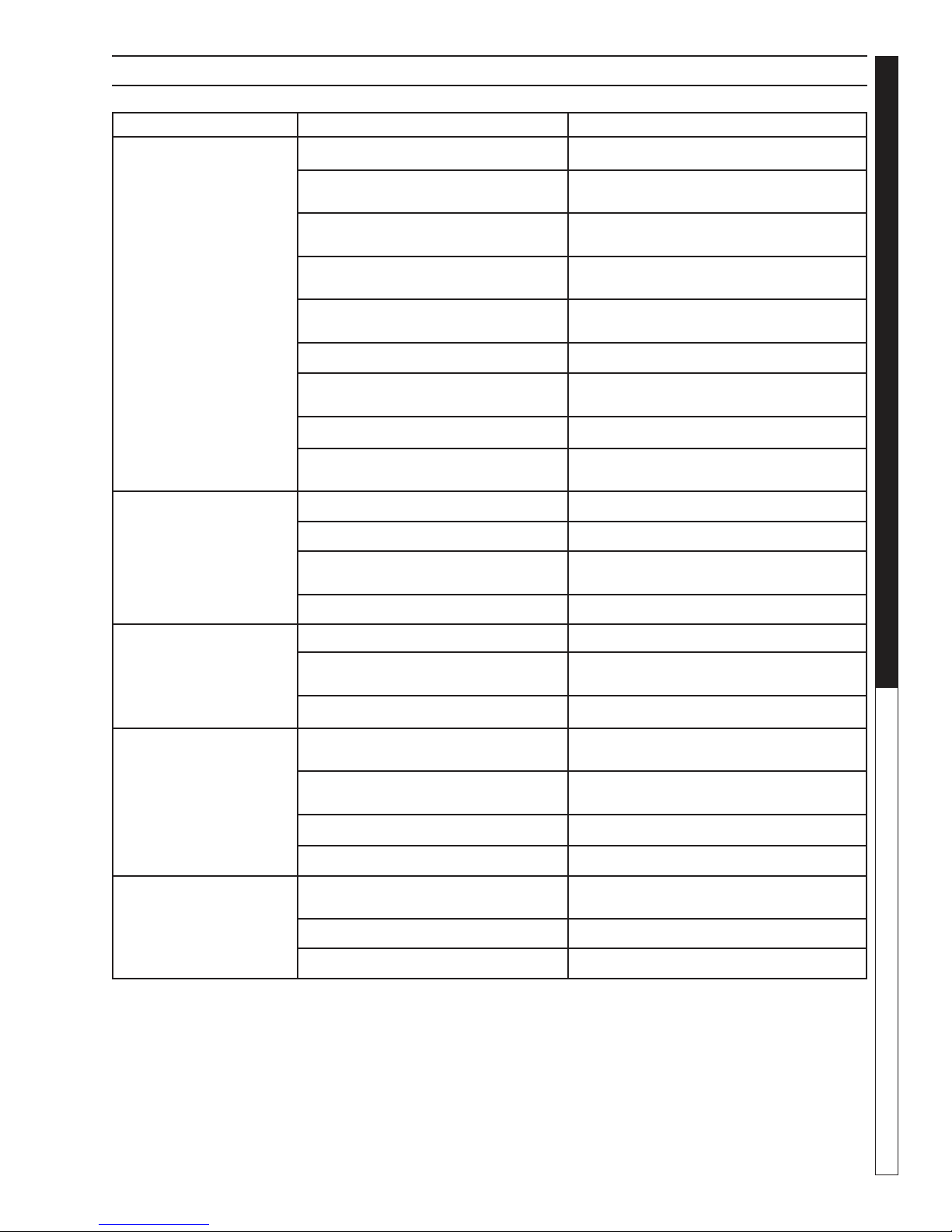

WHAT THIS WARRANTY COVERS

All Shark pressure washers are warranted by Shark to the original purchaser to be free from defects in materials and workmanship

under normal use, for the periods specified below. This Limited Warranty, subject to the exclusions shown below, is calculated from

the date of the original purchase, and applies to the original components only. Any parts replaced under this warranty will assume

the remainder of the pressure washer’s warranty period.

FIVE YEAR PARTS AND ONE YEAR LABOR WARRANTY

Components manufactured by Shark, such as frames, handles, float tanks, fuel tanks, belt guards, and heating coils. Pro-Duty rated units

(DD Series) have a three-year limited warranty against defects and workmanship. Internal components on the oil-end of Kärcher axial pumps

have a 5 year warranty. Kärcher crankshaft pumps have a 7 year warranty on non-wear parts. Heating coils are pro-rated at 25% after 2 years.

Kärcher and non-Kärcher swash and wobble plate pumps have a one year warranty; other pumps carry their manufacturer’s warranty.

ONE YEAR PARTS AND ONE YEAR LABOR WARRANTY

All other components, excluding normal wear items as described below, will be warranted for one year on parts and labor. Parts and la-

bor warranty on these parts will be for one year regardless of the duration of the original component manufacturer’s part warranty.

WARRANTY PROVIDED BY OTHER MANUFACTURERS

Motors, generators, and engines, which are warranted by their respective manufacturers, are serviced through these manufacturers’

local authorized service centers. Shark is not authorized and has no responsibility to provide warranty service for such components.

Motors manufactured outside of the United States will be warranted by Shark.

WHAT THIS WARRANTY DOES NOT COVER

This warranty does not cover the following items:

1. Normal wear items, such as nozzles, spray guns, discharge hoses, wands, quick couplers, seals, filters, gaskets, O-rings,

packings, pistons, pump valve assemblies, strainers, belts, brushes, rupture disks, fuses, pump protectors.

2. Any components or other devices incorporated into a Shark product that are not manufactured by Shark, including, but

not limited to gasoline engines, pumps, etc.

3. Defects caused by improper or negligent operation or installation, accident, abuse, misuse, neglect, unauthorized

modifications, repair or maintenance of the product by persons other than authorized representatives of

Shark

, including,

but not limited to, the failure of the Customer to comply with recommended product maintenance schedules.

4. Shark products that have been returned by the original Customer and are ultimately re-sold by an Authorized Servicing

Dealer or other sales or service outlet to another purchaser.

5.

Shark products that are sold by any distributor or retailer that is not an official authorized dealer or retailer of Shark products.

6. Defects caused by acts of nature and disaster including, but not limited to, floods, fires, wind, freezing, earthquakes,

tornadoes, hurricanes and lightning strikes.

7. Defects caused by water sediments, rust corrosion, thermal expansion, scale deposits or a contaminated water sup-

ply (such as water in the unit with chloride content higher than that of 80 mg/liter or use of chemicals not approved or

recommended by Shark).

8. Defects caused by improper voltage, voltage spikes or power transients in the electrical supply.

9. Devices or accessories not distributed or approved by Shark.

10. Any cost of labor arising from the removal and reinstallation of the alleged defective part by Customer.

11. Transportation of the product to an Authorized Servicing Dealer, field labor, replacement rental and any freight charges.

Any components, accessories or other devices provided with the product but not manufactured by Shark (such as engines, pumps,

etc.) are subject to warranties and service through their respective manufacturers authorized service centers and according to the

applicable terms and conditions of such manufacturers warranties. Such components or other devices not manufactured by Shark

should be referred by the Customer to an authorized service center or their respective manufacturers for repair or replacement.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES OF ANY KIND, WHETHER ARISING BY LAW, CUSTOM

OR CONDUCT. SHARK MAKES NO ADDITIONAL WARRANTIES, EITHER EXPRESSED OR IMPLIED, INCLUDING, WITHOUT

LIMITATION, ANY EXPRESSED OR IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS OF EQUIPMENT FOR A

PARTICULAR PURPOSE AND ANY SUCH WARRANTIES ARE EXPRESSLY DISCLAIMED. SHARK FURTHER DISCLAIMS

ANY WARRANTY THAT THE PRODUCT PURCHASED BY CUSTOMER WILL MEET ANY PARTICULAR REQUIREMENT

OF CUSTOMER EVEN IF SHARK HAS BEEN ADVISED OF SUCH REQUIREMENT.

THE RIGHTS AND REMEDIES PROVIDED UNDER THIS WARRANTY ARE EXCLUSIVE AND IN LIEU OF ANY OTHER RIGHTS

OR REMEDIES OF CUSTOMER. SHARK SHALL NOT UNDER ANY CIRCUMSTANCES BE LIABLE TO ANY PERSON OR

ENTITY INCLUDING, BUT NOT LIMITED TO, THE CUSTOMER OR ANY END USER OF THE PRODUCT FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR ECONOMIC LOSS, LOSS OF PROFITS OR LOSS OF USE OF

THE PRODUCT, ARISING IN CONNECTION WITH THE SALE, DELIVERY, INSTALLATION, TRAINING OR USE OF PRODUCT.

SHARK’S LIABILITY, WHETHER IN CONTRACT OR IN TORT, ARISING OUT OF ANY WARRANTIES OR REPRESENTA-

TIONS, INSTRUCTIONS OR DEFECTS FROM ANY CAUSE, SHALL BE LIMITED EXCLUSIVELY TO THE COST OF REPAIR OR

REPLACEMENT PARTS UNDER AFORESAID CONDITIONS.

The purpose of the foregoing limitations on liability and Customer remedies is to protect Shark from unknown or undeterminable

risks. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to the Customer.

Shark sales and service representatives are not authorized to waive or alter the terms of this warranty, or to increase

the obligations of Shark under the warranty.

Shark reserves the right to make design changes in any of its products without prior notification to the Customer.

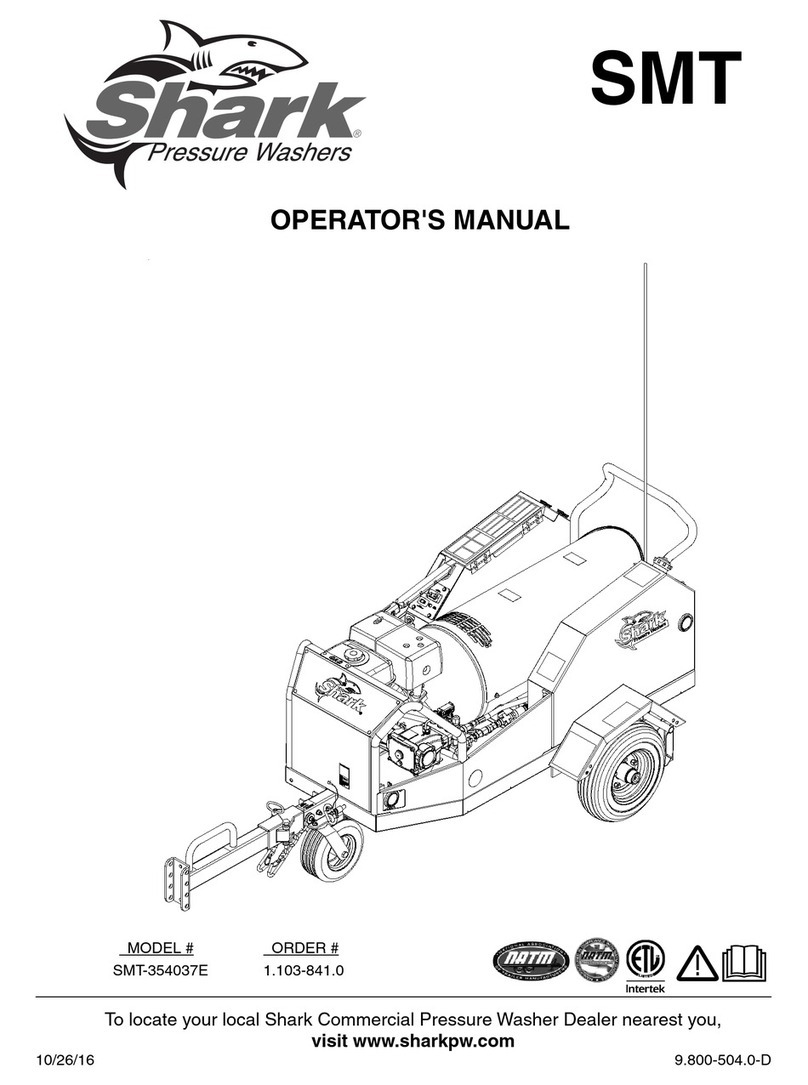

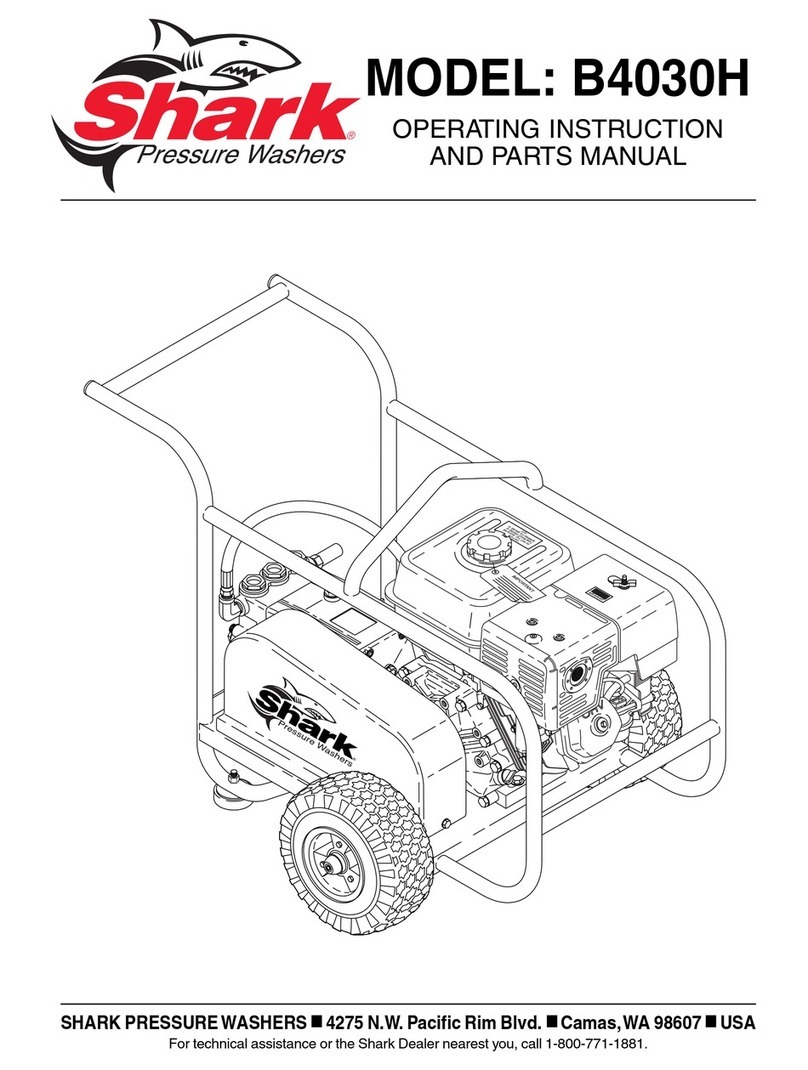

LIMITED NEW PRODUCT

WARRANTY—COMMERCIAL

PRESSURE WASHERS

Phone: 800-771-1881

Fax: 877-526-3246

www.sharkpw.com