Page 7.

US US

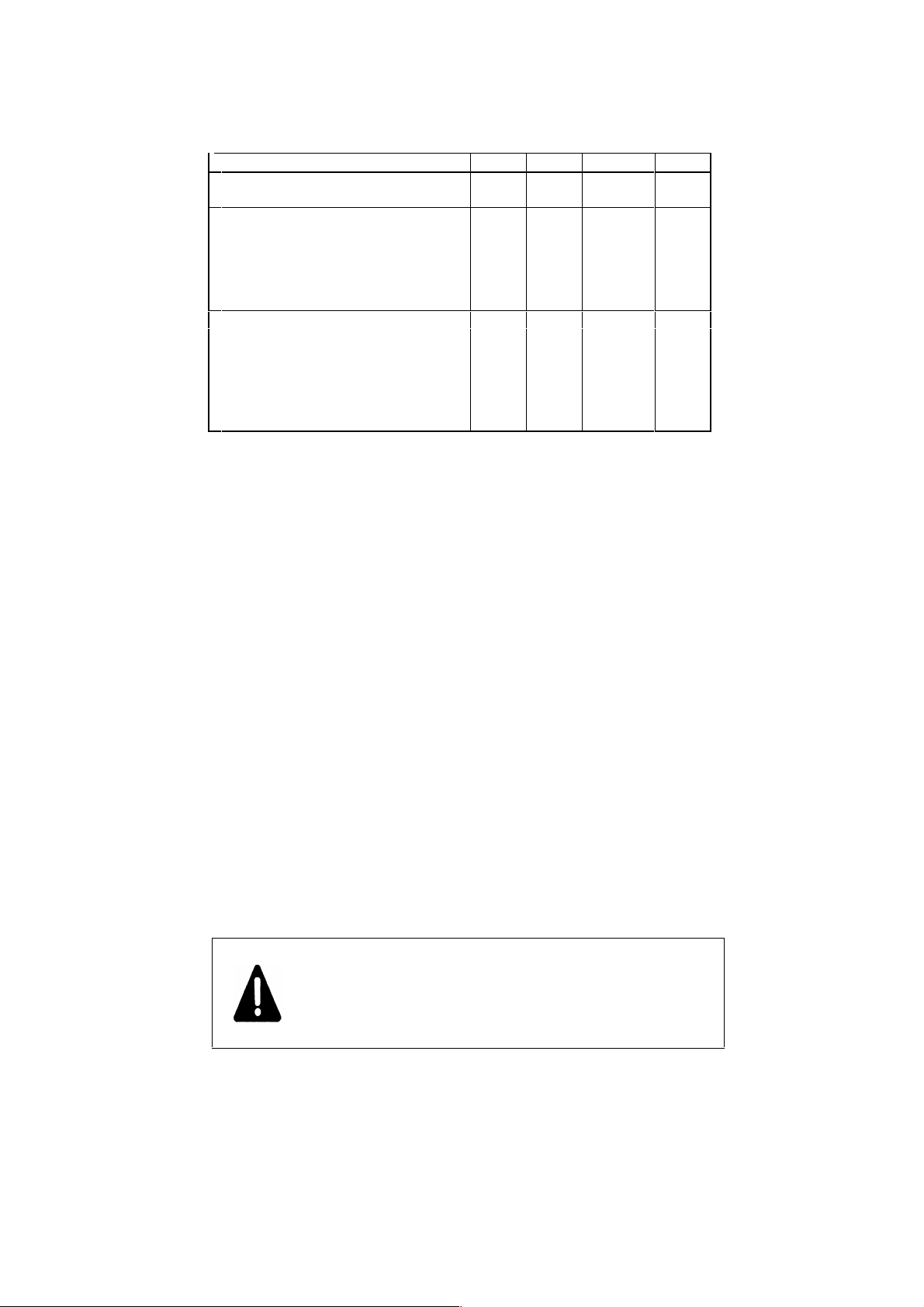

AXI U TRANSPORT SPEED km/h miles/h 9.2 6

WORKING SPEED km/h miles/h 6 - 12 4 - 8

SUPPORT WHEEL SYSTE

Number of wheels pcs. pcs. 2 2

spacing of wheels mm inch 1400 55 1/6"

Dimensions – diam mm inch 380 15“

Dimensions – width mm inch 160 6 1/3”

POWER TAKE OF SHAFT – PTO

Power size Nm Nm 210 210

Nominal transmission of power kW kW 12 12

Lenght mm inch 460 18 1/6"

Yoke ends splined splined 6 6

Revolution rpm rpm 540 540

4.4 Equ pment

With

BALTIMATIC

®Hay Tedder should be supplied owners manual with instructions and

sparepart catalogue.

4.5 Preparat on of tractor to work w th BALTIMATIC

®

hay tedder

Preparation of tractor to work with

BALTIMATIC

®Hay Tedder should be made in

accordance to general instruction in owners manual for the tractor.

Lift arm pins on the tractor should be adjusted to same height as the lift arm pins on the

tedder. That will make it easier to mount

BALTIMATIC

®tedder to tractor.

4.6Preparat on of mach ne for work

Check

BALTIMATIC

® tedder that it is in correct technical condition.

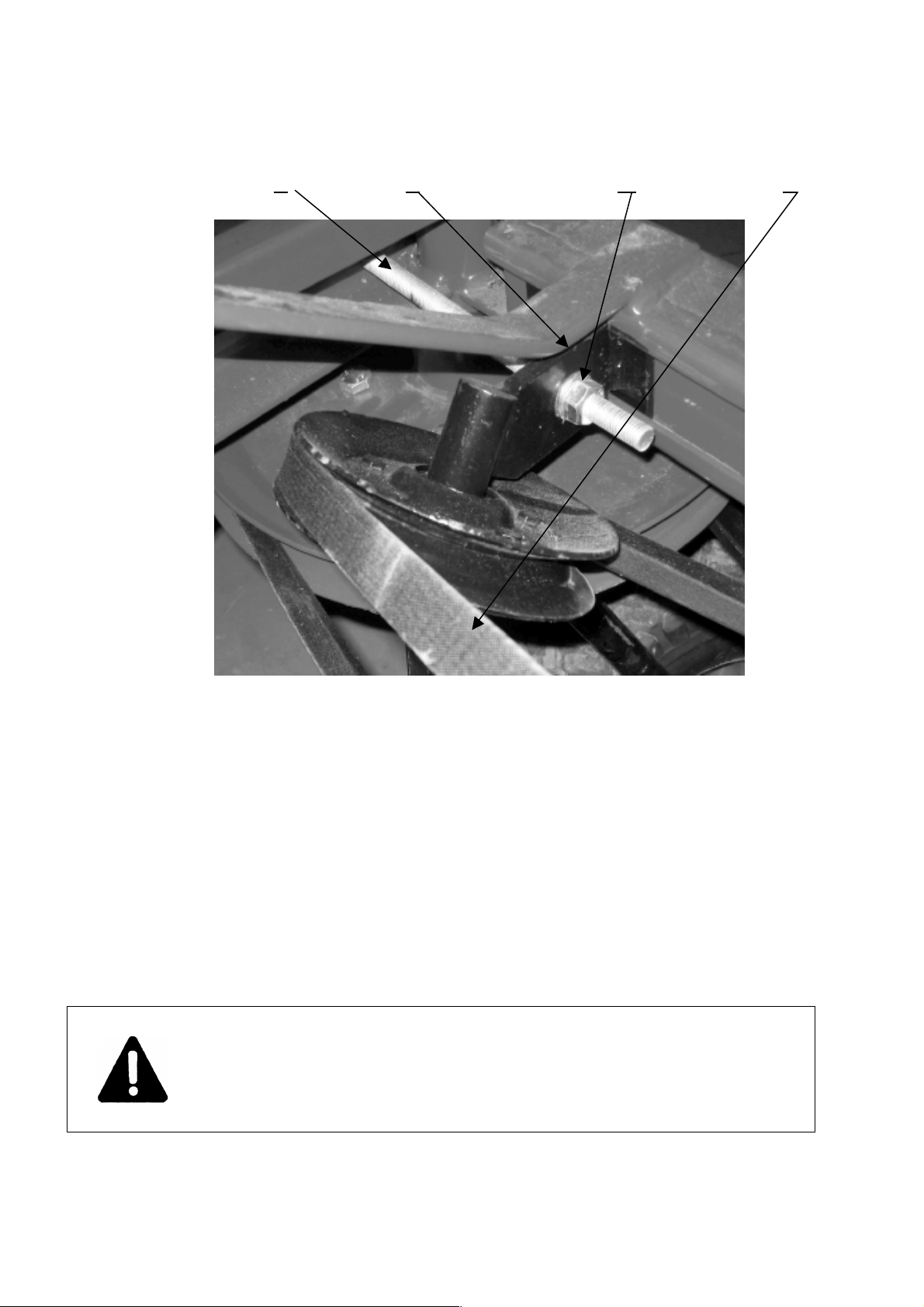

Check bolt connections of springs to arms

Check bolt connections of arms to belt pulley

Check springs for wear and broken springs

In case of worn or damaged springs these must be replaced

Check condition of V belt, if damaged or worn out it should be

Replaced with a new one.

Check the tension of V Belt. Belt must not be loose.

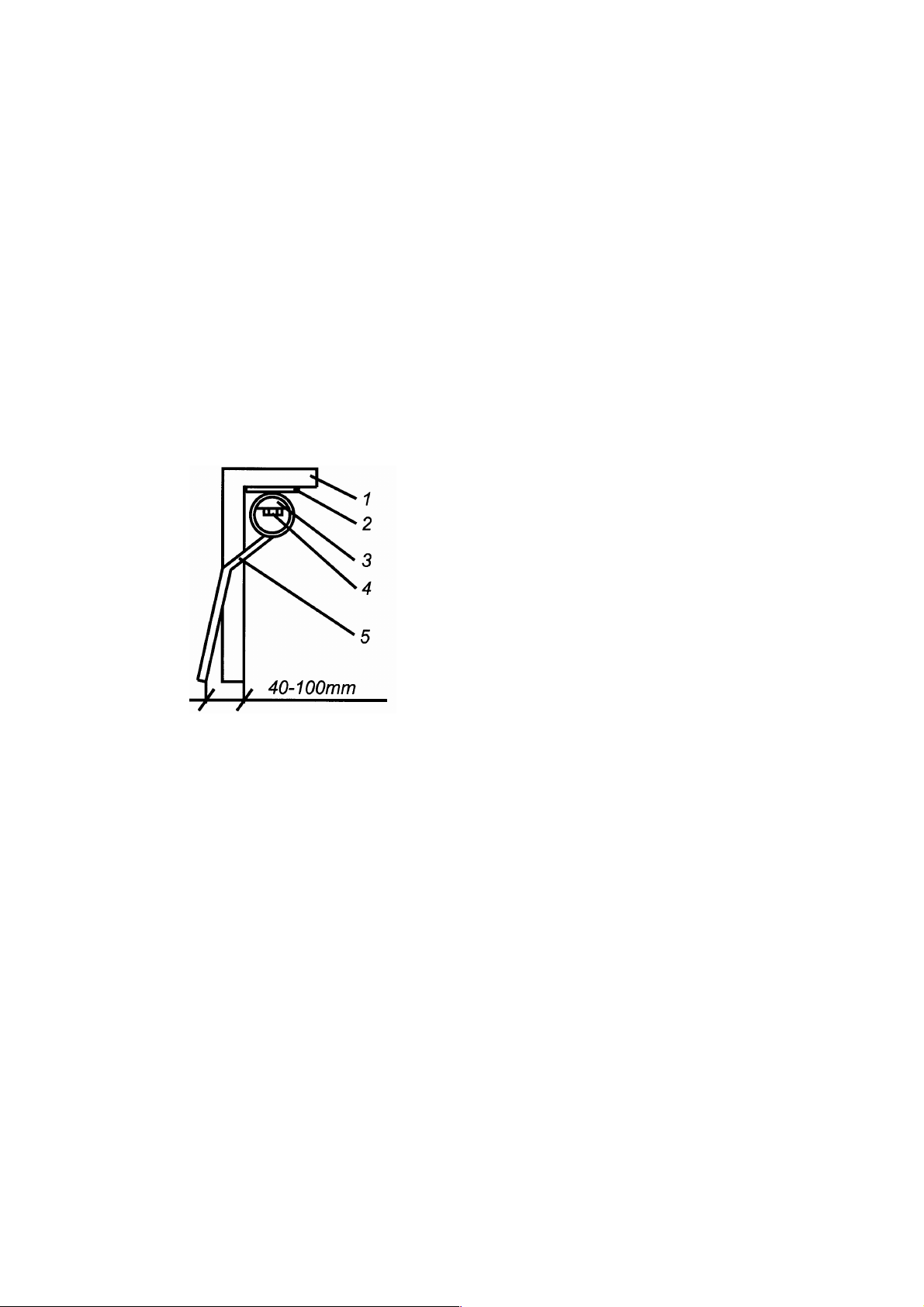

If regulation of tension is necesserary it can be done by nut (3) on

drawing 3. The slack of the V belt between belt pulley and tightnere

should be approx 6’ when a force of 110 lbs is applied to the V belt.

Checking if support wheels are turning slightly, without stopping

Mount PTO shaft on machine.

Remember every time before wor , to chec technical

condition of spring fingers, bolt connections of springs to

arms and bolt connections of arms to belt pulley.

.