9

211M -

1 RST IN Auto clear terminal.

Signal is input to reset the LSI to the initial state when power is applied.

Temporarily set to "L" level the moment power is applied, at this time the LSI is

reset. Thereafter set at "H" level.

2 INT IN Signal coming from encoder.

When the encoder is turned, the contacts of encoder make pulse signals. And

pulse signals are input into INT.

3 AVSS IN A/D converter power source voltage.

The power source voltage to drive the A/D converter in the LSI. Connected to

VC.

4 VREF IN Reference voltage input terminal.

A reference voltage is applied to the A/D converter in the LSI.

5K0INSignal coming from potentiometer.

ByinputtingDCvoltagecorrespondingtothepowerlevelsetbythepotentiometer,

thisinputisconvertedintothepowerlevelbytheA/DconverterbuiltintotheLSI.

6K1INTerminal to change functions according to the model.

Signalinaccordancewiththemodelinoperationisappliedtosetupitsfunction.

7 AVDD IN A/D converter power source voltage.

The power source voltage to drive the A/D converter in the LSI.

8 NC No connection terminal.

9 S0 OUT Digit selection signal.

Signal is input to the anodes of the light-emitting diodes (LD19 - LD24).

10 S1 OUT Digit selection signal.

Signal is input to the anodes of the light-emitting diodes (LD13 - LD18).

11 S2 OUT Digit selection signal.

Signal is input to the anodes of the light-emitting diodes (LD7 - LD12).

12 S3 OUT Digit selection signal.

Signal is input to the anodes of the light-emitting diodes (LD1 - LD6).

13-14 NC No connection terminal.

15 D0 OUT Segment data signal.

Signalisinput tothecathodesofthelight-emittingdiodes(LD1,LD7,LD13and

LD19).

16 D1 OUT Segment data signal.

Signalisinput tothecathodesofthelight-emittingdiodes(LD2,LD8,LD14and

LD20).

17 CNVS IN Reference voltage input terminal.

AreferencevoltageisappliedtotheA/DconverterintheLSI.ConnectedtoVC.

18 VSS IN Power source voltage: -5V.

The power source voltage to drive the LSI is input to VSS terminal. Connected

to VC.

19 D2 OUT Segment data signal.

Signalisinput tothecathodesofthelight-emittingdiodes(LD3,LD9,LD15and

LD21).

20 D3 OUT Segment data signal.

Signalisinputtothecathodesofthelight-emittingdiodes(LD4,LD10,LD16and

LD22).

21 D4 OUT Segment data signal.

Signalisinputtothecathodesofthelight-emittingdiodes(LD5,LD11,LD17and

LD23).

22 D5 OUT Segment data signal.

Signalisinputtothecathodesofthelight-emittingdiodes(LD6,LD12,LD18and

LD24).

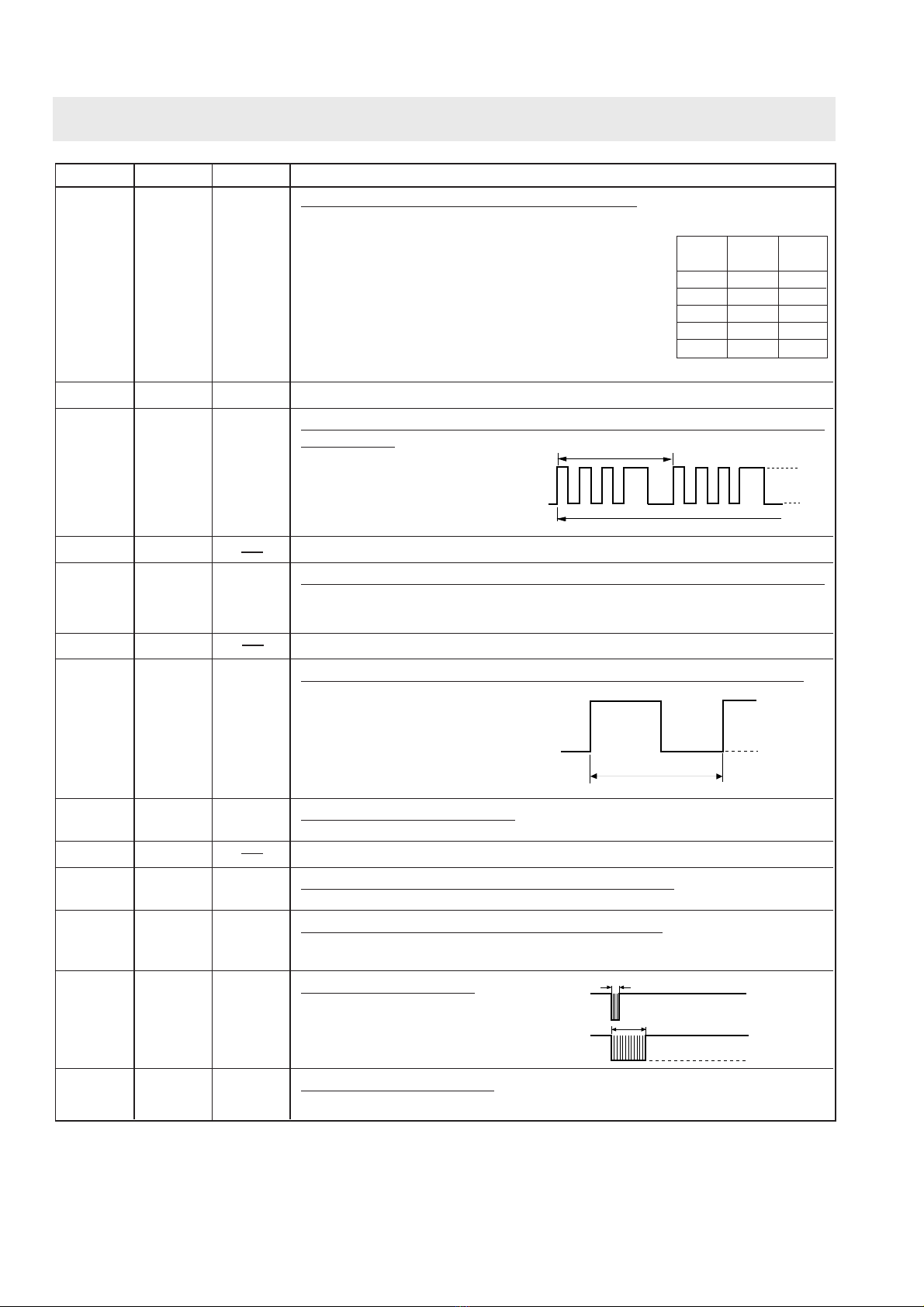

DESCRIPTION OF LSI

LSI(IZA882DR)

The I/O signal of the LSI(IZA882DR) are detailed in the following table.

Pin No. Signal I/O Description

DIGITAL ANALOGUE CONTROL PANEL