8-1 8-2

8

21GT-22

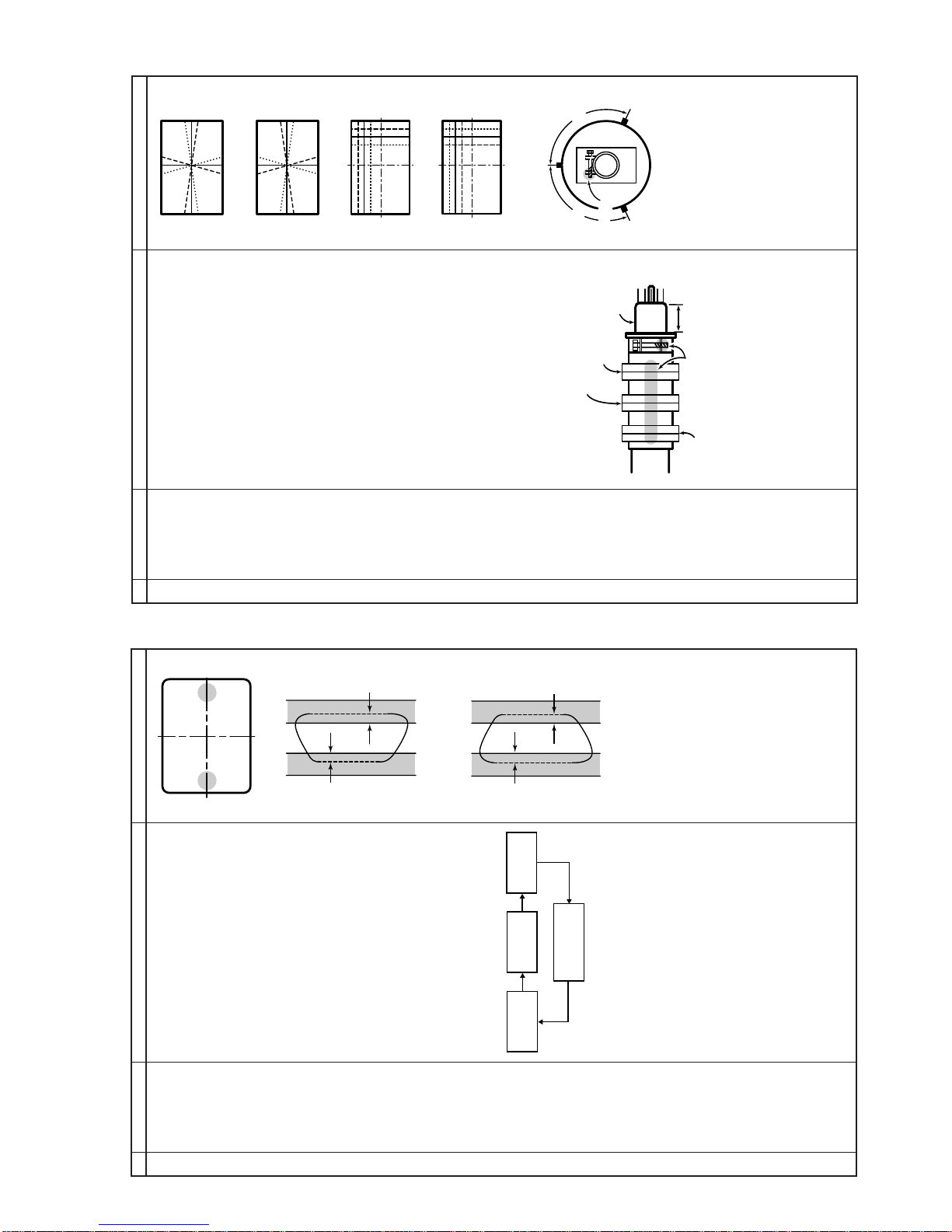

1. Call " SUB-BRI" in service mode. (Receive Cross-

hatch pattern with 5 black level windows)

2. Adjust the " SUB BRIGHT " bus data in order that

the line 1and 2 have the same darkness wherelse

line 3 is one step (data) brighter than line 2. Finally

data minus 1 to make line 1, 2, and 3 are in same

level (darkness).

Remark

1. Before CRT cutoff adjustment, SUB-BRIGHT, DRI-

RS/RW/RC, DRI-GS/GW/GC, DRI-BS/BW/BC,

CUT-R and CUT-G must be INITIAL DATA.

2. CRT Cutoff adjustment must be done inside a dark

room.

1. Switch TV to VIDEO mode,BLUE BACK OFF, with

NO VIDEO signal.

2. Press R/C to set Picture Normal condition.

3. First, off the screen by adjust screen variable resistor.

*4.Next,checkingAKB circuitfunction by slowlyincrease

screen variable resistor until colour raster suddenly

on and off (AKB start function).

5. Then continue adjust until retrace line appear.

6. Finally, slowly decrease the screen variable resistor

until screen retrace line cut off (Not Raster)

Note :

Must confirm theAKB function in set before continue

the next adjustment.

CRT CUT-OFF, BACKGROUND AND SUB-CONTRAST ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1

2 SUB-

BRIGHTNESS

ADJUSTMENT

(I2C BUS

CONTROL)

Line 3 is one step (data) brighter than line 2

CRT CUTOFF

ADJUSTMENT

(I2C BUS

CONTROL)

3 WHITE

BALANCE

SERVICE

MODE ADJ.

(I2C BUS

CONTROL)

1. Receive the "WHITE" pattern with BURST signal.

2. Press R/C to set Picture NORMAL condition.

3. Connect the DC miliammeter between TP602 (-)

TP603 (+).

4. Check Beam current should be around 1100 µA.

5. Set it to service mode and adjust the DRI-GS, & DRI-

BS data to have a colour temperature of 12300°K (

white ). * Note .

6. Receive "WHITE" pattern, WITH BURST signal, and

set BRIGHTNESS Y by generator, to **10 cd/m2

(MINOLTA CA-100) by reducing LUMINATE Y sig-

nal.

7. Adjust "CUT-R" & "CUT-G" to get desired colour tem-

perature #. Then go back NORMAL mode (HIGH

BRIGHT**) to check colour temperature.

If out of range, back to 1.

Note:This adjustment must be done after warm-

ing up the unit for 30 minutes or longer with

a beam current over 700µA.

* Adjust DRI-GC/GW, DRI-BC/BW as following DATA,

after finishing DRI-BS and DRI-GS DATAADJUST-

MENT.

DRI-RW = 32 (FIXED), DRI-RS = 32 (FIXED)

DRI-BC = "DRI-BS"

(For 12300°K Condition)

# 12300°K X : 0.272

Y : 0.275

(MINOLTACOLOURANALYZER CA-

100)

*Note:Above Data can be UP/DOWN

by Volume key.

LOW HIGH

21" 10cd/m2 120cd/m2

4 Max.

beam check 1. Receive the "Monoscope Pattern" signal.

2. Press R/C to set Picture NORMAL condition.

3. Connect the DC miliammeter between TP603 (+) &

TP602 (–).

(Full Scale: 3 mA Range)

4.

Beam current must be within 1100 ±100 µA.

1 2 3 4 5

t

3.2Vdc

0

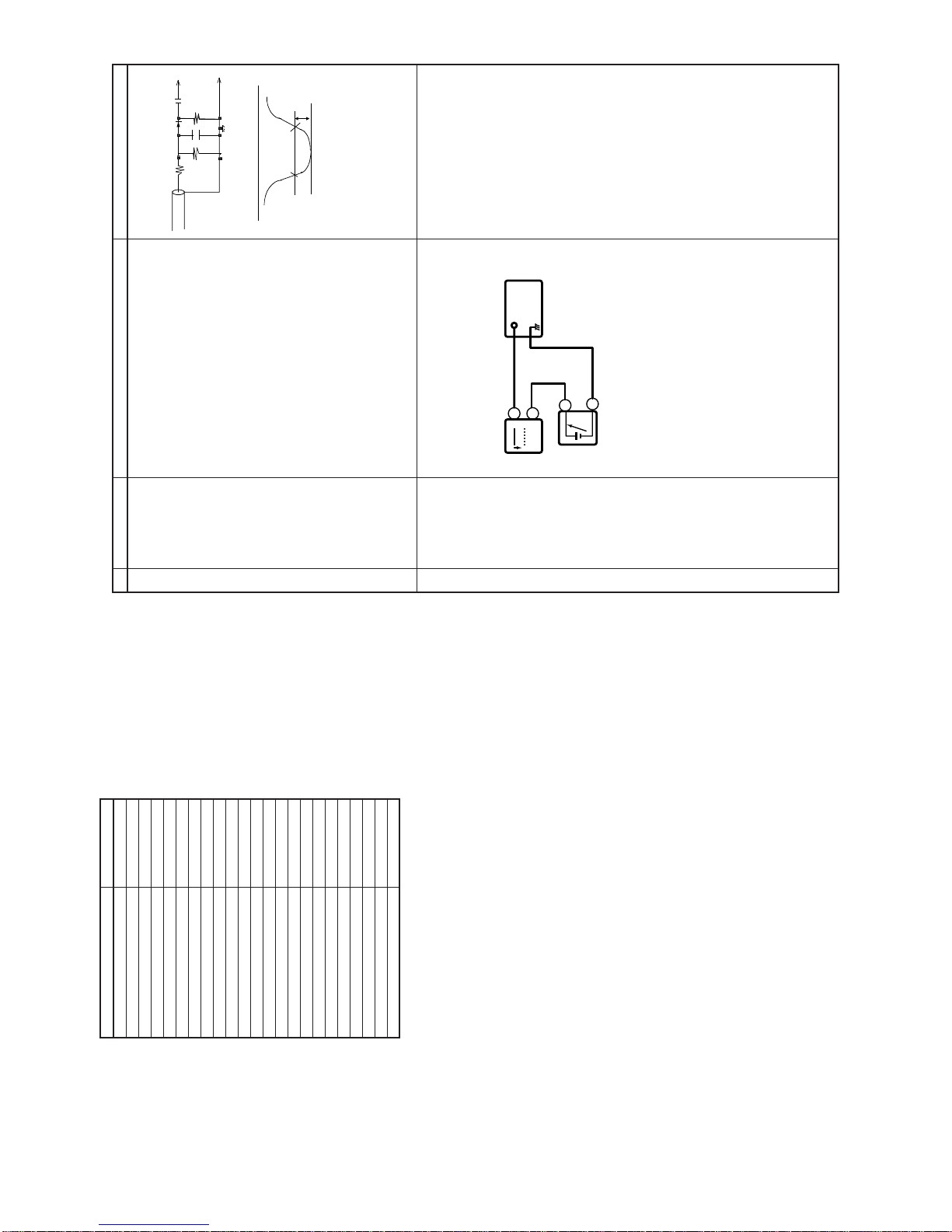

*Alternative Procedure

(1) Step (1), (2), (3) and (4) are same

as beside procedure.

(2) Then continue adjust until retrace

line appear and make sure the col-

our appear whether red, green or

biue.

(3) Connect the oscilloscope to related

test points as below which is based

on colour appear at (2) RED=TP47R,

GREEN=TP47G,BLUE=TP47B

(4) Then adjust Screen VR until the tip

of signal reach 3.2Vdc.

1 2 3 4 5

1

2

* 12300°K DRI-GW="DRI-GS"-7

DRI-BW="DRI-BS"-7

DRI-GC="DRI-GS"-7

DRI-RC=25

HORIZONTAL AND VERTICAL DEFLECTION LOOP ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1

2

3

4

5

6

V-SLOPE (I2C

BUS CON-

TROL)

V-SHIFT-50

(I2C BUS

CONTROL)

V-AMP50

(I2C BUS

CONTROL)

H-SHIFT (50)

(H-CENTER)

S-CORREC-

TION (I2C BUS

CONTROL)

SUB-

SHARPNESS

1. Receive Monoscope Pattern Signal.

2. Call the "V-LIN" mode.

3. Increase or decrease "V-LIN" by Volume key

till the horizontal line in the center of

monoscope is just at the position where the

blanking starts.

1. Call the "V-CENT" mode.

2. Increase or decrease "V-CENT" by Volume key

till the picture is centered.

1. Call the "V-AMP" mode.

2. Increase or decrease "V - AMP" by Volume

key to set overscan of 9.5% typical.

Adjustment Spec 9.5% range +1% -0%.

1. Call the "H-CENT" mode.

2. Increase or decrease"H-CENT"byVolume key

to center the picture horizontal.

1. SET DATA TO 20

* Check the E-5 CH Monoscope Pattern then re-

adjustV-Slope,V-Shift and V-Ampto makesure

adjustment is in acceptable Ring-Shaped.

1. SET DATA TO 20

PAL CHROMA ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1 SUB COLOUR

(I2C BUS

CONTROL)

1. Receive the "PAL Color Bar" signal.

2. Press R/C to set Picture Normal condition.

3. Connect the oscilloscope to

Red cathode(D882 Chathode) for 21" (Normal

Neck).

»Range : 20 V/div. (AC) (Using 10:1 probe)

»Sweep time : 10 µsec/div.

4. Using the R/C call "SUB COL" in SERVICE

mode.Adjust SUB COLOUR bus data, so that

the 75% White & Red portions of PAL Color

Bar be at the same level shown as Fig. 1-1.

5. Add another 6 steps up into the value of SUB-

COL obtained in 4.

6. Clear the SERVICE Mode.

1 Focus 1. Receive the "Monoscope Pattern" signal.

2. Press R/C to set Picture NORMAL condition.

3. Adjust the focus control to get the best focus-

ing.

Fig. 1-1

Cy GB

WY 100%W

75% Mg R