Shark Pressure Washers B4030H Service manual

SHARK PRESSURE WASHERS

■

4275 N.W. Pacific Rim Blvd.

■

Camas,WA 98607

■

USA

For technical assistance or the Shark Dealer nearest you, call 1-800-771-1881.

MODEL: B4030H

OPERATING INSTRUCTION

AND PARTS MANUAL

IMPORTANT

CAUTION

DONOTFILL GASOLINE

TANKWHILEENGINEIS

RUNNINGORENGINEIS

HOT

DANGER

2

MACHINE SPECIFICATIONS

●●

●●

●Pump Volume At Pump Head:

B4030H 3.0 GPM

●●

●●

●Pump Pressure At Pump Head:

B4030H 4000 PSI

Output specifications are based on engine power curves at 100 meters above sea level

and 25o C ambient temperature in accordance with SAE J1349.

● ●

● ●

●

Machine Dimensions: B4030H Length = 42" Width = 27" Height = 30"

●●

●●

●Machine Power:

B4030H 13 HP Gasoline Engine

Manual Start

●●

●●

●Shipping Weight:

B4030H 270 Lbs.

CONTENTS

3

Shark B4030H Manual • Form 97-6136 • Revised 12/02

SERIAL NUMBER:

DATE PURCHASED:

FOR SALES AND SERVICE, PLEASE CONTACT:

Component Identification ........................................ 4

Introduction............................................................. 5

Important Safety Information ............................... 5-6

Assembly Instructions ............................................. 6

Installation ........................................................... 6-7

Pre-Operation Checklist .......................................... 7

Operating Instructions ......................................... 7-8

Washing Procedures .............................................. 8

Shutdown Procedures ............................................ 8

Storage ................................................................... 8

Maintenance & Service........................................ 8-9

Machine Assembly & Parts List ....................... 10-11

Trigger Gun/Wand Assembly & Parts List ............. 12

Pump Assembly & Parts List ................................ 13

Pump Exploded View & Parts List .................... 14-15

Troubleshooting Guides ........................................ 16

Preventive Maintenance ....................................... 17

Oil Change Record ............................................... 17

Warranty

4

B4030H PRESSURE WASHER OPERATOR’S MANUAL

Shark B4030H • Rev. 12/02

IMPORTANT

TOALLOWFORPROPERBA

TTERY

CHARGINGTHETHROTTLECONTROL

MUSTBEKEPTIN THEFULL

THROTTLEPOSITIONDURINGOPERA

TION

CAUTION

DONOTFILL GASOLINE

TANKWHILE ENGINEIS

RUNNINGORENGINEIS

HOT

FOR BEST RESULTS

USE

DETERGENTS

THEHOTSYCORPORATION

DANGER

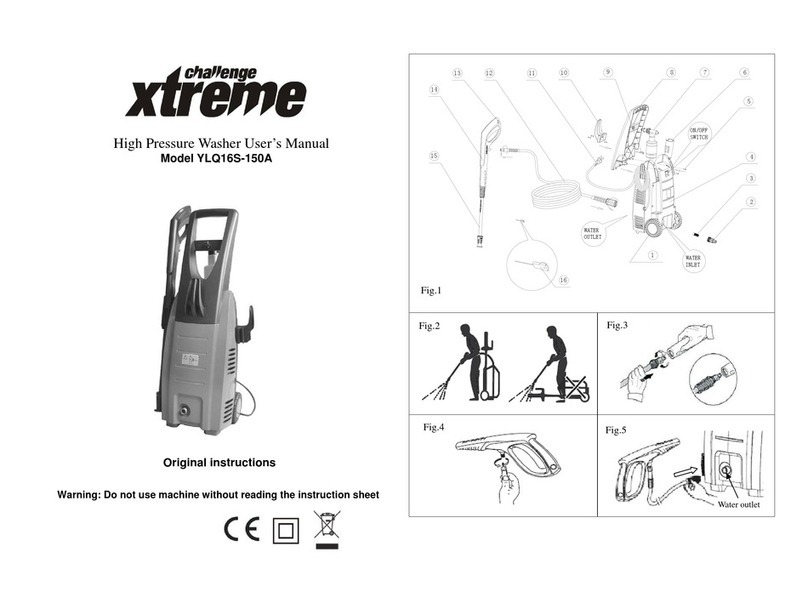

COMPONENT IDENTIFICATION

Pressure

Relief Valve

Garden Hose

Connector

Pressure

Hose

Unloader Valve

Engine

Wand

Pressure Nozzle

Gun

Trigger

Pump

B4030H PRESSURE WASHER OPERATOR’S MANUAL

5

Shark B4030H •Rev. 12/02

INTRODUCTION

Thank you for purchasing a Shark pressure washer.

This manual covers the operation and maintenance of

the B4030H pressure washer. All information in this

manual is based on the latest product information avail-

able at the time of printing.

Shark reserves the right to make changes at any time

without incurring any obligation.

The B4030H Series was designed for maximum

use of 4 hours per day, 5 days per week.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this Shark pressure washer. Warning infor-

mation should be emphasized and understood. If the op-

erator is not fluent in English, the manufacturer’s instruc-

tions and warnings shall be read to and discussed with

the operator in the operator’s native language by the pur-

chaser/owner, making sure that the operator compre-

hends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’instructions.

The operator must know how to stop the machine quickly

and understand the operation of all controls. Never per-

mit anyone to operate the engine without proper instruc-

tions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number.

IMPORTANT SAFETY

INFORMATION

CAUTION: To reduce the risk of

injury,read operating instructions

carefully before using.

1. Read the owner's manual thor-

oughly. Failure to follow instruc-

tions could cause malfunction

of the machine and result in

death, serious bodily injury and/

or property damage.

2. All installations must comply with local codes. Con-

tact your electrician, plumber, utility company or the

selling distributor for specific details.

WARNING

HIGH PRESSURE

SPRAY CAN PIERCE

SKIN AND TISSUES.

WARNING

RISK OF

ASPHYXIATION.

USE ONLY IN A WELL

VENTILATED AREA.

WARNING: Risk of asphyxiation

—Use this product only in a well

ventilated area.

3. Avoid installing machines in

small areas or near exhaust

fans. Exhaust contains poison-

ous carbon monoxide gas; ex-

posure may cause loss of con-

sciousness and may lead to

death. It also contains chemicals known, in certain

quantities, to cause cancer, birth defects or other

reproductive harm.

WARNING: Flammable liquids

can create fumes which can ig-

nite causing property damage or

severe injury.

WARNING: Risk of fire —Do not

add fuel when the product is

operating.

WARNING: Risk of explosion —

Do not spray flammable liquids.

4. Do not place machine near flammable objects as

the engine is hot.

5. Allow engine to cool for 2 minutes before refueling. If

any fuel is spilled, make sure the area is dry before

testing the spark plug or starting the engine. (Fire

and/or explosion may occur if this is not done.)

When refueling gasoline engines on mobile or por-

table equipment, make sure to refuel:

a. outdoors;

b. with the engine on the equipment stopped;

c. with no source of ignition within 10 feet of the

dispensing point; and

d. with an allowance made for expansion of the fuel

should the equipment be exposed to a higher

ambient temperature.

In an overfilling situation, additional precautions are

necessary to ensure that the situation is handled in

a safe manner.

WARNING: High pressure stream

of water that this equipment can

produce can pierce skin and its

underlying tissues, leading to se-

rious injury and possible ampu-

tation.

READ OPERATOR’S

MANUALTHOROUGHLY

PRIOR TO USE.

CAUTION

WARNING

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

6

B4030H PRESSURE WASHER OPERATOR’S MANUAL

Shark B4030H •Rev. 12/02

WARNING: High pressure spray

can cause paint chips or other

particles to become airborne and

fly at high speeds. To avoid per-

sonal injury, eye safety devices

must be worn.

6. Eye safety devices and foot pro-

tection must be worn when us-

ing this equipment.

7. High pressure developed by

these machines will cause

personal injury or equipment damage. Use caution

when operating. Do not direct discharge stream at

people, or severe injury or death will result.

8. Never make adjustments on machine while in

operation.

9. Do not operate with spray gun in the off position for

extensive periods of time as this may cause dam-

age to the pump.

10. The best insurance against an accident is precau-

tion and knowledge of the machine.

11. Shark will not be liable for any changes made to our

standard machines, or any components not pur-

chased from Shark.

12. Read engine safety instructions provided.

WARNING: Keep water spray

away from electrical wiring or fa-

tal electric shock may result.

13. Never run pump dry or leave

spray gun closed longer than 5

minutes.

14. Do not allow children to oper-

ate the pressure washer at any

time.

15. Inlet water supply must be cold and clean fresh

water.

ASSEMBLY INSTRUCTIONS

Pressure Hose, Trigger Gun and Wand:

Install the pressure hose on the pressure washer as

shown in illustration.

Assemble wand components as shown below.

INSTALLATION

Place machine in a convenient location providing ample

support, drainage and room for maintenance.

IMPORTANT: Proper initial installation of equipment

will assure more satisfactory performance, longer

service life, and lower maintenance cost.

IMPORTANT:The use of a backflow preventer on the

water supply hose is recommended and may be re-

quired by local code.

Location:

The location should protect the machine from damag-

ing environmental conditions, such as wind, rain, and

freezing.

This machine should be run on a level surface where it

is not readily influenced by outside sources such as

strong winds, freezing temperatures, rain, etc. It should

be located to allow accessibility for refilling of fuel, ad-

justments and maintenance. Normal precautions should

be taken by the operator of the machine to prevent mois-

ture from reaching the electrical controls.

It is recommended that a partition be made between the

wash area and the machine to prevent water spray from

coming in contact with the machine. Excess moisture

reaching any electrical components or electrical controls

will reduce machine life and may cause electrical shorts.

Avoid small locations or areas near exhaust fans.

In addition, the pressure washer should never be oper-

ated in an enclosed area where high ambient tempera-

tures exist. High ambient temperatures (above 100°F)

can cause engine oil failure and will greatly reduce the

engine's performance.

WARNING

PROTECTIVE

EYEWEAR AND

CLOTHING MUST

BE WORN.

Pressure Hose

WARNING

KEEP WATER SPRAY

AWAY FRO M

ELECTRICALWIRING.

Wand

Trigger Gun

Pressure Hose

Discharge

Nipple

Pump

B4030H PRESSURE WASHER OPERATOR’S MANUAL

7

Shark B4030H •Rev. 12/02

Gasoline Engine:

This gasoline engine is preset for operation at altitudes

below 3000 feet above sea level. If operated at higher

altitudes, it may be necessary to install a high altitude

main jet in the carburetor. Contact an authorized engine

sales and service center for details.

PRE-OPERATION CHECK

❑Check pump oil level. (Use SAE 30W non-detergent

oil). Dipstick is located on top of pump.

❑Cold water supply (minimum 6 GPM, 5/8", 20 PSI)

❑Hose, wand, nozzle (nozzle size per serial plate)

❑Water filter (intact, non restrictive)

❑Fuel (unleaded 86 or higher octane)

❑Open spray gun to relieve pressure before starting.

❑Engine oil (SAE 10W30)

These machines are designed for outdoor use.

Machine must be stored indoors when not in use.

OPERATING INSTRUCTIONS

1. Read all manuals provided with this pressure washer.

Become familiar with location and function of all op-

erating and safety controls.

WARNING: Check hoses, fittings, wand, trigger gun

and fuel connections daily for signs of wear, cracks

and looseness, and replace as required.

2. Connect water supply hose to the garden hose con-

nector located on pump. The water faucet and sup-

ply hose must be capable of providing a minimum of

3.0 gallons per minute.

WARNING: Do not fill engine fuel tank while engine

is running or hot. Let engine cool before refueling

or spontaneous fire may result. Fuel spillage or va-

pors could ignite if engine is hot.

3. Fill the engine fuel tank. It may be necessary to use

a funnel or long spout to clear the chassis if filling

with a gas can. Do not overfill, fill to the bottom of

filler neck only. Use lead free gasoline minimum 86

octane. Do not use gasoline containing more than

5% methanol, 10% ethanol or 15% MTBE. Refer

to the provided gasoline engine manual for additional

details.

4. Check pump and engine oil levels.

IMPORTANT: Before installing pressure nozzle on

initial start-up, turn on the water supply and allow

water to run from the end of the wand until clear to

prevent the nozzle from clogging.

IMPORTANT: If the pressure washer has not been

used for an extended period of time, remove the pres-

sure nozzle from the end of the wand and turn on

water supply. Allow water to run from the end of the

wand until clear.

5. Install the proper pressure nozzle for your cleaning

needs on end of wand. Refer to illustration below.

IMPORTANT: The trigger gun provided with this pres-

sure washer is equipped with a manual trigger lock

to prevent accidental operation of the trigger gun.

The trigger lock should be used whenever the trig-

ger gun is not in use.

To Start:

IMPORTANT: The water must be turned on before

starting. Running the pump dry will cause damage

and void warranty.

IMPORTANT: Do not allow machine to run with trig-

ger of the trigger gun released for more than 10 min-

utes at any one time or damage to pump may occur.

1. Turn on water supply.

2. Hold wand firmly, release trigger of trigger gun.

3. Place engine ON/OFF switch to ON position.

4. Turn fuel shut-off valve to ON position (if so

equipped). Move choke lever to full choke position

(choke may not be needed on warm engine). Move

throttle lever to half throttle position.

5. Pull the rope starter slowly until resistance is felt,

then pull briskly. Do not allow the rope starter to snap

back against the engine. Return it gently to prevent

damage to the starter.

6. When the engine starts, move choke lever until en-

gine runs smoothly. Move throttle lever to full throttle

position. When engine warms, move choke lever to

"no choke" position.

NOTE: If engine fails to start, refer to Troubleshoot-

ing Guide.

7. Squeeze trigger of trigger gun and allow air to purge

from system.

Pressure

Nozzle

Manual Trigger Lock

8

B4030H PRESSURE WASHER OPERATOR’S MANUAL

Shark B4030H •Rev. 12/02

WASHING PROCEDURES

WARNING: Some detergents may

be harmful if inhaled or ingested,

causing severe nausea, fainting

or poisoning. The harmful ele-

ments may cause property dam-

age or severe injury.

DANGER: Do not place hands or

fingers in front of high pressure

spray. Bodily injury may result.

1. Test pressure and spray pattern on hard surface (i.e.

cement) to gauge distance and impact of water spray.

2. If detergents are to be used, only use detergents

intended for pressure washers. Follow instructions

on the detergent container.

3. Wash from the bottom to the top, using side to side

motions. This washes away heavy dirt and allows

the detergent to soak as you work toward the top.

4. Do not wash at a 90oangle to the work (straight at

it). This will allow water to splash back at you and

reduces your cleaning power. Wash at a 30oto 60o

angle to the work.This will allow the water to splash

away from you and the water will wash the dirt away

faster and easier.

5. Use the full width of the spray pattern to wash in

a wide path. Overlap spray paths for complete

coverage.Wash from side to side, using slow, steady

motions.

6. The nozzle should be 12" to 24" from the work, closer

for tough areas. Be careful on painted or delicate

surfaces, the pressure may damage surface if nozzle

is too close.

7. Small parts should be washed in a basket so the

pressure does not push them away. Larger, light-

weight parts should be clamped down so the pres-

sure does not push them away.

NOTE: If pressure washer is running and not being

used for more than 2 minutes, turn off engine.

SHUTDOWN PROCEDURES

1. Move throttle lever to idle position.

2. Turn engine ON/OFF switch to the OFF position.

3. Turn fuel shut-off valve to OFF position (if so

equipped).

4. Turn water supply off.

CAUTION: Do not allow pump to run without water.

5. Squeeze trigger of trigger gun to relieve system

pressure.

STORAGE

DANGER: Do not store flammable

liquids (gasoline, diesel fuel, sol-

vents, etc.) near pressure washer,

or in non-ventilated areas.

Protect from freezing by storing in

a heated area, or by flushing the

system with antifreeze (use an

automotive engine antifreeze or

windshield washer solvent to anti-

freeze).To flush the system with an-

tifreeze, the following steps are to be followed:

1. Attach a short length of hose to the garden hose

connector located on the pump.

2. Place the other end of the hose into a container of

antifreeze.

3. Start engine and allow to run until antifreeze flows

from the end of the wand.

4. Squeeze and release the trigger of the trigger gun

several times to antifreeze the unloader system.

5. Release the trigger of the trigger gun. Stop engine.

6. Squeeze the trigger of the trigger gun to relieve sys-

tem pressure.

If the pressure washer is not to be used for an extended

length of time, it is recommended that the system be

flushed with antifreeze for rust protection. Refer to the

Gasoline Engine Manual for engine storage information.

MAINTENANCE & SERVICE

WARNING: Unauthorized machine modification or

use of non-approved replacement parts may cause

personal injury and/or property damage and will void

the manufacturer warranty.

Pump:

Lubrication: To lubricate pump, use 10W30 non-deter-

gent oil for pump crankcase. Crankcase must be filled to

red dot on oil gauge found on the rear of the pump (refer

to illustration below). During the break-in-period, make

WARNING

SOME DETERGENTS

MAY BE HARMFUL

IF INHALED OR

INGESTED.

WARNING

RISK OF FIRE.

DO NOT STORE

WITH FLAMMABLE

LIQUIDS.

Sight Glass

Oil Fill/Dipstick

Oil Drain

B4030H PRESSURE WASHER OPERATOR’S MANUAL

9

Shark B4030H •Rev. 12/02

sure the oil is changed after the first 25 hours of opera-

tion. After that, replace oil every 3 months or 300 hours

of operation, whichever comes first.

Proper Pump Care:

•Do not pump acids.

•Do not allow pump to run dry.

•Winterize if storing in freezing temperatures, refer to

Storage for details.

•Use a water softener on the water system if known

to be high in mineral content.

•Use only high quality detergents and follow

manufacturer’s mix recommendations.

•Flush the system with clear water immediately

after using detergent solutions.

•Clean filter screen on detergent inlet line periodically.

•Flush the pressure washer system with antifreeze if

storing for an extended period of time, refer to

Storage for details.

Gasoline Engine:

Refer to the provided gasoline engine manual for rec-

ommended maintenance.

Pressure Relief Valve:

The pressure relief valve on this pressure washer has

been factory set and sealed and is a field nonadjust-

able part. For replacement refer to Pump Assembly

illustration on page 13.

WARNING:Tampering with the relief valve's factory

setting may cause personal injury and/or property

damage, and will void the manufacturer warranty.

Unloader Valve:

The unloader valve on this pressure washer has been

factory set and sealed and is a field nonadjustable part.

For replacement refer to Pump Assembly illustration on

page 13.

WARNING:Tampering with the unloader valve's fac-

tory setting may cause personal injury and/or prop-

erty damage, and will void the manufacturer warranty.

10

B4030H PRESSURE WASHER OPERATOR’S MANUAL

Shark B4030H •Rev. 12/02

MACHINE ASSEMBLY

FRONT & BACK VIEW

12

10,11

7,8,9

6

4,5

2

3

1

13, 14, 15

16

14, 15

17

18

19, 20, 21, 22

23, 24, 25, 26

27

28

29

30

31

32

33

34

35

36,37,38

39

40

41

42

43

44

B4030H PRESSURE WASHER OPERATOR’S MANUAL

11

Shark B4030H •Rev. 12/02

ITEM PART NO. DESCRIPTION QTY.

1 4-0110341 Wand Assembly, w/ Side Grip 1

4-012421 Gun Assy, w/ SS Fem Coup &

STL Nipple 1

2 2-20061 Nipple, 3/8" x 3/8", SS, NPT ST,

Female 1

3 5-1808 Pump, Hawk, HC930R 1

5-3310 Unloader, XSM 4500 WP 1

4 90-102751 Bolt 1/2" x 3-1/2", NC HH 1

5 90-3096 ▲Washer 1/2", Flat 1

6 4-020750RCS Hose, 3/8" x 50', 2 Wire, Red, SS,

Fem Coup x STL Male Plug 1

7 90-10135 U Bolt 1/4" x 1", 1/4" x 2", 1/4"

w/ Plate 1

8 90-2000 Nut 1/4", ESNA, NC 2

9 90-4000 Washer 1/4", Flat, SAE 2

10 90-10343 Bolt 10 mm x 20 mm, HH 4

11 90-400910 Washer 7/16", Lock Split Ring 4

12 11-3203 Label, Caution, Gasoline, Red 1

13 90-1010 Bolt 5/16" x 1-3/4", NC HH 4

14 90-4001 Washer 5/16", Flat, SAE 12

15 90-2001 Nut 5/16", ESNA, NC 8

16 90-1001 Bolt 1/4" x 3/4", NC HH 3

17 95-07104016 Bracket, Pump/Belt Guard

Mount 1

18 11-3216 Label, Belt Guard Warning 1

19 5-40503201 Pulley, 2BK32H 1

20 5-511100 Bushing, H X 1" 1

21 90-5011 Key Stock, 1/4" x 1" 1

22 90-50046 Clip, Retaining, 10 mm Blk 1

23 2-01041 Pad, Soft Rubber, 50 Duno 2

24 90-4002 ▲ Washer 3/8", Flat, SAE 6

25 90-1021 ▲ Bolt 3/8" x 2-1/2", GR5 Zinc 2

26 90-2002 Nut 3/8", ESNA, NC 2

ITEM PART NO. DESCRIPTION QTY.

27 2-011720 Belt Guard, Plastic, Blk Shark 1

28 5-604038 Belt, BX 38 2

29 2-01443 Plug, Plastic 1-1/4" 2

30 11-3204 Label, Use Shark Detergent 1

31 2-0103 Grommet, Rubber, Nozzle

Holder 5

32 11-3218 Label, Nozzle Identification 1

33 11-3213 Label, Caution Winterize 1

34 2-2002 Coupler, 3/8" Female 1

35 4-0301 Wheel & Tire CX PL, 6" Mag 2

95-07104000 Axle, 5/8" x 26.25", Shark 1

36 90-200422 Cap, 5/8" Axle Hub, Black 2

37 90-200511 ▲ Nut, .61" ID, Push Flat 2

38 90-40181 ▲ Washer, Nylon Spacer 2

39 95-07104003 Frame, Weld Assy, Shark 1

40 11-3211 Label, Warning,

Carbon Monoxide 1

41 5-010721 Engine, Honda, GX390K1QA2,

13 HP 1

42 11-3101 Tag, Gasoline, Engine 1

43 4-02047825 Hose, 3/8" x 22", 2 Wire,

3/8" Male Swivel x 3/8" Female 1

44 11-3229 Label, Shark Belt Guard 1

▲ Not Shown

MACHINE ASSEMBLY

PARTS LIST

12

B4030H PRESSURE WASHER OPERATOR’S MANUAL

Shark B4030H •Rev. 12/02

TRIGGER GUN/WAND ASSEMBLY

VIEW AND PARTS LIST

ITEM PART NO. DESCRIPTION QTY.

1 4-12803500 Nozzle, SAQCMEG, 0003.5 (Red) 1

2 4-12803515 Nozzle, SAQCMEG, 1503.5 (Yellow) 1

3 4-12803525 Nozzle, SAQCMEG, 2503.5 (Green) 1

4 4-12803540 Nozzle, SAQCMEG, 4003.5 (White) 1

5 2-2000 Coupler, 1/4" Female 1

2-0119 ▲ O-Ring, Quick Coupler, 1/4" 1

6 4-011034 Lance, 48" x 1/4" 1

2-011735 ▲ Grip, Wand Side Handle (Replacement) 1

7 2-2005 Nipple, 1/4" x 1/4" NPT ST Male 1

8 4-01242 Gun, Shut-off, Hawk, Grey 1

9 2-2002 Coupler, 3/8" Female 1

2-0121 ▲ O-Ring, Quick Coupler, 3/8" 1

▲ Not Shown

1,2,3,4

5

6

5

7

8

9

B4030H PRESSURE WASHER OPERATOR’S MANUAL

13

Shark B4030H •Rev. 12/02

PUMP ASSEMBLY

VIEW AND PARTS LIST

1

2

3

4

5

6

7

8

91011 12

13 14

15

19

21

ITEM PART NO. DESCRIPTION QTY.

12 2-10862 Hose Barb, 3/8" Barb x 3/8"

ML Pipe 1

13 4-02120003 Hose, 3/8" Push-on 0.375 ft

14 2-0046 Tee, 1/2", Street 1

15 2-10942 Swivel, 1/2" MP x 3/4" GHF

w/ Strainer 1

16 2-30088 Valve, Relief, Open, 5000 WP 1

17 5-512025 Bushing, H x 25 mm 1

18 5-40509001 Pulley, 2BK90 H 1

19 2-30082 Pump Protector, 1/2" PTP 1

20 5-512025 Bushing, H x 25mm 1

21 5-40509001 Pulley, 2BK90H 1

▲ Not Shown

ITEM PART NO. DESCRIPTION QTY.

1 5-1808 Pump, Hawk, HC930R 1

2 4-02047825 Hose 3/8" x 22", 2 Wire, 3/8" Male

Swivel x 3/8" Female 1

3 2-1086 Hose Barb, 1/4" Barb x 3/8"

ML Pipe 1

4 4-02100000 Hose 1/4", Push-on,

Per Ft. 1.25 ft

5 5-3310 Unloader, XSM 4500 WP 1

6 2-20061 Nipple, 3/8" x 3/8", SS, NPT ST,

Female 1

7 2-0031 Elbow 3/8", Street 1

8 2-0045 Tee 3/8", Street 1

9 2-1084 Hose Barb, 1/4" Barb x 1/8"

ML Pipe 1

10 2-9040 Clamp, Hose, UNI 2

11 2-30089 Valve, Relief, Start, 5000 WP 1

16

14

B4030H PRESSURE WASHER OPERATOR’S MANUAL

Shark B4030H •Rev. 12/02

PUMP EXPLODED VIEW

31

33 34 35 36

24 30

32

26 2816

37 38 39

40

15 14 12 11 10 9

56

7

86

7123

4

29

28 27 26 52 25 16 24

51 50 49 48 47 46 45

41

42

43

44

14

23

21

22

17

12

20

19

18

16

15

13

40

B4030H PRESSURE WASHER OPERATOR’S MANUAL

15

Shark B4030H •Rev. 12/02

PUMP EXPLODED VIEW

PARTS LIST

ITEM PART NO. DESCRIPTION QTY.

26 926649 Bearing Housing O-Ring 2

27 926651 Crankshaft Seal 2

28 808401 Roller Bearing 2

29 Teflon Ring 20 mm 3

30 753100 Crankshaft Key 8 x 7 x 50 mm 1

31 615374 Closed Bearing Housing 1

32 630930 Single-Ended Crankshaft 1

33 926691 Connecting Rod Pin

Snap Ring 6

34 914138 Connecting Rod Pin 3

35 928640 Connecting Rod Assembly 3

36 936933 Spring Washer 6

37 735311 Allen Screw 6

38 735313 Crankcase Cover

Allen Screw 6

39 858430 Sight Glass 1/2" 1

40 855892 Gasket 1/2" 2

41 915630 Plug 3/8" 1

42 855893 Gasket 3/8" 1

43 826680 Crankcase Cover 1

44 855890 Crankcase Cover Gasket 1

45 829931 Plunger Rod 3

46 Copper Spacer 3

47 Plunger Sleeve 20 mm 3

48 Teflon Ring 3

49 Plunger Bolt O-Ring 3

50 Copper Spacer 3

51 Plunger Assembly Bolt 3

877651 ▲ Ceramic Sleeve Kit 20 mm 3

52 944784 Shim 2

▲ Not Shown

ITEM PART NO. DESCRIPTION QTY.

1 636930 Crankcase 1

2 860360 Plunger Guide 3

3 Plunger Seal 3

877653 ▲ Plunger Seal Kit 1

4 Pressure Ring O-Ring 3

5 Pressure Ring 20 mm 3

6 V-Sleeve 20 mm 6

7 Support Ring 20 mm 6

8 Intermediate Ring 20 mm 3

877649 ▲ Seal Packing Kit 20 mm 1

877646 ▲ Complete Seal Packing

Kit 20 mm 3

9 915630 Plug 3/8" 1

10 780565 Copper Washer 3/8" 1

11 784930 Manifold Housing 1

12 Valve Seat O-Ring 6

13 835280 Oil Dipstick 1

14 Manifold Plug O-Ring 6

15 829939 Manifold Plug 6

16 936931 Lock Washer 8

780560 Washer 8

17 875937 Manifold Stud Bolt 8

18 936932 Copper Washer 1/2" 1

19 915634 Plug 1/2" 1

20 Valve Seat 6

21 Valve Plate 6

22 Valve Spring 6

23 Valve Cage 6

753110 ▲ Valve Assembly Kit 6

24 735314 Hex Screw 8

25 867750 Bearing Housing 1

16

B4030H PRESSURE WASHER OPERATOR’S MANUAL

TROUBLESHOOTING

Shark B4030H •Rev. 12/02

PROBLEM POSSIBLE CAUSE SOLUTION

GAS ENGINE WILL

NOT RUN

Out of gas Replenish supply. Use only recommended

fuels. Refer to Operation Section.

Fuel valve closed (if so equipped) Open valve.

Loose spark plug wire Reconnect.

Choke or throttle set incorrectly Refer to Operation Section.

Low engine oil level Replenish supply. Engine will not start or run if

oil is low (on engines equipped with low oil

protection).

Engine ON/OFF switch in OFF

position

Place engine ON/OFF switch in ON position.

Refer to provided gasoline engine manual for additional troubleshooting.

PRESSURE WASHER

RUNS BUT WON'T SPRAY

Trigger of trigger gun released Squeeze trigger.

Water supply not turned on Open water supply valve.

Clogged pressure nozzle Clean pressure nozzle opening.

LOW SPRAY PRESSURE

AT PRESSURE NOZZLE

Inadequate water supply Fully open faucet. Check for kinked or

damaged hose. Use 5/8 inch minimum hose.

Check for debris clogging inlet screen.

Partially clogged or damaged

pressure nozzle

Clean or replace.

Air being drawn through detergent

inlet line

Refill detergent container. Ensure that pickup

screen is fully immersed.

Engine throttle not in full throttle

position

Place engine throttle in full throttle position.

UNEVEN SPRAY

PATT ERN

Partially clogged or damaged

pressure nozzle

Clean or replace.

B4030H PRESSURE WASHER OPERATOR’S MANUAL

17

Shark B4030H •Rev. 12/02

Date Oil Changed

Month/Day/Year

Estimated Operating

Hours Since Last

Oil Change

Date Oil Changed

Month/Day/Year

Estimated Operating

Hours Since Last

Oil Change

OIL CHANGE RECORD

Check pump oil and engine oil level before first use of your new pressure washer.

MAINTENANCE SCHEDULE

Engine Oil

Inspect Every 8 hours or daily

Change Every 50 hours or monthly

Air Cleaner/Filter

Inspect Every 8 hours or daily

Change Every 50 hours or monthly

Fuel Tank Filter Every 100 hours or yearly

Spark Plug Maintenance Every 100 hours or yearly

Check Valve Clearance Yearly

Water Filter

Check Every 8 hours or daily

Clean Yearly

Pump Oil

Inspect Every 25 hours or weekly

Change Yearly

PREVENTATIVE MAINTENANCE

This B4030H machine was produced with the best available materials and quality craftsmanship. However, you as

the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative main-

tenance procedures will assist in preserving the performance of your equipment. Contact your Shark Pressure

Washers dealer for maintenance. Regular preventative maintenance will add many hours to the life of your pressure

washer. Perform maintenance more often under severe conditions.

B4030H PRESSURE WASHER

WARRANTY

SHARK LIMITED NEW PRODUCT WARRANTY

PRESSURE WASHERS

WHAT THIS WARRANTY COVERS

All SHARK PRESSURE WASHERS are warranted by SHARK to the original purchaser to be free from defects in materials and

workmanship under normal use, for the periods specified below. This LimitedWarranty is subject to the exclusions shown below,

is calculated from the date of the original purchase, and applies to the original components only. Any parts replaced under this

warranty will assume the remainder of the part’s warranty period. This warranty applies to the original purchaser and is not

transferable.

LIMITED LIFETIME PARTS WARRANTY:

Components manufactured by SHARK, such as frames, handles, coil wraps, float tanks, and belt guards. All heating coils will

have a one year warranty. Internal components on the oil-end of all pressure washer pumps will have a seven year warranty.

ONE YEAR PARTS WARRANTY:

All other components, excluding normal wear items as described below, will be warranted for one year on parts. Warranty on

these parts will be for one year regardless of the duration of the original component manufacturer’s part warranty.

WARRANTY PROVIDED BY OTHER MANUFACTURERS:

Motors, generators, and engines, which are warranted by their respective manufacturers, are serviced through these manufac-

turers’local authorized service centers. SHARK cannot provide warranty on these items.

WHAT THIS WARRANTY DOES NOT COVER

This warranty does not cover the following items:

1. Normal wear items, such as nozzles, guns, discharge hoses, wands, quick couplers, seals, filters, gaskets, O-rings,

packings, pistons, pump valve assemblies, strainers, belts, brushes, rupture disks, fuses, pump protectors.

2. Damage or malfunctions resulting from accidents, abuse, modifications, alterations, incorrect installation, improper

servicing, failure to follow manufacturer’s maintenance instructions, or use of the equipment beyond its stated usage

specifications as contained in the operator’s manual.

3. Damage due to freezing, chemical deterioration, scale buildup, rust, corrosion, or thermal expansion.

4. Damage to components from fluctuations in electrical or water supply.

5. Normal maintenance service, including adjustments, fuel system cleaning, and clearing of obstructions.

6. Transportation to service center, shop labor charges, field labor charges, or freight damage.

WHAT YOU MUST DO TO OBTAIN WARRANTY SERVICE

While not required for warranty service, we request that you register your SHARK pressure washer by returning the completed

registration card. In order to obtain warranty service on items, you must return the product to an Authorized SHARK Dealer,

freight prepaid, with proof of purchase, within the applicable warranty period. If the product is permanently installed, you must

notify your Authorized SHARK Dealer of the defect. The Authorized Dealer will file a claim, which must subsequently verify the

defect. In most cases, the part must be returned to SHARK freight prepaid with the claim. For warranty service on components

warranted by other manufacturers, the Authorized Dealer can help you obtain warranty service through these manufacturers’

local authorized service centers. If you are unable to resolve the warranty claim satisfactorily, write to SHARK at 4275 N.W.

Pacific Rim Blvd., Camas, WA 98607, ATTN: Warranty Dept., detailing the nature of the defect, the name of the Authorized

Dealer, and a copy of the purchase invoice.

LIMITATION OF LIABILITY

SHARK’S liability for special, incidental, or consequential damages is expressly disclaimed. In no event shall SHARK’S liability

exceed the purchase price of the product in question. SHARK makes every effort to ensure that all illustrations and specifica-

tions are correct, however, these do not imply a warranty that the product is merchantable or fit for a particular purpose, or that

the product will actually conform to the illustrations and specifications. THE WARRANTY CONTAINED HEREIN IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF FITNESS FOR A PAR-

TICULAR PURPOSE. SHARK does not authorize any other party, including authorized Dealers, to make any representation or

promise on behalf of SHARK, or to modify the terms, conditions, or limitations in any way. It is the buyer’s responsibility to ensure

that the installation and use of SHARK products conforms to local codes. While SHARK attempts to assure that its products

meet national codes, it cannot be responsible for how the customer chooses to use or install the product.

SHARK PRESSURE WASHERS

4275 N.W. Pacific Rim Blvd. •Camas, WA 98607 •USA •1-800-771-1881

Shark B4030H •Rev. 12/02

4275 N.W. Pacific Rim Blvd. •Camas, WA 98607 •1-800-771-1881

Form #97-6136 •Revised 12/02 •Printed in U.S.A.

Table of contents

Other Shark Pressure Washers Pressure Washer manuals

Shark Pressure Washers

Shark Pressure Washers DE-2010 Service manual

Shark Pressure Washers

Shark Pressure Washers HE-3010 Service manual

Shark Pressure Washers

Shark Pressure Washers STP-231007D User manual

Shark Pressure Washers

Shark Pressure Washers SMT-354037E User manual

Shark Pressure Washers

Shark Pressure Washers EEC-422007C User manual

Shark Pressure Washers

Shark Pressure Washers DG-3022 Service manual

Shark Pressure Washers

Shark Pressure Washers DE-201007D User manual

Shark Pressure Washers

Shark Pressure Washers HNG-352007A User manual