LC-24LE170I

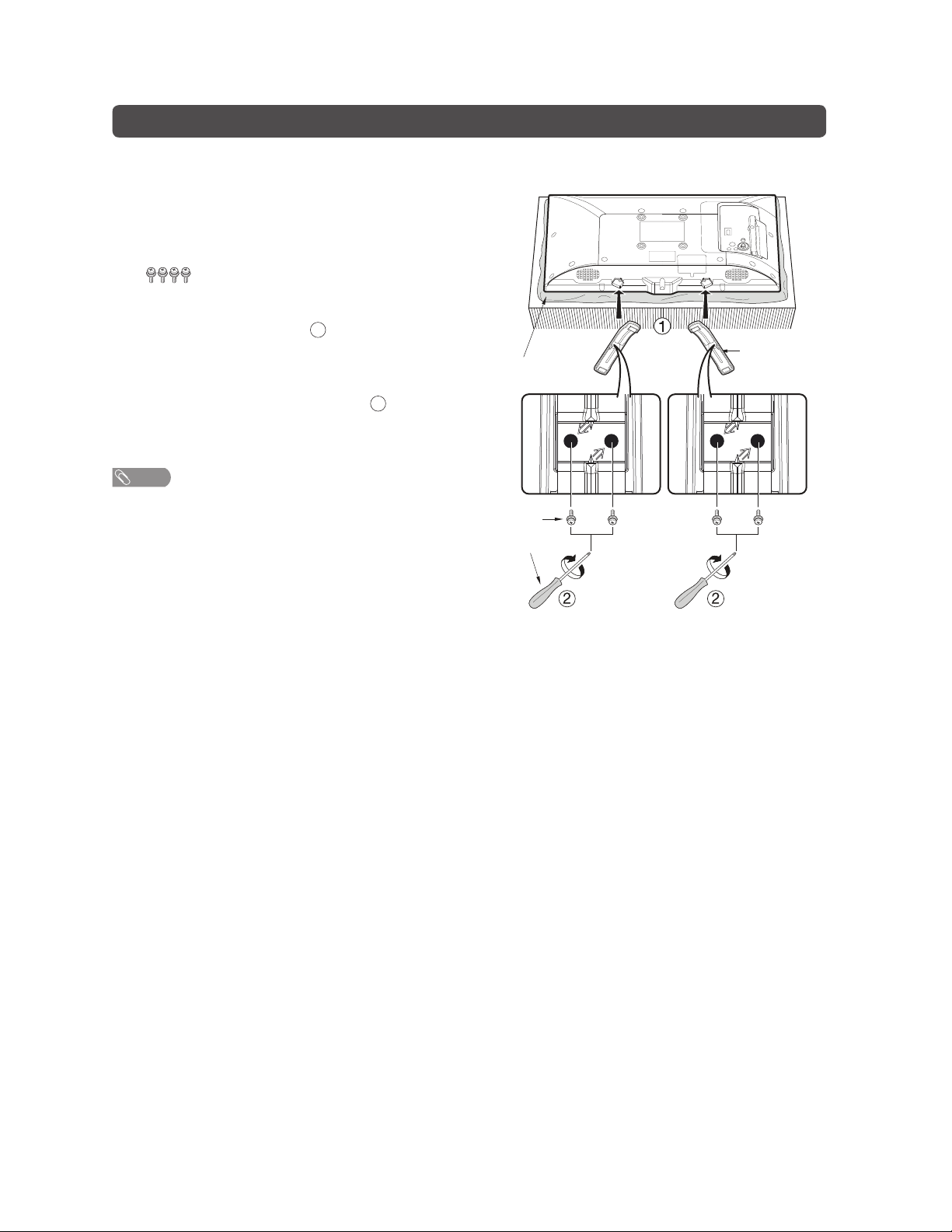

i

LC-90LE740X Service Manual

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE RECEIVER (Fire &

Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

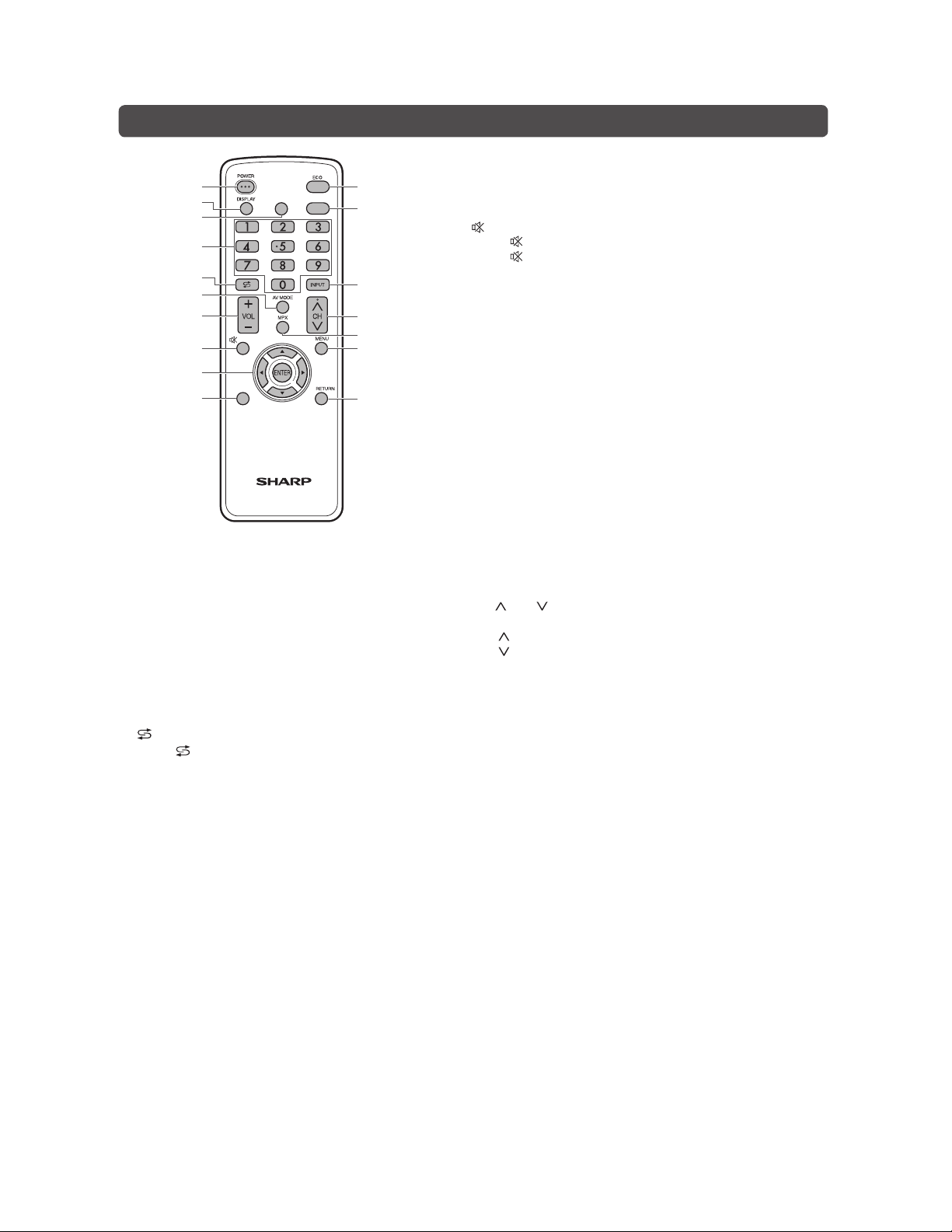

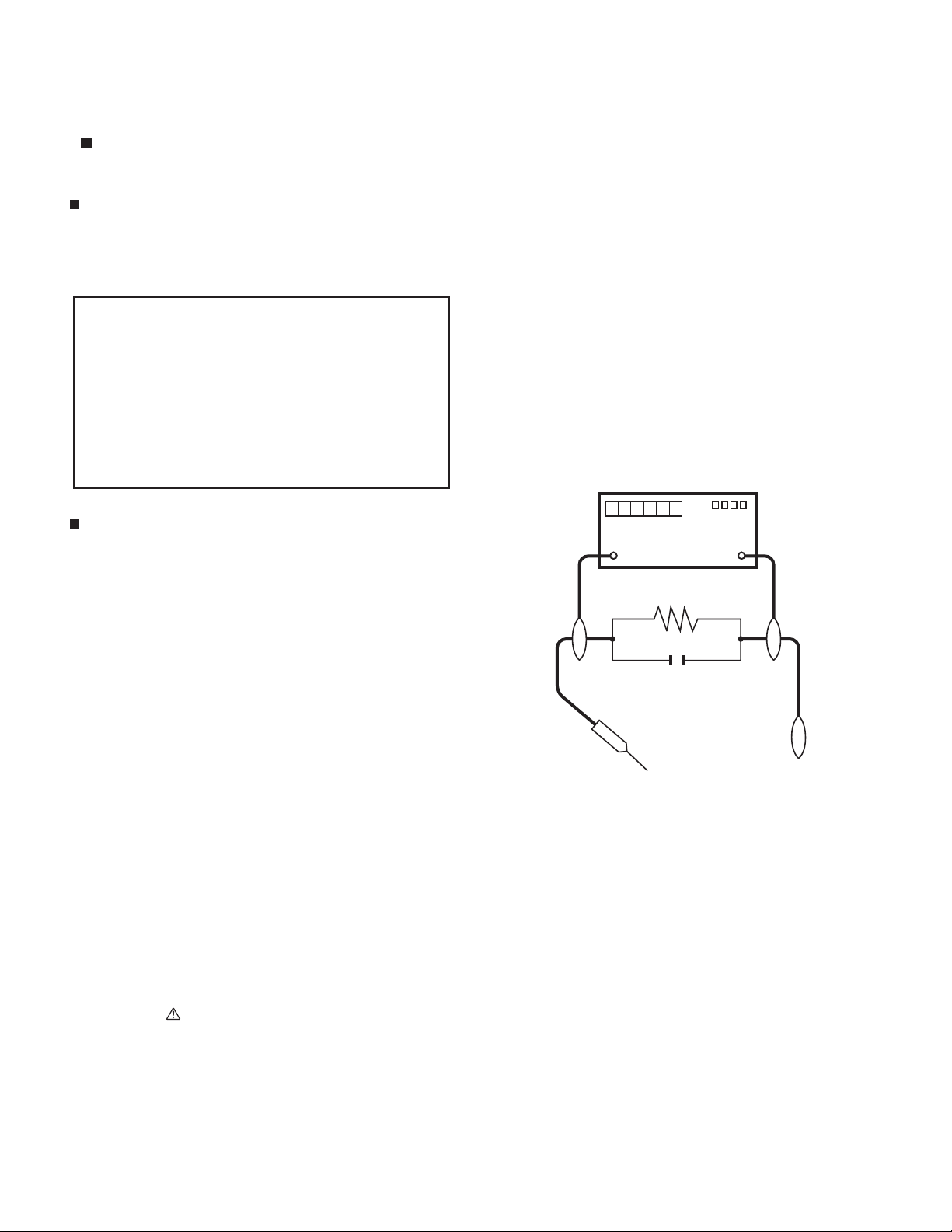

5. To be sure that no shock hazard exists, check for leakage current

in the following manner.

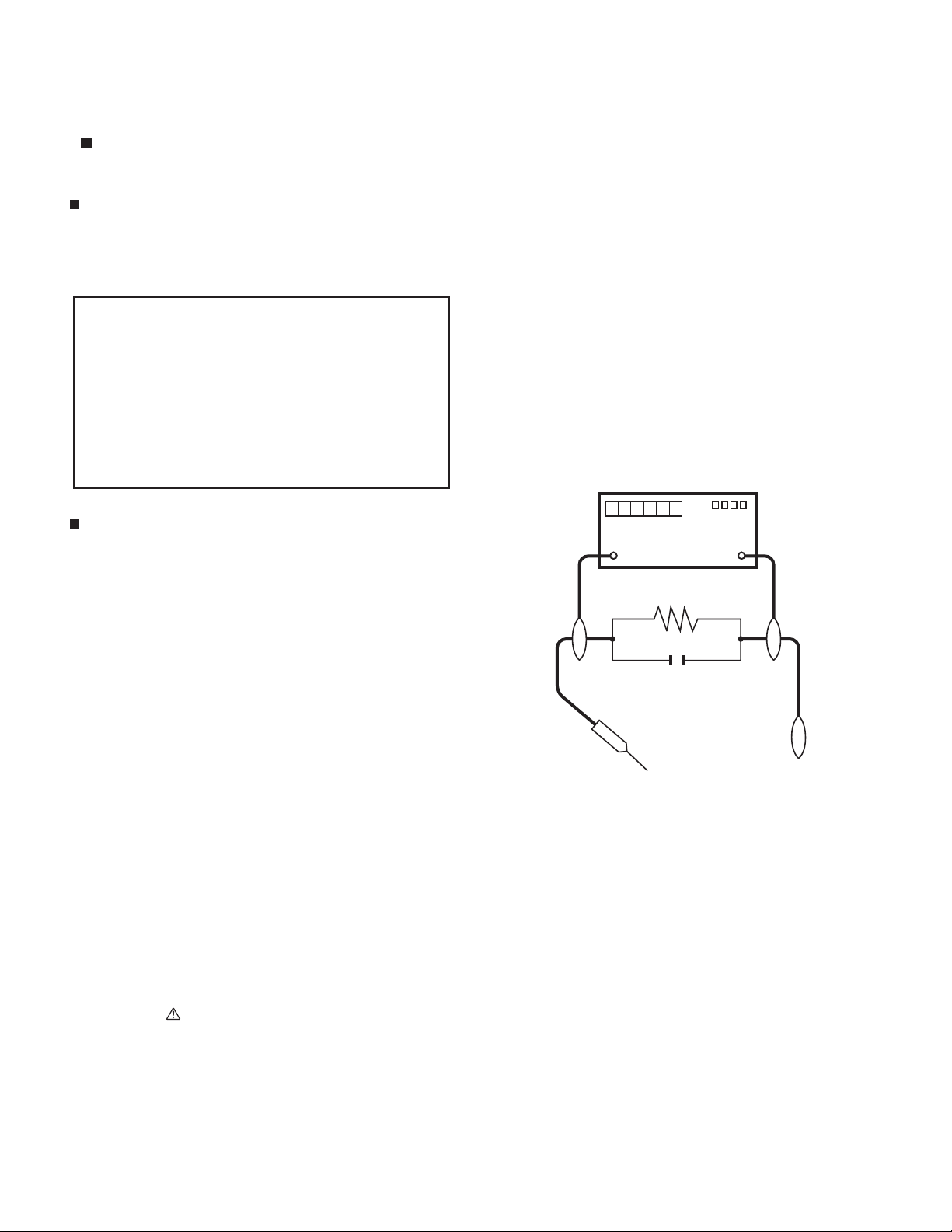

•Plug the AC cord directly into a 110-240 volt AC outlet.

•Using two clip leads, connect a 1.5k ohm, 10 watt resistor paral-

leled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or elec-

trical ground connected to an earth ground.

•Use an AC voltmeter having with 5000 ohm per volt, or higher, sen-

sitivity or measure the AC voltage drop across the resistor.

•Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

CAUTION:FOR CONTINUED PROTECTION

AGAINST A RISK OF FIREREPLACEONLYWITH

SAME TYPE FUSE.

F7001 (250V6.3A)

DVM

AC SCALE

1.5k ohm

10W

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

0.15

µ

F

TEST PROBE