R-4HlO

SENSOR COOKING CONDITION Cooking Sequence.

Using the SENSOR COOK function, the foods are

cooked without figuring time, power level or quantity.

When the oven senses enough steam from the food, it

relays the information to its microprocessor which will

calculate the remaining cooking time and power level

needed for best results.

When the food is cooked, water vapor is developed.

The sensor “senses” the vapor and its resistance in-

creases gradually. When the resistance reaches the

value set according to the menu, supplementary cook-

ing is started.

The time of supplementary cooking is determined by

experiment with each food category and inputted into

the LSI.

An example of how sensor works:

1. Potatoes at room temperature.

Vapor is emitted very slowly.

2. Heat potatoes. Moisture and humidity is emitted

rapidly. You can smell the aroma as it cooks.

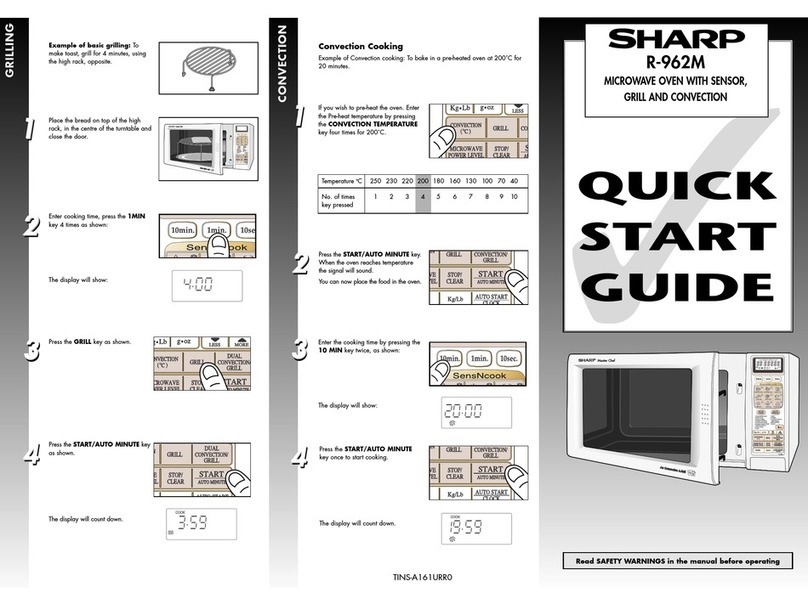

1. Touch SENSOR COOK pad.

NOTE:The oven should not be operated on SEN-

SOR COOK immediately after slugging in

the unit. Wait five minutes ’ fre cooking

on SENSOR COOK.

2. Select desired Sensor setting.

3. Touch START pad.

4.

The coil of shut-off relay (RY-1) is energized, the

oven lamp and cooling fan motor are turned on,

but the power transformer is not turned on.

After about 16 seconds, the cook relay (RY-2) is

energized. The power transformer is turned on,

microwave energy is produced and first stage is

started.

The 16 seconds is the cooling time required to re-

move any vapor from the oven cavity and sensor.

NOTE: During this first stage, do not open the door

5.

6.

7.

or touch STOP/CLEAR pad.

When the sensor detects the vapor emitted from the

food, the display switches over to the remaining

cooking time and the timer counts down to zero.

At this time, the door may be opened to stir food,

turn it or season, etc.

When the timer reaches zero, an audible signal

sounds. The shut-off relay and cook relay are

de-energized and the power transformer, oven

lamp, etc. are turned off.

Opening the door or touching the STOP/CLEAR

pad, the time of day will reappear on the display

and the oven will revert to an OFF condition.(RD71603U)

3. Sensor detects moisture and humidity and calcu-

iates cooking time and variable power.