A-3A56(W)

R-3A56(B)

SHARP.

SERVICE

MANUAL

MICROWAVE

OVEN

MODELS

R-3A56(W)

R-3A56(B)

R-3A56

In

interests

of

user-safety

the

oven

should

be

restored

to

its

original

condition

and

only

parts

identical

to

those

specified

should

be

used.

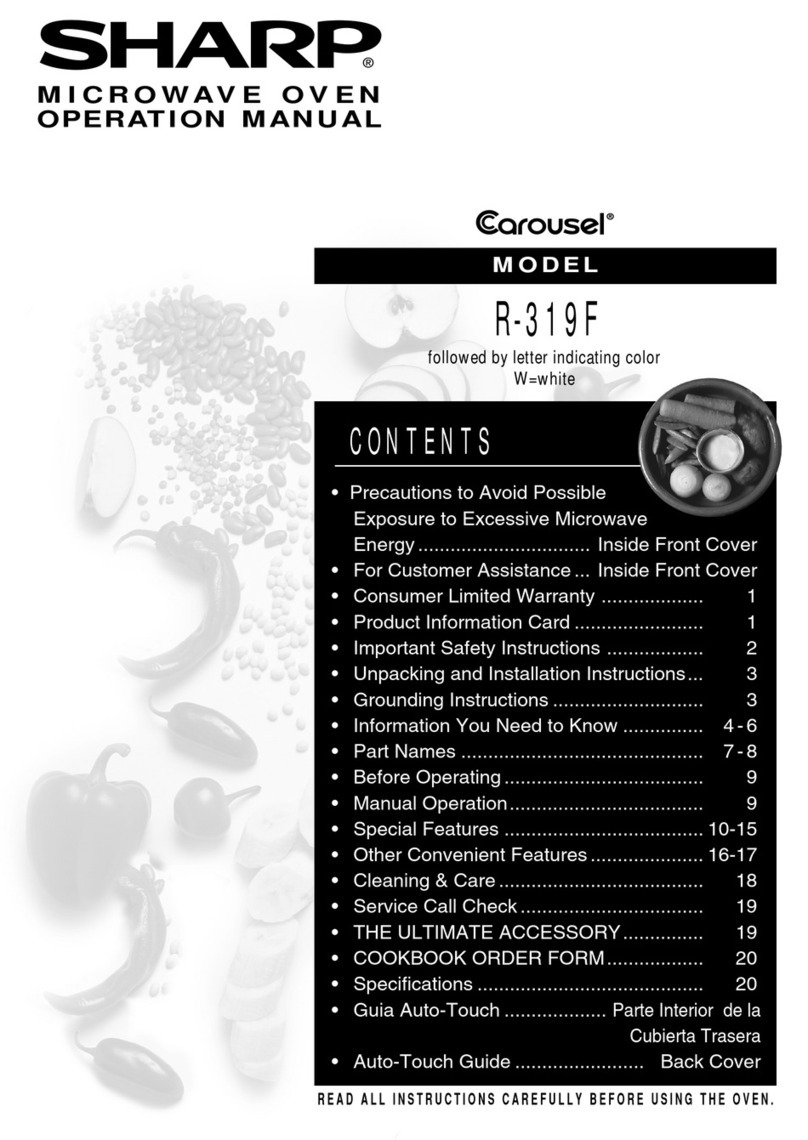

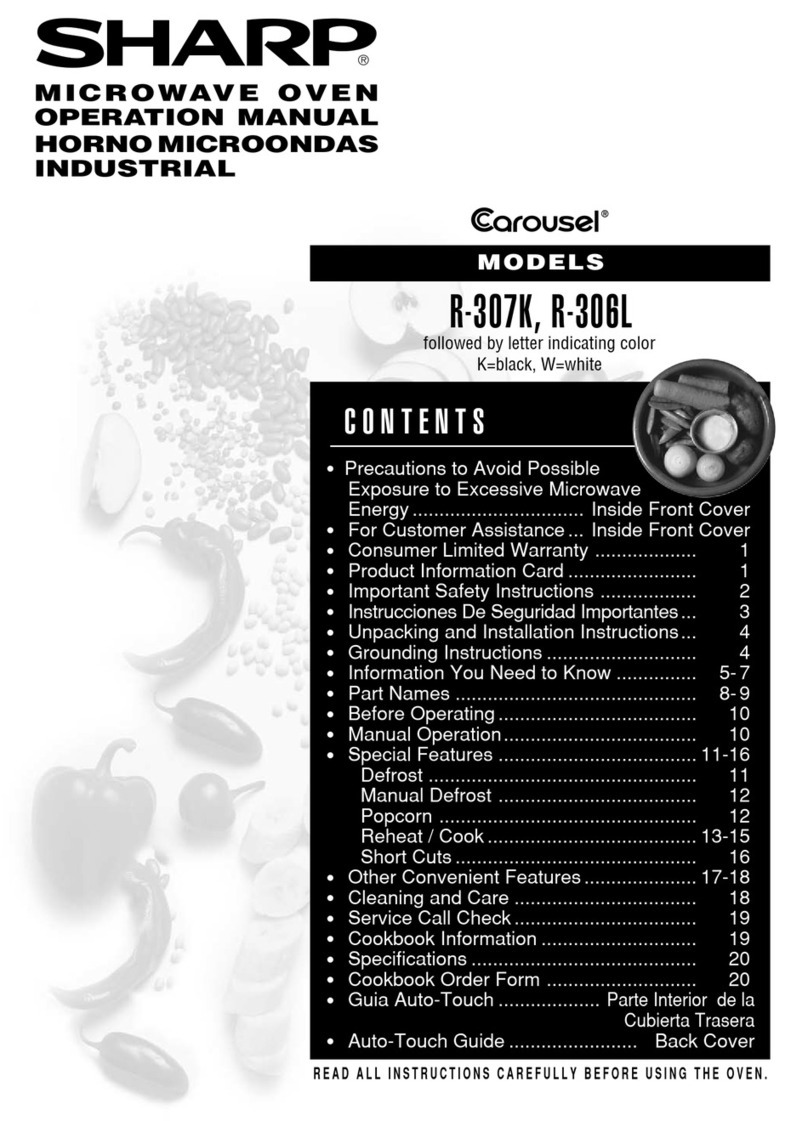

TABLE

OF

CONTENTS

Page

CAUTION,

MICROWAVE

RADIATION

GENERAL

IMPORTANT

INFORMATION,

WARNING

PRODUCT

SPECIFICATIONS

APPEARANCE

VIEW

OPERATION

SEQUENCE

FUNCTION

OF

IMPORTANT

COMPONENTS

SERVICING

TEST

PROCEDURE

TOUCH

CONTROL

ASSEMBLY?

cccic.t.ccists

locas

da

caaciaciccceqcug

colette

denvevevensetesdtanacedluardaieevebestsvgerbvoauenceusuaers

7

COMPONENT

REPLACEMENT

AND

ADJUSTMENT

PROCEDURE

.0000..

ee

eeseeeeeeseneseeeseeeeteeneeeeeaeaeen

2

MICROWAVE

MEASUREMENT

....0......ccccecscccsscssssessssasceecseeecsaeesseseeaeeeeesesdeceeeseaueseaeseaeseeeessecaneeseaeeeees

-

TEST

DATAAT:

A

GLANCE

iicsiiscccsecetiscwterssstusscsevsosevstarversertibecdvecesisusracacepeasduclasasndaasnbdasiedaddaednert

ofimeersen

-

WIRING:

DIAGRAM

ci.

cis.

ccei.

onteates

sleseesgidscevandiihanadsvents

oseusvacoucededede

cutpa

sunceviiisdesced

GewsdeeavaeVediwedandassdhastactudsTaaiy

.

30

PICTORIAL

DIAGRAM

5.150200

sSasvesezdisiasheiue

dosdiusecastasacasaecoats

Saceydsnscedents

sgeveuct

suuusvaeaasebadaaceustsecasacasaddapeadenesin

-

31

CONTROE

PANEL:

GIRCUUID:

i

screed

ccistesniccucctceSccuseeesgesscedecesatd

osat

tuakbeupccspensygtoundads

cvuadcvesuudyandeacenucned

tee

oa

.

32

PRINTED

WIRING

DIAGRAM

3...

nec.

ccs

cccaescececcceti

eceaiecnsatuteancteasasseveuceaweswedecentensencusicuved

dvlesuteaanaedueevevedn

-

33

PARTS

EIST

vncisvcccesevssessccsennancvtssatvctevesssadataobetisveresbevesveecacedseaedecutesdtctacesuepiucveleadvansdeusastcenedtduasuvestdeteeercnia

-

34

PACKING

AND

ACCESSORIES

.0......cccccccssesssssesceescseeseceesseeeeneeeteeeeeeesaesesueeanessanesassessesesseseeseneasenaeseessar

-

39

SHARP

CORPORATION