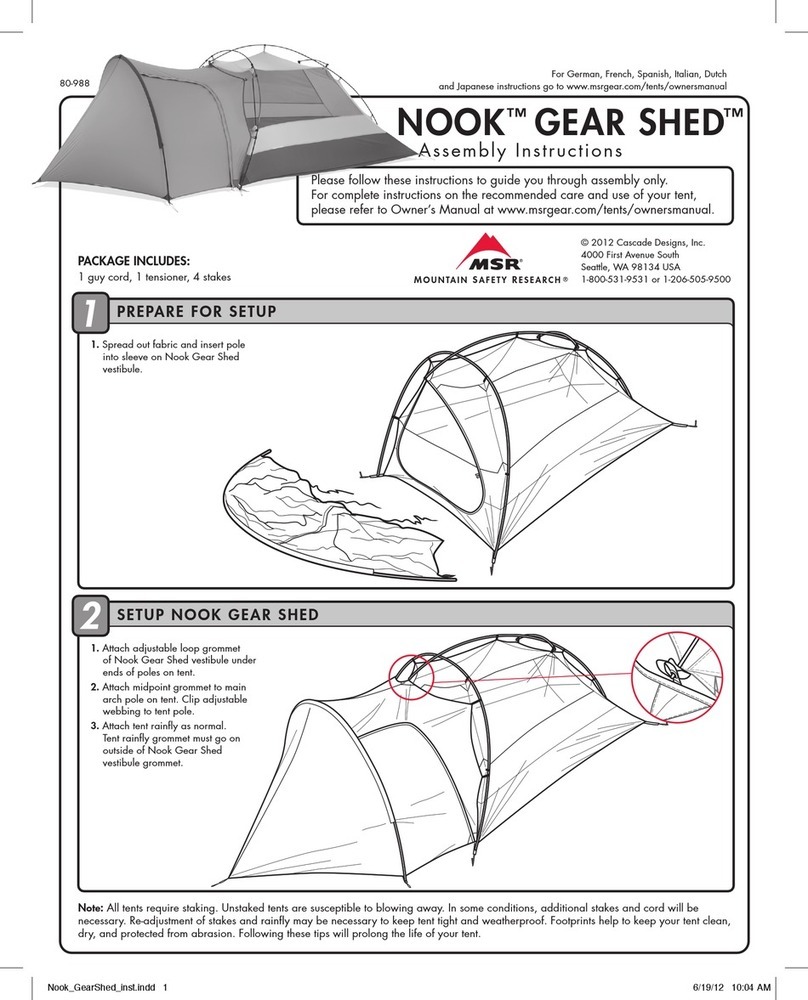

MSR

MSR NOOK GEAR SHED Assembly instructions

Big Agnes

Big Agnes Mine Mountain Series String Ridge 2 Setup instructions

Summit Racing

Summit Racing GSA-M1014 Setup instructions