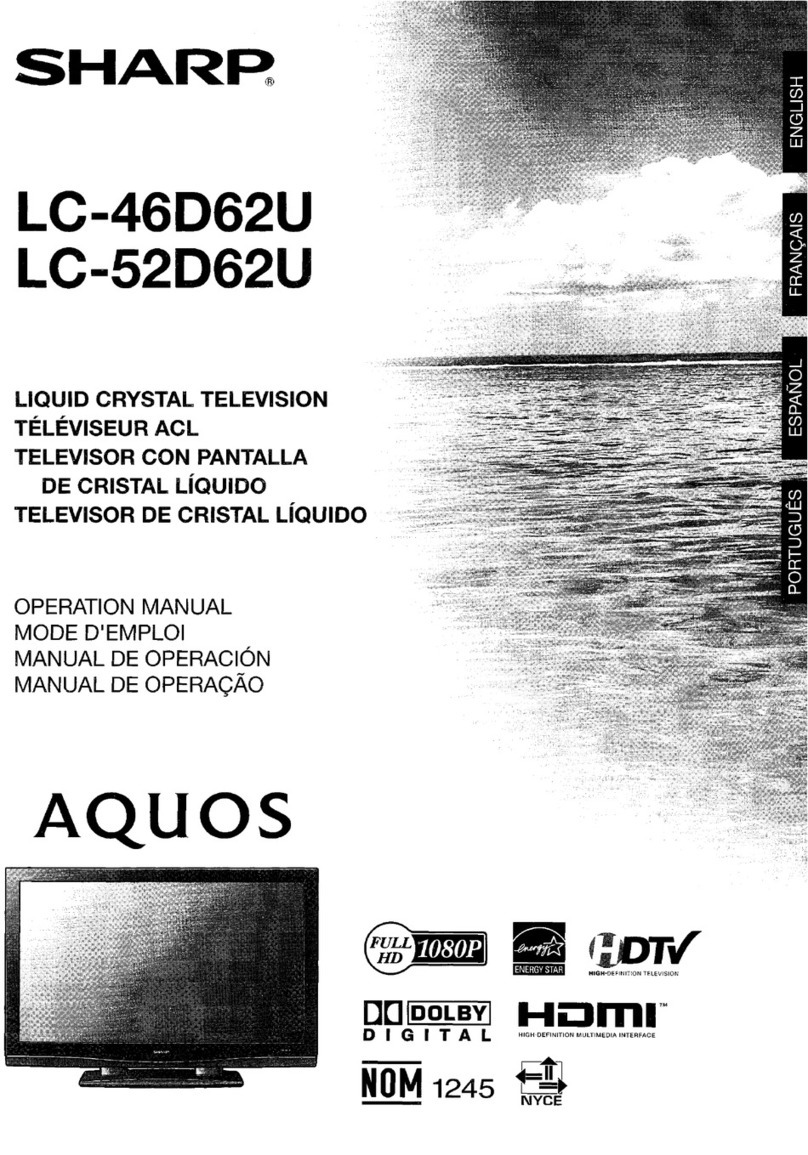

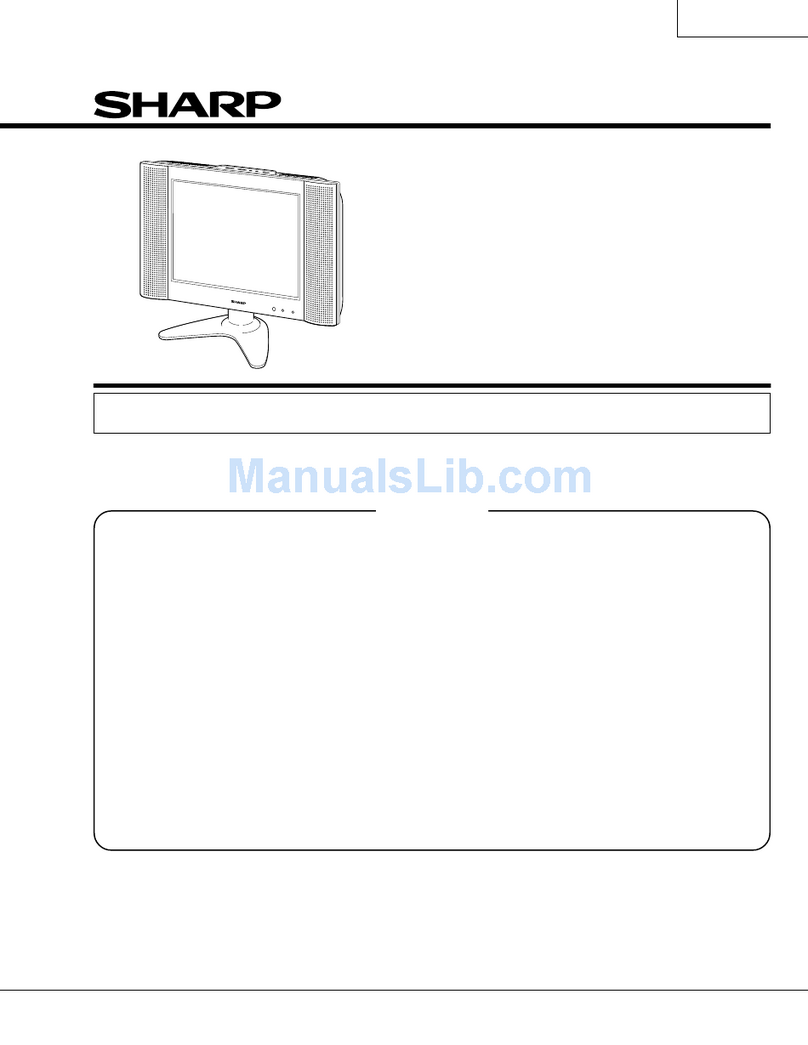

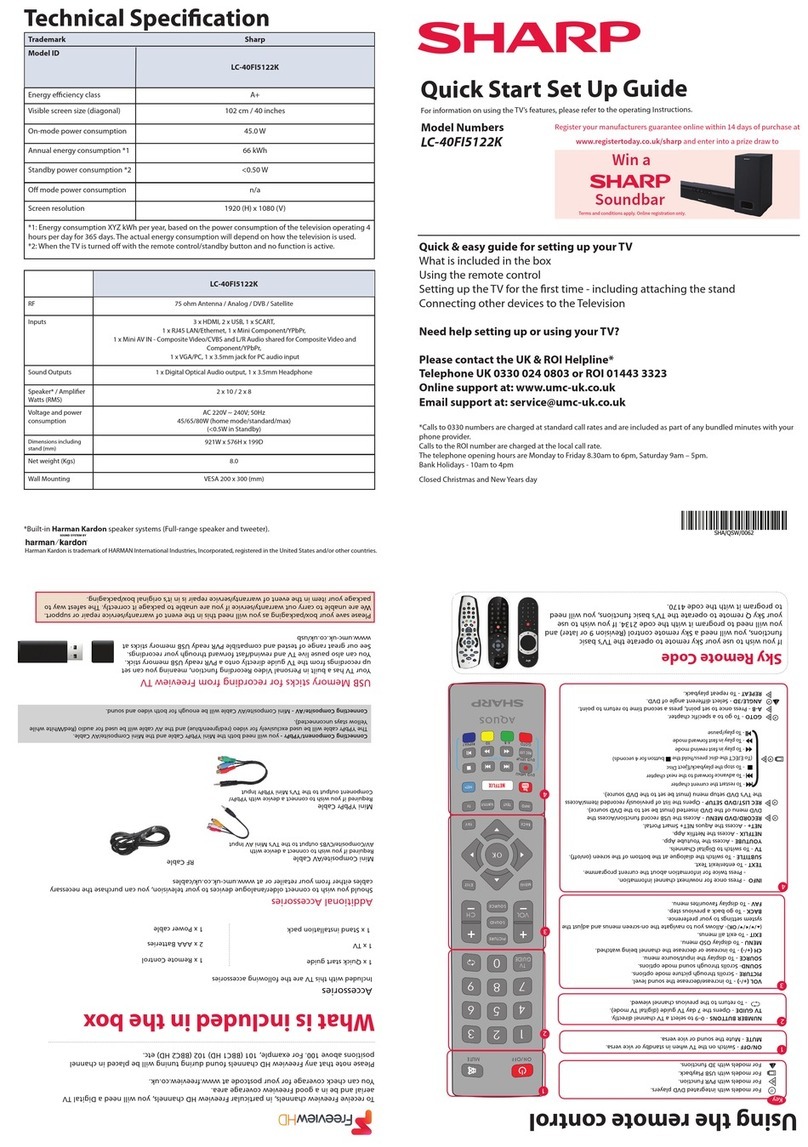

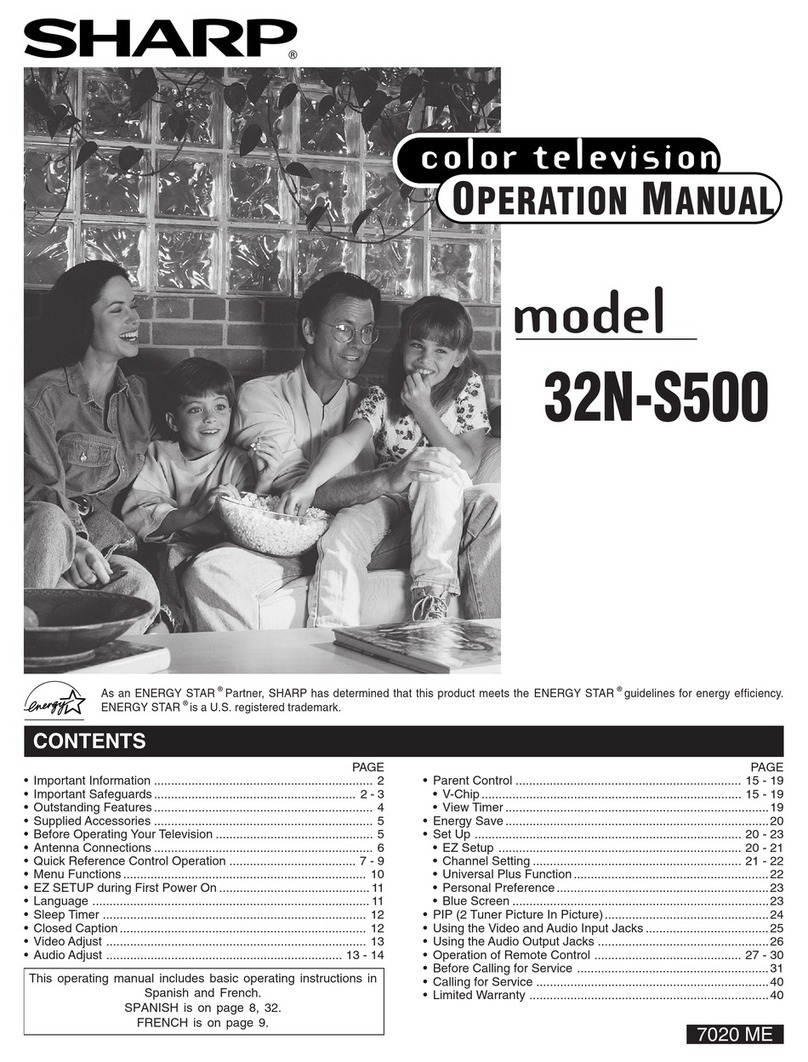

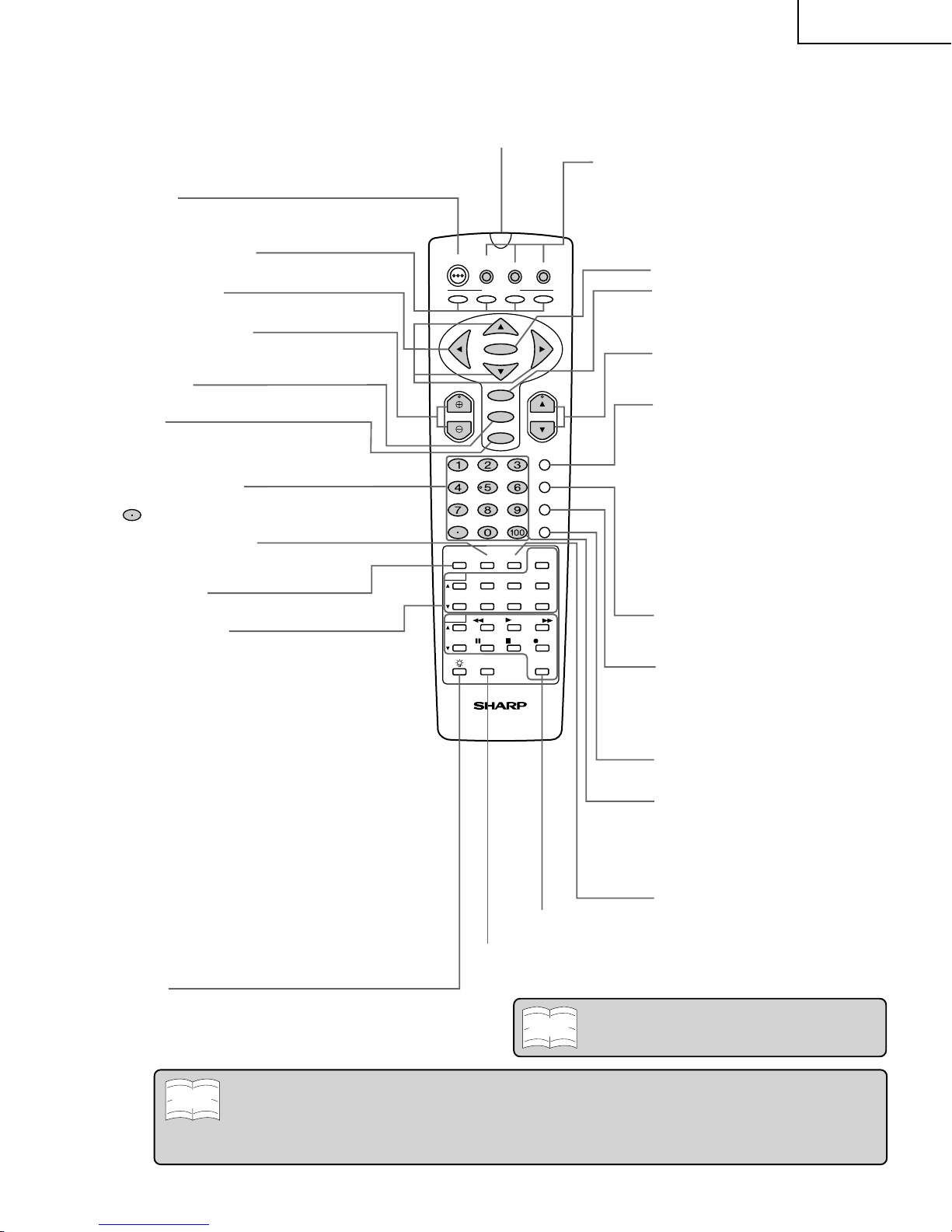

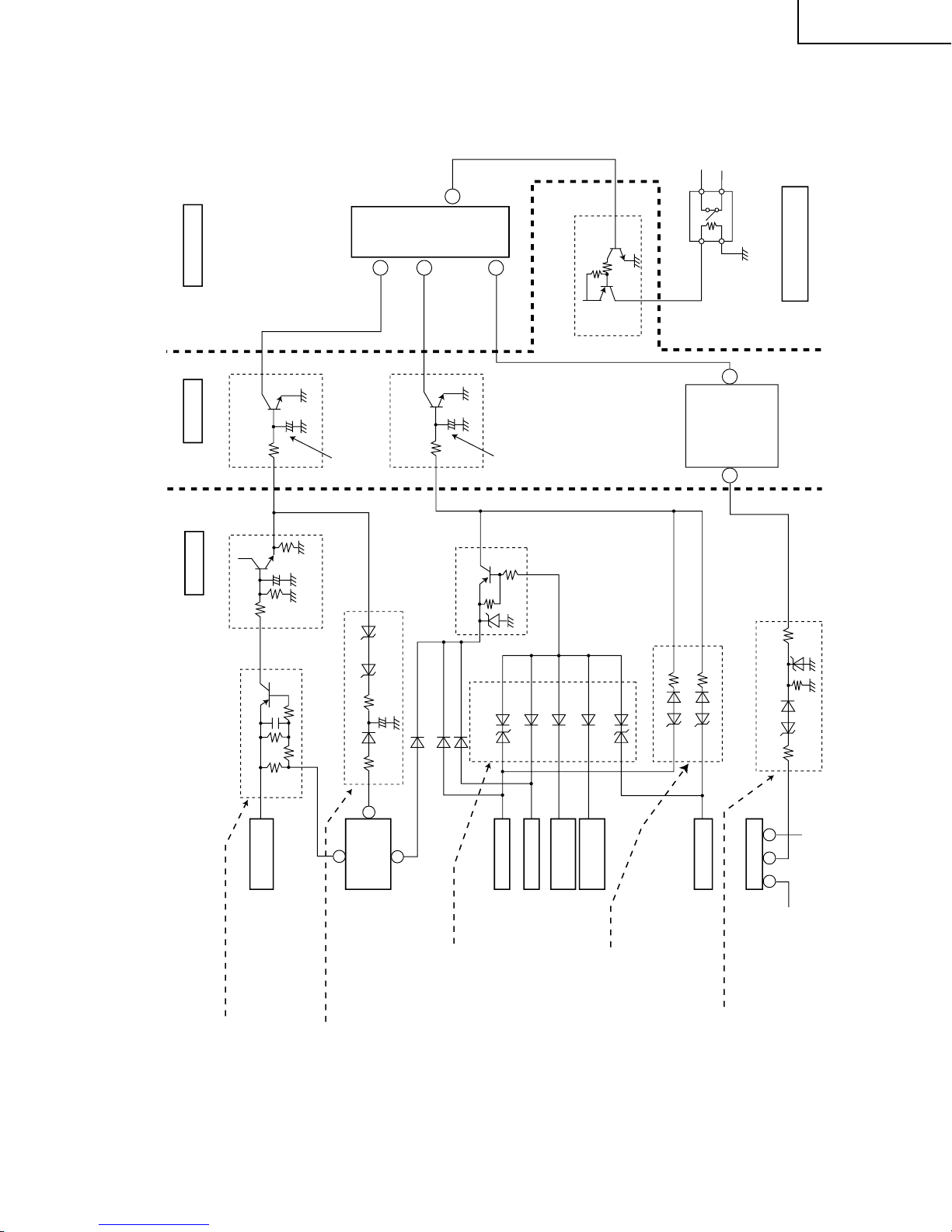

DTV

STB

POWER

TV

A

ENTER

MENU

VOL CH

AV MODE

MUTE

INPUT

ANT-A/B

DISPLAY

FLASHBACK

ENT.

CC

PLAY FF

POP

REW

PAUSE

STOP REC

SEARCH

SELECT

DDFC

G1550CE

TWIN CH

VIEW

MODE TWIN

PICTURE

VCR

POWER

MTS/SAP

L - TWIN ZOOM - R

SWAP FREEZE

BCD

CATV

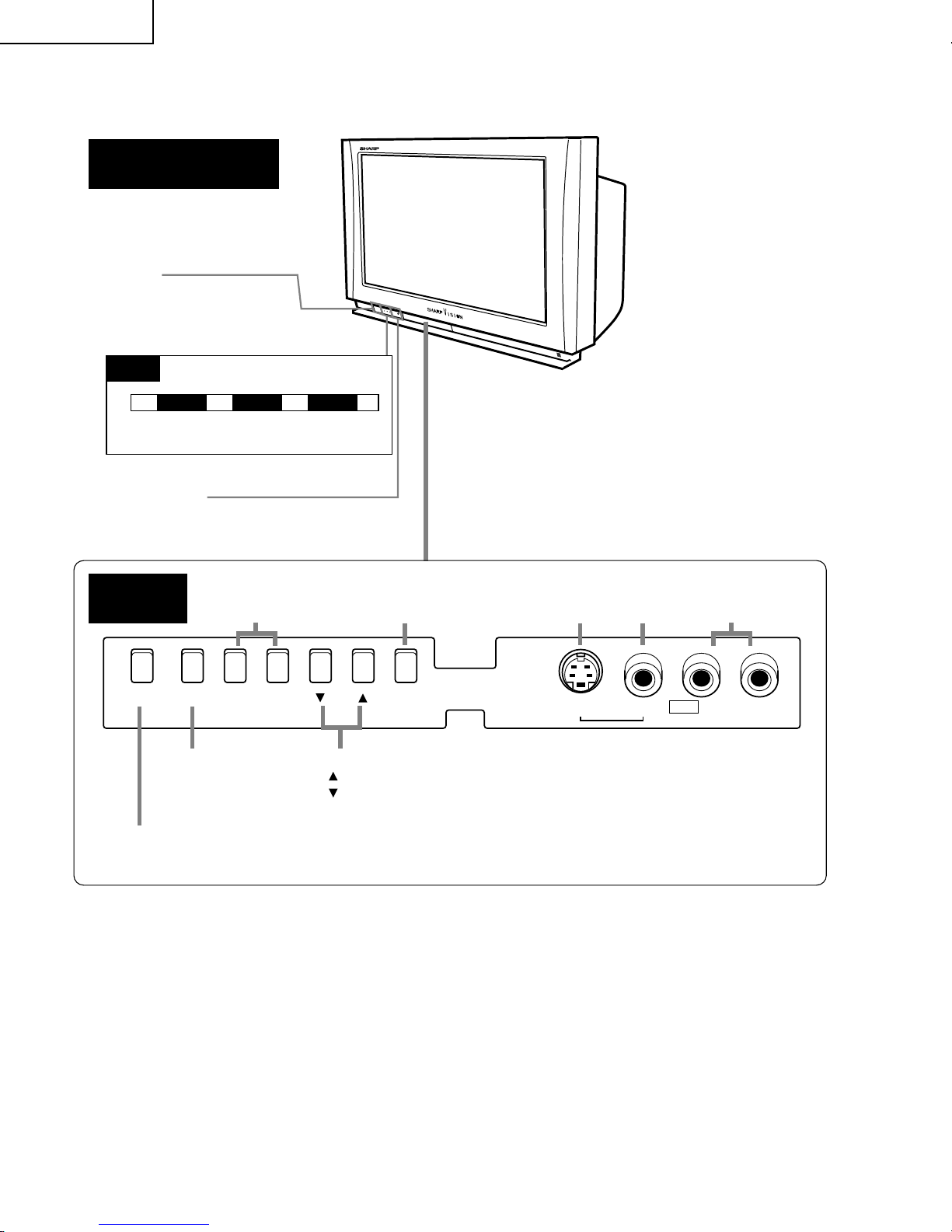

HD-Ready TV

VCR CH

FAVORITES

VCR

INPUT

Press →Switches to external video

INPUT 1 mode.

Press again →Switches to external video

INPUT 2 mode.

Press 3 times →Switches to external video

INPUT 3 mode.

Press 4 times →Switches to external video

INPUT 4 mode.

Press 5 times →Switches to external video

INPUT 5 mode.

Press 6 times →Switches back to the

original TV mode.

POWER

Press →On.

Press again →Off. (Stand-by)

FAVORITES buttons

•

Used to select any of four preset channels.

Cursor buttons

Used to move cursor on menu screen.

ENTER button

CHANNEL UP/DOWN

(+) Selects next higher channel.

(–) Selects next lower channel.

VOLUME UP/DOWN

(+) Increases sound.

(–) Decreases sound.

MENU

Press →Accesses MAIN MENU.

Press again →Exits MAIN MENU.

AV MODE

MUTE

Press →Mutes sound.

Press again →Restores sound.

•

CLOSED CAPTION appears when sound is muted.

DIRECT ACCESS

Accesses any channel by the keypad.

button: Sharp DTV Decoder only

ENT.

Used in some instances where a VCR or

Cable Converter Box requires an “enter”

command after selecting channels, when

using the DIRECT ACCESS button.

DISPLAY

Press →Displays receiving channel for 4

seconds.

Press again →Displays remaining time of

SLEEP TIMER and VIEW

TIMER for 4 seconds.

FLASHBACK

Returns to previously viewed channel.

VIEW MODE

Select view size.

CC (Closed Caption)

Displays captions during

closed-caption broadcasts.

MTS/SAP

MTS/SAP select

VCR CONTROL

DDFC

Used to select High-quality image.

LIGHT

When this button is pressed , some buttons on the

remote control unit will light. The lighting will turn off if no

operations are performed within about six seconds. This

button is used for performing operations in dark places.

ANT-A/B button

Press to switch between ANTENNA-A and

ANTENNA-B when you wish to watch TV.

Remote control mode select buttons

Use to switch the remote control unit modes.

•

This remote control can be used to operate the TV,

a DTV/STB Decoder and a Cable TV converter.

•

By selecting one of the three mode select buttons,

this remote control can be used to adjust common

functions, such as channel selection, for that device.

INFRARED TRANSMITTER WINDOW

POP FUNCTION

With the VIDEO inputs, you can watch two pictures at

the same time.

"-TWIN CH-': Used to switch the channel for the

sub-picture of the TWIN PICTURE

screen.

TWIN PICTURE: Press to turn the TWIN PICTURE

screen function on and off.

SEARCH: Press to select the SEARCH

screen mode.

SELECT: Selects the screen for switching

the channel or input source.

FREEZE: When this button is pressed with

the regular screen, will change to the

TWIN PICTURE screen and the

picture at the time the button was

pressed will become the sub-picture,

displayed as a frozen image.

L-TWIN ZOOM: The left screen is enlarged with the

TWIN PICTURE function.

TWIN ZOOM-R: The right screen is enlarged with the

TWIN PICTURE function.

SWAP: The left and right screens are

interchanged with the TWIN

PICTURE function.

Note

For use of this remote control with an analog TV.

Note

•The above shaded buttons on the Remote Control glow in the dark. To use the glow-in-the-dark display on the

remote control, place it under a fluorescent light or other lighting.

•The phosphorescent material contains no radioactive or toxic material, so it is safe to use.

•The degree of illumination will vary depending on the strength of lighting used.

•The degree of illumination will decrease with time and depending on the temperature.

•The time needed to charge the phosphorescent display will vary depending on the surrounding lighting.