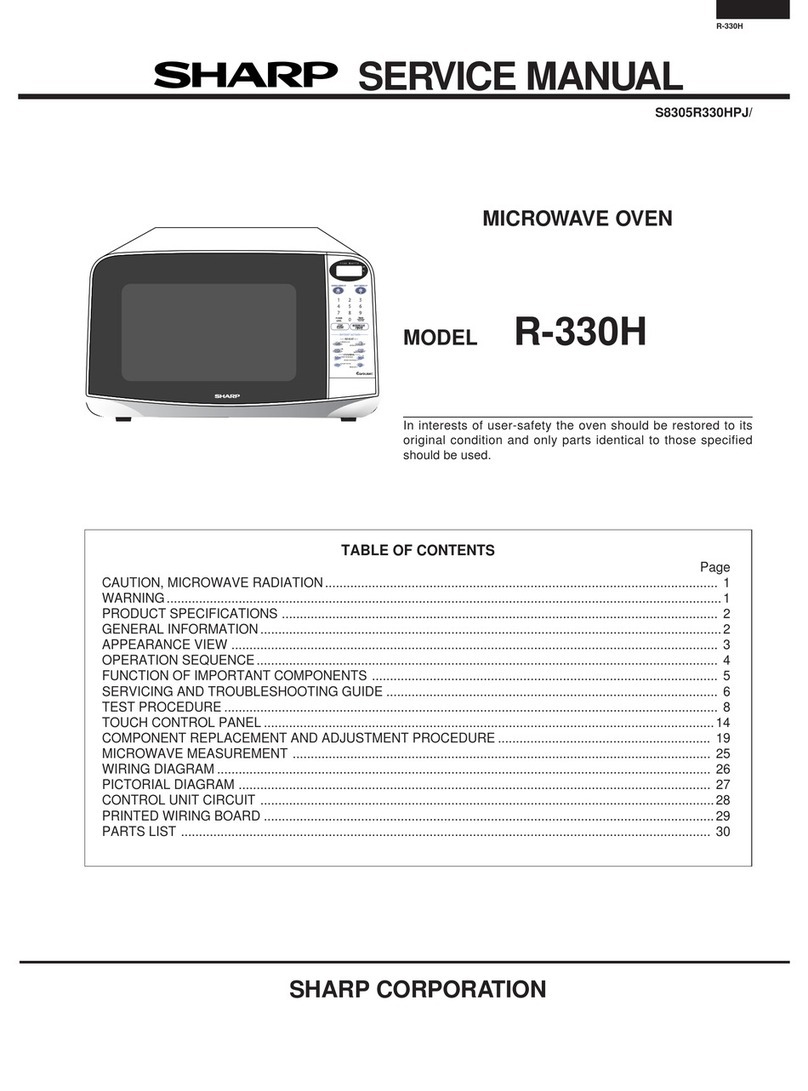

CONTENTS

CHAPTER 1. BEFORE SERVICING

[1] GENERAL IMPORTANT INFORMA-

TION ........................................................... 1-1

[2] WARNING................................................... 1-1

[3] CAUTION MICROWAVE RADIATION ........ 1-2

CHAPTER 2. WARNING TO SERVICE PERSON-

NEL

CHAPTER 3. PRODUCT SPECIFICATIONS

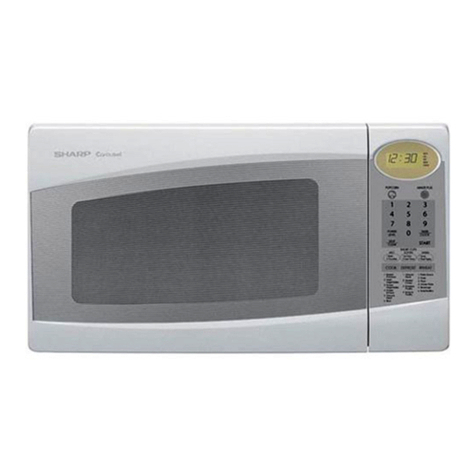

CHAPTER 4. APPEARANCE VIEW

[1] OVEN.......................................................... 4-1

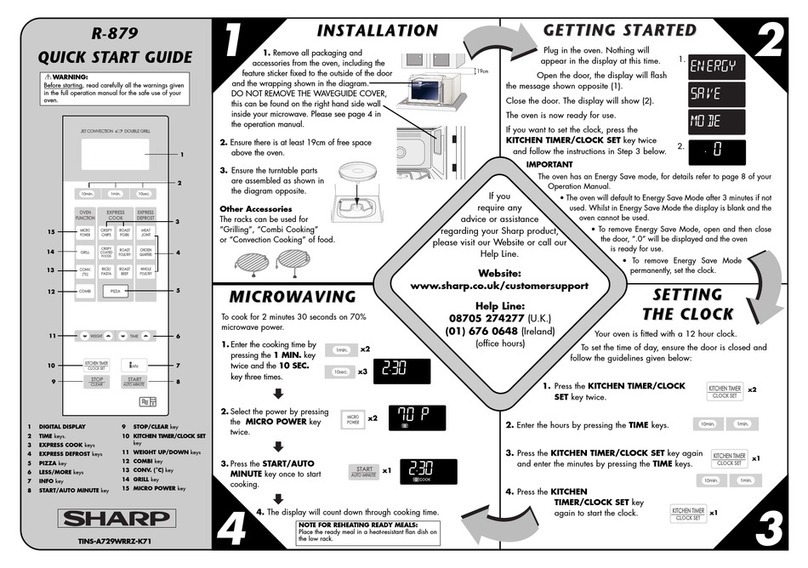

[2] TOUCH CONTROL PANEL ........................ 4-1

CHAPTER 5. OPERATION SEQUENCE

[1] OFF CONDITION........................................ 5-1

[2] MICROWAVE COOKING CONDITION....... 5-1

[3] GRILL COOKING CONDITION .................. 5-2

[4] CONVECTION COOKING CONDITION..... 5-2

[5] DUAL COOKING CONDITION ................... 5-2

[6] ON/OFF TIME RATIO ................................. 5-3

[7] AUTOMATIC COOKING ............................. 5-3

[8] POWER OUTPUT REDUCTION ................ 5-3

[9] FAN MOTOR OPERATION......................... 5-3

[10] CONVECTION MOTOR OPERATION........ 5-3

CHAPTER 6. FUNCTION OF IMPORTANT COM-

PONENTS

[1] DOOR OPEN MECHANISM ....................... 6-1

[2] MONITORED LATCH SWITCH (SW1) ....... 6-1

[3] STOP SWITCH (SW2)................................ 6-1

[4] MONITOR SWITCH (SW3)......................... 6-1

[5] FUSE (F1) 20A 250V .................................. 6-1

[6] FUSE (F2) F8A 250V (NOISE FILTER) ...... 6-1

[7] TC TRANSFORMER .................................. 6-1

[8] THERMAL CUT-OUT (TC1) 125C (MG)..... 6-1

[9] THERMAL CUT-OUT (TC2) 170C

(GRILL) ....................................................... 6-1

[10] THERMAL CUT-OUT (TC3) 170C

(CONV.)....................................................... 6-1

[11] ASYMMETRIC RECTIFIER ........................ 6-1

[12] NOISE FILTER............................................ 6-2

[13] TURNTABLE MOTOR (TTM)...................... 6-2

[14] FAN MOTOR (FM) ...................................... 6-2

[15] CONVECTION MOTOR (CM)..................... 6-2

[16] GRILL HEATING ELEMENT (GH) .............. 6-2

[17] CONVECTION HEATING ELEMENT

(CH) ............................................................ 6-2

[18] CONVECTION COOKING SYSTEM .......... 6-2

[19] FIRE SENSING FEATURE ......................... 6-2

[20] OPEN JUDGE BY THERMISTOR .............. 6-2

[21] DAMPER OPEN-CLOSE MECHANISM..... 6-2

CHAPTER 7. TROUBLESHOOTING GUIDE

[1] FOREWORD............................................... 7-1

[2] CHART........................................................ 7-2

CHAPTER 8. TEST PROCEDURES

[1] Procedure A: MAGNETRON TEST ............ 8-1

[2] Procedure B: HIGH VOLTAGE TRANS-

FORMER TEST .......................................... 8-2

[3] Procedure C: HIGH VOLTAGE RECTIFI-

ER TEST..................................................... 8-2

[4] Procedure D: HIGH VOLTAGE CAPACI-

TOR TEST .................................................. 8-2

[5] Procedure E: SWITCH TEST...................... 8-3

[6] Procedure F: THERMISTOR TEST ............ 8-3

[7] Procedure G: THERMAL CUT-OUT

TEST........................................................... 8-3

[8] Procedure H: MOTOR WINDING TEST..... 8-3

[9] Procedure I: NOISE FILTER TEST............. 8-4

[10] Procedure J: BLOWN FUSE (F1) 20A........ 8-4

[11] Procedure K: BLOWN FUSE (F2) 8A

(NOISE FILTER) ......................................... 8-4

[12] Procedure L: GRILL HEATING ELE-

MENTS (TOP) AND CONVECTION

HEATING ELEMENT TEST ........................ 8-4

[13] Procedure M: CONTROL PANEL AS-

SEMBLY TEST ........................................... 8-4

[14] Procedure N: JOG AND SWITCH UNIT

TEST........................................................... 8-5

[15] Procedure O: RELAY TEST ........................ 8-6

[16] Procedure P: PROCEDURES TO BE

TAKEN WHEN THE FOIL PATTERN ON

THE PRINTED WIRING BOARD (PWB)

IS OPEN ..................................................... 8-6

CHAPTER 9. TOUCH CONTROL PANEL ASSEM-

BLY

[1] OUTLINE OF TOUCH CONTROL PAN-

EL ............................................................... 9-1

[2] SERVICING FOR TOUCH CONTROL

PANEL ........................................................ 9-1

CHAPTER 10. PRECAUTIONS FOR USING LEAD-

FREE SOLDER

CHAPTER 11. COMPONENT REPLACEMENT

AND ADJUSTMENT PROCEDURE

[1] BEFORE OPERATING ..............................11-1

[2] OUTER CASE REMOVAL .........................11-1

[3] HIGH VOLTAGE COMPONENTS RE-

MOVAL.......................................................11-1

[4] HIGH VOLTAGE TRANSFORMER RE-

MOVAL.......................................................11-2

[5] MAGNETRON REMOVAL .........................11-2

[6] CONTROL PANEL ASSEMBLY RE-

MOVAL.......................................................11-2

[7] FAN MOTOR REREPLACEMENT.............11-2

[8] TURNTABLE MOTOR REPLACEMENT....11-3

[9] CONVECTION MOTOR AND CONVEC-

TION HEATING ELEMENT REMOVAL .....11-3

[10] POSITIVE LOCK........................................11-4

[11] OVEN LAMP SOCKET REMOVAL............11-4