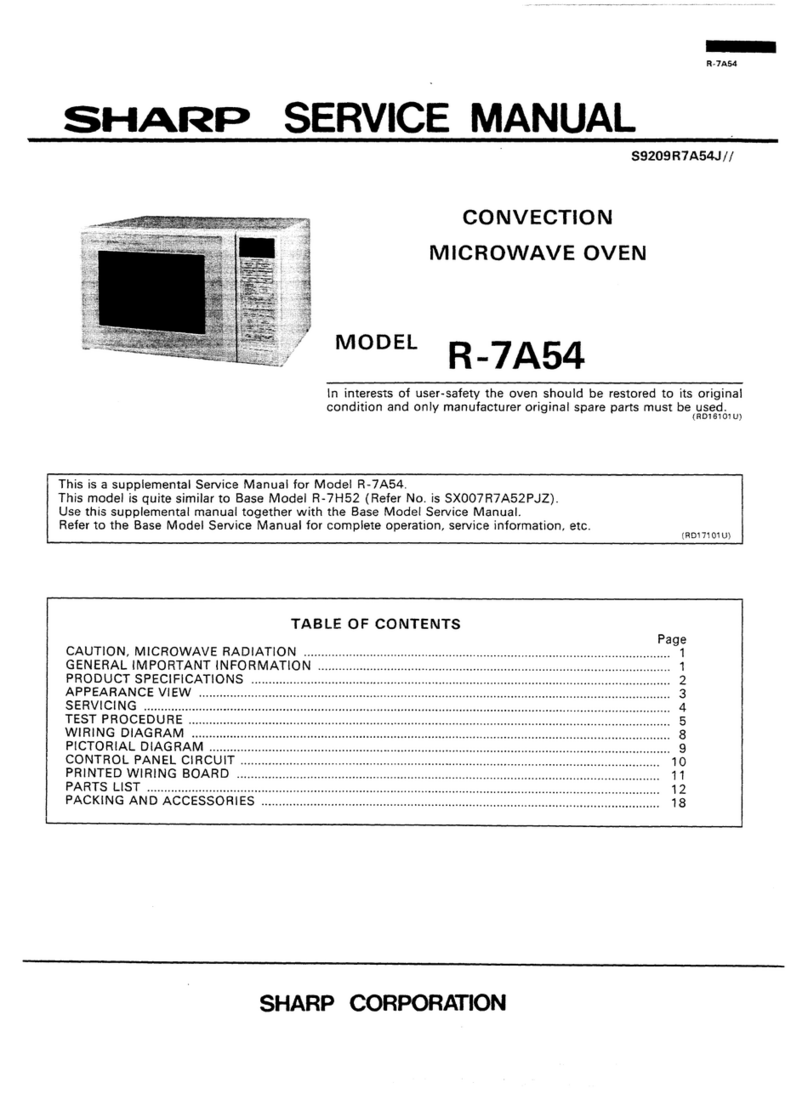

ITEM

Power

Requirements

Power

Consumption

Power

Output

Grill

Heating

element

Power

Output

Case

Dimensions

Cooking

Cavity

Dimensions

Turntable

diameter

Control

Complement

set

Weight

PRODUCT

DESCRIPTION

SPECIFICATION

DESCRIPTION

220

Volts

50

Hertz

Single

phase,

3

wire

earthed

Microwave

cooking

1.25

kW

Dual

cooking

2.55

kW

(Except

R-6R50)

Grill

cooking

1.35

kW

_

600

watts

nominal

of

RF

microwave

energy

(2

ner

water

load)

Operating

frequency

of

2450MHz

1.3

kW

Width

520

mm

Height

341

mm

mnelpeine

foot

Depth

416

mm

Width

340

mm

Height

203

mm

Depth

350

mm

330mm

Touch

Control

System

Clock(

1:00

-

12:59

)

Timer

(0

-

99

min.

99

sec.

)

Microwave

Power

for

Variable

Cooking

Repetition

Rate;

FULL:

POWER®.

-wsssazeesraseazace

Full

power

gusuanaut

the

cooking

time

ROA

cetierersittrcasscetecsei

ve

cocascvcnecs

Sctaab

asics

approx.

70%

of

Full-Power

SSIES”

‘evianshiniewei

canes

vertveeiveaseoetecieveseacaas

approx.

50%

of

Full

Power

.

DEFROST

| -

sasticsaiccedunediceeivestennnnieacetires:

approx.

30%

of

Full

Power

von

ss

aate

dba

aaa

dewearere

Sadie

Calpeata

seukeiite

site:

approx.

We

of

Full

Power

(FUNCTION.

a

ae

Pads

|

ann

med

a

|

Dual

Pads

Gril!

cooking

Rotisserie

Pad’

-

Easy

Defrost

pad

.

Less

/

More

pads

kg

/

Pes

pad

g

pad

|

a

Timer

/

Hold

pad

a

on

|

Auto

Start

/

Clock

pad

sa

as

ae

naa

Stop

/

Clear

pad

Minute

Plus

/

Start

pad

ae

Wa

Numeral

keys

:

10min.

1min.

10sec.

Approx.

23

kg

TE:

.

Numbers

and

letters

shown

after

sentences

such

as

“RD44101U”

are

for

factory

use

only.

2

tt

Hn

(RD44101U)

eae

{i

"

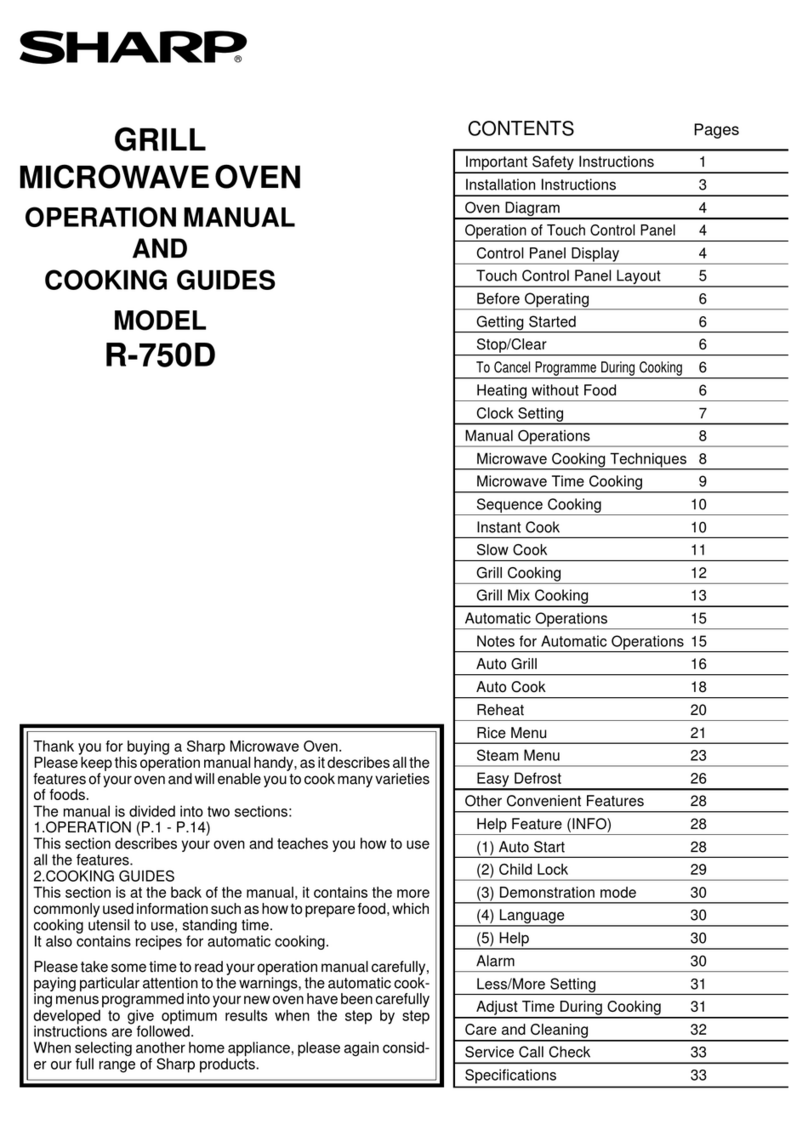

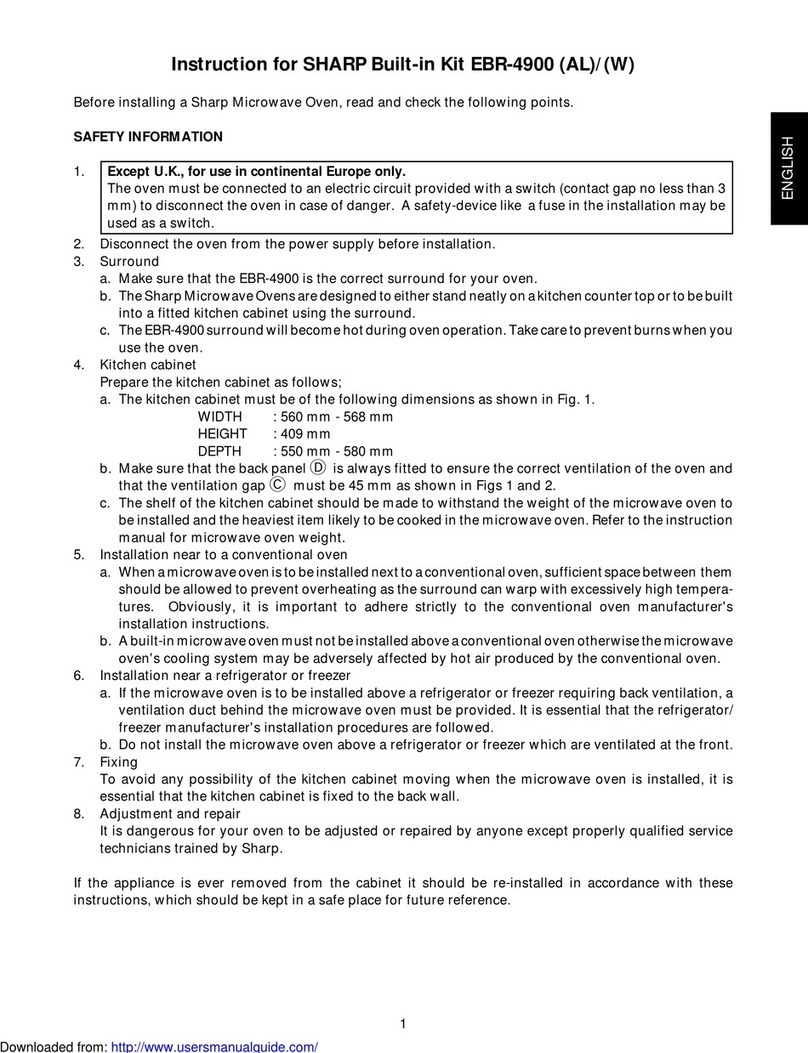

GENERAL

INFORMATION

WARNING

THIS

APPLIANCE

MUST

BE

EARTHED

IMPORTANT

THE

WIRES

IN

THIS

MAINS

LEAD

ARE

COLOURED

IN

ACCORDANCE

WITH

THE

FOLLOWING

CODE:

:

EARTH

:

NEUTRAL

-

:

LIVE

-

.GREEN-AND-YELLOW

BLUE

BROWN

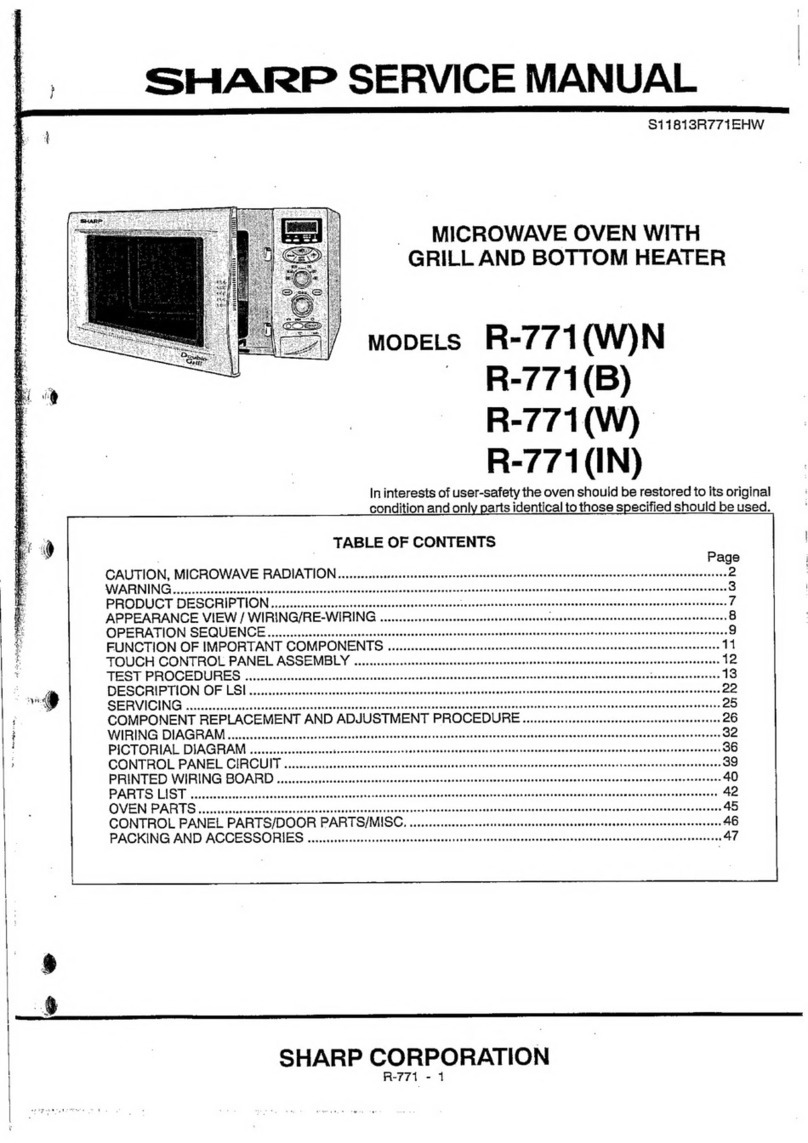

OPERATING

INSTRUCTIONS

R-6G50,.

R-6G52

.

R-6R50,

R-6R70

:

’

dior

Waveguide

cover

Oven

lamp

Access

caver

for

oven

lamp

replacement

.

Ventilation

openings

.

Grill

heater

unit

(See

page

E-19)

Qven

door

with

see-through

window

Doar

latches

Hinges

.

Roller

stay

Removable

turntable

Low

rack

(50

mm}

.

High

rack

(135

mm)

.

Door

open

button{

VW}

.

Auto-Touch

control

panel

.

Digital

readout

.

Skewer

(R-GR50,

R-GR7O

only}

17.

Prongs

(R-6R50,

R-6R70

only)

18.

Skewer

support

{R-6R50,

R-6R70

only)

.

19,

Handles

(R-6R50,

R-6R70

only)

ahs

es

ANMAWNAObDI]GAHD

NOTES:

THE

SKEWER

SUPPORT

IS

FOR

ROTISSERIE

COOKING

ONLY.

AFTER

ROTISSERIE

COOKING

1S

FINISHED,

REMOVE

THE

SKEWER

SUPPORT

AND

STORE

WITH

OTHER

ACCESSORIES.

G@)

Time

pad

;

EASY

DEFROST

pad

Grill

syrnbol

Indicators

@

MICROWAVE

pad

MORE/LESS

pad

AE

ee

Sa

ee

ee

eee

ee.

@.

GRILL

pad...

@

-

Weight

pad

Microwave

and

Defrost.

Digital

display

@

DUAL

COOK

pad

@

TIMER/HOLD

pad

can

@

ROTISSERIE

pad

-

@

AUTO

STARTICLOCK

pad

Rotisserie

symbo!

(A-GRSO,

Indicators

®

Menu

Guide

@

-

STOP/CLEAR

pad

@

COMPUCOOK

pad

@

MINUTE

PLUS/START

pad

R-6R70

only)

EASES

ae

))

Sw

ean]

4OR+

1

byl

eae

rT}

-Siais}+'s

@®

@-

?

£

t

Ba

eee

33

af

sie

,

ofa

}-s

ofeetee*

eer

2m

a

{R-6R50}

(R-6R70)

ae

{R-6G50)

R-6R50(W)

R-6G50(W)

R-6G52(W)

R-6R70(W)

a

(B)

(B)

(B)

{B)

/

f