Shelbourne Powerspread Pro 1800-2300 User manual

Issue 6 16/05/2018

1800 –3200 GALLON

OPERATORS MANUAL

ORIGINAL INSTRUCTIONS

MAN-06000

POWERSPREAD PRO

Issue 2

12.04.18

DEALER PRE-DELIVERY / INSTALLATION CHECK AND WARRANTY REGISTRATION –POWERSPREAD

DEALERS PRE-DELIVERY / INSTALLATION CHECK

IMPORTANT ⚠

All items listed below must be checked, and adjusted if necessary. The person conducting the inspection should tick each

item in the space provided, indicating whether or not adjustments were required. In the event of additional work being

needed, details should be given in the additional work / discrepancy box, located at the bottom of this sheet, or on a

separate sheet if required. When the inspection is complete, THIS FORM MUST BE COPIED & RETURNED TO: -

Shelbourne Reynolds within 30 days of delivery to customer, otherwise the invoice date to the dealer will be deemed to

be the start date for the warranty period.

SERIAL NUMBER: ......................................................... MACHINE NUMBER: ..........................................................

MODEL: .........................................................................

PLEASE TICK APPROPRIATE COLUMN FOR EACH ITEM UNDERTAKEN

Dealer Pre Customer Delivery / Installation / Commissioning

Checks OK

Adjusted

Check the PTO shaft length is compatible with the tractor.

Rotate the auger & check there is no unusual scratching or knocking sounds.

Ensure the chain-oiler system (Contractor only) is working correctly, & the chains are pre-greased.

Check chains are tensioned correctly.

Rotate the impeller, check it rotates freely, and is clear of the door and drip tray. Adjust impeller blades

(Dairy) or impeller adjuster studs (Contractor & Pro) as required.

Ensure the hoses are not taught when connected to the tractor.

Check operation of all hydraulic services.

Check hydraulic system for leaks.

Check brake ram operation & adjustment.

Check braking system for oil leaks.

Check tyre pressures.

Check wheel nuts for correct torque setting.

Check operation of handbrake.

Lubricate all grease points.

Check in general that nuts & bolts are tight.

Check paintwork & finish.

Ensure that all safety guards & decals are fitted.

Ensure that an operator‟s manual is supplied with the machine.

Additional Comments:

...........................................................................................................................................................................................

..........................................................................................................................................................................................

Dealer Representative‟s Name: ..............................................................................................

Date: .........................................

Customer Instruction

Actioned

Explain the correct setting & operation of the machine to the customer.

Ensure the machine is correctly attached to the customer‟s tractor.

Ensure the maintenance schedule is explained to the customer.

Ensure the lubrication & grease points are indicated to the customer.

Ensure all safety precautions & warning decals are explained to the customer.

Ensure the warranty policy is explained to the customer.

Ensure that the operators manual is handed to the customer.

Additional Comments:

...........................................................................................................................................................................................

...........................................................................................................................................................................................

Dealer Representative‟s Name: .............................................................................................

Date: .........................................

For specific details please refer to the operator’s manual. Page 1 of 2

Issue 2

12.04.18

DEALER PRE-DELIVERY / INSTALLATION CHECK AND WARRANTY REGISTRATION –POWERSPREAD

Dealer Name: ............................................................................

Address: .........................................................................................................................................................................

.........................................................................................................................................................................

Post / Zip code: .........................................................................

Dealer Salesman Name: ............................................................

Customer Name: ......................................................................

Business Name (if different from above): ............................................................................................................................

Address: .........................................................................................................................................................................

.........................................................................................................................................................................

Post / Zip code: ........................................................................

Email Address: ........................................................................

Tel No. Home / Office: ............................................................... Cell / Mobile:...................................................................

SERIAL NUMBER: ....................................................................MACHINE NUMBER: ......................................................

MODEL: ..................................................................................

Dealer Signature: ...................................................................

Print Name: .......................................................................... Date:.................................................................................

Privacy Notice

Here at Shelbourne Reynolds Engineering Ltd we take your privacy seriously and will only use your personal information to administer your account and

provide the products and services you have requested from us.

We would occasionally like to contact you with details of other products you may be interested in, special offers we provide and details/invitations to

shows, working demonstrations and open days, however this would be no more than once or twice per year. If you consent to us contacting you for this

purpose please tick a box or boxes to say how you would like us to contact you.

Post Email Telephone/SMS

If you prefer not to be contacted, then please tick this box

For further information please refer to our Privacy Policy at www.shelbourne.com

Customers Signature: .............................................................

Print Name:........................................................................... Date:.............................................................

The customer’s signature certifies that the machine was delivered in a satisfactory condition and that adequate instruction was received as to

its correct operation, safety requirements, and maintenance as stated in the operator’s manual, and that the customer has read, understood,

and agrees to the Terms and Conditions of Sale and Warranty (including the disclaimers and limitations) contained in Section 1.5 of the

operator’s manual.

Additional work / discrepancies:

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

This page must be faxed or emailed to Shelbourne Reynolds Engineering Ltd.

Fax No: +44 (0)1359 250464 Email: warranty@shelbourne.com

Page 2 of 2

Dear Customer,

Parts manuals are not supplied with this machine, but they can be ordered from your Shelbourne

Reynolds dealer. Alternatively they can be downloaded from the Shelbourne Reynolds website

www.shelbourne.com by clicking on the Parts and Service section of the website, and then

selecting manuals followed by Powerspread Manuals.

The Machine and Parts Manual number for your machine is:

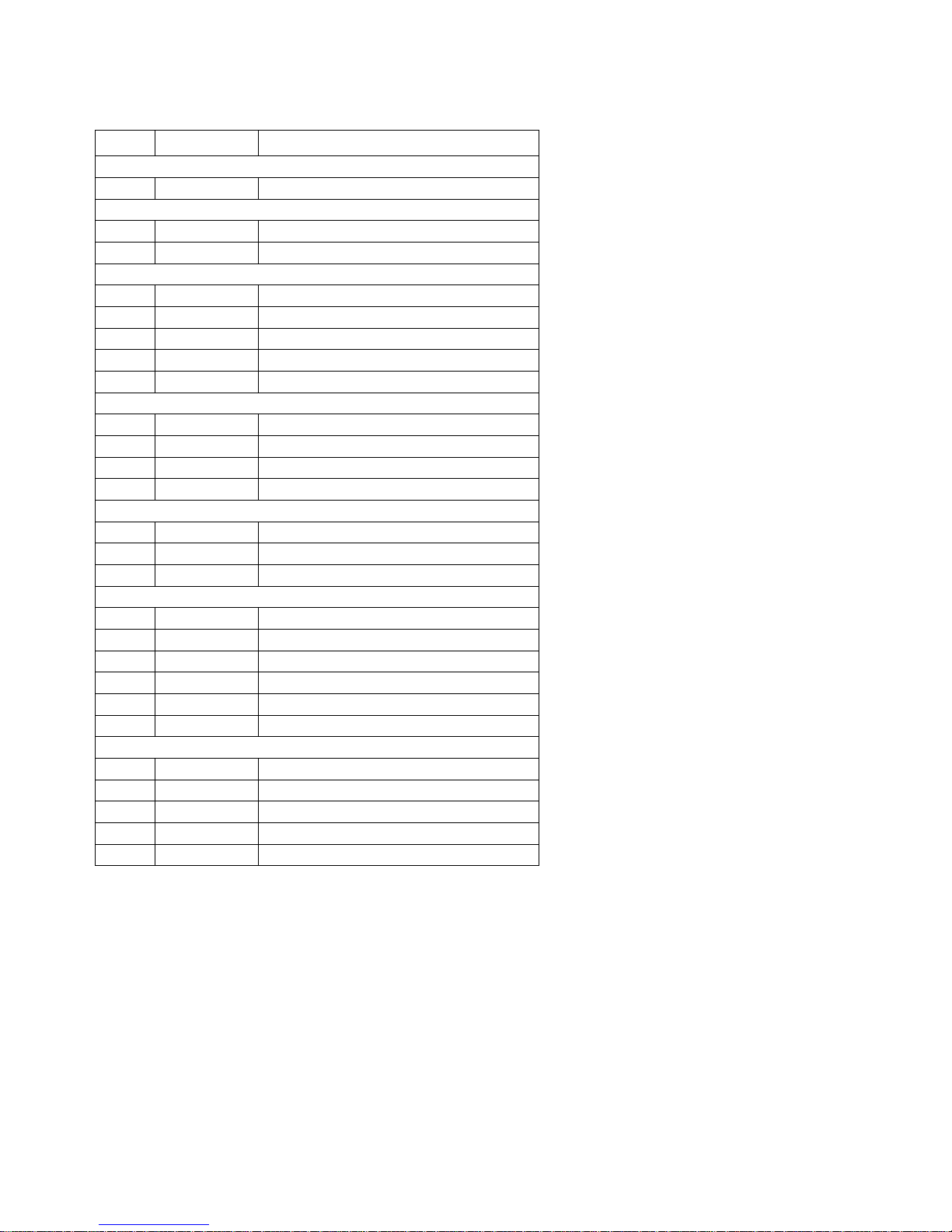

Tick

Machine No.

Manual No.

Machine Description

609905 01

MAN-06100

Powerspread Pro 2400-3200

609905 02

MAN-06100

Powerspread Pro 1800-2300

Powerspread Pro Serial Number

ORDERING SPARE PARTS

To ensure you order the correct part from your SRE dealer please use the following procedure:

ALWAYS QUOTE THE MACHINE AND SERIAL NUMBERS WHEN ORDERING.

Refer to the Parts Manuals front page/s, listing the machine numbers. Select the correct machine

number which is printed in the top left corner of the page (starting with 6099_ _ 01). Your

machines number is listed above or can be found printed on the identification plate located on the

LH side of the front sheet of the tub.

Scan down the page, and select the relevant sub assembly your required part falls within. Sub-

assemblies start from 6090_ _ 01. Note the year or serial number of the machine may determine a

correct sub assembly if more than one is listed.

Continue through the manual and find the relevant sub assembly parts listing. Again the number

will be printed in the top left corner; the sub-assemblies are in numerical order.

Having found the correct parts list, you will find the corresponding drawing by either looking at the

facing page or progressing through the manual to the next drawing.

The drawings indicate the components by item numbers, which you will find, are repeated in the

left-hand side of your parts listing, and therefore referring to the correct part.

Please note that if certain parts cannot be found listed below the sub-assembly numbers, they are

likely to form part of a specific optional kit. These kits will be found in numerical order further

through the manual and start with KIT- _ _ _ _ _.

The tick list located on the following page of this manual will highlight the optional build kits that

were specified with your machine.

PSP

OPTIONAL BUILD KIT LISTING

Tick

Part No.

Description

PTO Shaft Options

KIT-03799a

Wide angle PTO shaft

Towing Eye / Drawbar Options

KIT-03742

Heavy duty UK tow eye

KIT-03764

Heavy duty UK drawbar

Wheel & Tyre Options

KIT-03643

650/65-R30.5 Trelleborg

KIT-03883

560/60-22.5 8 Tandem

KIT-03914

560/60-22.5 10 Tandem

KIT-03892

620/75 R26 Standard

KIT-03915

650/65 R30.5 Trelleborg

Axle Options

KIT-03806

Single hydraulic axle (2400-3200)

KIT-03807

Tandem rear steering hydraulic axle (2400-3200)

KIT-03808

Single hydraulic axle (1800-2300)

KIT-03913

Tandem rear steering hydraulic axle (2400-3200)

Extension / Slurry canopy Options

KIT-03784

Slurry canopy kit (1800-3200)

KIT-03891

Extension side kit (1800-2300)

KIT-03911

Extension side kit (2400-3200)

Anti-bridge kit Options

KIT-03823

Anti-bridging kit (2400-3200)

KIT-03823a

Anti-bridging kit (1800-2300)

KIT-03824

Automatic hydraulic kit (All models)

KIT-03825

Manual hydraulics kit (All models)

KIT-03762

Anti-bridge rear pivot kit (2400-3200)

KIT-03762a

Anti-bridge rear pivot kit (1800-2300)

Other Options

KIT-03745

Straw plate kit (2400-3200)

KIT-03749

Transfers kit

KIT-03770

Blanking plate kit (1800-2300)

KIT-03771

Blanking plate kit (2400-3200)

KIT-03771a

Blanking plate kit (2400-3200)

EC Declaration of conformity for machinery

(Machinery Directive 2006/42/EC, Annex II., sub. A)

Manufacturer: Shelbourne Reynolds Engineering Ltd.

Address: Shepherds Grove Industrial estate,

Stanton,

Bury St Edmunds,

Suffolk.

England.

IP31 2AR

Name and address of the person (established in the European Community/EEA)

authorised to compile the technical file (to the authorities on request):

Name: Mr Neil Smith

Address: As stated above.

Herewith we declare that: DESIGNATION MANURE SPREADER

MAKE: POWERSPREAD PRO

MACHINE No: 609905

SERIAL No: PSP

is in conformity with the relevant provisions of the Machinery Directive (2006/42/EC)

Neil Smith

Director

Place : Stanton, England. Date :

1

2

CONTENTS PAGE

Section 1 INTRODUCTION

1.1 FOREWORD.

1.2 IMPROVEMENTS AND CHANGES.

1.3 SERVICE PARTS.

1.4 MACHINE IDENTIFICATION.

1.5 STANDARD WARRANTY POLICY.

Section 2 SAFETY PROCEDURES

2.1 ACCIDENT PREVENTION.

2.2 SAFETY SIGNS.

2.3 ACCIDENT PREVENTION BEFORE STARTING THE MACHINE.

2.4 ACCIDENT PREVENTION WHEN COUPLING & UNCOUPLING TO THE

TRACTOR.

2.5 ACCIDENT PREVENTION WHEN USING THE HYDRAULIC SYSTEM.

2.6 ACCIDENT PREVENTION WHEN USING THE PTO SHAFT.

2.7 ACCIDENT PREVENTION WHEN OPERATING THE MACHINE.

2.8 ACCIDENT PREVENTION WHEN TAKING ON PUBLIC ROADS.

2.9 ACCIDENT PREVENTION WHEN LEAVING THE MACHINE.

2.10 ACCIDENT PREVENTION WHEN CHANGING A WHEEL.

2.11 ACCIDENT PREVENTION WHEN REMOVING A FOREIGN OBJECT

FROM THE MACHINE.

2.12 ACCIDENT PREVENTION WHEN SERVICING OR WORKING ON THE

MACHINE.

2.13 ACCIDENT PREVENTION WHEN CLEANING & STORING THE

MACHINE.

2.14 NOISE EMISSIONS.

2.15 PROPER USE.

2.16 NO LIABILITY FOR CONSEQUENTIAL DAMAGE.

Section 3 SPECIFICATION AND DESCRIPTION

3.1 DESCRIPTION.

3.2 INTENDED USE.

3.3 FEATURES & BENEFITS.

3.4 TECHNICAL SPECIFICATIONS.

Section 4 HANDLING &TRANSPORTATION

4.1 HANDLING

4.2 TRANSPORTATION

3

Section 5 PREPARATION FOR USE

5.1 ADJUSTING THE DRAWBAR HEIGHT.

5.2 RAISING THE DETACHABLE PARKING FOOT.

5.3 ADJUSTING THE PTO DRIVE SHAFT LENGTH.

5.4 COUPLING & UNCOUPLING

5.5 CONNECTING THE HYDRAULIC SUPPLY

5.6 CONNECTING THE POWER SUPPLY

5.7 USING THE HANDBRAKE

5.8 RAISING & LOWERING THE LADDER EXTENSION

5.9 CHECK BEFORE USE.

Section 6 FIELD OPERATION AND SPREADING

6.1 GENERAL WEIGHTS OF DIFFERENT MATERIALS.

6.2 LOADING THE MACHINE

6.3 DISCHARGE RATE

6.4 DOOR OPENING SETTINGS

6.5 SETTING THE SPREADING DEFLECTOR.

6.6 PROCEDURE FOR SPREADING

6.7 OPERATING THE ANTI-BRIDGE ARM

6.8 REMOVING FOREIGN OBJECTS FROM THE MACHINE.

6.9 SHEARBOLT PROTECTION

6.10 AUGER REVERSING FACILITY.

6.11 LOWERING THE IMPELLER.

6.12 SHEARBOLT PROTECTED AUGER PADDLES

6.13 OPERATING THE STEERING AXLE

Section 7 ADJUSTMENTS AND MAINTENANCE

7.1 IMPELLER BLADE ADJUSTMENT

7.2 DRIVE CHAIN TENSIONING

7.3 CHECK / TIGHTENING WHEEL NUTS.

7.4 ELECTRICAL WIRING DIAGRAMS

7.5 TYRE PRESSURES.

7.6 MAINTAINING THE HYDRAULIC SYSTEM

7.7 RECOMMENDED TORQUE FOR FASTENERS

7.8 CHECKING THE AXLE HUBCAPS.

7.9 CHECKING THE WHEEL BEARINGS.

7.10 CHECKING BRAKE CLEARANCE & WEAR.

7.11 MAINTENANCE OF THE STEERING AXLE

7.12 MAINTENANCE OF THE BOGIE SUSPENSION

7.13 CHANGING A WHEEL.

7.14 STORAGE & CLEANING.

Section 8 LUBRICATION

4

SECTION 1 INTRODUCTION

1.1 FOREWORD

This manual will aid the user when setting, operating and servicing their Shelbourne

Reynolds Powerspread Pro. Scheduled information is listed to ensure the operator

follows safe and efficient working procedures. It must be read & understood by all

persons who are required to carry out work either on or with the machine, and should be

used in conjunction with the operator‟s manual of the tractor or prime mover.

1.2 IMPROVEMENTS AND CHANGES

Shelbourne Reynolds Engineering are continually improving their products to meet the

farmers needs and therefore reserve the right to make improvements and changes

when practical to do so, without incurring any obligation to make changes and additions

to equipment which has been sold previously.

1.3 SERVICE PARTS

Use guaranteed and genuine Shelbourne Reynolds Engineering service parts on

Shelbourne Reynolds machinery to ensure maximum life and best performance. These

are available through your Shelbourne Reynolds Engineering dealer.

When ordering service parts always quote the model, serial number and machine

number.

5

1.4 MACHINE IDENTIFICATION

The serial and machine numbers of the Powerspread Pro spreaders are printed on a

plate located on the left hand side of the machine.

6

1.5 STANDARD WARRANTY POLICY

NEW MACHINE WARRANTY

All new machines supplied by Shelbourne Reynolds Engineering Ltd.

(“Shelbourne”), are warranted to the original purchaser (who is not the Shelbourne

dealer), under normal use and service, to be free from defects in material and

workmanship for a period of 12 months from the date of delivery to the original

purchaser (“Warranty Period”). This limited warranty gives you specific legal rights and

is in addition to any statutory rights to which you may be entitled. Your statutory rights

are not affected by this warranty.

To qualify for the full benefit of this warranty, the dealer must ensure that the

warranty registration details have been returned to Shelbourne within 30 days

from the date of delivery. Using the machine implies the knowledge and

acceptance of these instructions and the limitations contained here in this

Manual. Shelbourne reserves the right to suspend the operation of these warranty

conditions unless and until the purchaser has paid in full for the goods or parts in

question.

WARRANTY CLAIMS

If the original purchaser:

1) gives notice in writing to Shelbourne during the Warranty Period, and within a

reasonable time of discovery, that the machine supplied does not comply with the

warranty given above;

2) gives Shelbourne a reasonable opportunity of examining the machine or the

damaged or defective parts; and

3) if requested by Shelbourne, returns damaged or defective parts (via the original

authorised Shelbourne dealer) within 30 days of notification of a defect,

then Shelbourne shall, at is option, repair or replace the defective machine or parts, or

refund the price of the defective machine in full.

If Shelbourne authorises the original purchaser to arrange a repair of the machine, all

claims for repair costs must be submitted to Shelbourne by an authorised Shelbourne

dealer within 15 days of the date of the repair on a Shelbourne Warranty Claim Form.

The submission of a claim is not a guarantee of payment. Any decision reached by

Shelbourne is final.

This Warranty Policy does not give the original purchaser any additional rights other

than those specified above. In particular, Shelbourne shall not be liable for any loss of

profit, loss of or damage to goodwill, loss of contract business or business opportunity,

or indirect or consequential loss, arising from any failure by a machine to comply with

the terms of this warranty.

7

LIMITATIONS AND EXCLUSIONS

Shelbourne will not be liable for the machine‟s failure to comply with this warranty in any

of the following circumstances:

1) any repairs or modifications are carried out without Shelbourne‟s prior consent to

the work being done;

2) where damage or depreciation caused by normal wear and tear;

3) where any non-genuine Shelbourne parts have been fitted or used within the

machine,

4) wilful or accidental damage, damage caused by foreign objects (e.g. stones,

metals and any materials other than those suitable for the machines intended

use).

5) where damage or depreciation is caused by neglect or failure to carry out proper

maintenance as recommended in the Shelbourne Operators Manual.

6) where damage or depreciation caused by abnormal or in-proper use in

accordance with Shelbourne recommendations and/or as per the Operating

Instructions.

7) where the original purchaser or any third party continues to use the machine after

notifying a defect to Shelbourne, or after becoming aware of such a defect.

This warranty shall not apply in respect of:

1) chains, bearings or any other items which are considered to be a normal wearing

or consumable item; and

2) items not manufactured by Shelbourne such as trade accessories e.g. tyres,

belts, hydraulic motors, hydraulic valves, PTO shafts etc. are warranted by their

respective manufacturer.

TRANSFER OF WARRANTY

Shelbourne may at its sole discretion allow this warranty to be transferred to a

subsequent owner of the machinery for the balance of the warranty period, subject to all

of the warranty conditions being met and only with Shelbourne giving prior written

consent.

WARRANTY ON PARTS

Shelbourne warrants that any part or components supplied by Shelbourne in

accordance with this limited warranty are free from defects in material or workmanship

from the date of sale to the original purchaser for 6 months. Shelbourne will at its option,

either repair or replace the defective part free of charge. Original Purchaser shall be

8

responsible for labour and all freight charges to and from the place where the warranty

work is performed.

Shelbourne Reynolds Engineering Ltd. cannot be held responsible for any

failures or safety implications arising from the use of non-genuine parts. Use of

non-genuine parts may seriously affect the machine’s performance and safety.

9

SECTION 2: SAFETY PROCEDURES

2.1 ACCIDENT PREVENTION

The following safety instructions are applicable for all sections of this manual.

Accident prevention programmes can only avert accidents with the co-operation of the

persons responsible for the operation of the equipment.

For the safety of yourself and others, operate equipment with care and do not take

unnecessary risks.

Please read all safety instructions contained in this operating manual with the utmost

care and observe all safety signs attached to the Powermix.

Follow these instructions to help prevent accidents. These instructions must also be

made available to all other users.

The tractor‟s manufacturer‟s operator‟s manual and listed safety precautions should also

be adhered to when using the Powermix.

All relevant accident prevention regulations governing the operation of agricultural

machinery, as well as other generally acknowledged health and safety regulations and

road traffic regulations must be strictly observed.

The „Safe stop‟ procedure is mentioned throughout this manual. It is extremely

dangerous to carry out any work on a machine while it is under power. The most

important safety measure to follow is the Safe Stop procedure; use it before carrying out

any maintenance or adjustments, including dealing with a blockage or other problem:

The procedure is as follows:

Put the tractors handbrake on.

Make sure the tractors controls are in neutral (equipment made safe).

Stop the engine (or turn off the power).

Remove the key (or lock-off the power supply).

CAUTION

This symbol will appear throughout this manual whenever your safety, the safety

of others or the machinery, is involved.

10

2.2 SAFETY SIGNS

The following safety signs appear on the machine, they provide important instructions

for safe work. –Take them into consideration for your safety and the safety of others.

Ensure that you identify each symbol and understand its warning.

Attached to the PTO guards are additional safety signs, refer to the driveshaft operators

manual for their meaning.

These safety signs must be kept in a legible condition and must be replaced if

missing or damaged. This is especially the case when whole sections are

replaced when making repairs. Replacement safety signs are available as spare

parts through your dealer or importer.

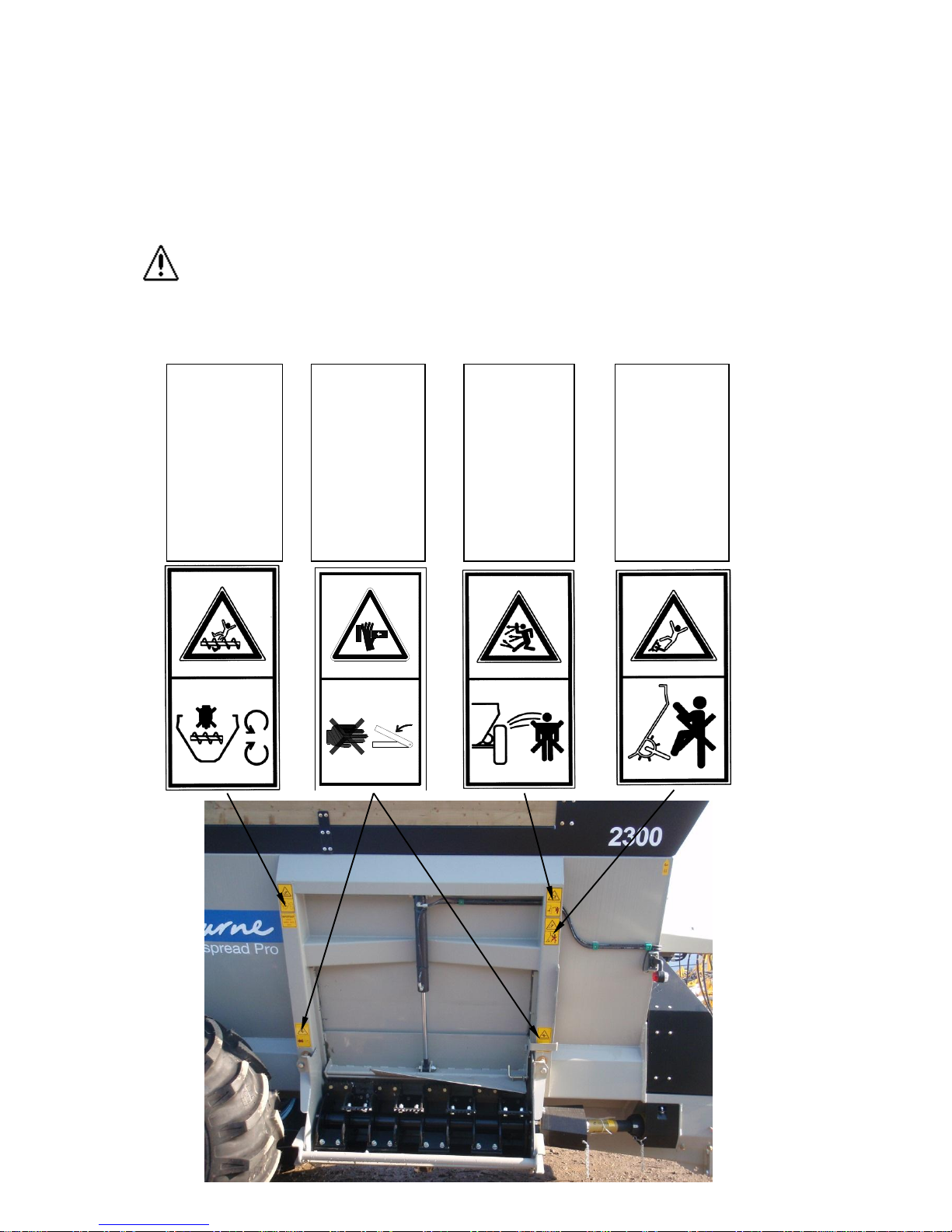

SAFETY SIGNS

800215 01

There is a crushing

hazard, between the

frame of the

impeller and the

door frame of the

tub when

hydraulically raising

the impeller

assembly.

590479 01

Beware of rotating

auger. Do not reach

or lean into tub. Do

not attempt to clear

blockage when the

tractor engine is

running. Serious

injury may result

from falling into the

tub with auger

rotating.

(Also located on LH

side & rear of

machine)

590476 01

Do not use safety

rail on the impeller

as a step. Serious

injury may result

from slipping or

falling into the

impeller.

590477 01

Ensure there are

no persons

standing in the

vicinity of the

machine when the

tractor engine is

running. Serious

injury may result

from rotating parts

and flying objects.

800215 01

There is a crushing

hazard between the

frame of the

impeller and the

door frame of the

tub when

hydraulically raising

the impeller

assembly.

11

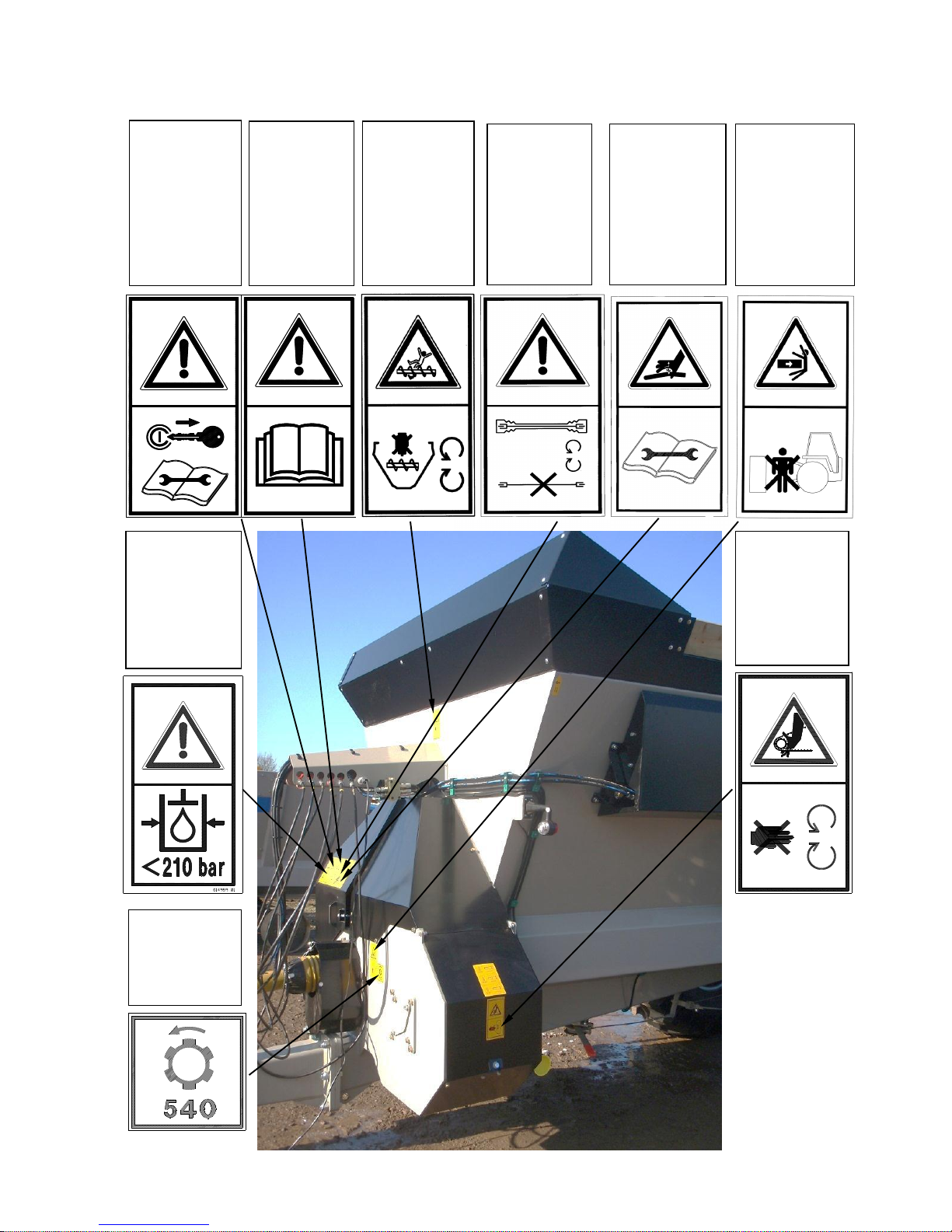

TNF-0011

Carefully read the

operating manual

before handling

the machine.

TNF-0011

Stop the engine

and remove the

key from the

tractor‟s ignition

before carrying out

any work on the

machine.

590475 01

The rotational

speed of the PTO

Drive shaft must

not be greater than

the speed stated.

614959 01

Ensure hydraulic

components are not

exposed to more

than 210bar of

pressure. There is a

risk of explosive

damage to hoses

and other

components.

800221 01

Hydraulic oil is

dangerous when

under pressure and

can be injected into

the body. Always

ensure the hoses

are in good order

before operating.

260060 01

Risk of crushing

torso. Do not stand

between

Powerspread and

tractor when hitching

to tractor.

590479 01

Beware of rotating

auger. Do not

reach or lean into

tub. Do not attempt

to clear blockage

when the tractor

engine is running.

Serious injury may

result from falling

into the tub with

auger rotating.

193392 01

Do not open or

remove safety

guard while engine

is running. There is

a risk of hand

entanglement.

193391 01

Ensure PTO shaft

guards are fitted

and chains

attached.

12

2.3 ACCIDENT PREVENTION BEFORE STARTING THE MACHINE.

Read the manual thoroughly.

If moving the Powerspread by overhead lifting, use the designated lifting points. (See

section 4.1). Ensure that the slings / chains are rated accordingly, and that the angles of

the slings / chains are set in accordance to lifting regulations.

Ensure bystanders are at a safe distance when the Powerspread is being suspended

above the ground while lifting and unloading.

Pay particular attention to the width of the machine while unloading the machine from

the delivery trailer. A portion of the tyre may overhang the bed of the trailer, so care

must be taken to keep the machine central, whilst moving.

Ensure bystanders are at a safe distance while moving the Powerspread from the

delivery trailer using a tractor.

Ensure the hydraulic brakes are attached to the tractor before attempting to move the

Powerspread.

Ensure a suitably sized tractor is used to move the Powerspread.

Ensure the tractor is fitted with Mirrors to guarantee the lateral visibility on both sides of

the machine.

Ensure the machine is parked on a firm & level site and the handbrake is applied.

Do not carry out any PDI work without appropriate protective clothing and long hair tied

back. (Gloves, safety boots, close fitting clothing etc.)

Review the PDI checklist, printed at the start of this manual. Check the items listed. Pay

particular attention to checking wheel nuts & tyre pressures, along with checking the

hydraulics and braking systems.

Before adjusting the position of the tow eye ensure the machine is parked on a firm &

level site, with the handbrake applied. Ensure the machine is uncoupled from the tractor

and is sitting securely on the parking foot. The tow eye weighs 35kg; therefor suitable

lifting apparatus is advisable to take the weight while the fixing bolts are removed.

If the length of the PTO shaft needs adjusting always follow relevant workshop & power

tool health and safety procedures / guidelines.

Follow appropriate manual handling procedures, when lifting PTO shaft.

Check there are no foreign objects inside the machine.

Always perform an internal inspection inside, around and under the machine before

attempting to start, transport or load the machine.

The Powerspread may be used only if all safety devices, e.g. detachable guards, are

fitted and in proper working order.

Familiarise yourself with the controls and functions of the machine and practice them in

a safe location before attempting to start work.

13

2.4 ACCIDENT PREVENTION WHEN COUPLING AND UNCOUPLING TO THE

TRACTOR.

The work of coupling and uncoupling the Powerspread involves a high risk of injury

Follow the procedure described in section 5.4 for further information.

Ensure the pickup hitch of the tractor is rated to withstand the maximum load seen at

the drawbar, and that it matches the drawbar eye of the Powerspread.

Ensure the max permissible rear axle load of the tractor will not be exceeded by the

weight of the Powerspread.

Ensure the machine is parked on a firm level site for attaching and detaching, ensure

the handbrake of the Powerpsread is applied.

Check that all observers are clear of the Powerspread and tractor. Warn bystanders by

sounding the horn of the tractor several times.

Slowly drive the tractor towards the Powerspread –always ensure that there are no

other persons in the vicinity or between the machine and the tractor.

Connect the Powerspread to the tractor hitch using only the method recommended in

the tractor‟s operator manual.

Ensure there is sufficient clearance between the PTO shaft and the drawbar when

turning on undulating ground.

Ensure the machine is parked on a firm & level site, and the „safe stop‟ procedure is

followed before raising / lowering the parking foot. This is to ensure that the unit does

not unexpectedly move while the operator or person is in close proximity to the machine

Be aware of the pinch point between the parking foot and the drawbar while raising the

parking foot.

Never leave the driver seat whilst the tractor or machine is running.

Ensure the machine is parked on a firm & level site and the „safe stop‟ procedure is

followed before checking the operation of the rear road lights and before connecting /

disconnecting the power supply. This is to ensure that the unit does not unexpectedly

move while the operator or person is in close proximity to the machine.

2.5 ACCIDENT PREVENTION WHEN USING THE HYDRAULIC SYSTEM

Ensure the machine is parked on a firm & level site and the „safe stop‟ procedure is

followed before connecting / disconnecting the hydraulic couplings. This is to ensure

that the unit does not unexpectedly move while the operator or person is in close

proximity to the machine.

Do not connect to tractor‟s hydraulic system if it can deliver more than 210 bar.

Due to the possibility of oil contamination on your hands / contact with hot or

pressurised oil, it is recommended to use PPE (Personnel Protective Equipment), when

handling hydraulic hoses & connectors.

Do not connect the hydraulic hoses to the tractor‟s hydraulic system until you have

made sure that the system is at zero pressure on both the tractor and the Powerspread.

Do not check the hydraulic system for leaks unless the system is at zero pressure.

This manual suits for next models

1

Table of contents

Other Shelbourne Farm Equipment manuals

Popular Farm Equipment manuals by other brands

MacDon

MacDon NEW HOLLAND D2 Series Unloading and assembly instructions

GREAT PLAINS

GREAT PLAINS TURBO-TILL II Series Predelivery Manual

Precision Manufacturing Inc.

Precision Manufacturing Inc. Add-A-Grapple Operator's manual

Knight

Knight 1800V Series Operating and maintenance manual

Monosem

Monosem TFC 2 user manual

DeLaval

DeLaval SCB3 Instruction book