ëìíîïðïëïìî ñ òó

v. 02/14B

OPERATOR’S MANUAL

PRESSUREWASHER

ôõ

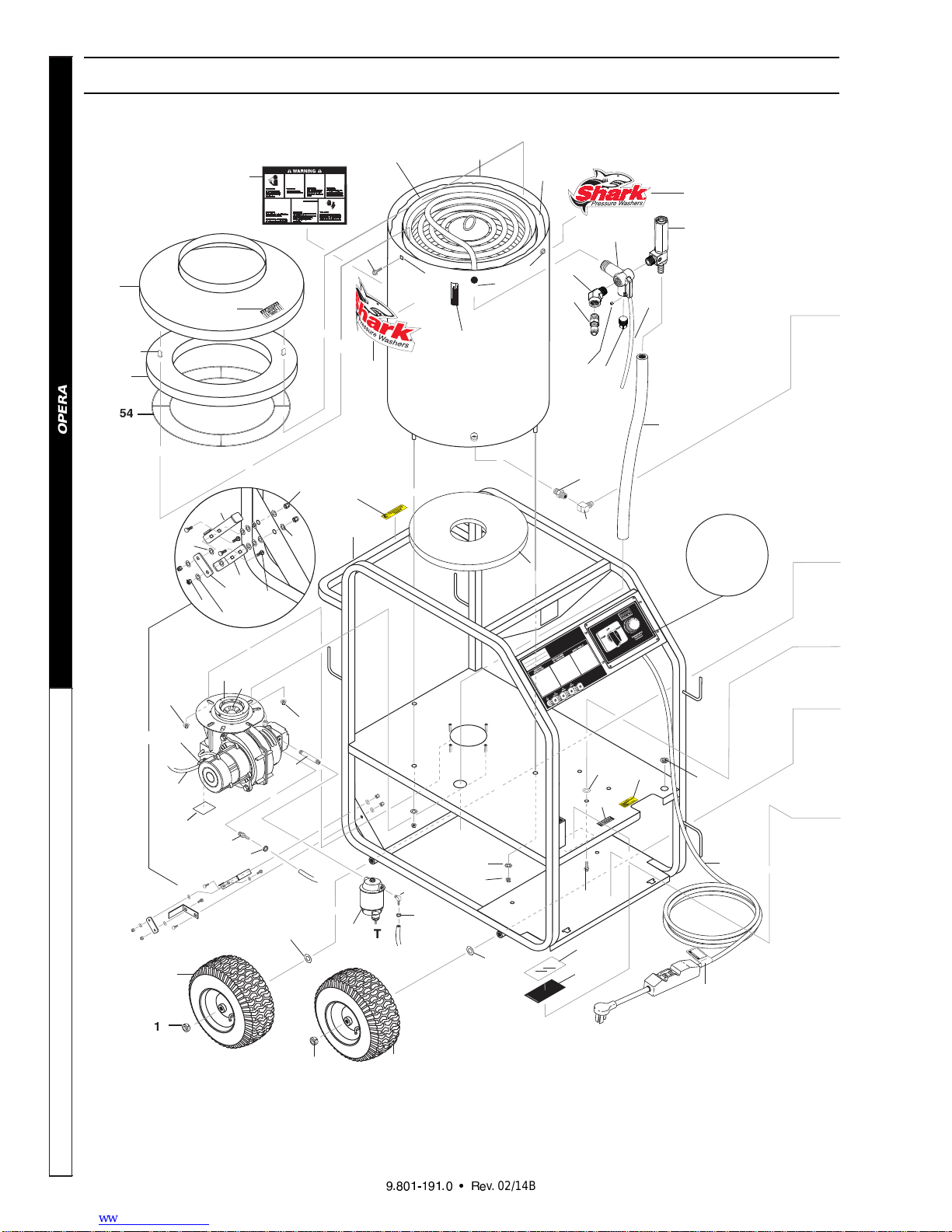

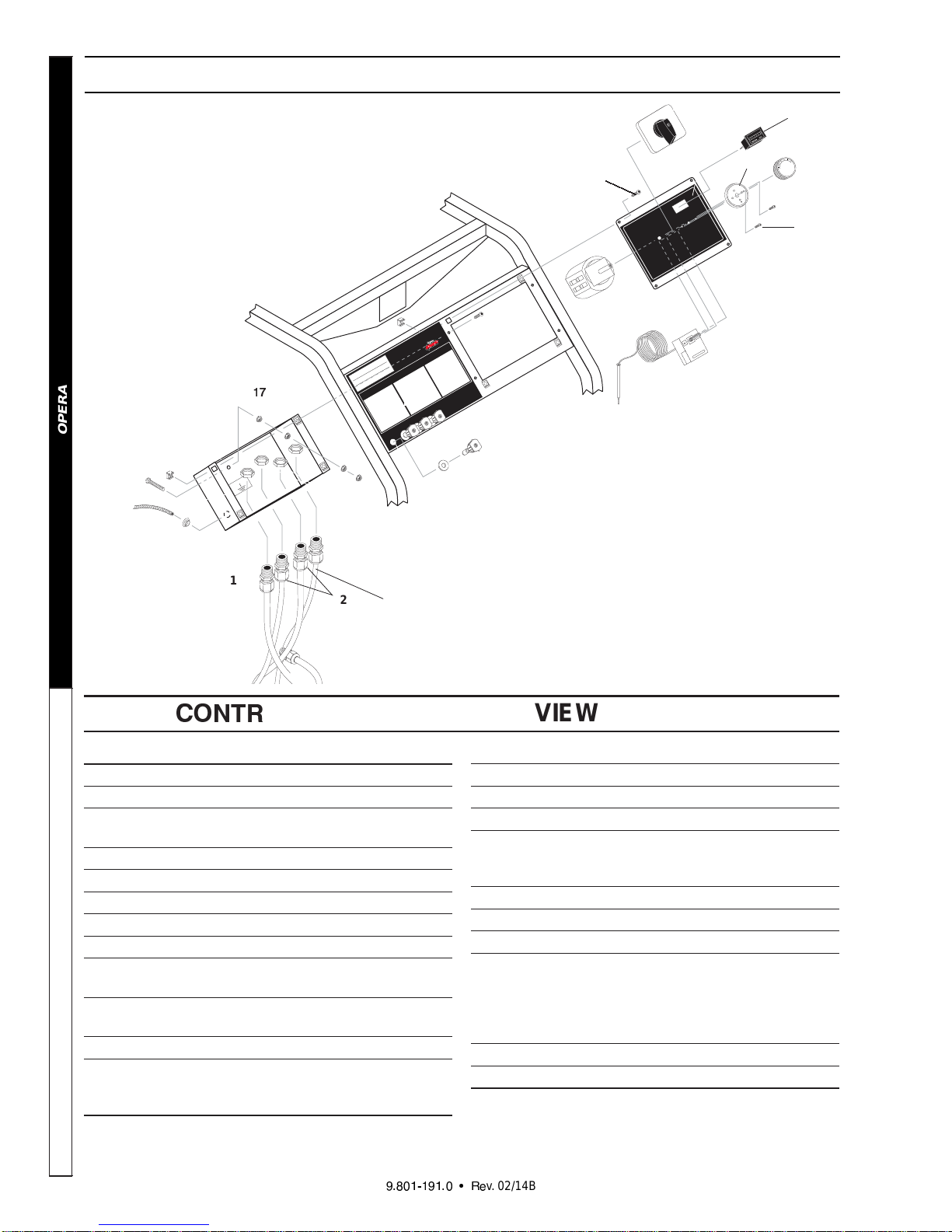

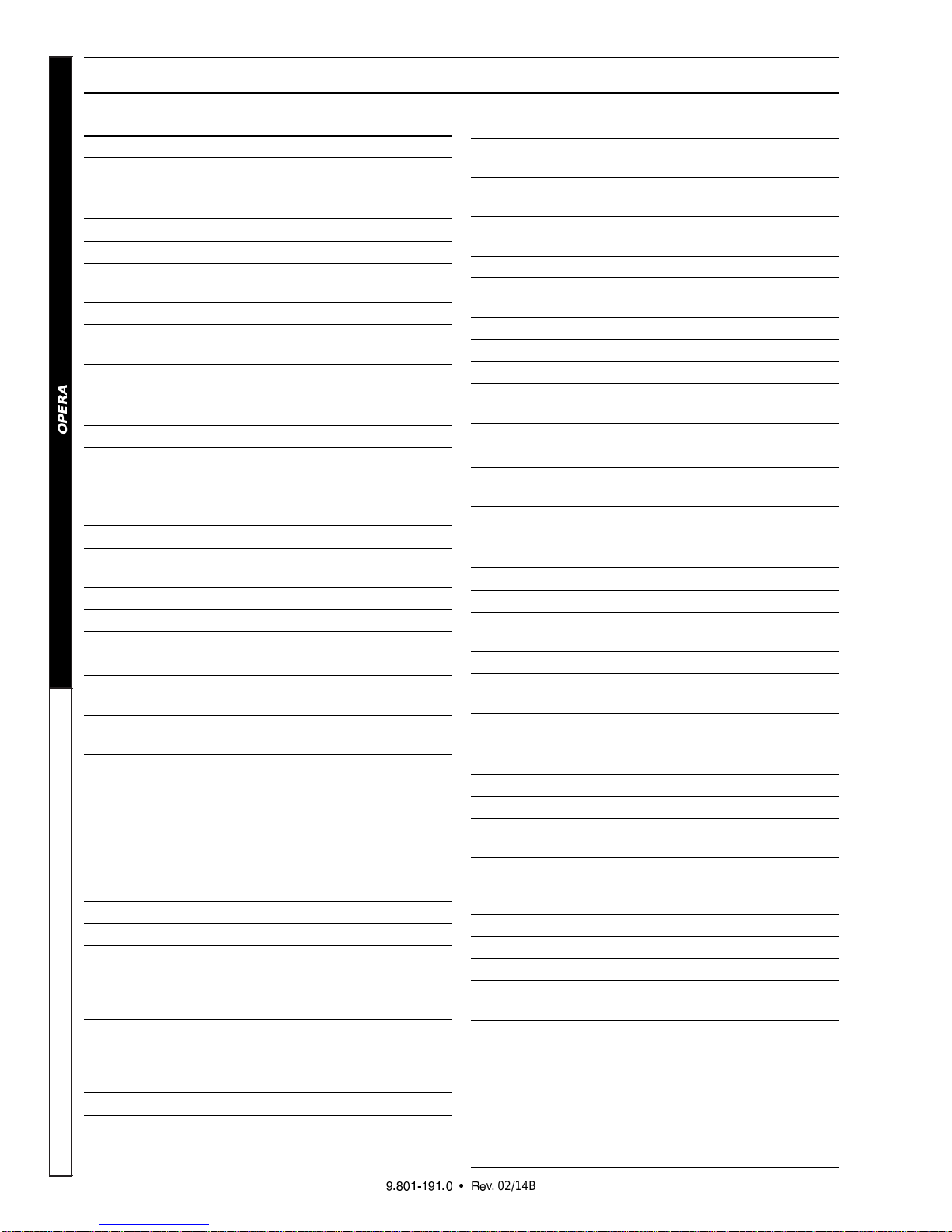

EXPLODEDVIEWS PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 9.802-782.0 Collar, 5/8" Bore Shaft 4

2 9.802-271.0 Wheel & Tire Assy,

6" Steel Rim w/Tube 4

3 9.802-810.0 Washer, 5/8", Flat, SAE 4

4 8.922-672.0 Axle Long 2

5 9.802-081.0 Tank, Fuel 6 Gallon Blank 1

6 9.802-089.0 Cap, Fuel Tank,

Plastic H60-AV 1

7 9.802-053.0 Bushing, Rubber, Nitrile 2

8 9.802-141.0 Hose Barb, 1/4" Barb x 3/8"

Barb, Double 1

9 9.802-177.0 Valve, 1/4" Shut-Off 1

10 9.802-138.0 Hose Barb,

1/4" Barb x 1/4" ML Pipe 1

11 6.390-126.0 Clamp, Hose, UNI .46 - .54 4

12 9.802-254.0 Hose, 1/4" Push-On,

Fuel Line 11"

13 9.802-254.0 Hose, 1/4" Push-On,

Fuel Line 7"

14 9.800-018.0 Label, Tipover Hazard 1

15 9.802-146.0 Swivel, 1/2" MP x 3/4"

GHF w/Strainer 1

16 9.198-014.0 Washer 21/64 X 1" 4

17 9.802-039.0 Elbow, 1/2 JIC 3/8, 90° 1

18 9.804-025.0 Pump Protector, 1/4", 145° 1

20 9.802-720.0 Bolt, 3/8" x 1", NC HH 4

21 9.802-814.0 Washer, 3/8" Split Ring Lock,

Zinc 4

22 9.803-815.0 Pump 2020S (231007D) 1

9.803-818.0 Pump, 3525F (352007A) 1

23 9.802-458.0 Switch, Pressure,

N/O, 1/4" NPT SS 1

24 9.804-516.0 Motor, 1.5 HP 120V

1725 RPM (231007D) 1

9.804-517.0 Motor, 2HP 1PH 120V

1725 RPM (201507D) 1

9.802-341.0 Motor, 5HP 1PH 230V

3450 RPM (352007A) 1

25 8.718-980.0 Washer, 5/16" Flat 8

26 9.802-776.0 Nut, 5/16" ESNA, NC 8

27 9.802-427.0 Cord, Service, SOWA, 3 ft.

12/3 (201507D)

9.802-436.0 Cord, Service, SEO, 2.67 ft.

10/3 (231007D, 352007A)

28 8.752-969.0 Strain Relief,

Small (231007D, 201507D) 1

9.802-518.0 Strain Relief,

STRT Lq Tite (352007A) 1

29 9.802-526.0 Locknut, 3/4" 8465 1

ITEM PART NO. DESCRIPTION QTY

30 9.175-018.0 UU1 3500PSI,

UNIVERSAL UNLOADER 1

31 9.800-049.0 Label, Manufacturer's

Cleaning Solution 1

33 8.918-425.0 Hose, 3/8" x 29", 2 Wire,

Pressure Loop 1

34 9.800-002.0 Label, Use Only Kerosene 1

35 9.149-003.0 Manifould Coil

Outlet Dicharge 1

36 8.902-433.0 Valve Safety, Relief 1

37 9.196-012.0 Plug 10-24UNF x 1/4 1

38 8.711-785.0 Hose, 3/8" Push-On 2.75 ft.

39 9.802-171.0 Nipple, 3/8" x 3/8" NPT

ST Male 1

41 9.800-021.0 Label, Hot Water Outlet 1

42 8.900-870.0 Label, Shark Logo Die-Cut 2

43 8.919-733.0 Coil, Wrap, Outer,

Weldement 1

44 9.802-753.0 Screw, 1/4" x 3/4" HH NC,

Whiz Loc 8

45 9.802-793.0 Nut, Cage, 1/4" x 16 Gauge 4

46 8.919-133.0 Coil, Assembly 1

47 9.800-041.0 Label, Warning, Text 1

48 9.800-006.0 Label, Hot/Caliete

w/Arrows Warning 1

49 8.719-913.0 Top Hat, Coil 1

50 9.802-904.0 Insulation, Tank Head,

16" OD x 8" ID 1

51 9.802-825.0 Clip, Retaining U-Type 4

52 9.802-042.0 Elbow, 1/2" JIC x 3/8"

Fem, 90° 1

53 9.801-266.0 Label, Shark Clear Flame 1

54 9.803-108.0 Retainer Ring, Insulation 1

55 9.802-900.0 Insulation, Tank Bottom,

1" Blanket 1

56 9.803-120.0 Assembly, Frame, Black 1

8.922-545.0 Assembly, Frame 1

(133.0 & 134.0)

57 8.705-974.0 Nipple, 3/8" x 3/8" Hex 1

58 8.750-094.0 Thermostat, 150C/302F 1

59 8.706-241.0 Plug, 3/8, SQ head 1

60 9.802-041.0 Elbow, 3/8", Steel,

Street, 45° 1

61 9.802-753.0 Screw, 1/4-20 x 3/4" 2

62 8.918-907.0 Burner KNA, 120V, 1

(231007D, 201507D)

9.802-555.0 Burner, AFG, 120V, F4 Cone 1

(231007D, 201507D)

9.804-518.0 Burner, Beckett, 1

230V AFG (352007A)

8.918-909.0 Burner KNA, 230V (352007A)1