ADJUSTMENT WATER TEMPERATURE

1. Using the temperature control button.

1.1. The heater will automatically set the default temperature when starts. The factory value is 34oC

which can be modified according to user preferences by adjust the water temperature to the

desired temperature and lock the temperature by holding any of the temperature control button

for 3 seconds. The temperature indicator will flash 3 times.

* Do not set to high default temperature as children may turn on the heater by themselves and

get hurt.

1.2. Changing from the default temperature can simply be done by pressing the temperature control

button up and down to adjust the temperature according the preference, which can be set

between 32oC - 48oC. When pressed, the “beep” tone will be heard and the temperature will

change by a degree.

1.3. The temperature indicator displays the preset temperature.

1.4. The new temperature can be adjusted anytime. If you do not want to bath at the default

temperature, see section 1.2.

1.5. The heater will remember the preset temperature during the bath though the heater has been

turned off temporary. (The heater will revert back to the default temperature if it is off for more

than 2.5 minutes).

4

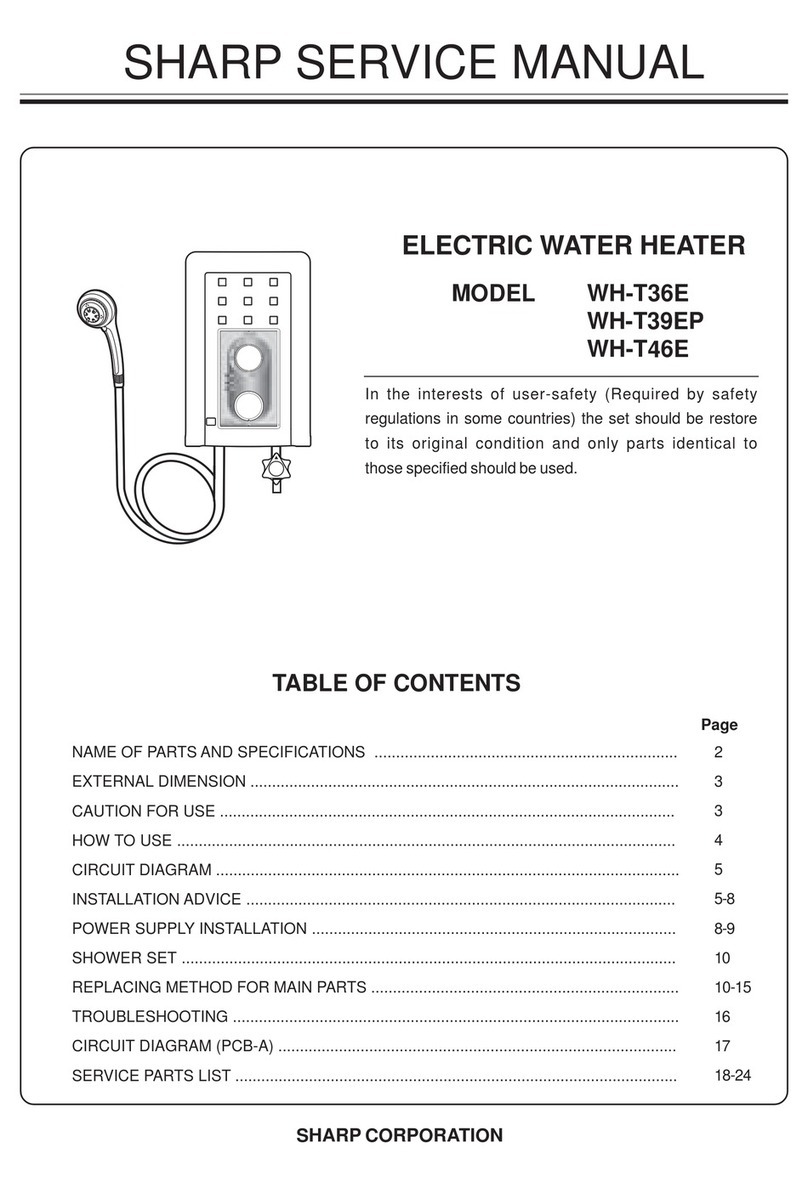

HOW TO USE

BEFORE USE

The installation work is to be done by the Authorized “SHARP” Dealer.

The electric home shower unit must earthed.

Special skill is required. Never try to repair the unit by yourself.

1. Open the main water valve from the home main water pipe.

2. Open the main breaker switch.

3. Push up ELB breaker to activate the heater electrical system.

4. Press the Power SW. button on the heater. Normal temperature water will flow and the ELB lamp

indicator (green) will illuminate.

5. Turn the water volume knob clockwise or counterclockwise to increase or decrease water from the

shower head (see the water volume knob detail in water temperature adjustment).

6. Press the temperature button to adjust the desired temperature. The power lamp (red) will be

illuminated and the warm water will flow from the shower head (see the detail in water temperature

adjustment).

7. After use, press the Power SW. button to shut the heater off and water will stop flowing and the

electricity will be cut. For the next use, just simply press the Power SW. button and the water will

flow at the prevailing volume and temperature.

Note : In case of electricity or tap water outage while using, always press the Power SW. button

before leaving the bathroom.

ELB lamp

Power lamp

ELB checker button

Control lamp

Temperature button