R-950A

38

Note: The parts marked "∆" may cause undue microwave exposure.

The parts marked "*" are used in voltage more than 250V.

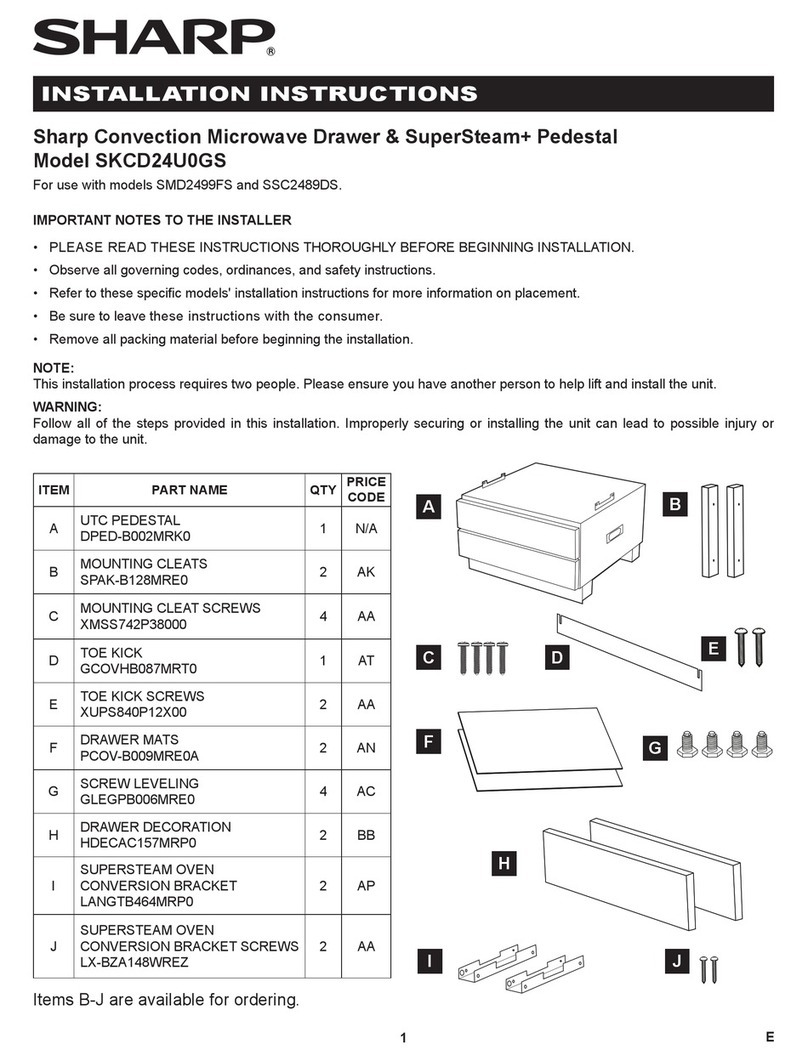

REF. NO. PART NO. DESCRIPTION Q'TY CODE

∆

Q20-23 VSKRA101M//-3 Transistor (KRA101M) 4 AB

Q24-25 VSKRA223M//-3 Transistor (KRA223M) 2 AB

Q26 VSKRC243M//-3 Transistor (KRC243M) 1 AB

Q27 VSKRA223M//-3 Transistor (KRA223M) 1 AB

Q40 VSKRA101M//-3 Transistor (KRA101M) 1 AB

Q60 VSKRC101M//-3 Transistor (KRC101M) 1 AB

Q90-91 VSKRA101M//-3 Transistor (KRA101M) 2 AB

R3-4 VRS-B13AA471J Resistor 470 ohm 1W 2 AA

R7-8 VRD-B12EF472J Resistor 4.7k ohm 1/4W 2 AA

R10-11 VRS-B13AA180J Resistor 18 ohm 1W 2 AA

R30 VRD-B12EF153J Resistor 15k ohm 1/4W 1 AA

R31 VRD-B12EF472J Resistor 4.7k ohm 1/4W 1 AA

R40 VRD-B12EF332J Resistor 3.3k ohm 1/4W 1 AA

R50 VRD-B12EF153J Resistor 15k ohm 1/4W 1 AA

R51 VRD-B12EF472J Resistor 4.7k ohm 1/4W 1 AA

R62 VRN-B12EK753F Resistor 75k ohm(F) 1/4W 1 AA

R63 VRN-B12EK101F Resistor 100 ohm(F) 1/4W 1 AA

R64 VRN-B12EK222F Resistor 2.2k ohm(F) 1/4W 1 AA

R70-81 VRD-B12EF332J Resistor 3.3k ohm 1/4W 12 AA

R90-94 VRD-B12EF104J Resistor 100k ohm 1/4W 5 AA

RY1-3 RRLY-A083DRE0 Relay (OMIF-S-118LM) 3 AK

RY4-6 RRLY-A078DRE0 Relay (OJ-SS-118LM) 3 AG

RY7 RRLY-A083DRE0 Relay (OMIF-S-118LM) 1 AK

SP40 RALM-A014DRE0 Buzzer (PKM22EPT) 1 AG

T1 RTRNPA089DRE0 Transformer 1 AU

VRS1 RH-VZA032DRE0 Varistor (10G471K) 1 AE

ZD3 VHEHZ5C2///-1 Zener diode (HZ5C-2) 1 AA

ZD4 VHEHZ4A2///-1 Zener diode (HZ4A2) 1 AA

3- 2 DPNLCB460WRK0 Control panel frame with key unit 1 BE

3- 2-1 FUNTKA836WRE0 Key unit 1 BA

3- 2-2 JBTN-B060WRF0 Open button 1 AF

3- 2-3 MSPRCA050WRE0 Open button spring 1 AB

3- 3 LANGTA340WRW0 Control panel back plate 1 AK

3- 4 MLEVFA057WRW0 Open lever 1 AE

3- 5 NSFTTA042WRE0 Open shaft 1 AE

3- 6 XEPSD30P10XS0 Screw ; control unit mtg. 3 AA

3- 7 XCPSD40P12000 Screw ; control panel back plate mtg. 2 AA

OVEN PARTS

4- 1 FOVN-A402WRY0 Oven cavity assembly 1 BV

4- 2 FROLPA072WRK0 Turntable support 1 AL

4- 3 NTNT-A019WRH0 Turntable tray 1 AT

4- 4 FBRGMA002WRE0 Bearing ass’y 1 AQ

4- 5 PREFHA028WRW0 Thermal protection plate (left) 1 AR

4- 6 LANGTA196WRW0 Bearing mounting plate 1 AD

4- 7 LBNDK0054WRE0 Heater element holder 2 AB

4- 8 LFIX-A013WRW0 Bearing holder plate 1 AB

4- 9 NFANMA019WRW0 Convection fan 1 AE

4-10 NPLYBA025WRF0 Pulley (F) 2 AC

4-11 FDUC-A279WRK0 Heater duct assembly 1 AT

4-12 PFPF-A138WRE0 Thermal protection sheet (left) 1 AK

4-13 LANGQA410WRP0 Thermal cut-out mounting plate 1 AG

4-14 PCUSUA167WRP0 Cushion 2 AF

4-15 PCUSUA424WRP0 Cushion 1 AG

4-16 PDUC-A680WRW0 Steam duct assembly 1 AY

4-17 MCAMPA030WRF0 Damper cam 1 AC

4-18 NSFTTA114WRE0 Damper shaft 1 AB

4-19 FFTA-A034WRK0 Damper door ass’y 1 AM

4-20 PDUC-A269WRW0 Damper duct 1 AK

4-21 PCUSGA410WRP0 Cushion 1 AD

4-22 NCPL-A021WRF0 Turntable coupling 1 AE

4-23 PCOVPA301WRE0 Waveguide cover 1 AE

4-24 PCUSUA197WRP0 Cushion 2 AD

4-25 PGLSPA485WRE0 Light glass 1 AF

4-26 PFPF-A139WRE0 Thermal protection sheet (Right) 1 AF

4-27 PREFHA053WRW0 Thermal protection plate (Right) 1 AP

4-28 PSKR-A153WRW0 Air guide (Bottom) 1 AK

4-29 PSKR-A329WRW0 Divide plate (Right) 1 AM

4-30 LANGQA407WRW0 Convection motor mounting plate 1 AG

4-31 LANGQA369WRP0 Thermal cut-out mounting angle 1 AC

4-32 NFANJA020WRE0 Fan blade 1 AE

4-33 PDUC-A270WRF0 Cooling fan duct 1 AL

4-34 LANGFA089WRW0 Chassis support 1 AE

4-35 MHNG-A165WRM0 Oven hinge (Upper) 1 AE

4-36 NBLTKA005WRE0 Convection fan belt 1 AF

4-37 LANGQA475WRP0 Noise unit angle 1 AR

∆