Sheldon 2015 User manual

LOW TEMPERATURE

ILLUMINATED

INCUBATOR

MODEL: 2015

INSTALLATION AND OPERATION MANUAL

RECEIVING AND INSPECTION

Your satisfaction and safety require a

complete understanding of this unit. Read the

instructions thoroughly and be sure operators

are given adequate training before attempting

to put the unit into service. This equipment

must be used only for its intended application;

any alterations or modifications will void your

warranty.

1.1 Inspection: The carrier, when

accepting shipment, also accepts responsibilityfor

safe delivery and is liable for loss or damage. On

delivery, you must inspect for visible exterior

damage, note and describe on the freight bill any

damage found, and enter your claim on the form

supplied by the carrier. Inspect for concealed loss

or damage on the unit itself, both interior and

exterior. If necessary, the carrier will arrange for

official inspection to substantiate your claim.

1.2 Return Shipment: Save the shipping

crate until you are sure all is well. If for any reason

you must return the unit, first contact your

customer representative for authorization. Supply

nameplate data, including model number and

serial number.

2.0 INSTALLATION:

2.1 Location: When selecting asitefor the

incubator, consider all conditions which may affect

performance, such as extreme heat from steam

radiators, stoves, ovens, autoclaves, etc. Avoid

direct sun, fast-moving air currents,

heating/cooling ducts, and high traffic areas. To

ensure air circulation around the unit allow a

minimum of 2" between incubator rear and sides

and any walls, partitions or obstructions to free

airflow.

2.2 Leveling: The unit must sit level and

solidly. Turn the leveling feet counterclockwise to

raise level. If the unit must be moved, turn the

leveling screws in all the way to prevent bending

of the feet.

2.3 Power Source: See the incubator's

serial data plate for the voltage, cycle, phase and

wattage requirements. VOLTAGE SHOULD NOT

VARY MORE THAN 10% FROM THE DATA

PLATE RATING. Electrical supply to the unit must

conform to all national and local electrical codes.

A separate circuit is recommended to avoid

overloading.

2.4 Cleaning: The incubator's interior was

cleaned at the factory, but it should be recleaned

now. Remove all interior parts, including shelves

and shelf clips.

3.0 THEORY OF OPERATION:

The refrigeration system, heater, and air

circulating fan are used in conjunction with the

temperature control circuit to achieve sensitive

temperature control. The thermostat sensor

located in the air stream senses any temperature

deviation from the control point, and heat is

provided to maintain desired temperature. The

circulating fan provides even air distribution

throughout the chamber and assures temperature

uniformity.

Regardless of temperature maintained, the

compressor operates continuously. This

constant operation alleviates component failures

associated with the cycle type operation.

(Compressor will be shut off by the Low Limit

Thermostat).

This unit should remain upright for 24

hours prior to turning on. This will allow the

oil to settle in the compressor.

4.0 EXPLANATION OF CONTROLS:

Switch "I/O" (On/Off) for operation of power

to incubator.

DEFROST SYSTEM: If temperature

instability or reduced air flow is noted, turn on

defrost switch for twenty-four hours. This will

energize the defrost circuit, which will thaw the ice

that is blocking air flow. It is advisable to perform

this procedureonceeverythirtydays. Thisswitch

is located at the rear of the shadowbox.

1

5.0 CONTROL PANEL OVERVIEW:

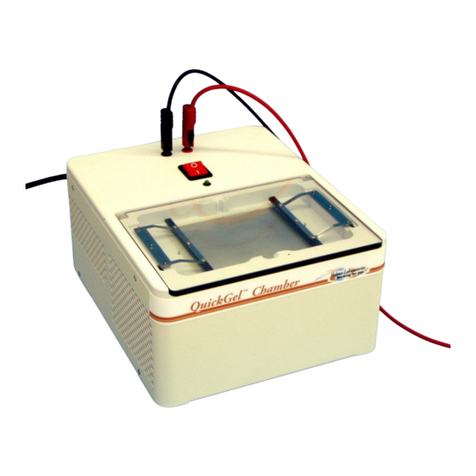

Figure 1

5.1 Day (or high) Temperature Control:

On the front panel, this control consists of the

Up/Down arrow pads and the digital display.

5.2 Night (or low) Temperature Control:

On the front panel, this control consists of the

Up/Down arrow pads and the digital display.

5.3 High Limit Safety Thermostat:

Located on thecontrol panel, this Safety is marked

High Limit Safety. Completely independent of the

Main Controller, the Safety guards against any

failure of the Main Controller which would allow

temperature to rise past set point. If temperature

rises to the safety set point, the Safety takes over

control of the heating element and allows

continued use of the incubator until service can be

arranged.

5.4 Temperature Program Timer: This is a

continuous timer with a 24 hour dial. To set day or

night temperature, the program timer must be in

either day for day (or high) temperature, or night

for night (or low) temperature.

5.5 Light Program Timer: Continuous

timer with 24 hour dial to control illumination or

darkness mode.

5.6 Safety Indicator Light: If this light is on

or flickering, the High Limit Safety has taken over

control and shut down heaters.

6.0 OPERATING PROCEDURES:

6.1 Loading Procedure: Adequate spacing

should be allowed between items wherever

possible. Proper spacing will allow maximum air

circulation, which is necessary for temperature

uniformity. The area below the lower shelf is most

critical, and should ALWAYS be kept clear of

objects.

6.2 Frost Buildup: Excessive frost buildup

on the evaporator coil located on the lower rear

wall could affect temperature uniformity. Liquid

containers should never be placed in the chamber

without covers. The evaporation of moisture within

the chamber will only add frost and hasten the

need for defrosting. Defrosting is accomplished

simply, byturning thedefrost switch on and turning

it off twenty four hours later. Optionally, defrost

switch may be left on at all times as defrost system

will only function when needed. During defrost

cycle, temperature in incubator will increase. In

extreme cases, it will be necessary to turn the

incubator off and leave the door open for 24 hours

and allow all the frost to melt. Before turning on the

incubator make sure to completely dry out interior

and the catch tray in the bottom of the body.

6.3 Set Main Temperature Control: Enter

desired set point temperature. To enter set point

mode on the Control, press either the Up or Down

arrow pad one time. The digital display will start to

blink, going from bright to dim. While blinking, the

digital display is showing the set point. To change

the set point, use the Up and Down arrow pads. If

the arrow pads are not pressed for five (5)

seconds, the display will stop blinking and will read

the temperature of the unit. Note that the High

Limit Safety Thermostat should be turned to its

2

maximum position, (clockwise) until the unit has

stabilized at desired set point temperature. Allow the incubator at least 24 hours to stabilize.

To re-calibrate the digital display to your reference

thermometer, follow the calibration instructions

given in Appendix 1. This incubator was calibrated

at the factory at 20oC.

6.4 Set High Limit Safety Thermostat: As

mentioned in step 6.3, the Safety Thermostat

should be initially set to its maximum position,

(clockwise), to allow the unit to stabilize. Once the

incubator is stabilized at the desired set point, turn

the Safety Thermostat counterclockwise until the

Safety Indicator Light turns on. Next, turn the

Safety Thermostat clockwise until the Safety

Indicator Light just stays off. This will set the Safety

Thermostat at approximately 1oC above main

temperature set point.

6.5 Timer Instructions: Your model 2015

has two separate timer controls. One is labeled

Temperature Program Timer and the other is

labeled Light Program Timer.

Each timer control rotates in a clockwise direction.

On the face of each dial you will note an outer

orange colored band, 96 small black actuator

segment switches and the inner clock face. Note

that one actuator segment switch will represent a

15 minute period of time.

A. CLOCK SET (Both Dials): To set the

correct time, gently grasp the outer diameter

(orange band and tips of actuator segments)

of the timer dial and rotate in a clockwise

direction until the arrow in the center of the

dial is pointing to the desired time. (Note:

Each clock face is divided into two 180

degree twelve hour sections, indicating

"day/night" time frames). You will note that

the outer orange band, actuator segment

switches and clock face all rotate together.

Only the inner arrow(s) should remain

stationary during dial rotation.

B. TEMPERATURE TIMER CONTROL

PROGRAM (Left Dial): When

programming the Temperature Timer

Control, if an actuator segment switch is

pressed inward (close to the inner clock face,

exposing the outer orange band) the day

(high) temperature control is activated

(section 5.1). When a Temperature Timer

Control actuator segment switch is in an

outward position, (away from the inner clock

face, covering the orange band) the night

(low) temperature controlis activated (section

5.2).

C. LIGHT TIMER CONTROL PROGRAM

(Right Dial): On the Light Timer control, if

an actuator segment switch is pressed

inward, (towards the inner clock face,

exposing the outer orange band) the light

function is activated. When a Light Timer

Control actuator segment switch is in the

outward position, the light program function is

deactivated during that period.

6.6 There is an electrical outlet inside the

chamber for use with equipment not exceeding 1

amp.

7.0 MAINTENANCE:

The design of the chamber is such that

periodic maintenance is kept to a minimum. NO

lubrication or adjustments of components is

needed. If the incubator is used frequently at

temperatures below room ambient or in any

manner that increases moisture build-up within the

chamber, a frequent defrosting schedule is

recommended.

3

8.0 PARTS LIST

Part # Description

101758 Circuit Breaker

100001 High Limit Control

103364 MP Control Ass'y

891024 Control Relay

200020 Pilot Light

103552 Timer(24 hour)

700024 Florescent Light

700003 Ballast/Fixture

210002 Cooling Fan

101672 Low Limit Control

101971 System Logic Relay

100576 Safety Control

X1000124 "I/O" (On/Off) Power Switch

X1000124 Defrost Switch

120V

100020 Outlet

101981 Power Cord

220V

101483 Outlet

101990 Power Cord

103372 Step Down Transformer

EUROPEAN MODELS

X1000778 Cord Set

X1000779 Outlet

ENGLAND & UK MODELS

103103 Cord Set

103104 Outlet

APPENDIX 1

CALIBRATION PROCEDURES

1. Plug incubator into electrical service

corresponding to data label rating.

2. Place reference thermometer in the center of

the chamber and allow to stabilize for 24 hours.

(The thermometer should not be touching any

shelves).

3. Turn power switch located on the front of the

unit to the "I" (On) position and set the

Temperature Controller to desired operating

temperature. Adjust the High Limit Safety

Thermostat all the way clockwise.

4. Allow unit to stabilize at desired temperature.

NOTE: unit is stabilized when it has been

running at a constant temperature for 60

minutes.

5. Compare the reading on the reference

thermometer with the digital display. If there is a

difference, put the display into calibrate mode by

pressing on boththe Upand the Downarrowpads

at the same time and holding them in for about five

(5) seconds or until the two outside decimal points

start to flash. When the decimal points are

flashing, the display can be calibrated tomatch the

reference thermometer by pressing on the Up or

Down arrow pad until the displayreads the correct

value.

6. Allow the unit to stabilize again.

Rev 5/95

#4860707

Table of contents

Other Sheldon Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Lafayette Instrument

Lafayette Instrument 63502IR instruction manual

Emtek

Emtek R100 user manual

Thermo Scientific

Thermo Scientific 3050 user manual

Andor Technology

Andor Technology Dragonfly 500 Hardware guide

Viso Systems

Viso Systems LabRail user manual

Omni International

Omni International Bead Ruptor 12 user manual

Julabo

Julabo MAGIO MS-310F operating manual

Cleaver Scientific

Cleaver Scientific OmniPAGE Series instruction manual

Nippon Genetics

Nippon Genetics Fastgene FG-05 instruction manual

Linkam Scientific Instruments

Linkam Scientific Instruments TST350 user guide

Altana

Altana BYK byko-drive S Short instructions

Selecta

Selecta AGIMAN instruction manual