- 5 -

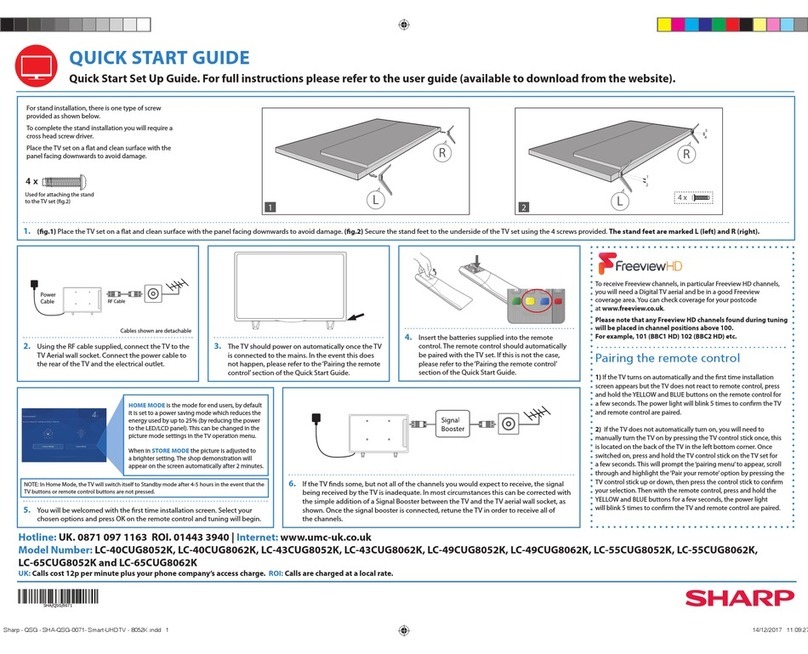

27J-S100/180/260

CJ27S10/26

VERIFICATIONS CONTRE L'INCEN-DIE ET

LE CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur,effectuer

les vérifications suivantes.

»Toucher avec la sonde d'essai les pièces métalliques

exposées qui présentent une voie de retour au

châssis (antenne, coffret métallique, tête des vis,

arbres de commande et des boutons, écusson, etc.)

et mesurer la chute de tension CA en-travers de la

résistance. Toutes les vérifications doivent être

refaites après avoir inversé la fiche du cordon

d'alimentation. (Si nécessaire, une prise d'adpatation

non polarisée peut être utilisée dans le but de

terminer ces vérifications.)

Tous les courants mesurés ne doivent pas dépasser

0.5 mA.

Dans le cas contraire, il y a une possibilité de choc

électrique qui doit être supprimée avant de rendre le

récepteur au client.

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

1

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

1

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les téléviseurs présentent des caractéristiques spéciales

relatives à la sécurité, qui ne sont souvent pas évidentes

à vue. Le degré de protection ne peut pas être

nécessairement augmentée en utilisant des pièces de

remplacement étalonnées pour haute tension,

puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel; les

pièces électriques qui présentent ces particularités sont

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

(Suite)

1. Inspecter tous les faisceaux de câbles pour s'assurer

que les fils ne soient pas pincés ou qu'un outil ne

soit pas placé entre le châssis et les autres pièces

métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme

les boutons de commande non-métalliques, les

isolants, le dos du coffret, les couvercles ou blindages

de réglage et de compartiment, les réseaux de

résistance-capacité, les isolateurs mécaniques, etc.

3. S'assurer qu'il n'y ait pas de danger d'électrocution

en vérifiant la fuite de courant, de la facon suivante:

»Brancher le cordon d'alimentation directem-ent à une

prise de courant de 120V. (Ne pas utiliser de

transformateur d'isolation pour cet essai).

»A l'aide de deux fils à pinces, brancher une résistance

de 1.5 kΩ10 watts en parallèle avec un condensateur

de 0,15µF en série avec toutes les pièces métalliques

exposées du coffret et une terre connue comme une

conduite électrique ou une prise de terre branchée à

la terre.

»Utiliser un voltmètre CA d'une sensibilité d'au moins

5000Ω/V pour mesurer la chute de tension en travers

de la résistance.

1.5k ohm

10w

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS CONNECT TO

KNOWN EARTH

GROUND

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

identifiées par la marque " å" et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques.

Pour assurer la protection, ces pièces doivent être

identiques à celles utilisées dans le circuit d'origine.

L'utilisation de pièces qui n'ont pas les mêmes

caractéristiques que les pièces recommandées par

l'usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies, radiations X ou autres

accidents.

VoltmètreCA