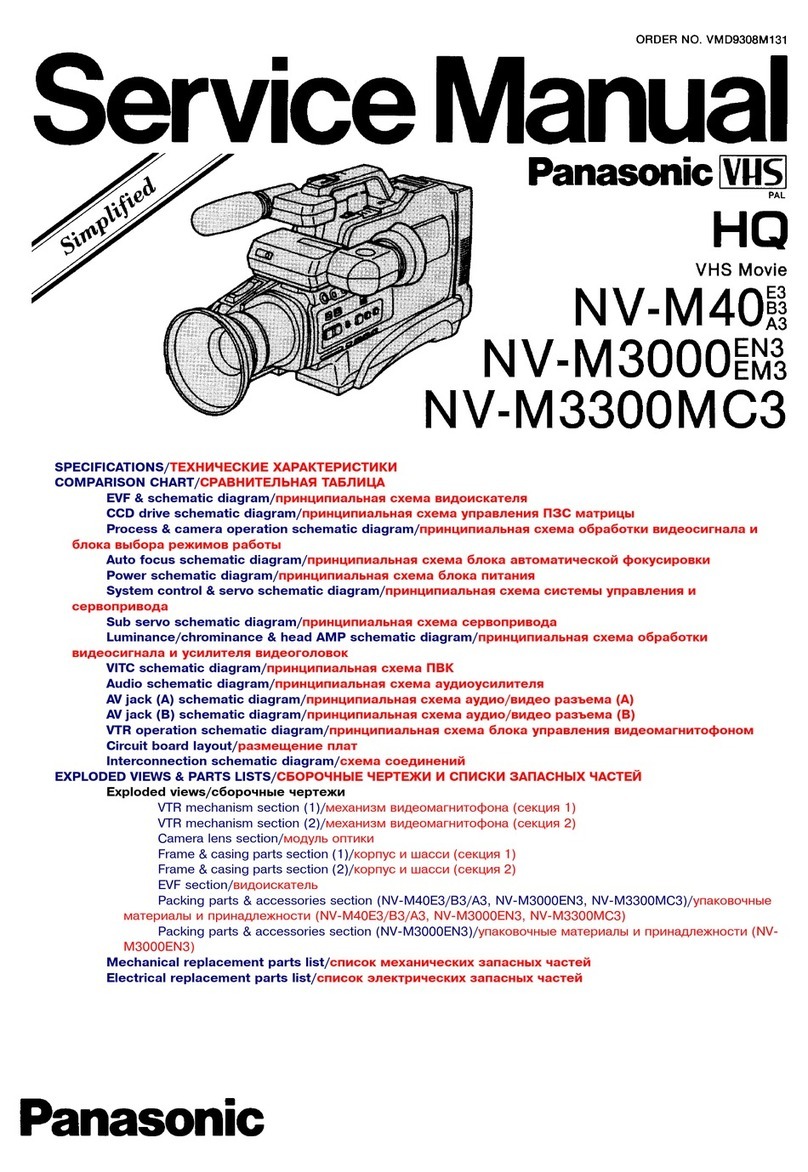

VL-E990E

VL-A10S/H/E

VL-AH30S/H/E

2

Signal System: PAL standard

Recording System: 2 rotary heads, helical scanning system

Cassette: 8 mm video tape, MP type or Hi8 MP, ME type

Recording/Playback Time: 120 minutes (P5-120)

Tape Speed: 20.051 mm/second

Pickup Device: 1/4" (6.4mm, effective size: 4.5 mm) CCD image sensor (with approx.

320,000 pixels including optical black)

Lens: 16 ×power zoom lens (F1.4, f=4.0-64.0 mm), and full-range auto focus

Lens Filter Diameter: 46 mm

Monitor: 3" (7.5 cm) full-color LCD screen (TFT active matrix)

Microphone: Electret monaural microphone

Color Temperature Compensation: Auto white balance with white balance lock

Minimum Illumination: 0.8 lux* (with gain-up, F1.4)

Video Output Level: 1.0 Vp-p 75-ohm unbalanced

Audio Output Level: –8 dBs, impedance less than 2.2 kohms

Speaker Output: 200 mW

Power Requirement: DC 3.6V (with battery pack)

DC 7.0V (with AC adapter)

Power Consumption:

4.9W (during camera recording in full auto mode with zoom motor off

and backlight in normal mode)

Operating Temperature: 0°C to + 40°C

Operating Humidity: 30% to 80%

Storage Temperature: –20°C to +60°C

Dimensions (approx.): 183 mm (W) ×109 mm (H) ×99 mm (D)

Weight (approx.): 710g

(without battery pack, lithium battery, video cassette, and lens cap)

1. SPECIFICATIONS

AC Adapter (UADP-0313TAZZ)

Power Requirement: AC 110-240 V, 50/60 Hz

DC Output: 7.0 V

Power Consumption: 15 W

Dimensions (approx.): 68 mm (W) ×37 mm (H) ×130 mm (D)

Weight (approx.): 233 g

Specifications are subject to change without notice.

*Minimum illumination: Since there is no widely accepted testing procedure for determining minimum illumination

capability, lux ratings are comparable only between models from the same manufacturer.