Sharp VZ-3000H User manual

Other Sharp Speakers manuals

Sharp

Sharp CD-C607H User manual

Sharp

Sharp GX-BT3 User manual

Sharp

Sharp AD-AT11ST User manual

Sharp

Sharp CD-C1W User manual

Sharp

Sharp GX-BT60 User manual

Sharp

Sharp PS-940 User manual

Sharp

Sharp HTSB200 - Sound Bar Speaker User manual

Sharp

Sharp GX-BT180 User manual

Sharp

Sharp Sound Partner User manual

Sharp

Sharp CD-C472 User manual

Sharp

Sharp CP-SS30 User manual

Sharp

Sharp CP-SS30BK User manual

Sharp

Sharp HT-SB106 User manual

Sharp

Sharp GX-BT280 User manual

Sharp

Sharp GX-BT9 User manual

Sharp

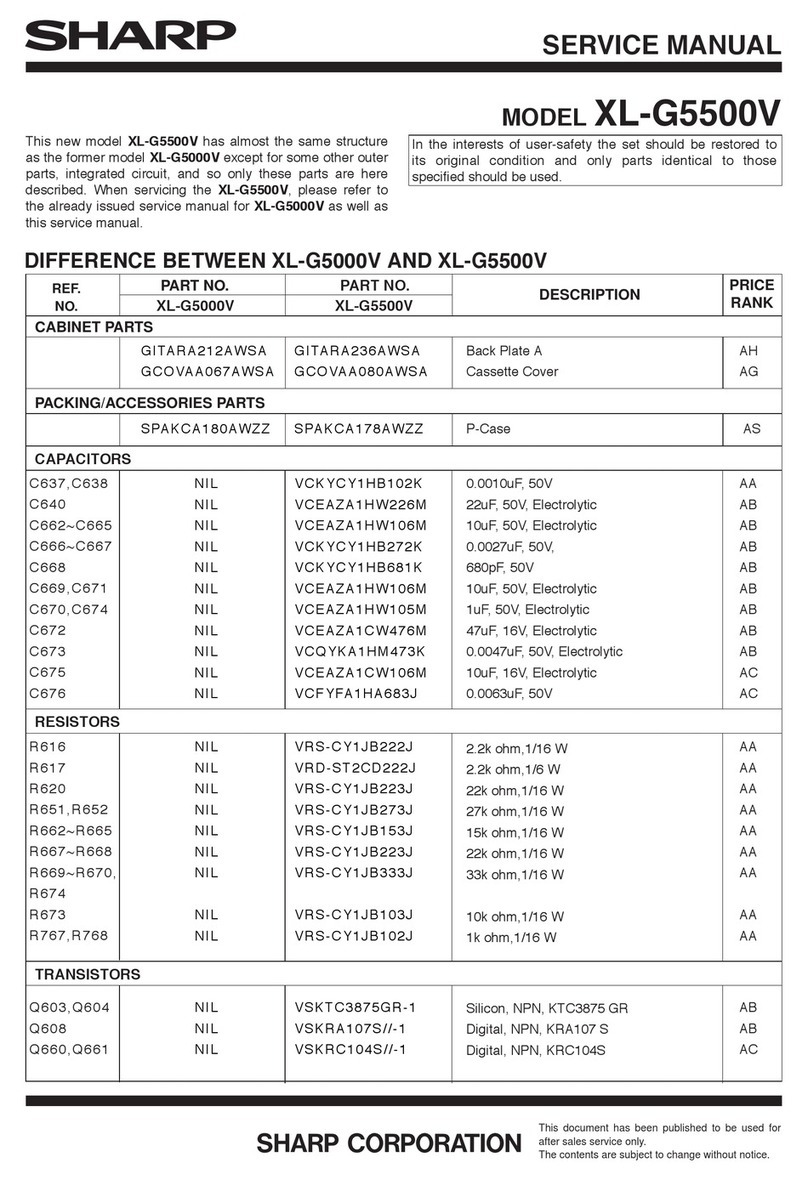

Sharp XL-G5500V User manual

Sharp

Sharp HT-SB500 User manual

Sharp

Sharp CD-M5000W User manual

Sharp

Sharp HT-SB600 User manual

Sharp

Sharp GX-BT180 User manual