Shelbourne Cubicle bedder Series User manual

MAN-i

3200

ider

MODELS

120,

200,

320

OPERATORS

MANUAL

&

PARTS

LIST

____

EYN

0

LD

S

Shelbourne

Reynolds

Engineering

Ltd

Stanton

Suffolk

lP3l

2AR

England

Telephone:

(01359)

250415

Fax: (01359)

250464

(Stores

direct

Tel

:(01359) 251231)

(Stores

direct

Fax:

(01359)

252031)

ISSUE

5

21.08.2008

visit

our

website

www.shelbourne.com

MANUFACTURERS

ADDRESS:

SHELBOURNE

REYNOLDS ENGINEERING

LTD.

SHEPHERDS

GROVE

INDUSTRIAL

ESTATE,

STANTON,

BURY

ST.

EDMUNDS,

SUFFOLK.

1P31

2AR

ENGLAND.

MACHINE

SPECIFICATION:

MAKE:

MODEL:

SERIAL

NO:

Cubbicle

Bedder

L

DIRECTIVES COMPLIED

WITH:

MACHINERY

DIRECTIVE

981371EC

APPLIED

HARMONISED

STANDARDS:

BS

EN

292

PARTI

BS

EN

294:

1992

BS

EN

349:1993

&

2:

1991

SHELBOURNE

REYNOLDS

SIGNATORY:

ERIC

TAYLOR

OPERATIONS

DIRECTOR

DATE:

EC

DECLARATION

OF

CONFORMITY

PLACE

:

Stanton,

England.

PARTS

AND

OPERATORS

MANUAL

CONTENTS

Section

1

INTRODUCTION

1.1

Foreword

1.2

Improvements and

changes

1.3

Service

Parts

1.4

Machine

Identification

1.5

Warranty

Section

2

SAFETY

PROCEDURES

2.1

Accident

prevention

2.2

Before

starting

the

machine

2.3

The

machine

in

use

2.4 Leaving

the

machine

2.5

Servicing

the

Cubicle

Bedder

2.6

Machine

attachment

Section

3

SPECIFICATION

AND

DESCRIPTION

3.1

Description

3.2

Intended

use

3.3

Technical

Specification

Section

4

TRANSPORTATION

Section

5

PREPARATION FOR

USE

5.1

Checks

5.2

Attaching

to

tractor

I

handler

5.3

Removal

from

tractor

/

handler

Section

6

OPERATION

6.1

Metering

plates

6.2

Side

plates

6.3

Agitator

tines

6.4 Loading

the machine

6.5 Discharging

the

bedding

material

6.6

Discharge

rates

6.7

Spread

distance

and pattern

Section

7

MAINTENANCE

7.1

Lubrication

7.2

Belt

tension

7.3

Storage

Section

8

PARTS

LISTINGS

1

SECTION

1

INTRODUCTION

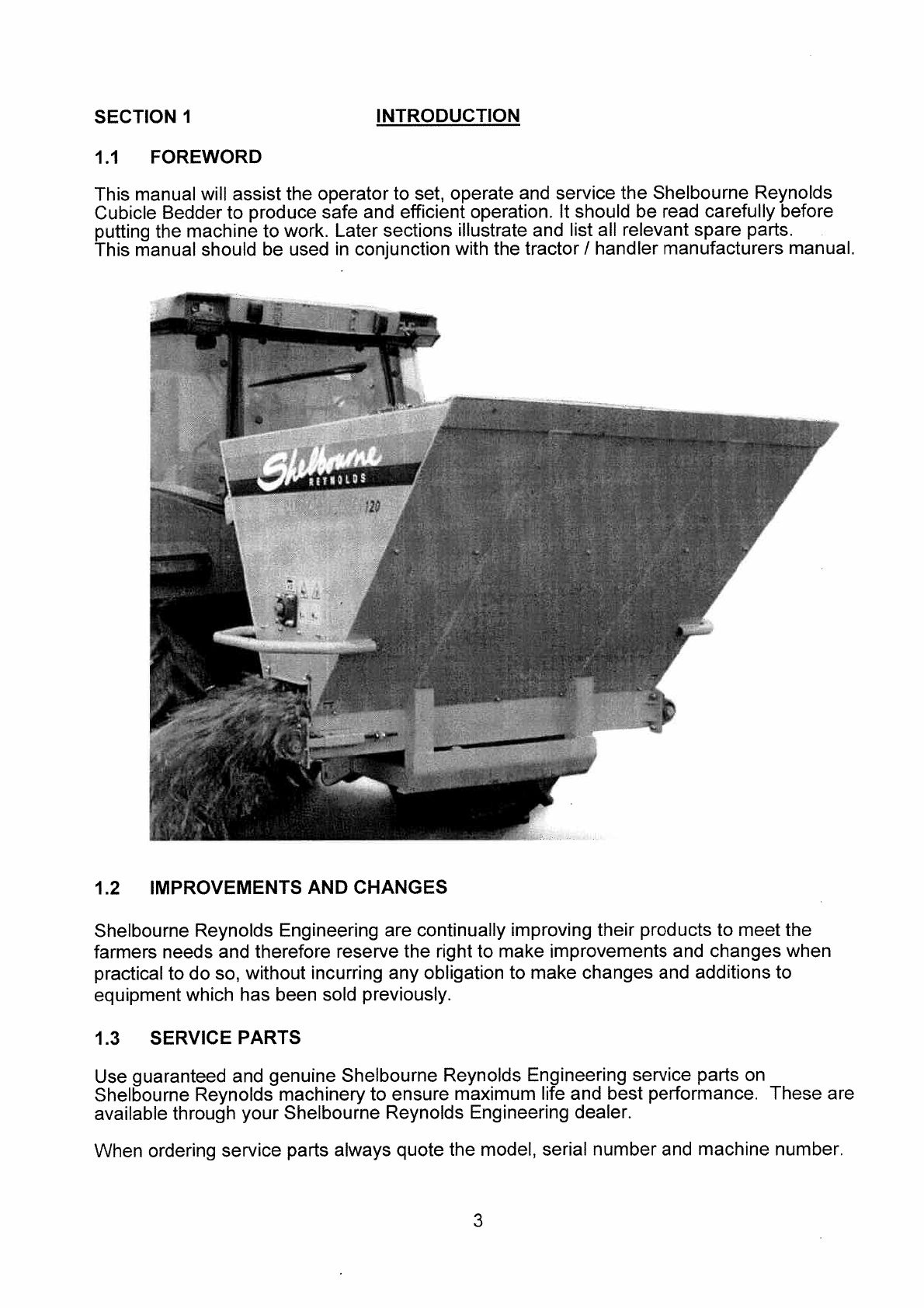

1.1

FOREWORD

This

manual

will

assist

the

operator

to

set,

operate

and

service

the

Shelbourne

Reynolds

Cubicle

Bedder

to

produce

safe

and

efficient

operation.

It

should be

read

carefully

before

putting

the

machine

to

work.

Later

sections

illustrate

and

list

all

relevant

spare

parts.

This

manual

should be

used

in

conjunction

with

the tractor

/

handler

manufacturers

manual.

1.2

IMPROVEMENTS

AND

CHANGES

Shelbourne

Reynolds

Engineering

are

continually

improving

their

products

to

meet

the

farmers

needs

and

therefore

reserve

the

right

to

make improvements and

changes

when

practical

to

do

so,

without

incurring

any

obligation

to

make

changes

and additions

to

equipment

which

has

been

sold previously.

1.3

SERVICE

PARTS

Use

guaranteed

and

genuine

Shelbourne

Reynolds

Engineering

service parts

on

Shelbourne

Reynolds machinery

to

ensure

maximum

life

and

best

performance.

These

are

available

through

your

Shelbourne

Reynolds

Engineering

dealer.

When

ordering

service parts

always

quote

the

model,

serial

number

and

machine

number.

3

1.4

MACHINE

IDENTIFICATION

CE

The serial and

machine numbers

of

the

Cubicle

Bedder

are

printed

on

a

plate

located

on

the

front

of

the

tub.

WEIGHT

YEAR TOTAL

Kg

FOR

SPARES

QUOTE

BOTH

MC

SERIAL

No.

No.

SHELBOURNE

REYNOLDS ENGINEERING

LTD

STANTON.

SUFFOLK.

1P31

2AR.

ENGLAND

1.5

SHELBOURNE

REYNOLDS

ENGINEERING

LTD

-

WARRANTY

TERMS

AND

CONDITIONS

TO THE

PURCHASER

GENERAL

This

warranty

will

become

available

to

you

when

you

have

paid

for

the

equipment

and

returned,

duly

completed, the

delivery

and

warranty registration

forms.

It

will

expire

on

the

anniversary

of

purchase

from

the dealer.

After

that

date

Shelbourne

Reynolds

will

have

no

further

liability

under

this

warranty

to

you

except

in

respect

of

claims

already

notified,

This

warranty

is

not

transferable

and

is

available

only

to

the

original

purchaser

from

our

dealer.

In

the

case

of

purchasers

having

leasing

or

similar

arrangements

the

first

user

shall

be

deemed

the

original

purchaser

and

you

shall

be

deemed

to

have

paid

for

the

equipment.

USE

AND

MAINTENANCE

2.

To

maintain

the

benefit

of

the

warranty

throughout

the

twelve month

period

you

must

have

the

machine

serviced

in

accordance

with

our

recommendations

and

use

the

machine

properly.

If

on

inspection

the machine

appears

to

have

been

either

misused,

overloaded,

improperly

operated,

neglected,

not

properly

maintained,

altered

or

repaired

without

our

consent

this

will

invalidate

the

warranty. We

shall

have

no

further

liability

under

it

to

you

at

all.

(If

you

require

any

guidance

as

to

use

you

should

contact

the

dealer.)

3.

Our

liability

under

this

warranty

is

dependent

upon

your making

the

equipment

and

facilities

available,

for

inspection

and

testing.

4.

In

this

warranty

the expression,

“defective

product”

means

any

part

of

the

equipment

you

have

purchased

which

shows

evidence

of

a

defect

in

the

materials,

design

(due

regard

being

given

for

the

state

of

the

art

at

the

time

we

designed

it)

or

Shelbourne

Reynolds’

workmanship.

Wearing

parts,

such

as

belting,

are

excluded.

Parts

not

manufactured

by

Shelbourne

Reynolds,

for

example

tyres

and

alternators,

are

also excluded.

4

OUR OBLIGATIONS

5.

If

you

discover

a

defective

product

you

should

contact

the

dealer

from

whom

your

machine

was

purchased.

The

dealer

will

notify

us

of

your

claim.

Our

obligation

will

then

be

to

either replace,

or

if

we

consider

it

appropriate,

repair

the

defective

product.

Alternatively,

we may

arrange

for

our

dealer

to

carry

out

this

work.

YOU

MUST

NOTIFY

THE DEALER

OF

THE

DEFECT

WITHIN

SEVEN

DAYS

OF

THE

DAY

ON

WHICH

IT

IS

DISCOVERED

AND

YOU

MUST

NOT

USE

THE

EQUIPMENT

AFTER

DISCOVERY.

FAILURE

TO

OBSERVE

EITHER

OF

THESE

OBLIGATIONS

WILL

INVALIDATE

THE

WARRANTY AS

IS

APPLIES

TO

THAT

DEFECT.

Any

defective

products

replaced

must

be

returned

to

SRE

for

inspection.

NO

ADMISSION

6.

On

occasions

we

may,

to

preserve

goodwill,

replace

parts even

though

they

are

not

in

our

opinion

defective.

Accordingly,

our

agreeing

to

repair

or

replace

a

part

cannot

in

any

circumstance

be

deemed

an

admission

that

it

was

defective.

LIMITATIONS

7.

This

warranty

shall

not

apply

to

products

made

up

in

accordance

with

customer

originated

designs.

8.

No

warranty, condition

or

other

term

implied

by

statute

or

common

law

as

to

the

merchantability

or

fitness

for

a

particular

purpose,

is

intended

or

given

by

this

warranty.

All

such

warranties

which

may

apply

between

Shelbourne

Reynolds and

yourself

are

excluded

to

the

fullest

extent

permitted

by

law.

9.

In

any

case,

except

in

respect

of

death

or

personal

injury

caused

by

our

negligence,

we

shall

not

be

liable

to

you

by

reason

of

any

representation

or

implied

warranty,

condition

or

other

term,

or

any

duty

at,

law

or

under the

express

terms

of

any

contract,

for

the

consequential

loss

or

damage

(whether

for

loss

or

profit

or

otherwise

and

including

delay

in

harvesting,

loss

of

crops,

expense

incurred

for

labour,

additional

or

substitute

material,

rental

whatsoever

and

whether

caused

by

our

negligence,

the

negligence

or

our

employees

or

agents

or

otherwise)

which

arises

out

of

or

in

connection

with

the

use

of

the

goods

by

you.

10.

Time

of

repair

is

not

of

the

essence.

11.

No

person

or

persons

are

authorised

to

alter,

modify

or

enlarge

this

warranty

on

behalf

of

Shelbourne

Reynolds.

12.

Shelbourne

Reynolds

shall

not

be

liable for

any

failure

to

comply

with

any

part

of

the

warranty

where

such

failure

is

due

to

circumstances

beyond

their

reasonable

control,

including

difficulty

in

obtaining

materials

or

replacement

parts.

CALL

OUT

CHARGES

13.

Shelbourne

Reynolds and

all

dealers

reserve

the

right

to

make

a

reasonable

charge

for

call

outs

made

at

your

request

which

do

not turn

out

to

relate

to

defective

products.

YOUR

STATUTORY RIGHTS ARE

UNAFFECTED.

5

C)

SECTION

2

SAFETY

PROCEDURES

2.1

ACCIDENT

PREVENTION

The

following

safety

instructions

are

applicable

for

all

chapters

of

this

manual.

Careful

heed must

be

paid not

only

to

the

safety

instructions

contained

in

this

operating

manual,

but

also

to

the

accident

prevention

regulations

governing

the

operation

of

agricultural

machinery.

Accident

programmes

can

only

prevent

accidents

with

the

co-operation

of

the

persons

responsible

for

the

operation

of

the

equipment.

For

safety

of

yourself and others,

operate

equipment

with

care

and

do

not

take

unnecessary

risks

which

could

cause

an

accident.

The

tractor

or

prime

mover manufacturer’s

operators

manual

safety

precautions

should

be

adhered

to

along

with

the

following

additional

safety precautions

listed

when

using

a

Cubicle

Bedder

CAUTION

LI\

In

addition

to

the

following

list,

this

symbol

will

appear

throughout

this

manual

whenever

your

safety

is

involved.

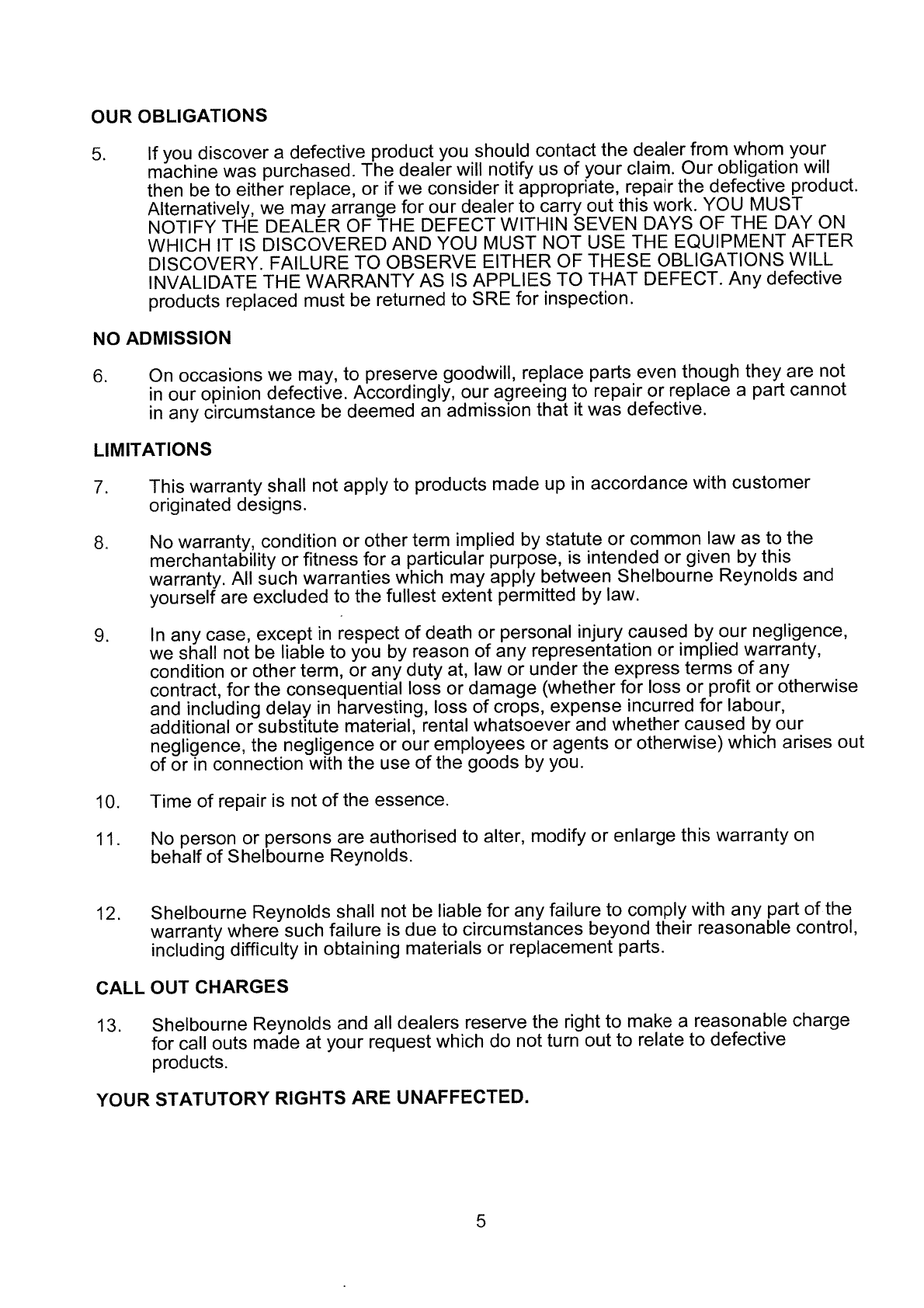

DANGER

SYMBOLS

On

the

machine

-

the

following

symbols

appear

on

the machine

and

are

for

your

safety

and

the safety

of

other

people.

Ensure that

you

identify

each

symbol

and

understand

it’s

warning.

Carefully

read

the

operating manual

before

handling

the

machine.

Stop

the engine

and

remove

the

key

from

the

tractor

I

handler

before

carrying

out

any

work on

the

machine.

7

4->

I*I÷÷i

Thrown

or

flying

objects.

Keep

a

safe

distance

from

Cubicle

Bedder

when

machine

is

working

Risk

of

hand

entanglement

in

conveyor.

Keep

a

safe distance

from

Cubicle

Bedder

when

machine

is

working.

Risk

of

entanglement

in

agitator.

Do

not

reach

into

Cubicle

Bedder

tub

whilst

engine

is

running

on

tractor/handler

Risk

of

crushing

of

torso.

Do

not

stand

between

Cubicle

Bedder

and

tractor/handler

*

8

__

GENERAL SAFETY

Please

read

all

safety

instructions

contained

in

this

operating

manual

with

the

utmost

care

and

also

observe

all

warning

signs

attached

to

the

Cubicle

Bedder.

These

warning

signs

must be

kept

in

a legible

condition

and

must

be

replaced

if

missing

or

damaged.

This

is

especially

the

case

when

whole

sections are

replaced

when

making

repairs.

Warning

signs

are

available

from

your

dealer

or importer.

Follow

these

instructions

to

prevent

accidents.

These

instructions

must

also

be

made

available

to

all

other

users.

You

are

advised

to

refrain

from

any

working

methods

which

may

be

hazardous.

PROPER

USE

Shelbourne

Reynolds

Cubiäle

Bedders

are

based

on

state-of-the-art

technology

and

are

manufactured

in

accordance

with

recognised

safety

requirements.

Nevertheless

the

use

of

the

Cubicle

Bedder

does

not

preclude the

risk

of

injury

to

the

user

or

third

parties

and

/

or

the

risk

of

damage

to

the

Cubicle

Bedder

itself

or

to

other materials

or

items

of

equipment.

Always

make

sure

that

the

Shelbourne

Reynolds

Cubicle

Bedder

is

in

a

technically

perfect

condition

and

that

it

is

used

properly

and

for

it’s

intended

purpose

and

entirely

in

accordance

with

the

instructions

given

in

this

manual.

Any

malfunctions

or

defects

which

might

affect

the

safe

operation

or

the

Cubicle

Bedder must

be

immediately eliminated.

The

Shelbourne

Reynolds

Cubicle

Bedder

must

be

used,

maintained

and repaired

only

by

persons

who

are

familiar

with

it’s

working

and

have

been made

fully

conversant

with

the

risks

involved.

OEM

replacement

parts

and

accessories

from

Shelbourne

Reynolds

have

been

specially

designed

for

use

with

the

Shelbourne

Reynolds

Cubicle

Bedder.

Any

replacement

parts

and

accessories

not

supplied

by

Shelbourne

Reynolds

have

not

been

tested

and

approved

by

us.

The

installation

and/or the

use

of

non-Shelbourne

Reynolds

products

may

under

certain

circumstances

have

a

negative

influence

on

the

given

design

features

of

your

machine and

may

therefore adversely

affect

it’s

safe

and

reliable

operation and

your

safety.

Shelbourne

Reynolds

cannot

therefore

be

held

liable

for

damage

or

injury

caused

by

the

use

of

non-OEM

replacement

parts

or

accessories.

The

Shelbourne

Reynolds

Cubicle

Bedder

is

intended

for

use

on

typical

farms

and

to

be

employed

in

distributing

bedding

material.

Any

uses

other

than

those

for

which

the

Cubicle

Bedder

is

intended,

such

as

transportation,

will

automatically

exempt

Shelbourne

Reynolds

or

the

supplier

from

it’s/his

liability

in

respect

of

ensuing

damage.

Such

cases

of

improper

use

will

therefore

be

entirely

at

the

user’s

own

risk.

All

relevant

accident

prevention regulations,

as

well

as

other

generally

acknowledged

health

and

safety

regulations and

road

traffic

regulations

must

be

strictly

observed.

Improper

use

also

comprises

failure

to

observe

the

instructions

given

in

this

operating

manual and

the manufacturer’s

maintenance

and

servicing

requirements.

9

___

OPERATIONAL SAFETY

The

Shelbourne

Reynolds

Cubicle

Bedder

must

not

be

put

into

operation

until

the

user

has

been

given

proper

initial

instructions

either

by

the

dealer

or

by

one

of

Shelbourne

Reynolds’

representatives

or

employees.

The

Shelbourne

Reynolds

Cubicle

Bedder

may

be

used

only

if

all

safety

devices,

e.g.

detachable

guards,

are

fitted

and

in

proper

working

order.

Nuts

and

bolts

should

be

checked

at regular

intervals

and

tightened

if

necessary.

In

the

event

of

amalfunction,

immediately

cease

operation

and

secure

the

Shelbourne

Reynolds

Cubicle

Bedder

in.

its

stationary

position.

Malfunctions

must

be

eliminated

immediately.

No

liability

for

consequential

damage

Even

though

your

Shelbourne

Reynolds

Cubicle

Bedder

has been

manufactured

with

the

utmost

care

and

you

are

using

it

properly,

fluctuations

in

performance

may

still

occur.

It

is

the

duty

of

the operator

/

user

to

ensure

that

foreign

objects,

e.g.

stones,

metal

objects

etc.

are

not

allowed

to

enter

the

Cubicle

Bedder.

Failure

to

observe

this

may

result

in

damage

to

the

machine

and

/

or

injury

to

the

operator

/

user

Any

claims

for

damages

not directly

incurred

by

the

Shelbourne

Reynolds

Cubicle

Bedder

cannot

be

accepted.

By

the

same

token,

Shelbourne

Reynolds

cannot

be

held

liable

for

any

consequential

damage

resulting

from

incorrect

use

of

the

Cubicle

Bedder.

ROAD

SAFETY

Road

traffic

regulations

must

be

observed

when

taking

the

Shelbourne

Reynolds

Cubicle

Bedder

on

roads,

paths

and

other

public

places.

The

Cubicle

Bedder

must

be

in

a

road

worthy

condition.

Observe

the

maximum

permissible

width

for

road

transport

and

fit

all

necessary

warning

signs

and

guards.

Fully

secure

guards

and

covers

so

that

they

cannot

cause

injury

or

damage

to

other

users

of

the

public

place.

When

coupling

the

Shelbourne

Reynolds

Cubicle

Bedder

to

the

tractor

I

handler.

The

work

of

coupling

and

uncoupling

of

the

Cubicle

Bedder

involves a

high

risk

of

injury

Follow

the

procedure

described

further through

this

manual

for

Cubicle

Bedder

attachment

and

detachment.

See

Section

5.2

Check that

the

combined

weight

of

the

Cubicle

Bedder

and

the

heaviest

load

of

bedding

material

does

not

exceed

the

manufacturers

recommended

safe

loading

of

axle,

wheels

and

tyres.

10

Ensure

that

the

machine

is

parked

on

even

level

ground.

Slowly

drive

the

tractor

/

handler towards

the

Cubicle

Bedder

—

always

ensure

that

there are

no

other

persons

in

the

vicinity

of

the

machine

and

tractor

/

handler.

Connect the

Cubicle

Bedder

to

the

tractor

linkage

using

only

the

method

recommended

in

the

tractor’s

operator

manual.

Connect the

Cubicle

Bedder

to

the handler

using

manufacturer approved bracket

in

the

manner

recommended

in

the

handler

operators

manual.

If

Brackets

are

to

be welded

to

the

Loader

Frame

it

is

absolutely

vital

that

the

welding

is

carried

out

by

a

Professional

Welder.

When

using

the

hydraulic

system

Do

not

connect

the

hydraulic

hoses

to

the tractor

I

handler

hydraulic

system

until

you

have

made

sure

that

the system

is

at

zero

pressure

on

both

the

tractor

/

handler

and

the

Cubicle

Bedder.

The

hydraulic

system

generates

extremely

high

pressures.

All

piping,

hoses

and

connections

must

therefore

be

checked

regularly

for

leakage

and

visible

external

damage.

Use

proper

and

thorough

means

of

searching

for

leakage

and

repair

all

damage

immediately.

Spurting

hydraulic

oil

can

cause

injuries

and

fires.

Seek

medical

advice

immediately

in

the event

of

injury.

___

PRECAUTIONS

2.2

BEFORE

STARTING

THE

MACHINE

1.

Read

the

manual

thoroughly.

2.

Check

that

all

guards are

properly

secured.

3.

Ensure

that

no

person

is

working on

or

inside

the

machine,

4.

Check

that

all

observers

are

clear

of

the

machine.

Warn

bystanders

by

sounding

the

horn

several

times.

2.3

THE

MACHINE

IN

USE

5.

Do

not

permit

anyone

other

than

the

operator

to

ride

on

the

tractor

I

handler.

6.

Always

stop

the engine,

remove

the

key

and

apply

handbrake

before

removing

or

opening

any

guards

or

clearing

a

blockage.

7.

Do

not

go

under

the

Cubicle

Bedder

unless

it

is

securely

blocked

8.

NEVER

go

near

the

machine

whilst

the

conveyor

is

running.

9.

Always

replace

all

guards

after

making

any

adjustments

or lubricating

the

machine,

Replace

or

repair any

damaged

or

missing

guards

immediately.

10.

Do

not

work

around

the

machine

in

loose

clothing

that

might

get caught

in

moving

parts.

11.

Keep

hands

away

from

moving

parts.

12.

Keep children

away

from

and

off

the machine

at

all

times.

11

2.4

LEAVING

THE

MACHINE

13.

Park

the

machine

on

reasonably

level

ground.

14.

Apply

the

parking

brake.

15.

Lower

the

Cubicle

Bedder

to

the

ground.

16.

Stop

the

engine

and remove

ignition

key.

2.5

SERVICING

THE

CUBICLE

BEDDER

17.

Ensure

that

the

Cubicle

Bedder

is

on

the

ground

or

if

in

the raised

position,

that

it

is

securely

blocked

18.

Stop

engine, remove

the

key

and

apply

handbrake

before

performing

any

adjustments

or

lubrication

and before

opening

or

removing

any guard.

19.

Always

re-install

all

safety

guards

on

completion

of

servicing.

2.6

MACHINE

ATTACHMENT

20

Follow

the

procedure described

further through

this

manual

for

Cubicle

Bedder

attachment

and

detachment.

See

Section

5.2/5.3

12

SECTION

3

SPECIFICATION

&

DESCRIPTION

31

DESCRIPTION

The

machine

consists

of

a

tub

(a)

which

is

used

to

hold

the

bedding

material.

The

tub

is

fitted

to

the

tractor

I

handler

and

can either

be loaded

manually

or

used

to

scoop

up

bulk

material

if

fitted

with

a

hydraulic

top

link

(b)

or

loader

frame

(c).

Bolted

inside

the

tub

are

fill

in

sheets

(d)

which

alter

the

internal

shape

of

the

tub

Positioned

underneath the

tub

is

a

conveyor

(e)

which

is

driven

by

a

hydraulic

motor

and

is

used

to

discharge

the

bedding

material

to

either the

left

or

right

hand

side

of

the

machine.

A

horizontal rotating

agitator

(f)

is

used

to

loosen

the

bedding material

in

the

tub

ensuring that

the

material

flows

through

the

metering

plates

onto

the

conveyor.

The

metering

plates

(g)

consist

of

two

adjustable

slides

which

fit

inside

the

tub

and regulate

the

amount

of

material

which

flows

onto

the

belt

by

adjusting

the

gap

between

them.

On

the

side

of

the

tub

are

two

adjustable

side

plates

(h)

under

which

the

conveyor

passes.

The

machine

can

either

be

fitted

to

the

three

point

linkage

of

the

machine

using

a

standard

top

link

where

by

it

must

be loaded

manually

or

from

an

overhead

hopper.

Alternatively

a

hydraulic top

link

can

be

supplied

which

alters the

angle

of

the

tub

allowing

it

scoop

bedding

material

form

a

bulk

heap

on

the

floor.

A

loader frame can

also

be supplied

onto

which

the

correct

brackets

can be

fitted

this allows

the

Cubicle

Bedder

to

be

fitted

to

a

front

end

loader

or

handler

13

3.2

INTENDED

USE

The

Cubicle

Bedder

is

intended

to

be

used

on

typical

farms

for

transporting

and

discharging

suitable

animal

bedding

materials

into

the

animal

bedding

area,

usually cubicle

beds.

3.3

TECHNICAL

SPECIFICATION

Sizes

and weights

are

as

follows:

(all

dimensions

and

weights

are approximate)

120

200

320

Machine

Capacity

1

.40m

3

I

.70m

3

2.20m

3

Overall

Height

(A)

1422mm

1422mm

1574mm

Overall

Depth

(B)

1670mm 1670mm 1864mm

Overall

Width

(C)

1996mm

2300mm 2300mm

Tub

Width

(D)

1524mm 1830mm 1830mm

Width

of

Discharge

Belt

(E)

0.3m

0.3m

0.3m

Tractor

Size

Mm

50hp

Mm

50hp

Mm

5Ohp

Mm

Hydraulic

Flow

*

30-35

litres/mm

30-35

litres/mm

30-35

litres/mm

Mm

Hydraulic

Pressure

125

bar

125

bar

125

bar

Weight

495kg

550kg

600kg

*

-

Lower

flow

rates

can

be

used

with

changes

to

machine,

please

consult

Shelbourne

Reynolds

Right

and

left

of

the

machine

is

termed

in

the

manual

as

viewed

from

the

drivers

seat

with

the

Cubicle

Bedder

fitted

to

the

front

of

a

handler.

CUBUCLE BEDDER

LH

RH

DIRECTION

OF

TRAVEL.

HANDLER

14

SECTION

4TRANSPORTATION

To

prevent

damage

to

the

Cubicle

Bedder

the

machine

should

only

be

moved

by

one

of

the

following

methods:

Attaching

to

a

tractor

Attaching

to

handler

or

front

end

loader

Using

a

suitable

support

pallet

By

slinging

the

tub

using

the

four

designated

sling

points

for

overhead

lifting.

15

91

SECTION

5

PREPARATION FOR

USE

5.1

CHECKS

All

assembly

work

and

pre

delivery

checks

should

have

been undertaken

by

your

dealer.

As

a

precaution,

before

using

check:

1

There

are

no

foreign

objects

in

the

tub

2

There

are

suitable

auxiliary

hydraulic

outlets

on

your

tractor

or

loader

3

The

correct

manufacturer

approved

brackets

have

been

fitted

in

a

suitable

manner

to

the loader

frame

(if

fitted)

5.2

ATTACHMENT TO

THE

TRACTOR

I

HANDLER

The

machine

is

provided

with

provision

for

it

to

be

carried

on

the

three-point

linkage

when

using a

standard

top

link

or

hydraulic

top

link.

Alternatively

the

Cubicle

Bedder

can

be

fitted

to

a

Handler

when

a

loader

frame

is

specified.

STANDARD

TOP

LINK

Reverse the

tractor

slowly

to

the

machine

and

connect

the

lower

links.

Adjust

the

top

link

length

to

enable

it

to

be

attached

to

the

machine.

Set

the

machine

at

the

desired

working

height

and

adjust

the

top

link

to

such

a

position

that

the

conveyor

is

parallel

with

the

ground.

Adjust

the

check

chains

so

that

there

is

no

sideways

sway and

the machine

sits

centrally

to

the

tractor.

There

are

multiple

hole

positions

for

both

the

lower

and

top

links

which

enable

the

machine

to

be

fitted

to

most

tractors,

ensure

the

correct

hole

positions

are

chosen

to

suit

the tractor

being

used.

Once

the machine

has

been

attached

and

the

linkage

adjusted,

the

two

hoses

for

the

conveyor and

agitator

drive

must be

connected

to

the tractor

auxiliary

hydraulic

outlet.

This

requires

one

double

acting

service

with

a

minimum

flow

of

30-35

litres/mm

at

125

bar

pressure.

HYDRAULIC

TOP

LINK

When

using

the

hydraulic

top

link

option

reverse

the

tractor

to

the

machine

in

the

usual

manner

and

attach

the

lower

links

to

the

lowest

set

of

holes

on

the

Cubicle

Bedder.

Attach

the

hydraulic

top

link

to

the

tractor,

the

bolted clevis

end

fits

onto

the

tractor.

Connect

the

cylinder

hydraulic

pipes

into

the

tractor

auxiliary

outlet,

ideally

this

requires

a

second

double

acting

service.

Extend

the

cylinder

to

locate

the

swivel

ball

end

close

to

the

top

link

position

hole

on

the

machine.

Adjust

the

swivel

end

accordingly

to

allow

the

top

link

pin

to

be

fitted,

fit

the

top

link

pin

and

spacers

and

adjust the

locking

collar

up

to

the

cylinder

rod.

Ensure

that

the

swivel

end

is

not

unwound

too far

and

at

least

50

mm

of

thread

is

still

within

the

cylinder.

17

This manual suits for next models

3

Table of contents

Other Shelbourne Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions