R-7H55

5

2. Thecoilofrelay(RY6)isenergizedbytheCPUunit.The

damper is moved to the closed position, opening the

damper switch contacts. The opening of the damper

switchcontactssendsasignaltotheLSIontheCPUunit

de-energizing the relay (RY6) and opening the circuit to

the damper motor.

3. The coil of heater relay (RY3) is energized by the CPU

unitandthe main supplyvoltageisaddedtotheconvec-

tion heater.

4. Whentheoventemperaturereachestheselectedpreheat

temperature, the following operations occur:

4-1. Theheaterrelay(RY3)isde-energizedbytheCPUunit

temperature circuit and thermistor, opening the circuit

to the convection heater.

4-2. The oven will continue to function for 30 minutes,

turning the convection heater on and off, as needed to

maintain the selected preheat temperature. The oven

will shut-down completely after 30 minutes.

CONVECTION COOKING CONDITION

Whenthepreheattemperatureisreached,abeepsignalwill

sound indicating that the holding temperature has been

reached in the oven cavity. Open the door and place the

food to be cooked in the oven. Program desired cooking

time and convection temperature by touching the number

pad, CONVECTION pad and Temperature pad. When the

START pad is touched, the following operations occur:

1. The numbers of the digital readout start the count down

to zero.

2. The oven lamp, turntable motor, cooling fan motor and

convection motor are energized.

3. Heater relay (RY3) is energized (if the cavity tempera-

tureislowerthantheselectedtemperature)andthemain

supply voltage is applied to the convection heater to

return to the selected cooking temperature.

4. Upon completion of the cooking time, the audible signal

will sound, and oven lamp, turntable motor, cooling fan

motor and convection motor are de-energized. At the

end of the convection cycle, if the cavity air temperature

isabove118˚C,thecircuitto(RY4)willbemaintained(by

thethermistorcircuit)tocontinueoperationofthecooling

fan motor until the temperature drops below 118˚C, at

which time the relay will be de-energized, turning off the

fan motor. Relay (RY5) will however, open as soon as

the convection cycle has ended, turning off the convec-

tion fan motor. This will now cool and allow the damper

door to open.

5. At the end of the convection cook cycle, shut-off relay

(RY6) is energized turning on the damper motor. The

damper is returned to the open position, closing the

damper switch contacts which send a signal to the

control unit, de-energizing shut-off relay (RY6).

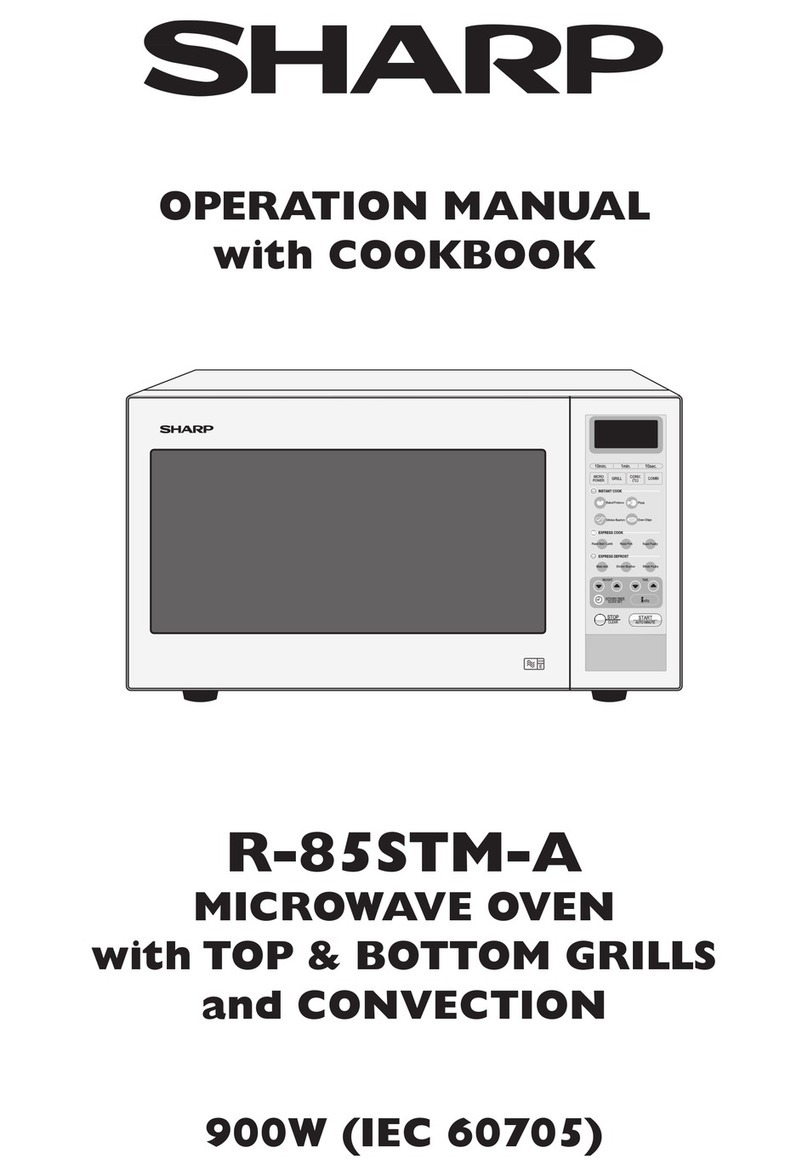

MIX COOKING CONDITION

Program desired cooking time and the LOW MIX or HIGH

MIXandtemperature.WhentheSTARTpadistouched,the

following operations occur:

1. The numbers of the digital readout start the count down

to zero.

2. The shut-off relay (RY1+RY5+RY4) energized, turning

ontheovenlamp,turntablemotor,coolingfanmotorand

convection motor.

3. The shut-off relay (RY6) is energized.

The damper door is closed from the open position.

4. The heater relay (RY3) is energized, adding the mains

supply voltage to the convection heater.

5. Now, the oven is in the convection cooking condition.

6. When the oven temperature reaches the selected tem-

perature, the following operations occur:

6-1. The power supply voltage is added to the convection

heater and power transformer alternately.

6-2. The convection heater operates through the heater

relay (RY3) contacts and the power transformer oper-

ates through the cook relay (RY2) contacts.

6-3. These are operated by the CPU unit to supply alter-

nately within a 32 second time base, convection heat

and microwave energy.

The relationship between the convection and micro-

wave power operations are as follows.

Note: The ON and OFF time ratio does not correspond

with the percentage of microwave power, because

approx. 2 seconds are needed for heating of the

magnetron filament.

EASY DEFROST COOKING

TheEASYDEFROSTkeyisaspecialfunctionkeytodefrost

meats and poultry faster and better. EASY DEFROST

automatically defrosts roast beef, etc.. When the EASY

DEFROST is selected and the food weight is entered by

using the number pads, the oven will cook according to the

special cooking sequence.

AUTO COOK CONDITION

AUTOCOOKwillautomaticallycomputetheoventempera-

ture, microwave power and cooking time for baking, roast-

ingandbroiling.Itisbasedonspecificfoodsandthequantity

or weight of the food. Program the AUTO COOK mode by

touchingtheAUTOCOOKpadandNumberpads,enterthe

weight of the food by touching the Number pads. When the

START pad is touched, the oven will generate the micro-

waveenergy and/or convection heater energy according to

the programmed special cooking sequence.

12 SEC. 20 SEC.

32 SEC.

LOW MIX

HIGH MIX

MICROWAVE POWER

= APPROX. 30%

CONVECTION

TEMPERATURE

= 200˚C

MICROWAVE POWER

= APPROX. 10%

CONVECTION

TEMPERATURE

= 180˚C

26 SEC.6 SEC.

ON

ON

OFF

OFF

OFF

ON

(MICRO.)

(CONVEC.)

(MICRO.)

(CONVEC.)

Note: During alternate Microwave/Convection operation,

the convection heater is energized only if the cavity

temperature drops below the set temperature.