R-4A56

5

FUNCTION OF IMPORTANT COMPONENTS

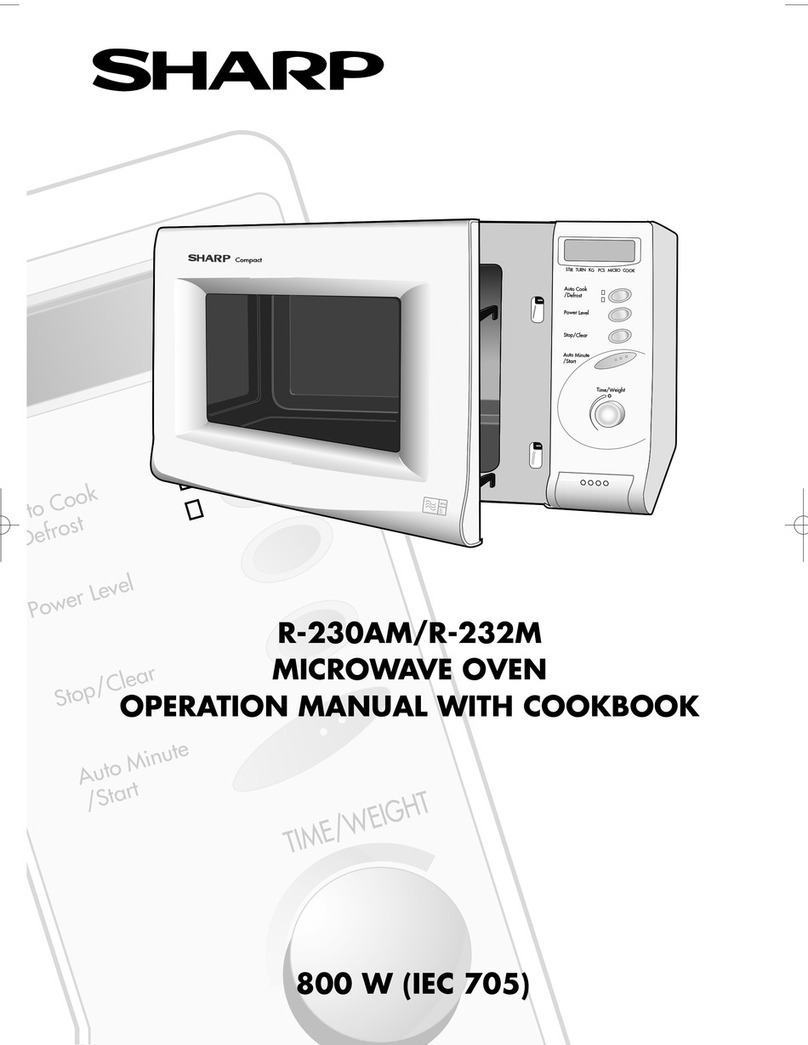

DOOR OPEN MECHANISM

Thedoorcanbeopenedbypushingthedooropenbuttonon

thecontrolpanel.Whenthedooropenbuttonispushed,the

latch lever is moved upward, operating the latch head. The

latch head is moved upward, and released from the latch

hook. Now, the door can be opened.

MONITOR

SWITCH

UPPER

LATCH

SWITCH

STOP

SWITCH

LOWER

LATCH

SWITCH

LATCH

LEVER PLUNGER

SWICTH

LATCH

HEAD

DOOR

OPEN

BUTTON

LATCH

HEAD

LATCH

HOOK

DOOR

Figure D-1. Door Open Mechanism

UPPER LATCH SWITCH, LOWER LATCH SWITCH

AND STOP SWITCH

1. Whenthe oven door is closed, the contacts (COM -NO)

must be closed.

2. Whentheovendoorisopened,thecontacts(COM-NO)

must be opened.

MONITOR SWITCH

1. When the oven door is closed, the contacts (COM- NC)

must be opened.

2. Whentheovendoorisopened,thecontacts(COM-NC)

must be closed.

3. If the oven door is opened and the contacts (COM- NO)

of the upper and lower latch switches fail to open, the

fuse(M8A)blowssimultaneouslywithclosingthecontacts

(COM-NC) of the monitor switch.

CAUTION: BEFOREREPLACINGABLOWNFUSE(M8A)

TEST THE UPPER AND LOWER LATCH

SWITCHES, MONITOR SWITCH AND MONI-

TORRESISTORFORPROPEROPERATION.

(REFERTOCHAPTER“TESTPROCEDURE”.)

MONITOR RESISTOR (0.8Ω20W)

Themonitorresistorpreventsthefuse(M8A)burstingwhen

the fuse blows due to the operation of the monitor switch.

ASYMMETRIC RECTIFIER

Theasymmetricrectifierisasolidstatedevicethatprevents

currentflow inboth directions. Andit preventsthe tempera-

tureriseofthepowertransformerbyblowingthefuse(M8A)

when the high voltage rectifier is shorted.

The rated peak reverse voltage of D1 of the asymmetric

rectifier is 6 KV The rated peak reverse voltage of D2 of the

asymmetricrectifieris1.7KV.D1andD2oftheasymmetric

rectifier or high voltage rectifier are shorted when the each

peak reverse voltage goes beyond the each rated peak

reverse voltage. (The process of blowing the fuse M8A.)

1. Thehighvoltagerectifierisshortedbyanycauseswhen

microwave cooking.

2. The peak reverse voltage of D2 of the rectifier goes

beyond the rated peak reverse voltage 1.7 KV in the

voltage doubler circuit.

3. D2 of the rectifier is shorted.

4. The large electric currents flow through the high voltage

winding of the power transformer.

5. The large electric currents beyond 8A flow through the

primary winding of the power transformer.

6. The fuse (M8A) blows by the large electric currents.

7. The power supply to the power transformer is cut off.

THERMAL CUT-OUT 145˚C (OVEN)

The thermal cut-out located on the top of the oven cavity is

designed to prevent damage to the oven if the foods in the

oven catch fire due to over heating produced by improper

setting of cook time or failure of control unit. Under normal

operation, the oven thermal cut-out remains closed. How-

ever, when abnormally high temperatures are reached

within the oven cavity, the oven thermal cut-out will open at

145˚C, causing the oven to shut down. The thermal cut-out

will be close its contacts again when its temperature goes

down lower than -20˚C.

FUSE (M8A)

1. If the wire harness or electrical components are short-

circuited, this fuse blows to prevent an electric shock or

fire hazard.

2. The fuse blows when the asymmetric rectifier, H.V.

rectifier,H.V.wireharness,H.V.capacitor,magnetronor

secondary winding of power transformer is shorted.

3. Thefusealsoblowswhenupperandlowerlatchswitches

remains closed with the oven door open and when the

monitor switch closes.

TEMPERATURE FUSE 150˚C (MG)

Thisfuseprotectsthemagnetronagainstoverheating.Ifthe

temperature goes up higher than 150˚C because the fan

motor is interrupted, the air inlet duct is blocked or the

ventilationopeningsareobstructed,thefuseblowsandputs

the oven out of operation.

The defective fuse must be replaced with new rated one.

D2 D1

ASYMMETRIC

RECTIFIER

HIGH VOLTAGE RECTIFIER

AB

C